Njengempahla yesizukulwane sesithathu semiconductor substrate,i-silicon carbide (SiC)Ikristalu eyodwa inamathemba okusebenza abanzi ekukhiqizeni amadivaysi kagesi anemvamisa ephezulu namandla aphezulu. Ubuchwepheshe bokucubungula be-SiC budlala indima ebalulekile ekukhiqizeni izinto ezisezingeni eliphezulu ze-substrate. Lesi sihloko sethula isimo samanje socwaningo lobuchwepheshe bokucubungula i-SiC kokubili e-China naphesheya, ihlaziya futhi iqhathanise izindlela zokusika, ukugaya, nezinqubo zokupholisha, kanye nezitayela zokugqagqana kwe-wafer kanye nokubangwa kwengaphezulu. Iphinde iveze izinselelo ezikhona ekucutshungulweni kwe-SiC wafer futhi idingide izikhombisi-ndlela zentuthuko zesikhathi esizayo.

I-Silicon carbide (SiC)ama-wafers ayizinto ezibalulekile eziyisisekelo zamadivayisi e-semiconductor esizukulwane sesithathu futhi abambe ukubaluleka okukhulu namandla emakethe emikhakheni efana ne-microelectronics, amandla kagesi, kanye nokukhanyisa kwe-semiconductor. Ngenxa yobulukhuni obuphezulu kakhulu kanye nokuzinza kwamakhemikhali weAmakristalu e-SiC eyodwa, izindlela zokucubungula ze-semiconductor zendabuko azifaneleki ngokuphelele ekusetshenzisweni kwazo. Nakuba izinkampani eziningi zamazwe ngamazwe zenze ucwaningo olubanzi mayelana nokucutshungulwa kwekristalu eyodwa ye-SiC okufuna ubuchwepheshe, ubuchwepheshe obufanele bugcinwa buyimfihlo kakhulu.

Eminyakeni yamuva nje, i-China iye yandisa imizamo yokuthuthukisa i-SiC single crystal materials namadivayisi. Kodwa-ke, ukuthuthuka kobuchwepheshe bedivayisi ye-SiC ezweni okwamanje kuvinjelwe imikhawulo kubuchwepheshe bokucubungula kanye nekhwalithi ye-wafer. Ngakho-ke, kubalulekile ukuthi i-China ithuthukise amakhono okucubungula i-SiC ukuze kuthuthukiswe ikhwalithi yama-SiC single crystal substrates futhi kuzuzwe ukusetshenziswa kwawo okungokoqobo nokukhiqiza ngobuningi.

Izinyathelo zokucubungula eziyinhloko zihlanganisa: ukusika → ukugaya okumahhadla → ukugaya kahle → ukupholishwa okumahhadlahhadla (ukupholishwa ngomshini) → ukupholishwa kahle (ukupholisha ngomshini ngamakhemikhali, i-CMP) → ukuhlola.

| Isinyathelo | I-SiC Wafer Processing | I-Traditional Semiconductor I-Single-Crystal Material Processing |

| Ukusika | Isebenzisa ubuchwepheshe bokusaha obunezintambo eziningi ukusika ama-ingots e-SiC abe amawafa amancane | Ngokuvamile isebenzisa amasu okusika ama-blade angaphakathi-ububanzi noma angaphandle |

| Ukugaya | Ihlukaniswe yaba amaholoholo futhi ukugaya kahle ukususa amasaha kanye nomonakalo izingqimba okubangelwa ukusikwa | Izindlela zokugaya zingahluka, kodwa umgomo uyefana |

| Ukupholisha | Kubandakanya ukupholisha okumaholoholo nokunembe kakhulu kusetshenziswa ukupholisha ngomshini namakhemikhali (CMP) | Ngokuvamile kufaka phakathi ukupholisha kwamakhemikhali (CMP), nakuba izinyathelo ezithile zingahluka |

Ukusikwa kwe-SiC Single Crystals

Ekucutshungulweni kweAmakristalu e-SiC eyodwa, ukusika kuyisinyathelo sokuqala futhi esibucayi kakhulu. Umnsalo we-wafer, i-wafer, kanye nokuhlukahluka kogqinsi okuphelele (i-TTV) okubangelwa inqubo yokusika kunquma ikhwalithi nokusebenza kahle kwemisebenzi elandelayo yokugaya nokupholisha.

Amathuluzi okusika angahlukaniswa ngomumo abe amasaha edayimane langaphakathi (ID), ububanzi bangaphandle (OD), amasaha amabhande, namasaha ocingo. Amasaha ocingo, wona, angahlukaniswa ngohlobo lwawo olunyakazayo abe amasistimu ezintambo eziphindaphindayo kanye neziluphu (ezingapheli). Ngokusekelwe kumshini wokusika we-abrasive, amasu okusika amasaha angahlukaniswa abe izinhlobo ezimbili: ukusaha ngocingo olulimazayo lwamahhala kanye nokusaha ngocingo lwedayimane olunamekayo.

1.1 Izindlela Zomdabu Zokusika

Ukujula kokusika kwamasaha obubanzi bangaphandle (OD) kunqunyelwe ububanzi bensingo. Ngesikhathi sokusika, i-blade ijwayele ukudlidliza nokuphambuka, okuholela emazingeni aphezulu omsindo kanye nokungaqini kahle. Amasaha obubanzi obungaphakathi (ID) asebenzisa ama-abrasive edayimane esiyingini sangaphakathi se-blade njengomkhawulo wokusika. Lawa ma-blades angaba mncane njengo-0.2 mm. Ngesikhathi sokusikwa, i-ID blade izungeza ngesivinini esikhulu kuyilapho okokusebenza okufanele kusikwe kuhamba ngokukhulu ngokuhlobene nendawo ephakathi kwensika, kufinyelele ukusika ngalokhu kunyakaza okuhlobene.

