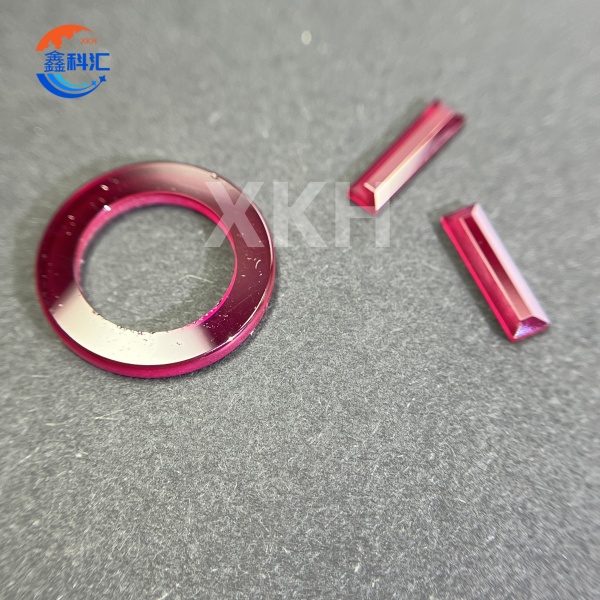

I-Ruby Optical Components Precision Windows Bearing Assemblies Ukumelana Nokushisa Okuphezulu

I-Sapphire (α-Al₂O₃) ivele njengento esebenzayo ebalulekile embonini yesimanje, ebonisa inani elingenakushintshwa kuzo zonke izinhlelo zokusebenza zobuchwepheshe obuphezulu ngenxa yezakhiwo zayo ezihlukile ze-physicochemical. Njengomhlinzeki oholayo wezixazululo zezinto zesafire, i-XKH inamakhono aphelele eketango lezimboni—kusuka ekukhuleni kwekristalu kuya ekwenzeni imishini enembile—okusenza sikwazi ukuletha izingxenye zesafire ezenziwe ngokwezifiso ezihlanganisa amawindi abonakalayo, ama-mechanical bears, nezici ze-laser. Ngokusebenzisa ubuchwepheshe obuthuthukisiwe bokukhiqiza kanye nezinhlelo eziqinile zokulawula ikhwalithi, sizibophezele ekunikezeni amaklayenti embonini ngezisombululo zomkhiqizo wesafire ezisebenza kahle kakhulu, ezinokwethenjelwa.

Ukucaciswa kobuchwepheshe:

| Isigaba sepharamitha | Ukucaciswa |

| Izakhiwo Eziyisisekelo | |

| Isakhiwo Sekristalu | I-Hexagonal (α-Al₂O₃) |

| Mohs Ukuqina | 9 |

| Ukuminyana | 3.98 g/cm³ |

| I-Melting Point | 2050°C |

| I-Optical Properties | |

| Ibanga Lokudlulisela | 0.15-5.5 μm |

| I-Refractive Index | 1.76 @ 589nm |

| I-Birefringence | 0.008 |

| Izakhiwo Zemishini | |

| Amandla e-Flexural | 400-700 MPa |

| I-Elastic Modulus | 345 GPA |

| I-Thermal Expansion Coeff. | 7.5×10⁻⁶/K (25-1000°C) |

| Ukwelashwa Okungaphezulu | |

| I-Standard Finish | I-Ra ≤ 0.05 μm |

| Ukunemba Okuphezulu Qeda | I-Ra ≤ 0.01 μm |

| Izinketho zokumboza | I-AR/HR/Metallic coatings |

Izici Eziyinhloko:

- Ukuguquguquka Kwemvelo Okukhethekile

Izingxenye zesafire zibonisa ukusebenza okuvelele ezindaweni ezidlulele, zigcina ukusebenza okuzinzile kulo lonke izinga lokushisa elibanzi elingu -200°C kuya +1000°C. Isakhiwo sabo sekristalu esiyingqayizivele sinikeza ukumelana nokushaqeka okushisayo okuphakeme, ukuvimbela ukuqhekeka noma ukuguqulwa ngisho nangaphansi kokuguquguquka okusheshayo kwezinga lokushisa. Ezimweni ze-vacuum, izingxenye zesafire zisebenza ngokuthembekile kumaleveli e-vacuum aphezulu kakhulu (10⁻⁶ Pa) ngaphandle kokungcoliswa kokukhipha umoya. Ukwengeza, isafire ikhombisa ukumelana kahle nemisebe, igcina ubuqotho besakhiwo kanye nokusebenza kumithamo yemisebe efika ku-10⁶ Gy.

- Ukuqina Okungenakuqhathaniswa

Ngobulukhuni be-Mohs obungu-9 (isibili kuphela kwedayimane), izingxenye zesafire zinikeza ukumelana nokugqokwa okukhethekile. Ukuhlola okuqhathanisayo kubonisa izingxenye zesafire zibonisa izilinganiso zokugqoka ezingu-1/10 nje zezingxenye zensimbi ezivamile. Ngokwekhemikhali, isafire imelana cishe nawo wonke ama-asidi aqinile (ngaphandle kwe-HF), ama-alkali, nezinyibilikisi eziphilayo. Lezi zakhiwo zenza izingxenye zesafire zithole ukuphila kwesevisi izikhathi ezingu-5-8 isikhathi eside kunezinto ezivamile, kunciphisa kakhulu izindleko zokulungisa kanye nesikhathi sokuphumula.

