I-Sapphire single crystal Al2O3 isithando somlilo sokukhulisa i-KY indlela ye-Kyropoulos ukukhiqizwa kwekristalu yesafire yekhwalithi ephezulu

Isingeniso Somkhiqizo

I-Kyropoulos Method iyindlela yokukhulisa amakristalu esafire ekhwalithi ephezulu, umnyombo wawo okuwukufinyelela ukukhula okufanayo kwamakristalu esafire ngokulawula ngokunembile indawo yokushisa nezimo zokukhula kwekristalu. Okulandelayo umphumela othize wendlela ye-KY yokwenza amagwebu ku-sapphire ingot:

1. Ukukhula kwekristalu kwekhwalithi ephezulu:

Ukuminyana okunesici esiphansi: Indlela yokukhula yebhamuza ye-KY yehlisa ukugudluka kanye nokukhubazeka ngaphakathi kwekristalu ngokupholisa okunensayo nokulawula izinga lokushisa okunembile, futhi ikhulisa ingot yesafire yekhwalithi ephezulu.

Ukufana okuphezulu: Inkambu eshisayo efanayo kanye nezinga lokukhula liqinisekisa ukwakheka kwamakhemikhali okungaguquki kanye nezakhiwo ezibonakalayo zamakristalu.

2. Ukukhiqizwa kwekristalu kasayizi omkhulu:

Ingot enobubanzi obukhulu: Indlela yokukhula kwebhamuza ye-KY ifanele ukutshala ingot yesafire enosayizi omkhulu enobubanzi obungu-200mm ukuya ku-300mm ukuze kuhlangatshezwane nezidingo zemboni zama-substrates anosayizi omkhulu.

I-Crystal ingot: Ngokulungiselela inqubo yokukhula, i-crystal ingot ende ingakhuliswa ukuze kuthuthukiswe izinga lokusebenzisa izinto.

3. Ukusebenza okuphezulu kwe-optical:

Ukudluliswa kokukhanya okuphezulu: I-KY ukukhula i-sapphire crystal ingot inezici ezinhle kakhulu zokubona, ukudlulisa ukukhanya okuphezulu, ifanele ukusetshenziswa kwe-optical kanye ne-optoelectronic.

Izinga lokumunca eliphansi: Yehlisa ukumuncwa ukulahleka kokukhanya kukristalu, uthuthukise ukusebenza kahle kwamadivayisi abonakalayo.

4. Izici ezinhle kakhulu ezishisayo nezemishini:

I-thermal conductivity ephezulu: I-thermal conductivity ephezulu ye-sapphire ingot ifanele izidingo zokulahla ukushisa zamadivayisi anamandla aphezulu.

Ukuqina okuphezulu nokumelana nokugqoka: I-Sapphire inobunzima be-Mohs obungu-9, okwesibili ngemuva kwedayimane, elifanele ukwakhiwa kwezingxenye ezingakwazi ukugqokwa.

I-Kyropoulos Method iyindlela yokukhulisa amakristalu esafire ekhwalithi ephezulu, umnyombo wawo okuwukufinyelela ukukhula okufanayo kwamakristalu esafire ngokulawula ngokunembile indawo yokushisa nezimo zokukhula kwekristalu. Okulandelayo umphumela othize wendlela ye-KY yokwenza amagwebu ku-sapphire ingot:

1. Ukukhula kwekristalu kwekhwalithi ephezulu:

Ukuminyana okunesici esiphansi: Indlela yokukhula yebhamuza ye-KY yehlisa ukugudluka kanye nokukhubazeka ngaphakathi kwekristalu ngokupholisa okunensayo nokulawula izinga lokushisa okunembile, futhi ikhulisa ingot yesafire yekhwalithi ephezulu.

Ukufana okuphezulu: Inkambu eshisayo efanayo kanye nezinga lokukhula liqinisekisa ukwakheka kwamakhemikhali okungaguquki kanye nezakhiwo ezibonakalayo zamakristalu.