Amasaha ebhendi yedayimane adinga ukuma nokuhlehliswa njalo, futhi isivinini sokusika siphansi kakhulu—ngokujwayelekile asidluli ku-2 m/s. Baphinde bahlupheke ngokuguga okubalulekile kwemishini kanye nezindleko eziphezulu zokunakekela. Ngenxa yobubanzi be-saw blade, i-radius yokusika ayikwazi ukuba yincane kakhulu, futhi ukusika izingcezu eziningi akunakwenzeka. Lawa mathuluzi okusaha endabuko anqunyelwe ukuqina kwesisekelo futhi awakwazi ukwenza ukusikeka okugobile noma anomkhawulo ophenduphendukayo werediya. Ziyakwazi kuphela ukusikeka okuqondile, zikhiqize ama-kerfs abanzi, zinenani eliphansi lesivuno, futhi ngenxa yalokho azikulungele ukusika.Amakristalu e-SiC.

1.2 I-Abrasive wire Saw yamahhala yokusika izintambo eziningi

Indlela yamahhala yokusika i-wire abrasive slicing isebenzisa ukunyakaza okusheshayo kocingo ukuze ithwale i-slurry ku-kerf, ivumela ukususwa kwezinto. Ngokuyinhloko isebenzisa ukwakheka okuphindaphindayo futhi njengamanje iyindlela evuthiwe nesetshenziswa kabanzi yokusika okuyisinkwa esiyisinkwa esine-multi-wafer kwe-silicon yekristalu eyodwa. Kodwa-ke, ukusetshenziswa kwayo ekusikeni kwe-SiC kufundwe kancane kakhulu.

Amasaha ocingo abrasive amahhala angacubungula amawafa anogqinsi olungaphansi kuka-300 μm. Banikeza ukulahleka kwe-kerf ephansi, abavamisile ukubangela ukuqhekeka, futhi kubangele ikhwalithi ephezulu kakhulu. Kodwa-ke, ngenxa yendlela yokususa izinto—ngokusekelwe ekugiqekeni nasekungeneni kwama-abrasives—indawo eyisicwecwana ijwayele ukuthuthukisa ukucindezeleka okuyinsalela okubalulekile, ama-microcracks, nezingqimba zokulimala ezijulile. Lokhu kuholela ku-wafer warping, kwenza kube nzima ukulawula ukunemba kwephrofayili engaphezulu, futhi kukhulisa umthwalo ezinyathelweni zokucubungula ezilandelayo.

Ukusebenza kokusika kuthonywa kakhulu yi-slurry; kuyadingeka ukugcina ubukhali be-abrasives kanye nokugxila kwe-slurry. Ukwelashwa kwe-slurry kanye nokugaywa kabusha kuyabiza. Uma usikwa ama-ingots anosayizi omkhulu, ama-abrasives aba nobunzima bokungena ezinhlotsheni ezijulile nezinde. Ngaphansi kosayizi ofanayo wokusanhlamvu olimazayo, ukulahleka kwe-kerf kukhulu kunalokho kwamasaha ocingo oluqinile.

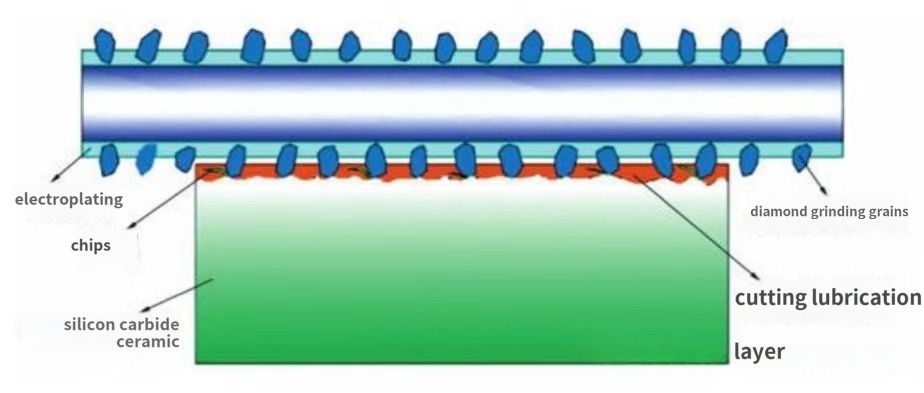

1.3 I-Fixed Abrasive Diamond Wire Saw Multi-Wire Cutting

Amasaha ezintambo zedayimane ezicijile ezigxilile ngokuvamile enziwa ngokushumeka izinhlayiya zedayimane endaweni yensimbi yensimbi ngokusebenzisa izindlela zokuhlanganisa i-electroplating, sintering, noma i-resin bonding. Amasaha ocingo lwedayimane ane-electroplated anikeza izinzuzo ezifana nezikefu eziwumngcingo, ikhwalithi engcono yocezu, ukusebenza kahle okuphezulu, ukungcoliswa okuphansi, kanye nekhono lokusika izinto ezinobulukhuni obuphezulu.

Isaha yedayimane ye-electroplated ephindaphindayo iyindlela esetshenziswa kabanzi yokusika i-SiC. Umfanekiso 1 (ongabonisiwe lapha) ubonisa ukukhanya okungaphezulu kwama-wafer e-SiC asikwe kusetshenziswa le nqubo. Njengoba ukusika kuqhubeka, i-wafer warpage iyanda. Lokhu kungenxa yokuthi indawo yokuthintana phakathi kwentambo nezinto ezibonakalayo iyakhula njengoba intambo iyehla, ikhulisa ukumelana nokudlidliza kwentambo. Uma intambo ifinyelela kububanzi obukhulu be-wafer, ukudlidliza kuba sezingeni eliphezulu, okuholela ekuphepheni okuphezulu.

Ezigabeni zakamuva zokusika, ngenxa yokusheshisa kocingo, ukunyakaza kwesivinini esizinzile, ukwehla, ukuma, nokuhlehla, kanye nobunzima bokukhipha imfucumfucu ngesipholile, ikhwalithi yangaphezulu ye-wafer iyawohloka. Ukuguqulwa kwentambo nokuguquguquka kwesivinini, kanye nezinhlayiya ezinkulu zedayimane ocingweni, yizona zimbangela eziyinhloko zokuklwebheka kwendawo.

