I-Precision Microjet Laser System ye-Hard & Brittle Materials

Izici Eziyinhloko

Isakhiwo Sesilayidi Esiqinile

Isisekelo sohlobo lwe-cross-slide esinesakhiwo esijiyile sika-symmetric sinciphisa ukuwohloka kokushisa futhi siqinisekise ukunemba kwesikhathi eside. Lesi sakhiwo sinikeza ukuqina okuhle kakhulu futhi sivumela ukusebenza kokugaya okuzinzile ngaphansi komthwalo oqhubekayo.

I-Independent Hydraulic System for Reciprocating Motion

Ukunyakaza okuphindaphindayo kwetafula kwesokunxele kuya kwesokudla kunikwa amandla isiteshi esisebenza ngaphansi kwamanzi esizimele esinesistimu yokuhlehlisa i-electromagnetic valve. Lokhu kubangela ukunyakaza okushelelayo, okunomsindo ophansi nokukhiqiza ukushisa okuphansi, okuyenza ifanelekele ukukhiqizwa kwesikhathi eside.

I-Anti-Mist Honeycomb Baffle Design

Ohlangothini lwesobunxele lwetafula lokusebenza, isihlangu samanzi sesitayela sezinyosi sinciphisa ngempumelelo inkungu ekhiqizwa ngesikhathi sokugaya okumanzi, sithuthukisa ukubonakala nokuhlanzeka ngaphakathi komshini.

I-Dual V-Guide Rails ene-Servo Ball Screw Feed

Ukunyakaza kwetafula elingaphambili nangemuva lisebenzisa ama-rails ahamba kabili anomumo we-V ane-servo motor kanye ne-ball screw drive. Lokhu kulungiselelwa kunika amandla ukuphakela okuzenzakalelayo, ukunemba okuphezulu kwesikhundla, nobude besikhathi bemishini enwetshiwe.

Okuphakelayo Okuqondile Ngomhlahlandlela Wokuqina Okuphezulu

Ukunyakaza okuma mpo kwekhanda eligayayo kusebenzisa imihlahlandlela yensimbi eyisikwele nezikulufu zebhola ezishayelwa yi-servo. Lokhu kuqinisekisa ukuzinza okuphezulu, ukuqina, kanye nokuhlehla okuncane, ngisho nangesikhathi sokusika okujulile noma amaphasi okugcina.

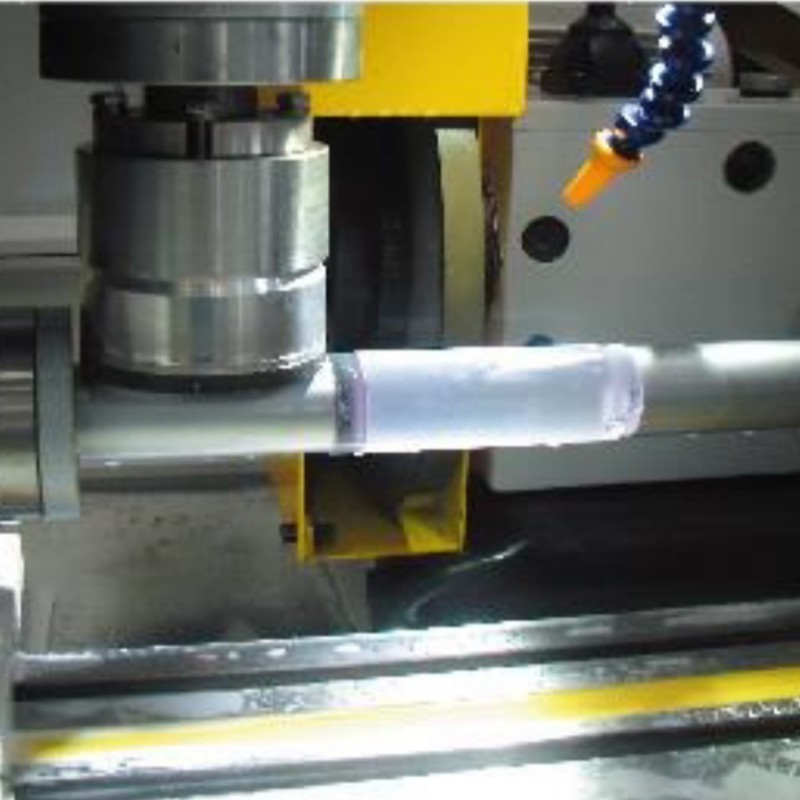

I-High-Precision Spindle Assembly

Ifakwe ukuphotha okuqinile okuphezulu nokunemba okuphezulu, ikhanda lokugaya liletha ukusebenza kahle kokusika okuphezulu. Ukusebenza okungaguquguquki kuqinisekisa ukuqedwa kwengaphezulu okuhle kakhulu futhi kwandisa impilo yokuphotha.

Uhlelo lukagesi oluthuthukisiwe

Kusetshenziswa ama-Mitsubishi PLCs, ama-servo motors, nama-servo drives, uhlelo lokulawula ugesi lwenzelwe ukwethembeka nokuvumelana nezimo. Isondo lesandla le-elekthronikhi langaphandle linikeza ukulungisa kahle mathupha futhi lenze lula izinqubo zokusetha.

