I-Ruby Bearings Precision Jewel Bearings

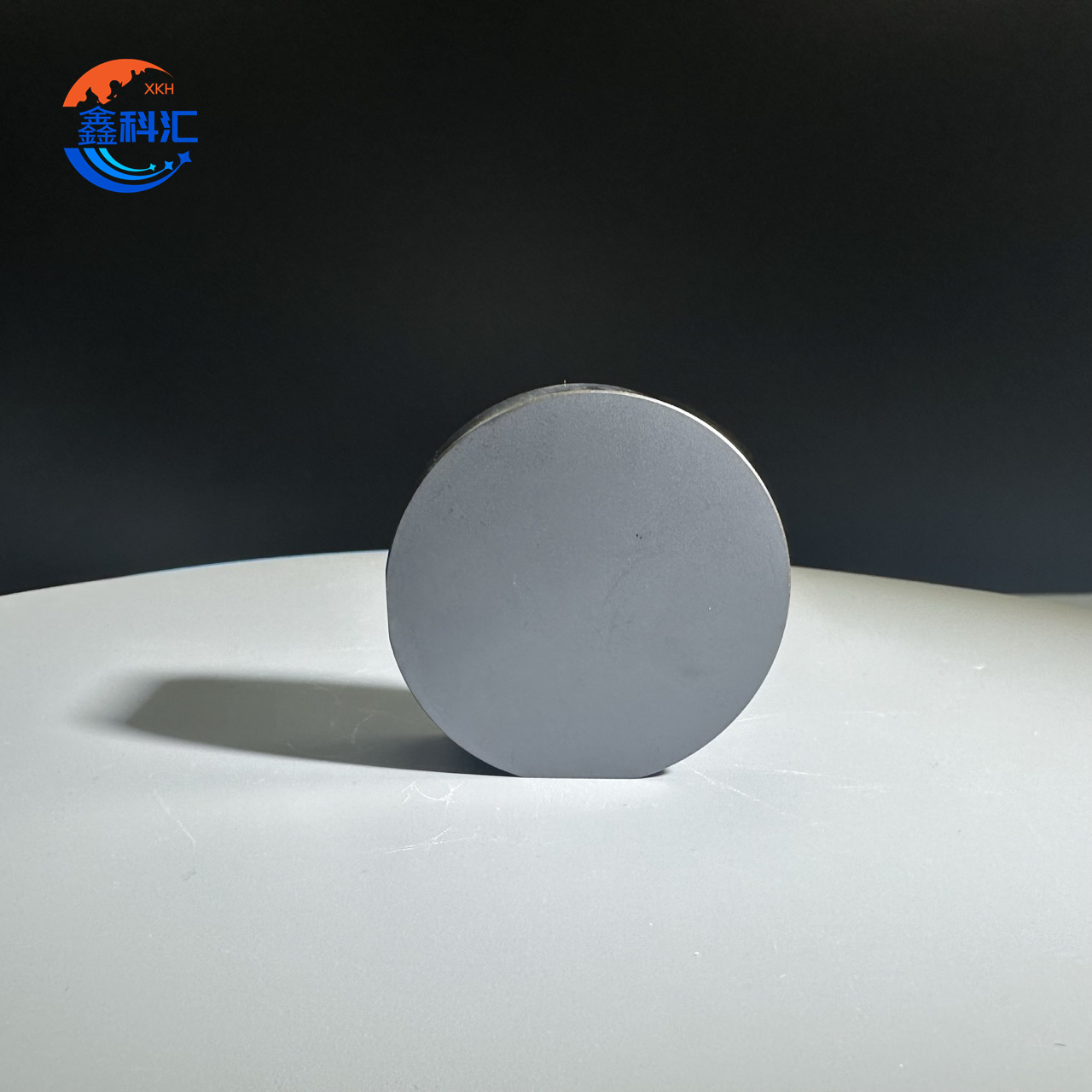

Umdwebo onemininingwane

Ukubuka konke kwe-Ruby Bearings

Ama-ruby bearings, abuye abizwe ngokuthi ama-jewel bearings, ayizingxenye zokunemba ze-premium-grade ezidizayinelwe izimboni lapho ukunemba, ukwethembeka, nokuphila isikhathi eside kungaxoxiswana khona. Enziwe ngerubi yokwenziwa, lawa mabheringi aletha ukungqubuzana okuphansi kakhulu, ukumelana nokugqokwa okuvelele, nokuqina okungenakuqhathaniswa, okuwenza abe yinketho ekhethwayo yezinhlelo zokusebenza kusukela kumawashi kanokusho kuya kumasistimu okuzulazula emkhathini.