2. Ukukhiqizwa kwekristalu kasayizi omkhulu:

Ingot enobubanzi obukhulu: Indlela yokukhula kwebhamuza ye-KY ifanele ukutshala ingot yesafire enosayizi omkhulu enobubanzi obungu-200mm ukuya ku-300mm ukuze kuhlangatshezwane nezidingo zemboni zama-substrates anosayizi omkhulu.

I-Crystal ingot: Ngokulungiselela inqubo yokukhula, i-crystal ingot ende ingakhuliswa ukuze kuthuthukiswe izinga lokusebenzisa izinto.

3. Ukusebenza okuphezulu kwe-optical:

Ukudluliswa kokukhanya okuphezulu: I-KY ukukhula i-sapphire crystal ingot inezici ezinhle kakhulu zokubona, ukudlulisa ukukhanya okuphezulu, ifanele ukusetshenziswa kwe-optical kanye ne-optoelectronic.

Izinga lokumunca eliphansi: Yehlisa ukumuncwa ukulahleka kokukhanya kukristalu, uthuthukise ukusebenza kahle kwamadivayisi abonakalayo.

4. Izici ezinhle kakhulu ezishisayo nezemishini:

I-thermal conductivity ephezulu: I-thermal conductivity ephezulu ye-sapphire ingot ifanele izidingo zokulahla ukushisa zamadivayisi anamandla aphezulu.

Ukuqina okuphezulu nokumelana nokugqoka: I-Sapphire inobunzima be-Mohs obungu-9, okwesibili ngemuva kwedayimane, elifanele ukwakhiwa kwezingxenye ezingakwazi ukugqokwa.

Imingcele yezobuchwepheshe

| Igama | Idatha | Umphumela |

| Usayizi wokukhula | Ububanzi 200mm-300mm | Nikeza usayizi omkhulu wekristalu yesafire ukuze uhlangabezane nezidingo ze-substrate yosayizi omkhulu, uthuthukise ukusebenza kahle kokukhiqiza. |

| Izinga lokushisa | Izinga lokushisa eliphezulu lingu-2100°C, Ukunemba okungu-±0.5°C | Indawo yokushisa ephezulu iqinisekisa ukukhula kwekristalu, ukulawula izinga lokushisa okunembile kuqinisekisa ikhwalithi yekristalu futhi kunciphisa amaphutha. |

| Isivinini sokukhula | 0.5mm/h - 2mm/h | Lawula izinga lokukhula kwekristalu, uthuthukise ikhwalithi yekristalu nokusebenza kahle kokukhiqiza. |

| Indlela yokushisa | I-Tungsten noma i-molybdenum heater | Inikeza inkambu eshisayo efanayo yokuqinisekisa ukuvumelana kwezinga lokushisa ngesikhathi sokukhula kwekristalu nokuthuthukisa ukufana kwekristalu. |

| Isistimu yokupholisa | Amanzi asebenzayo noma amasistimu okupholisa umoya | Qinisekisa ukusebenza okuzinzile kwemishini, uvimbele ukushisa ngokweqile, futhi welule impilo yemishini. |

| Isistimu yokulawula | I-PLC noma isistimu yokulawula ikhompuyutha | Thola ukusebenza okuzenzakalelayo kanye nokuqapha kwesikhathi sangempela ukuze uthuthukise ukunemba nokusebenza kahle kokukhiqiza. |

| Vacuum imvelo | Isivikelo se-vacuum ephezulu noma i-inert gas | Vimbela i-crystal oxidation ukuze uqinisekise ubumsulwa bekristalu nekhwalithi. |