Idizayini evaliwe ne-ergonomic

Idizayini evalekile ngokugcwele ayigcini nje ngokuthuthukisa ukuphepha kokusebenza kodwa futhi igcina indawo yangaphakathi ihlanzekile. I-aesthetic casing yangaphandle enobukhulu obuthuthukisiwe yenza umshini unakekele futhi uthuthwe kalula.

Izindawo Zokufaka Isicelo

I-Sapphire Wafer Ukugaya

Ibalulekile ezimbonini ze-LED ne-semiconductor, lo mshini uqinisekisa ukucaba kanye nobuqotho bonqenqema be-sapphire substrates, ebalulekile ekukhuleni kwe-epitaxial kanye ne-lithography.

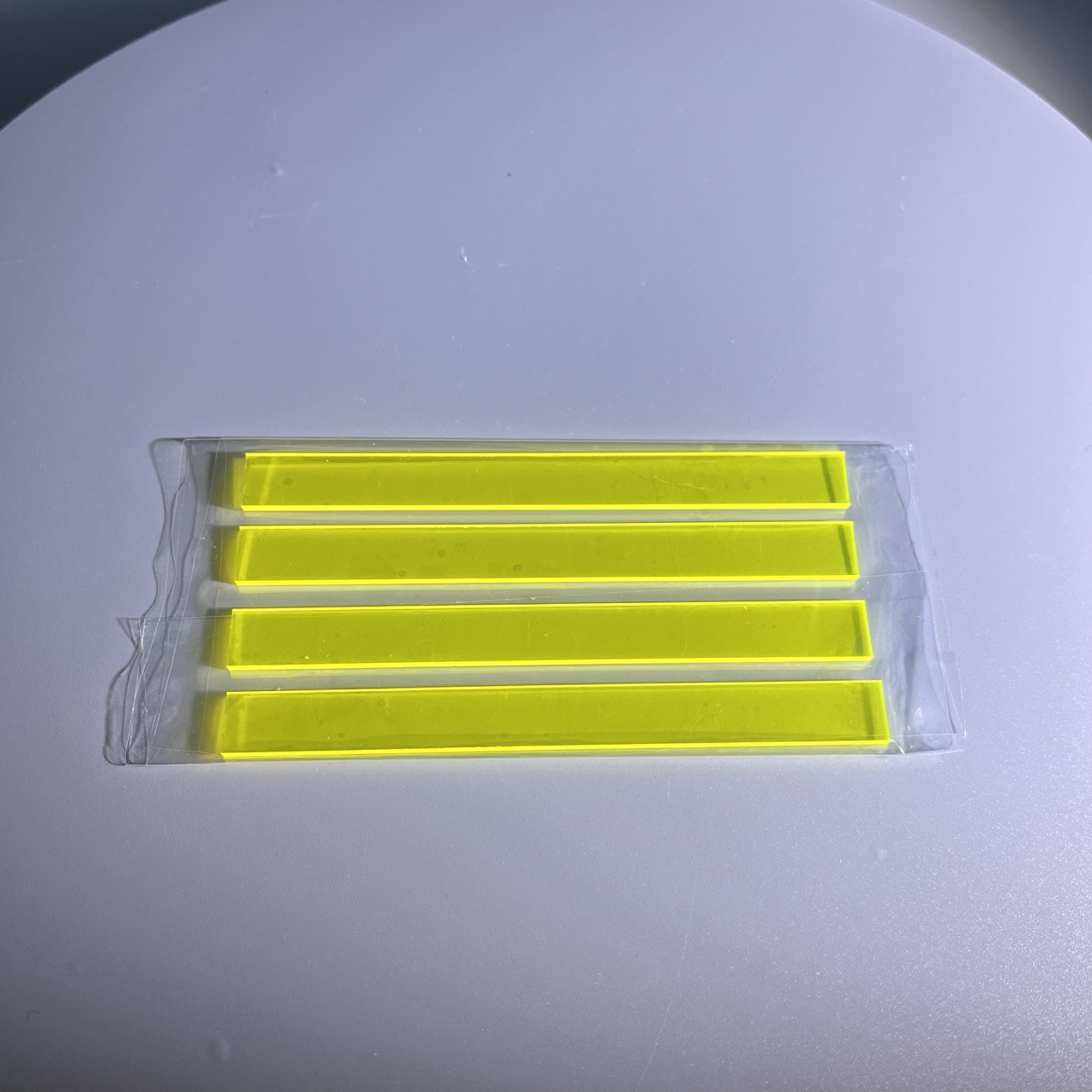

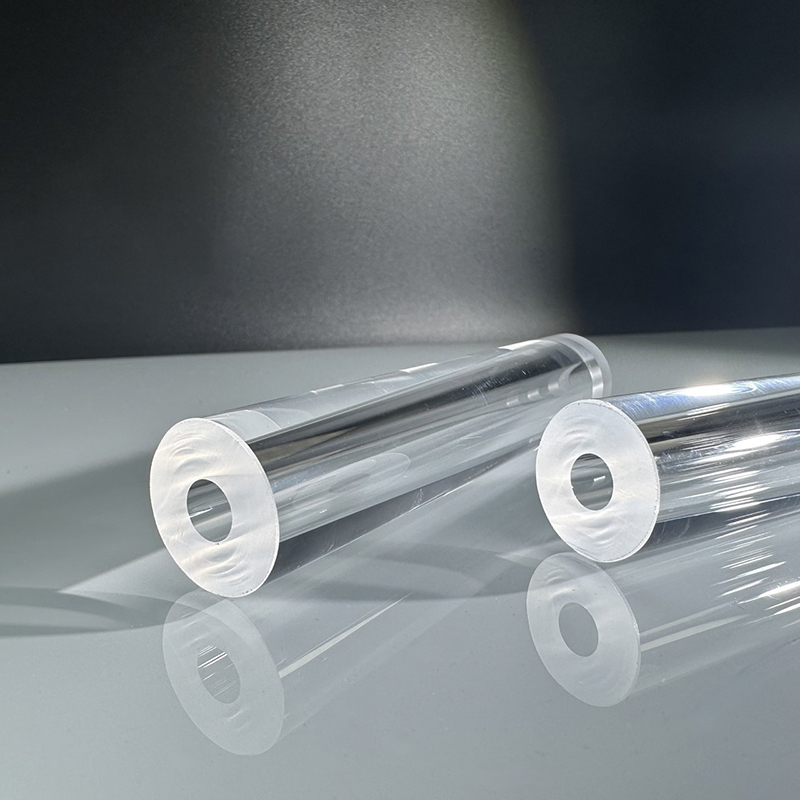

I-Optical Glass kanye ne-Window Substrates

Ilungele ukucubungula amawindi e-laser, ingilazi yesibonisi ehlala isikhathi eside, namalensi ekhamera avikelayo, aletha ukucaca okuphezulu nobuqotho besakhiwo.

I-Ceramic kanye ne-Advanced Materials

Isebenza ku-alumina, i-silicon nitride, ne-aluminium nitride substrates. Umshini uyakwazi ukuphatha izinto ezithambile ngenkathi ugcina ukubekezelelana okuqinile.

Ucwaningo Nentuthuko

Ikhethwa izikhungo zocwaningo ukuze kulungiselelwe izinto zokuhlola ngenxa yokulawula kwayo okunembayo nokusebenza okuthembekile.

Izinzuzo Uma Ziqhathaniswa Nemishini Yokugaya Yendabuko

● Ukunemba okuphakeme ngezimbazo eziqhutshwa yi-servo kanye nokwakhiwa okuqinile

● Izilinganiso zokususa izinto ezisheshayo ngaphandle kokufaka engozini ukuphela kwendawo

● Umsindo ophansi kanye nezigxivizo zezinyawo ezishisayo ngenxa ye-hydraulic kanye namasistimu e-servo