Kungani i-Ruby Bearings Igqama

Ubunjiniyela besimanje bufuna izingxenye ezingabekezelela izimo ezimbi kakhulu ngenkathi kugcinwa ukunemba kwezinga le-micron.Ama-ruby bearingshlinzeka ngqo lokho. Izindawo zabo ezibushelelezi kakhulu zinciphisa ukuguga ezingxenyeni zokukhwelana, zehlisa ukulahlekelwa amandla, futhi zisekele ukusebenza okuqhubekayo ngokulungiswa cishe iqanda.

Uma kuqhathaniswa nama-metal bearings,ama-ruby bearingszinikeza izinzuzo ezibalulekile: azigqwali, azithobi ngaphansi kwamakhemikhali, noma zilahlekelwa ukunemba ngaphansi kokushintsha kwezinga lokushisa. Lezi zakhiwo zizenza zibaluleke kakhulu emikhakheni lapho ukunemba kuchaza impumelelo.

Izinzuzo Zokusebenza Ezibalulekile Ze-Ruby Bearings

-

Ukuqina Okungenakuqhathaniswa:Ikalwe ngo-9 esikalini se-Mohs,ama-ruby bearingsukuletha ukumelana okuphezulu kokuhunyushwa kanye ne-deformation.

-

Ukusebenza Okungaguquki Kwe-Low-Friction:Igcina ukusebenza kahle ezinhlelweni zokusebenza ezinesivinini esikhulu nezithambile ngokufanayo.

-

Ukuthembeka Okungenayo Isondlo:Impilo ende yokusebenza inciphisa isikhathi sokuphumula kanye nezindleko zokushintshwa.