Isimiso sokusebenza

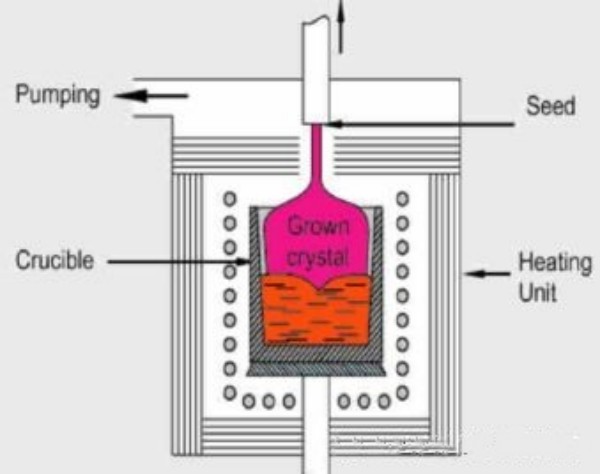

Isimiso sokusebenza se-KY indlela yesithando somlilo sekristalu yesafire sisekelwe endleleni ye-KY (indlela yokukhula kwebhamuza) ubuchwepheshe bokukhula kwekristalu. Umgomo oyisisekelo uthi:

1.Ukuncibilika kwempahla eluhlaza: I-Al2O3 impahla eluhlaza egcwaliswe ku-tungsten crucible ishiselwa endaweni yokuncibilika ngehitha ukuze kwakhe isobho elincibilikisiwe.

2.Ukuxhumana kwekristalu yembewu: Ngemva kokuba izinga loketshezi loketshezi oluncibilikisiwe lizinzile, ikristalu yembewu icwiliswa oketshezini oluncibilikisiwe oluzinga lokushisa kwalo lilawulwa ngokuqinile ukusuka ngaphezu koketshezi oluncibilikisiwe, futhi ikristalu lembewu noketshezi oluncibilikisiwe luqala ukumila amakristalu anesakhiwo sekristalu esifanayo nekristalu yembewu endaweni esibonakalayo enoketshezi oluqinile.

I-3.Ukwakheka kwentamo ye-Crystal: Ikristalu yembewu izungeza phezulu ngesivinini esincane kakhulu futhi idonswa isikhathi esithile ukuze yakhe i-crystal neck.

4. Ukukhula kwekristalu: Ngemva kokuba izinga lokuqiniswa kwesixhumi esibonakalayo phakathi koketshezi kanye nekristalu yembewu lizinzile, ikristalu yembewu ayisadonsi futhi ijikeleze, futhi ilawula kuphela izinga lokupholisa ukuze lenze ikristalu iqine kancane kancane kusukela phezulu kuya phansi, futhi ekugcineni ikhule ikristalu eyodwa yesafire ephelele.

Ukusetshenziswa kwe-sapphire crystal ingot ngemva kokukhula

1. I-substrate ye-LED:

I-LED yokukhanya okuphezulu: Ngemuva kokuthi i-sapphire ingot isikwe ibe yi-substrate, isetshenziselwa ukukhiqiza i-GAN-based LED, esetshenziswa kakhulu ekukhanyeni, ekuboniseni nasezinkundleni zokukhanya kwangemuva.

I-Mini/Micro LED: Ukucaba okuphezulu kanye nokuminyana okunesici esiphansi kwesapphire substrate kulungele ukukhiqiza izibonisi ze-Mini/Micro LED ezinokulungiswa okuphezulu.

2. I-Laser Diode (LD) :

Amalaser aluhlaza: Ama-substrates e-Sapphire asetshenziselwa ukwenza ama-laser diode aluhlaza okokugcina idatha, izinhlelo zokusebenza zokucubungula zezokwelapha nezimboni.

I-Ultraviolet laser: Ukudluliswa kokukhanya okuphezulu kweSapphire nokuzinza kokushisa kulungele ukwakhiwa kwamalaser e-ultraviolet.

3. Iwindi lokubuka:

Iwindi lokudlulisa ukukhanya okuphezulu: Ingot ye-Sapphire isetshenziselwa ukwakha iWindows optical yama-lasers, amadivaysi e-infrared namakhamera asezingeni eliphezulu.

Iwindi lokumelana nokugqoka: Ukuqina okuphezulu kweSapphire nokumelana nokugqokwa kuyenza ifanelekele ukusetshenziswa ezindaweni ezinokhahlo.