- Ukusebenza Okunembayo Okuphezulu

Sapphire components provide unique advantages in precision manufacturing. Their ultra-low thermal expansion coefficient (7.5×10⁻⁶/K) ensures dimensional stability, typically achieving ±0.1μm/100mm variation. Through precision machining, we achieve surface flatness of λ/10@632.8nm and angular tolerances of ±15 arc-seconds, meeting the most stringent optical system requirements. These characteristics make sapphire ideal for high-precision measurement and optical applications.

Izinzuzo Eziyinhloko:

- Isilinganiso Sokusebenza Nezindleko

Izingxenye zethu zesafire zigcina ngaphezu kuka-85% wamamethrikhi okusebenza angukhiye kuyilapho zinikeza ukonga kwezindleko ezingaphezu kuka-30% uma kuqhathaniswa nemikhiqizo yesafire evamile. Ngokukhula kwekristalu okuthuthukisiwe nezinqubo zokwenza, sifinyelela ibhalansi efanele phakathi kokusebenza nezindleko. Ukulawulwa kwekhwalithi okuqinile kuqinisekisa ukuvumelana kweqoqo-to-batch ngokuchezuka kwepharamitha engu-≤3%.

- Amakhono Esevisi Aphelele

Sigcina uhlelo lokuphendula olusheshayo, siletha izixazululo zobuchwepheshe phakathi namahora angu-48. Imodeli yethu yokukhiqiza eguquguqukayo ithatha ama-oda asuka ku-1 kuye ku-10,000 amayunithi. Iphrothokholi yokuhlola enezinyathelo ezingu-36 ihlanganisa ukunemba kobukhulu, ikhwalithi yendawo ephezulu, kanye nezakhiwo zokukhanda ukuze kuqinisekiswe izindinganiso zekhwalithi ye-premium.

Izicelo Eziyinhloko:

Izicelo Zezimboni Ezisezingeni Eliphezulu

Ukukhiqiza I-Semiconductor: Imikhombandlela yamarobhothi abamba ama-wafer

I-Precision Metrology: Ama-Probes ama-CMM (Coordinate Measuring Machines)

I-Fiber Optics: Imibhobho yokudweba enokuqina okushisayo okuphakeme

2. Izinhlelo Ezithuthukile Zokubona

Ubuchwepheshe be-Laser: I-High-LIDT (I-Laser-Induced Damage Threshold) windows nama-Q-switches

Izicelo Zokuvikela: I-infrared missile domes

I-Spectroscopy: Ama-Prisms namafasitela wezinsimbi zokuhlaziya

3. Izicelo Zemvelo Ezeqisayo

I-Aerospace: Ama-bearings okulawula isimo semikhumbi-mkhathi

I-Deep-Sea Exploration: Izizinda zokubuka ezimelana nokucindezela

Imboni Yenuzi: Amawindi okubuka avikelwe ngemisebe

XKH'sAmasevisi:

I-XKH inikezela ngezixazululo zengxenye yesafire yokuphela-siya-ekupheleni:

· Iphothifoliyo Yomkhiqizo: 200+ amamodeli ajwayelekile esitokweni; osayizi ngokwezifiso kusuka ku-0.5-300mm

· Imisebenzi Yezobuchwepheshe: Ubunjiniyela bezicelo, ukulingiswa kwe-FEA, ukuhlaziya ukwehluleka

· Ukwelapha Okungaphezulu: Izembatho ze-DLC, i-AR (Anti-Reflective).

· Ukuqinisekisa Ikhwalithi: Imibiko yokuhlola eqinisekisiwe yenkampani yangaphandle

· Logistics: iziphakamiso zobuchwepheshe zamahora angu-48; Amaviki angu-2-4 ukulethwa kwesampula

Isiphetho

Izingxenye zeSapphire ziletha inani eliyingqayizivele ezinhlelweni zokusebenza zezimboni ezisezingeni eliphezulu ngezakhiwo zazo ze-physicochemical ezingenakuqhathaniswa. Lo mbiko unemininingwane yezici zabo ezibucayi, izinzuzo, kanye nokusetshenziswa kwemikhakha eminingi. Ngokuhlanganisa amasistimu esevisi aqinile nokulawula ikhwalithi okuqinile, i-XKH inikeza izixazululo ezinokwethenjelwa, ezingabizi kakhulu zesafire. Ukuqhubekela phambili, sizoqhubeka sithuthukisa ukusebenza kwempahla kanye nokucubungula ubuchwepheshe ukuze sandise ukusetshenziswa kwesafire kuma-semiconductors, optics, aerospace, nangale kwalokho. Siyakwamukela ukusebenzisana nozakwethu bemboni ukuze ngokuhlanganyela siqhubekisele phambili ukuqanjwa kabusha kubuchwepheshe be-sapphire material.