-

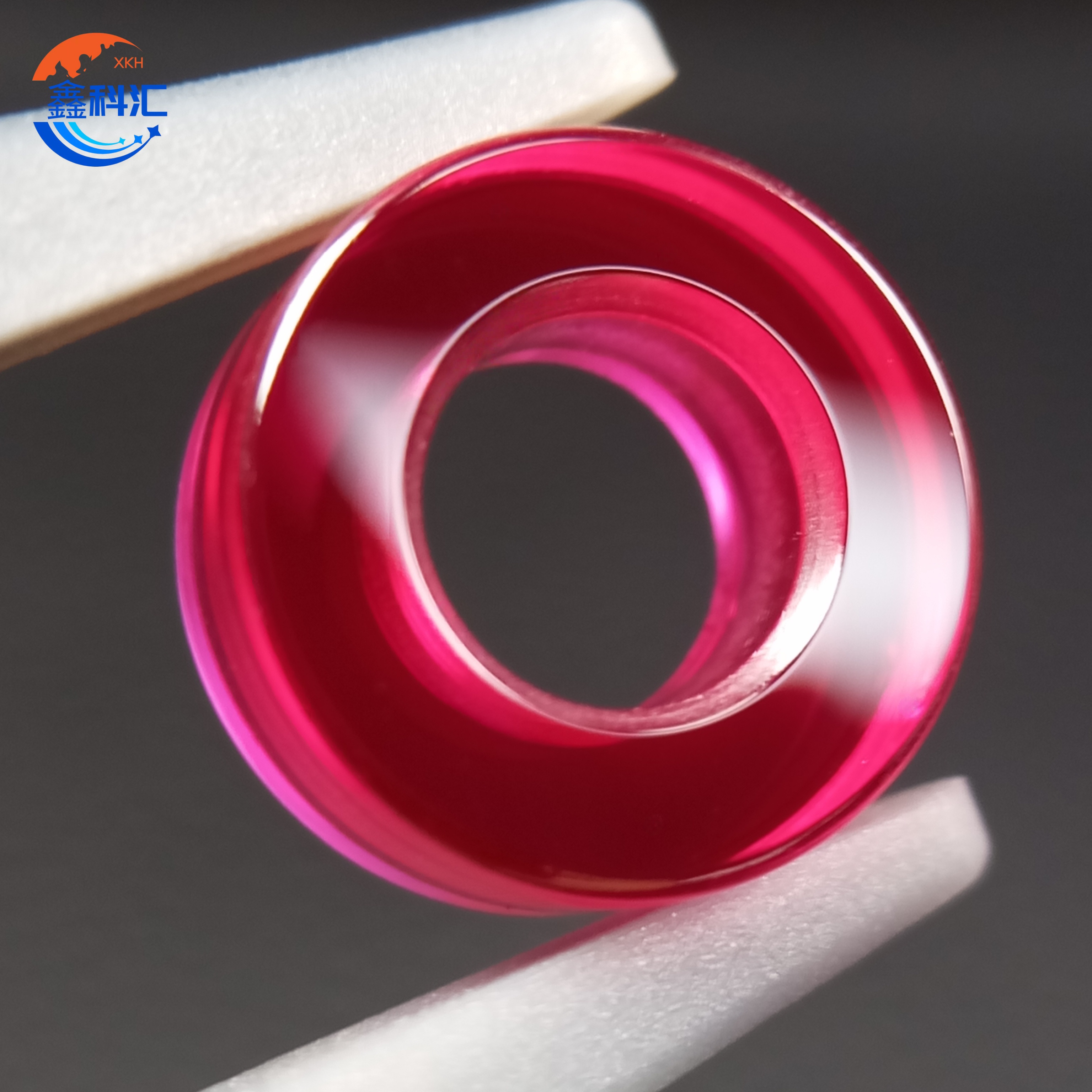

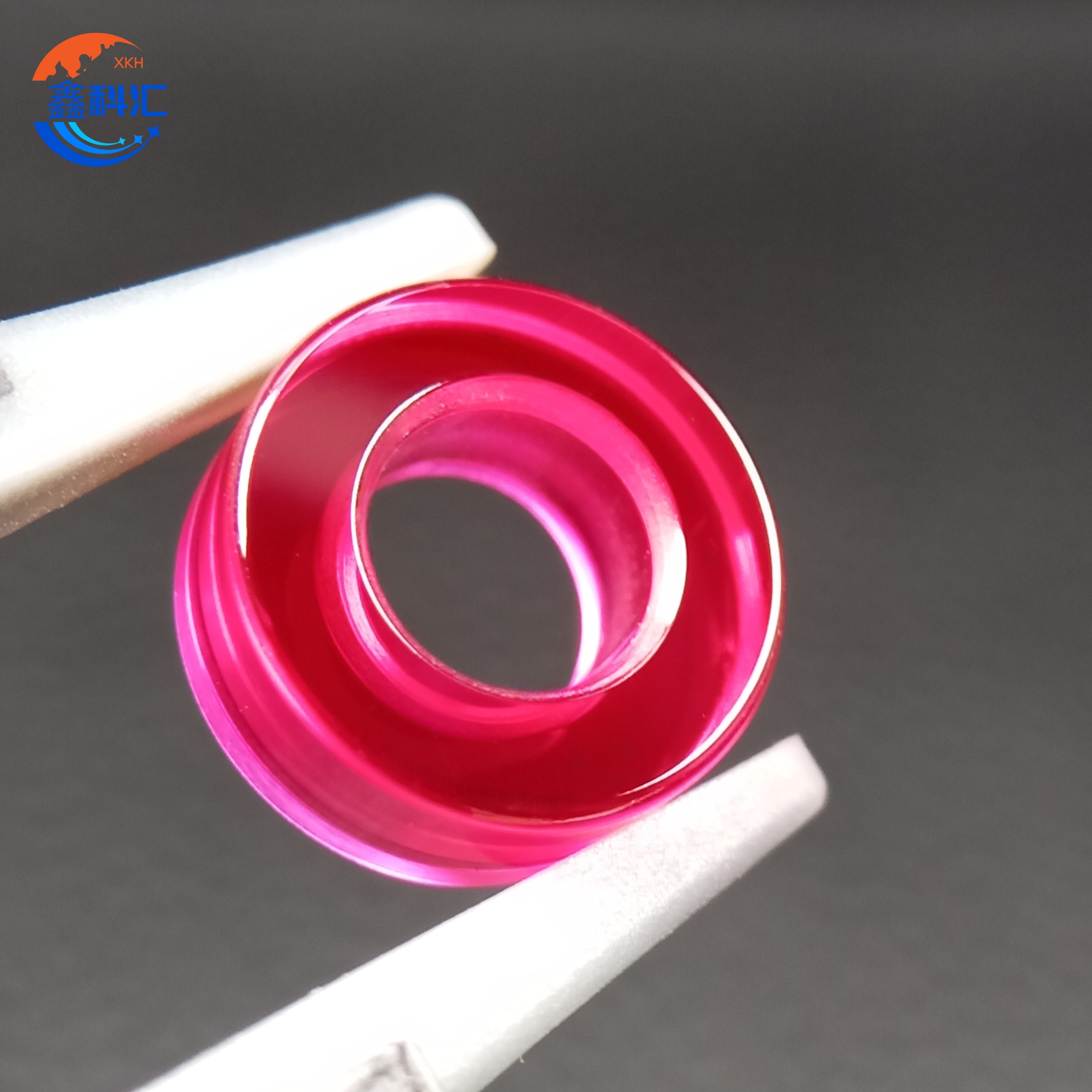

Ukuhlukahluka:Itholakala ngezinhlobo ezahlukene (izinkomishi, izindandatho, ama-pivots) ukuhlangabezana nezidingo ezihlukahlukene zobunjiniyela.

-

Ukukhuthazela Kwamakhemikhali Nokushisa:Isebenza ngokungenasici ezindaweni ezonakalisayo namazinga okushisa abanzi.

Izicelo ze-Ruby Bearings embonini yesimanje

I-Luxury Horology:

I-Ruby jewel bearingszibalulekile ekwenziweni kwamawashi okusezingeni eliphezulu, ukuqinisekisa ukunyakaza okunembayo, okushelelayo kwamagiya kanye nokuthuthukisa isikhathi eside sewashi.

Izisetshenziswa zezokwelapha nezelabhorethri:

Amadivayisi abalulekile njengamaphampu okufakelwa, izihlaziyo zegazi, nokubhoboza amazinyo kuncikeama-ruby bearingsukusebenza okuthembekile, okuhlanzekile, nokungakhathaleli.

Amarobhothi nokuzenzakalela:

Emajoyini amarobhothi, imishini ye-CNC, nemishini ye-semiconductor,ama-ruby bearingsvumela ukunyakaza okunembile, okungagugi emijikelezweni emide yokukhiqiza.

I-Aerospace & Navigation:

Kumasathelayithi, amathuluzi okuzulazula, nezinhlelo zokukhomba,ama-ruby bearingsukumelana nokucindezeleka okukhulu kanye nezici zemvelo ngaphandle kokulahlekelwa ukusebenza.

I-Optics & Laser Systems:

Ama-ruby bearings okwenziwaqinisekisa ukuqondanisa okunembile kanye nokunyakaza kwezinsimbi ezibonakalayo, izinhlelo ze-laser, namadivayisi wokuskena.

I-FAQ - I-Ruby Bearings (Ama-Jewel Bearings)

Q1: Uyini umehluko phakathi kwama-ruby nama-sapphire bearings?

I-A1: Zombili ziyizinhlobo ze-synthetic corundum ezinezakhiwo ezifanayo.Ama-ruby bearingszihlanganisa i-chromium, ibanike umbala obomvu, kuyilapho ama-sapphire bearings engenambala. Ngokokusebenza, ziyafana.

I-Q2: Ingabe ama-ruby bearings ayenzeka ngokwezifiso?

A2: Yebo.Ama-ruby bearingsingakhiqizwa ngobukhulu obuhlukahlukene, ubujamo, kanye nokubekezelelana ukuze kuhlangatshezwane nezidingo ezithile zokuklama.

Q3: Ngabe ama-ruby bearings anikela kanjani ekongeni izindleko?

I-A3: Ukuphila kwabo okude, izidingo zokunakekelwa okuphansi, nokusebenza okungaguquki kunciphisa izindleko zokusebenza zizonke ngokuhamba kwesikhathi.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.