● Ukubonakala okungcono nokusebenza okuhlanzekile ngenxa yezithiyo zokulwa nenkungu

● Ukusebenzelana okuthuthukisiwe komsebenzisi kanye nezinqubo zokulungisa ezilula

Isondlo Nokwesekwa

Ukunakekelwa okujwayelekile kwenziwa lula ngesakhiwo esifinyelelekayo kanye nesistimu yokulawula esebenziseka kalula. Amasistimu wokuphotha kanye nomhlahlandlela aklanyelwe ukuqina, adinga ukungenelela okuncane. Ithimba lethu losekelo lobuchwepheshe linikeza ukuqeqeshwa, izingxenye eziyisipele, nokuxilongwa ku-inthanethi ukuze kuqinisekiswe ukusebenza okuphezulu kuyo yonke impilo yomshini.

Ukucaciswa

| Imodeli | I-LQ015 | I-LQ018 |

| Ubukhulu be-Workpiece Usayizi | 12 intshi | 8 intshi |

| I-Max Workpiece Ubude | 275 mm | 250 mm |

| Isivinini Sethebula | 3–25 m/min | 5–25 m/min |

| Usayizi Wesondo Lokugaya | φ350xφ127mm (20–40mm) | φ205xφ31.75mm (6–20mm) |

| Isivinini se-Spindle | 1440 rpm | 2850 rpm |

| Ukucaba | ±0.01 mm | ±0.01 mm |

| Ukufana | ±0.01 mm | ±0.01 mm |

| Amandla Aphelele | 9 kw | 3 kw |

| Isisindo Somshini | 3.5 t | 1.5 t |

| Ubukhulu (L x W x H) | 2450x1750x2150 mm | 2080x1400x1775 mm |

Isiphetho

Kungakhathaliseki ukuthi okokukhiqiza ngobuningi noma ucwaningo, Umshini Wokugaya I-Sapphire CNC Surface uletha ukunemba nokuthembeka okudingekayo ekucutshungulweni kwezinto zanamuhla. Idizayini yayo ehlakaniphile kanye nezingxenye eziqinile kuyenza ibe yimpahla yesikhathi eside yanoma yimuphi umsebenzi wokukhiqiza wobuchwepheshe obuphezulu.

Umdwebo onemininingwane