1.4 I-Cold Separation Technology

Ukuhlukaniswa okubandayo kwamakristalu e-SiC eyodwa kuyinqubo emisha emkhakheni wokucubungula impahla ye-semiconductor yesizukulwane sesithathu. Eminyakeni yamuva nje, idonse ukunaka okukhulu ngenxa yezinzuzo zayo eziphawulekayo ekuthuthukiseni isivuno kanye nokunciphisa ukulahlekelwa kwezinto ezibonakalayo. Ubuchwepheshe bungahlaziywa kusuka ezicini ezintathu: umgomo wokusebenza, ukugeleza kwenqubo, kanye nezinzuzo ezibalulekile.

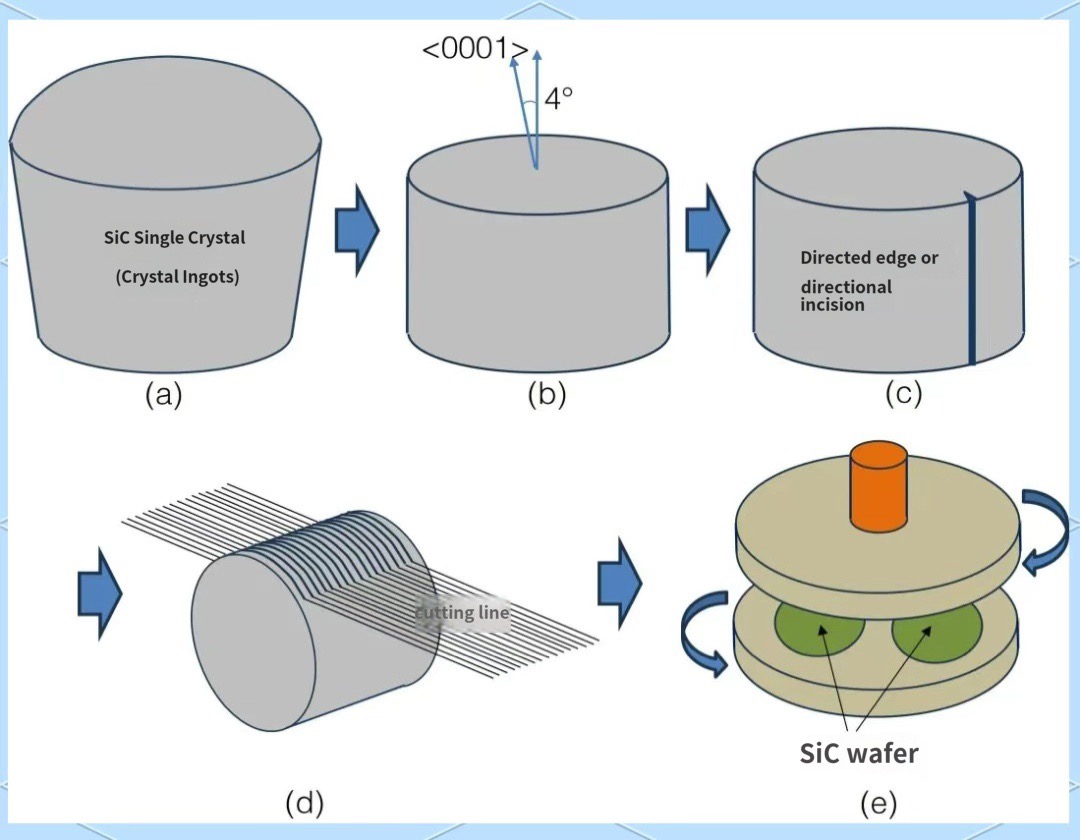

Ukunqunywa Kwe-Crystal Orientation kanye Nokugaya Ububanzi Bangaphandle: Ngaphambi kokucubungula, umumo wekristalu we-ingot ye-SiC kufanele unqunywe. Ingot ibe isibunjwa ibe isakhiwo esiyisilinda (esivame ukubizwa ngokuthi i-SiC puck) ngokusebenzisa ukugaya okungaphandle kobubanzi. Lesi sinyathelo sibeka isisekelo sokusika nokusika okuqondile okulandelayo.

I-Multi-Wire Cutting: Le ndlela isebenzisa izinhlayiya ezilumayo ezihlanganiswe nezintambo zokusika ukuze kusike i-cylindrical ingot. Kodwa-ke, ihlushwa ukulahleka okukhulu kwe-kerf kanye nezinkinga zokungalingani kwendawo.

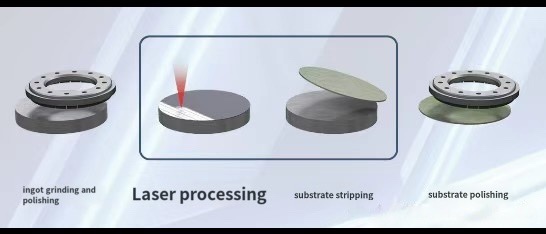

I-Laser Cutting Technology: I-laser isetshenziselwa ukwakha isendlalelo esilungisiwe ngaphakathi kwekristalu, lapho izingcezu ezincane zingahlukaniswa khona. Le ndlela yehlisa ukulahleka kwezinto futhi ithuthukise ukusebenza kahle kokucubungula, ikwenze kube isiqondiso esisha esithembisayo sokusika i-SiC wafer.

Ukuthuthukisa Inqubo Yokusika

I-Fixed Abrasive Multi-Wire Cutting: Lokhu okwamanje ubuchwepheshe obujwayelekile, obufaneleka kahle izici zokuqina okuphezulu kwe-SiC.

I-Electrical Discharge Machining (EDM) kanye Nobuchwepheshe Bokuhlukanisa Okubandayo: Lezi zindlela zinikeza izixazululo ezihlukene ezihambisana nezidingo ezithile.

Inqubo yokupholisha: Kubalulekile ukulinganisa izinga lokususwa kwezinto kanye nokulimala kwendawo. I-Chemical Mechanical Polishing (CMP) isetshenziselwa ukuthuthukisa ukufana kwendawo.