4. I-Semiconductor epitaxial substrate:

Ukukhula kwe-GaN epitaxial: Ama-substrates e-Sapphire asetshenziselwa ukukhulisa izendlalelo ze-GaN epitaxial ukuze kwenziwe ama-high electron mobility transistors (HEMTs) kanye namadivayisi e-RF.

Ukukhula kwe-AlN epitaxial: kusetshenziselwa ukukhiqiza amaledi e-ultraviolet ajulile namalaser.

5. I-Consumer Electronics:

Ipuleti lekhava yekhamera ye-smartphone: I-Sapphire ingot isetshenziselwa ukwenza ubulukhuni obuphezulu kanye nepuleti lekhava lekhamera elingazweli.

Isibuko sewashi elihlakaniphile: Ukumelana nokugqokwa okuphezulu kweSapphire kuyenza ifaneleke ukukhiqiza isibuko sewashi elihlakaniphile eliphezulu.

6. Izicelo zezimboni:

Izingxenye zokugqoka: I-Sapphire ingot isetshenziselwa ukwenza izingxenye ezigqokwayo zemishini yezimboni, njengama-bearings nama-nozzles.

Izinzwa zokushisa okuphezulu: Ukuzinza kwamakhemikhali kanye nezakhiwo zokushisa eziphezulu zesafire zifanelekile ukwakhiwa kwezinzwa zokushisa okuphezulu.

7. Umkhathi:

I-Windows lokushisa eliphezulu: Ingot ye-Sapphire isetshenziselwa ukukhiqiza izinga lokushisa eliphezulu iWindows nezinzwa zemishini ye-aerospace.

Izingxenye ezimelana nokugqwala: Ukuzinza kwamakhemikhali esafire kuyenza ifaneleke ukwakhiwa kwezingxenye ezimelana nokugqwala.

8. Imishini yezokwelapha:

Amathuluzi anembe kakhulu: I-Sapphire ingot isetshenziselwa ukwenza amathuluzi ezokwelapha anembe kakhulu njengama-scalpel nama-endoscope.

Ama-Biosensor: I-biocompatibility yesafire iyenza ifaneleke ukwakhiwa kwama-biosensors.

I-XKH inganikeza amakhasimende uhla olugcwele lwezinsiza zemishini yesithando somlilo yesafire ye-KY eyodwa ukuze kuqinisekiswe ukuthi amakhasimende athola ukwesekwa okuphelele, okufika ngesikhathi kanye nokusebenza ngempumelelo ohlelweni lokusebenzisa.

1.Ukuthengiswa kwemishini: Nikeza izinsiza zokuthengisa zemishini yesithando sesafire ye-KY, okuhlanganisa amamodeli ahlukene, imininingwane yokukhethwa kwemishini, ukuze kuhlangatshezwane nezidingo zokukhiqiza zamakhasimende.

Ukusekelwa kwe-2.Technical: ukunikeza amakhasimende ukufakwa kwemishini, ukuthunyelwa, ukusebenza kanye nezinye izici zokusekelwa kwezobuchwepheshe ukuze kuqinisekiswe ukuthi okokusebenza kungasebenza ngokujwayelekile futhi kuzuze imiphumela engcono kakhulu yokukhiqiza.

3.Izinsizakalo zokuqeqesha: Ukuhlinzeka amakhasimende ngokusebenza kwemishini, ukunakekelwa kanye nezinye izici zezinsizakalo zokuqeqesha, ukusiza amakhasimende ajwayele inqubo yokusebenza kwemishini, ukuthuthukisa ukusebenza kahle kokusetshenziswa kwemishini.

4. Izinsizakalo ezenziwe ngokwezifiso: Ngokwezidingo ezikhethekile zamakhasimende, hlinzeka ngezinsizakalo zemishini eyenziwe ngokwezifiso, okuhlanganisa ukuklama kwemishini, ukukhiqiza, ukufakwa kanye nezinye izici zezixazululo eziqondene nomuntu.

Umdwebo onemininingwane