Ukuqapha Kwesikhathi Sangempela: Ubuchwepheshe bokuhlola ku-inthanethi bayethulwa ukuze kuqashwe ukuhwaqeka kwendawo ngesikhathi sangempela.

I-Laser Slicing: Le nqubo inciphisa ukulahleka kwe-kerf futhi ifinyeze imijikelezo yokucubungula, nakuba indawo ethintekile ngokushisa isalokhu iyinselele.

I-Hybrid Processing Technologies: Ukuhlanganisa izindlela zemishini nezamakhemikhali kuthuthukisa ukusebenza kahle kokucubungula.

Lobu buchwepheshe sebuvele buzuze ukusebenza kwezimboni. I-Infineon, isibonelo, ithole i-SILTECTRA futhi manje inamalungelo obunikazi ayisisekelo asekela ukukhiqizwa okukhulu kwama-wafers angu-8-intshi. E-China, izinkampani ezifana ne-Delong Laser zithole ukusebenza kahle kwama-wafers angama-30 ingot ngayinye yokucutshungulwa kwe-wafer engama-intshi angu-6, okumelela ukuthuthuka okungama-40% kunezindlela zendabuko.

Njengoba ukukhiqizwa kwemishini yasekhaya kushesha, lobu buchwepheshe kulindeleke ukuthi bube yisixazululo esijwayelekile sokucutshungulwa kwe-substrate ye-SiC. Ngokukhula kobubanzi bezinto ze-semiconductor, izindlela zokusika zendabuko seziphelelwe yisikhathi. Phakathi kwezinketho zamanje, ubuchwepheshe be-diamond wire saw technology bubonisa amathuba okufaka isicelo athembisa kakhulu. Ukusika i-laser, njengendlela ekhulayo, kunikeza izinzuzo ezibalulekile futhi kulindeleke ukuthi kube indlela yokuqala yokusika esikhathini esizayo.

2,I-SiC Single Crystal Grinding

Njengommeleli wamasemiconductors esizukulwane sesithathu, i-silicon carbide (SiC) inikeza izinzuzo ezibalulekile ngenxa ye-bandgap yayo ebanzi, insimu kagesi ephukile, isivinini sokugcwala okuphezulu kwe-electron drift, kanye nokuhamba kahle kwe-thermal. Lezi zakhiwo zenza i-SiC ibe nenzuzo ikakhulukazi ezinhlelweni zamandla kagesi aphezulu (isb, izindawo eziyi-1200V). Ubuchwepheshe bokucubungula ama-substrates e-SiC yingxenye ebalulekile yokwenziwa kwedivayisi. Ikhwalithi ephezulu kanye nokunemba kwe-substrate kuthinta ngqo ikhwalithi ye-epitaxial layer kanye nokusebenza kwedivayisi yokugcina.

Inhloso eyinhloko yenqubo yokugaya ukukhipha amamaki e-surface saw kanye nezingqimba zokulimala okubangelwa ngesikhathi sokusikwa, nokulungisa ukuguqulwa okubangelwa inqubo yokusika. Uma kubhekwa ubulukhuni obuphezulu kakhulu be-SiC, ukugaya kudinga ukusetshenziswa kwama-abrasive aqinile njenge-boron carbide noma idayimane. Ukugaya okuvamile kuvame ukuhlukaniswa kube ukugaya okumahhadla nokugaya kahle.

2.1 Ukugaya Okumahhadla futhi Kahle

Ukugaya kungahlukaniswa ngokusekelwe kusayizi wezinhlayiyana ezilumayo:

Ukugaya Okumahhadla: Kusebenzisa ama-abrasive amakhulu ngokuyinhloko ukususa amasaha nezingqimba zokulimala okudalwe ngesikhathi sokusikwa, ukuthuthukisa ukusebenza kahle kokucubungula.

Ukugaya Okucolisekile: Kusebenzisa ama-abrasives acinene ukususa isendlalelo somonakalo esishiywe ukugaya okumahhadla, ukunciphisa ukuhwalala kwendawo, futhi kuthuthukise ikhwalithi yendawo.

Abakhiqizi abaningi basekhaya be-SiC substrate basebenzisa izinqubo zokukhiqiza ezinkulu. Indlela evamile ihlanganisa ukugaya okukabili kusetshenziswa ipuleti lensimbi elisansimbi kanye ne-monocrystalline diamond slurry. Le nqubo isusa ngempumelelo isendlalelo somonakalo esishiywe ngokusaha ngocingo, ilungisa umumo we-wafer, futhi yehlisa i-TTV (Total Thickness Variation), i-Bow, ne-Warp. Izinga lokususa impahla lizinzile, ngokuvamile lifinyelela ku-0.8–1.2 μm/min. Kodwa-ke, i-wafer surface ewumphumela i-matte enobunzima obuphakeme kakhulu-imvamisa ezungeze u-50 nm-okubeka izidingo eziphakeme ezinyathelweni zokupholisha ezilandelayo.

2.2 Ukugaya Uhlangothi Olulodwa

Ukugaya okuyingxenye eyodwa kuphela kwenza uhlangothi olulodwa lwe-wafer ngesikhathi. Phakathi nale nqubo, i-wafer ifakwa nge-wax epuleti lensimbi. Ngaphansi kwengcindezi esetshenzisiwe, i-substrate ithola ukuguqulwa okuncane, futhi indawo engaphezulu iyancipha. Ngemuva kokugaya, indawo engezansi ilinganiswe. Lapho ukucindezela kususwa, indawo engaphezulu ivame ukubuyela esimweni sayo sasekuqaleni, okuphinde kuthinte indawo ephansi kakade ephansi—okubangela izinhlangothi zombili ukuba zigoqe futhi ziwohloke ekusicaba.

Ngaphezu kwalokho, ipuleti lokugaya lingajika libe yi-convex ngesikhathi esifushane, kubangele ukuthi i-wafer ibe yi-convex. Ukugcina i-flatness yepuleti, ukugqoka njalo kuyadingeka. Ngenxa yokusebenza kahle okuphansi kanye nokuntengantenga kwe-wafer, ukugaya ohlangothini olulodwa akufanelekile ukukhiqizwa ngobuningi.

Ngokuvamile, amasondo okugaya angu-#8000 asetshenziselwa ukugaya okuhle. E-Japan, le nqubo isivuthiwe futhi isebenzisa #30000 amasondo okupholisha. Lokhu kuvumela ubulukhuni obungaphezulu bamawafa acutshunguliwe ukuthi bufinyelele ngaphansi kuka-2 nm, okwenza amawafa alungele i-CMP yokugcina (Chemical Mechanical polishing) ngaphandle kokucubungula okwengeziwe.

2.3 I-Single-Siding-Thinning Technology

I-Diamond Single-Sided Thinning Technology iyindlela entsha yokugaya ohlangothini olulodwa. Njengoba kubonisiwe kuMfanekiso 5 (ongabonisiwe lapha), inqubo isebenzisa ipuleti lokugaya eliboshwe ngedayimane. I-wafer ilungiswa nge-vacuum adsorption, kuyilapho kokubili i-wafer nesondo lokugaya idayimane kuzungeza kanyekanye. Isondo lokugaya kancane kancane liya phansi ukuze libe mncane i-wafer ibe ugqinsi oluqondiwe. Ngemva kokuba uhlangothi olulodwa luqediwe, i-wafer iyaphetshwa ukuze kucutshungulwe olunye uhlangothi.

Ngemuva kokunciphisa, i-wafer engu-100 mm ingafinyelela:

Ukugoba <5 μm

I-TTV <2 μm

Ubulukhuni bobuso < 1 nm

Le ndlela yokucubungula i-wafer eyodwa inikeza ukuzinza okuphezulu, ukungaguquguquki okuhle kakhulu, kanye nezinga eliphezulu lokususwa kwezinto. Uma kuqhathaniswa nokugaya okuvamile okunezinhlangothi ezimbili, le ndlela yokugaya ithuthukisa ukusebenza kahle kokugaya ngaphezu kuka-50%.

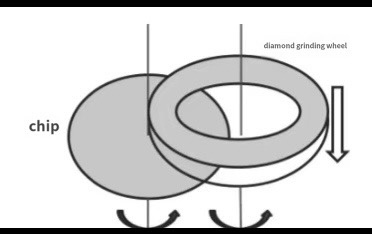

2.4 Ukugaya Okukabili

Ukugaya okunezinhlangothi ezimbili kusebenzisa kokubili ipuleti lokugaya elingaphezulu neliphansi ukuze kugaywe kanyekanye izinhlangothi zombili ze-substrate, kuqinisekiswe ikhwalithi ephezulu kakhulu yendawo nhlangothi zombili.

Phakathi nenqubo, amapuleti okugaya kuqala afaka ingcindezi ezindaweni eziphakeme kakhulu ze-workpiece, okubangela ukuwohloka nokususwa kwezinto kancane kancane kulawo maphuzu. Njengoba izindawo eziphakeme zilinganiswa, ukucindezela ku-substrate kancane kancane kuba okufanayo, okuholela ekuguquguqukeni okungaguquki kuyo yonke indawo. Lokhu kuvumela kokubili izindawo ezingaphezulu neziphansi ukuthi zigaywe ngokulinganayo. Uma ukugaya sekuqediwe futhi nokucindezela kukhululwa, ingxenye ngayinye ye-substrate ilulama ngokufanayo ngenxa yokucindezela okulinganayo eyabhekana nakho. Lokhu kuholela ekwehleni okuncane kanye ne-flatness enhle.

Ubulukhuni obungaphezulu be-wafer ngemva kokugaya buxhomeke kusayizi wezinhlayiyana ezihuqayo—izinhlayiya ezincane zikhiqiza izindawo ezibushelelezi. Uma usebenzisa ama-abrasives angu-5 μm ukuze ugaye izinhlangothi ezimbili, ukugqama kwe-wafer nokuhluka kogqinsi kungalawuleka phakathi kuka-5 μm. Izilinganiso ze-Atomic Force Microscopy (AFM) zibonisa ukuhwaqeka komhlaba (Rq) okungaba ngu-100 nm, nemigodi yokugaya efinyelela ku-380 nm ukushona namamaki abonakalayo alayini abangwe isenzo sokuhuzuka.

Indlela ethuthuke kakhulu ibandakanya ukugaya okukabili kusetshenziswa amaphedi egwebu enziwe nge-polyurethane ahlanganiswe ne-polycrystalline diamond slurry. Le nqubo ikhiqiza ama-wafer anobulukhuni obuphezulu obuphansi kakhulu, okuzuza u-Ra <3 nm, okuzuzisa kakhulu ukupholishwa okulandelayo kwama-substrates e-SiC.

Nokho, ukunwaya phezulu kuseyinkinga engaxazululiwe. Ukwengeza, idayimane le-polycrystalline elisetshenziswe kule nqubo likhiqizwa ngokusebenzisa ukuhlanganiswa kweziqhumane, okuyinselele ngokobuchwepheshe, kuthela amanani aphansi, futhi kubiza kakhulu.

Ukupholishwa kwe-SiC Single Crystals

Ukuze kuzuzwe indawo epholishiwe yekhwalithi ephezulu kumawafa e-silicon carbide (SiC), ukupholishwa kufanele kususe ngokuphelele imigodi yokugaya kanye nokuguquguquka kwesikali se-nanometer. Umgomo uwukukhiqiza indawo ebushelelezi, engenasici engenakho ukungcoliswa noma ukuwohloka, akukho monakalo ongaphansi komhlaba, futhi akukho ngcindezi yendawo eyinsalela.

3.1 I-Mechanical polishing kanye ne-CMP yama-SiC Wafers

Ngemuva kokukhula kwe-SiC single crystal ingot, ukukhubazeka okungaphezulu kuyivimbela ukuthi isetshenziselwe ukukhula kwe-epitaxial. Ngakho-ke, ukucubungula okwengeziwe kuyadingeka. Ingot iqala ukulolongwa ibe yifomu elijwayelekile eliyicylindrical ngokuzungezisa, bese isikwe ibe amawafa kusetshenziswa izintambo zokusika, kulandele ukuqinisekiswa kokuma kwekristalu. Ukupholisha kuyisinyathelo esibalulekile sokuthuthukisa ikhwalithi ye-wafer, ukubhekana nomonakalo ongase ube khona obangelwa ukukhubazeka kokukhula kwekristalu kanye nezinyathelo zokucubungula ngaphambilini.

Kunezindlela ezine eziyinhloko zokususa izendlalelo zomonakalo ongaphezulu ku-SiC:

Ukupholisha ngomshini: Kulula kodwa kushiya imihuzuko; ilungele ukupholishwa kokuqala.

I-Chemical Mechanical Polishing (CMP): Isusa imihuzuko nge-chemical etching; ilungele ukupholisha ngokunemba.

I-Hydrogen etching: Idinga imishini eyinkimbinkimbi, evame ukusetshenziswa ezinqubweni ze-HTCVD.

Ukupholisha okusizwa yi-Plasma: Kuyinkimbinkimbi futhi akuvamile ukusetshenziswa.

Ukupholishwa ngomshini kuphela kuvame ukudala imihuzuko, kuyilapho ukupholishwa ngamakhemikhali kuphela kungaholela ekushoniseni okungalingani. I-CMP ihlanganisa kokubili okuhle futhi inikeza isisombululo esiphumelelayo, esingabizi.

Umgomo Wokusebenza we-CMP

I-CMP isebenza ngokuzungezisa iwafa ngaphansi kwengcindezi emisiwe ngokumelene nephedi yokupholisha ejikelezayo. Lokhu kunyakaza okuhlobene, okuhlanganiswe nokuhuzuka komshini okuvela kuma-abrasive anosayizi we-nano ku-slurry kanye nesenzo samakhemikhali sama-ejenti asebenzayo, kufeza ukuhleleka kwendawo.

Izinto ezibalulekile ezisetshenzisiwe:

I-slurry epholishayo: Iqukethe izinto zokulunywa kanye nama-reagents amakhemikhali.

Iphedi yokupholisha: Iyawohloka ngesikhathi sokusetshenziswa, inciphisa usayizi wezimbotshana kanye nokusebenza kahle kokulethwa kwe-slurry. Ukugqoka okuvamile, ngokuvamile kusetshenziswa isigqoko sedayimane, kuyadingeka ukuze kubuyiselwe ubuhhadlahhadla.

Inqubo ye-CMP ejwayelekile

I-Abrasive: 0.5 μm i-diamond slurry

Ubulukhuni bendawo eqondiwe: ~0.7 nm

Ukupholisha kwe-Chemical Mechanical:

Imishini yokupholisha: I-AP-810 yokupholisha ohlangothini olulodwa

Ingcindezi: 200 g/cm²

Isivinini sepuleti: 50 rpm

Isivinini se-Ceramic holder: 38 rpm

Ukwakhiwa kwe-slurry:

I-SiO₂ (30 wt%, pH = 10.15)

0–70 wt% H₂O₂ (30 wt%, ibanga le-reagent)

Lungisa i-pH ibe ngu-8.5 usebenzisa u-5 wt% KOH no-1 wt% HNO₃

Izinga lokugeleza kwe-slurry: 3 L/min, lijikelezwe kabusha

Le nqubo ithuthukisa ngempumelelo ikhwalithi ye-SiC wafer futhi ihlangabezana nezimfuneko zezinqubo ezansi nomfula.

Izinselelo Zezobuchwepheshe Ekupholishani Komshini

I-SiC, njenge-bandgap semiconductor ebanzi, idlala indima ebalulekile embonini ye-electronics. Ngezakhiwo ezinhle kakhulu zomzimba namakhemikhali, amakristalu e-SiC eyodwa afanele izindawo ezibucayi, ezifana nezinga lokushisa eliphezulu, imvamisa ephezulu, amandla aphezulu, nokumelana nemisebe. Kodwa-ke, isimo sayo esiqinile nesishwabene sinezinselele ezinkulu zokugaya nokupholisha.

Njengoba abakhiqizi abahamba phambili emhlabeni jikelele beshintsha ukusuka kumawafa angama-intshi angu-6 intshi ukuya kwangu-8-intshi, izinkinga ezinjengokuqhekeka nokulimala kwe-wafer ngesikhathi sokucubungula sezigqame kakhulu, zibe nomthelela omkhulu ekukhiqizeni. Ukubhekana nezinselelo zobuchwepheshe zama-substrates angu-8-inch SiC manje kuwuphawu olubalulekile lokuthuthuka kwemboni.

Esikhathini esingu-8-intshi, ukucutshungulwa kwe-SiC wafer kubhekana nezinselelo eziningi:

Ukukala kwe-wafer kuyadingeka ukuze kukhuliswe ukuphuma kwe-chip ngeqeqebana ngalinye, ukunciphisa ukulahleka konqenqema, kanye nezindleko eziphansi zokukhiqiza—ikakhulukazi uma kubhekwa isidingo esikhulayo sezinhlelo zokusebenza zemoto kagesi.

Nakuba ukukhula kwekristalu eyodwa ye-SiC engu-8-intshi sekukhulile, izinqubo ezibuyela emuva ezinjengokugaya nokupholishwa zisabhekene namabhodlela, okuholela ekuvuneni okuphansi (kuphela u-40-50%).

Amawafa amakhulu ahlangabezana nokusabalalisa kwengcindezi eyinkimbinkimbi, okwandisa ubunzima bokulawula ingcindezi yokupholisha kanye nokuvumelana kwesivuno.

Yize ugqinsi lwamawafa angu-8 intshi kusondela kowamawafa angu-6-intshi, ajwayele ukulimala ngesikhathi ephathwa ngenxa yengcindezi nokungqubuzana.

Ukunciphisa ingcindezi ehlobene nokusika, i-warpage, kanye nokuqhekeka, ukusika kwe-laser kuya ngokuya kusetshenziswa. Nokho:

Ama-laser amaza amade adala umonakalo oshisayo.

Ama-laser amaza amafushane akhiqiza imfucumfucu enzima futhi ajulise isendlalelo somonakalo, akhulise ubunkimbinkimbi bokupholisha.

Ukugeleza Kokusebenza Kokupholisha Kwemishini kwe-SiC

Ukugeleza kwenqubo evamile kuhlanganisa:

Ukusika i-Orientation

Ukugaya okumahhadla

Ukugaya kahle

Ukupholisha ngomshini

I-Chemical Mechanical polishing (CMP) njengesinyathelo sokugcina

Ukukhethwa kwendlela ye-CMP, ukwakheka komzila wenqubo, nokwenza kahle kwamapharamitha kubalulekile. Ekwenziweni kwe-semiconductor, i-CMP iyisinyathelo esinqumayo sokukhiqiza amawafa e-SiC anezindawo ezibushelelezi, ezingenasici, nezingenamonakalo, ezibalulekile ekukhuleni kwekhwalithi ephezulu ye-epitaxial.

(a) Susa ingot ye-SiC ku-crucible;

(b) Enza ukubunjwa kokuqala usebenzisa ukugaya kwedayamitha yangaphandle;

(c) Nquma umumo wekristalu usebenzisa amafulethi okuqondanisa nokuqondanisa;

(d) Sika ingot ibe amawafa amancane usebenzisa i-multi-wire sawing;

(e) Zuza ubushelelezi obufana nesibuko ngokusebenzisa izinyathelo zokugaya nokupholisha.

Ngemva kokuqeda uchungechunge lwezinyathelo zokucubungula, unqenqema lwangaphandle lwe-wafer ye-SiC luvame ukuba bukhali, okwandisa ingozi yokuqhekeka ngesikhathi sokuphatha noma ukusetshenziswa. Ukuze ugweme ubuthakathaka obunjalo, ukugaya onqenqemeni kuyadingeka.

Ngaphezu kwezinqubo zendabuko zokusika, indlela entsha yokulungiselela ama-wafers e-SiC ihlanganisa ubuchwepheshe bokubopha. Le ndlela ivumela ukwenziwa kwe-wafer ngokuhlanganisa ungqimba oluncane lwekristalu ye-SiC ku-substrate ehlukahlukene (i-substrate esekelayo).

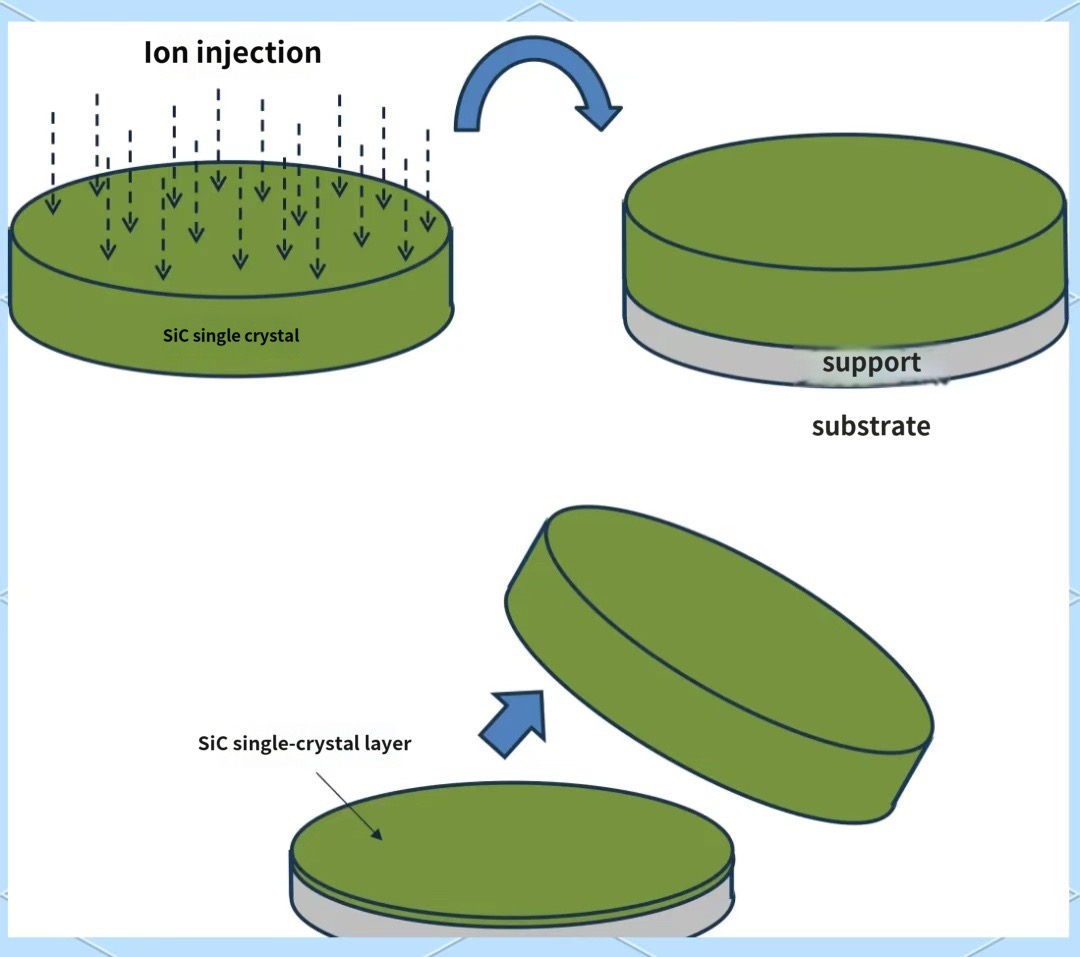

Umfanekiso 3 ukhombisa ukugeleza kwenqubo:

Okokuqala, ungqimba lwe-delamination lwakhiwa ekujuleni okucacisiwe ebusweni bekristalu eyodwa ye-SiC ngokufakwa kwe-hydrogen ion noma amasu afanayo. Ikristalu elilodwa le-SiC elicutshunguliwe libe seliboshelwa ku-substrate esekelayo eyisicaba futhi ingaphansi kwengcindezi nokushisa. Lokhu kuvumela ukudluliswa okuphumelelayo nokuhlukaniswa kwesendlalelo se-SiC single-crystal ku-substrate esekelayo.

Isendlalelo se-SiC esihlukanisiwe sibhekana nokwelashwa kwendawo ukuze kuzuzwe flatness edingekayo futhi singasetshenziswa kabusha ezinqubweni zokubopha ezilandelayo. Uma kuqhathaniswa nokusikwa kwendabuko kwamakristalu e-SiC, le ndlela yehlisa isidingo sezinto ezibizayo. Nakuba izinselele zobuchwepheshe zisekhona, ucwaningo nentuthuko ithuthuka ngenkuthalo ukuze kunikwe amandla ukukhiqizwa kwe-wafer ebiza kancane.

Uma kubhekwa ubulukhuni obuphezulu nokuzinza kwamakhemikhali e-SiC—okuyenza imelane nokusabela ekamelweni lokushisa—ukupholishwa ngomshini kuyadingeka ukuze kukhishwe imigodi yokugaya emihle, ukunciphisa umonakalo ongaphezulu, ukuqeda imihuzuko, ukugoba, nokukhubazeka kwekhasi lewolintshi, ukuhwalala okuphansi kwendawo, ukuthuthukisa ukucaba, nokuthuthukisa ikhwalithi yendawo.

Ukuze uthole indawo epholile yekhwalithi ephezulu, kuyadingeka:

Lungisa izinhlobo ze-abrasive,

Yehlisa usayizi wezinhlayiyana,

Lungiselela amapharamitha wenqubo,

Khetha izinto zokupholisha namaphedi anobulukhuni obanele.

Umfanekiso wesi-7 ubonisa ukuthi ukupholisha okunezinhlangothi ezimbili okunama-abrasives angu-1 μm kungalawula ukucaba nokuhluka kogqinsi phakathi kuka-10 μm, futhi kunciphise ukuhwaqeka kwendawo kufinyelele ku-0.25 nm.

3.2 I-Chemical Mechanical polishing (CMP)

I-Chemical Mechanical Polishing (CMP) ihlanganisa ukuhuzuka kwezinhlayiyana ze-ultrafine nokushumeka kwamakhemikhali ukwenza indawo ebushelelezi, eplaniwe ezintweni ezicutshungulwayo. Umgomo oyisisekelo uthi:

Ukusabela kwamakhemikhali kwenzeka phakathi kwe-slurry epholishwayo kanye ne-wafer surface, okwenza ungqimba oluthambile.

Ukungqubuzana phakathi kwezinhlayiya ezilumayo kanye nongqimba oluthambile kususa izinto.

Izinzuzo ze-CMP:

Inqoba izithiyo zokupholisha ngemishini noma ngamakhemikhali,

Ifinyelela kokubili ukuhleleka komhlaba kanye nendawo,

Ikhiqiza izindawo eziphansi eziphakeme kanye nama-roughness aphansi,

Ayishiyi umonakalo ongaphezulu noma ongaphansi komhlaba.

Imininingwane:

I-wafer ihamba ngokuhlobene nephedi lokupholisha ngaphansi kwengcindezi.

Ama-abrasive esikali se-Nanometer (isb, i-SiO₂) ekudaka abamba iqhaza ekugundani, ukwenza buthaka amabhondi ahlangene e-Si–C kanye nokuthuthukisa ukususwa kwezinto.

Izinhlobo zama-CMP Techniques:

I-Abrasive Polishing Yamahhala: Ama-Abrasives (isb, i-SiO₂) amisiwe ngokuludaka. Ukususwa kwezinto ezibonakalayo kwenzeka ngokuhuzuka kwemizimba emithathu (i-wafer-pad-abrasive). Usayizi oqhumayo (ngokuvamile u-60–200 nm), i-pH, nezinga lokushisa kufanele kulawulwe ngokunembile ukuze kuthuthukiswe ukufana.

I-Fixed Abrasive polishing: Ama-Abrasives ashumekwe kuphedi yokupholisha ukuze kuvinjelwe i-agglomeration—ilungele ukucutshungulwa okunembayo okuphezulu.

Ukuhlanza Ngemva Kokupholisha:

Ama-wafers aphucuziwe ayatholakala:

Ukuhlanza amakhemikhali (okubandakanya amanzi e-DI kanye nokususwa kwezinsalela ze-slurry),

Ukugeza ngamanzi e-DI, kanye

Ukomiswa kwe-nitrogen eshisayo

ukunciphisa ukungcola okungaphezulu.

Ikhwalithi Nokusebenza Kobuso

Ubulukhuni bobuso bungancishiswa bube ku-Ra <0.3 nm, buhlangabezane nezimfuneko ze-semiconductor epitaxy.

I-Global Planarization: Inhlanganisela yokuthambisa amakhemikhali kanye nokususwa ngomshini kunciphisa imihuzuko nokushuba okungalingani, okudlula izindlela ezimsulwa zemishini noma zamakhemikhali.

Ukusebenza Okuphezulu: Ifanele izinto eziqinile nezishwabene njenge-SiC, ezinamanani okususa izinto angaphezu kuka-200 nm/h.

Amanye Amasu Okupholisha Asafufusa

Ngaphezu kwe-CMP, ezinye izindlela ziye zahlongozwa, okuhlanganisa:

Ukupholisha nge-electrochemical, ukupholishwa okusizwa yi-Catalyst noma ukunamathisela, kanye

Ukupholisha kwe-Tribochemical.

Kodwa-ke, lezi zindlela zisesesigabeni socwaningo futhi zithuthuke kancane ngenxa yezakhiwo eziyinselele ze-SiC.

Ekugcineni, ukucutshungulwa kwe-SiC kuyinqubo ehamba kancane yokunciphisa i-warpage kanye nama-rough ukuze kuthuthukiswe ikhwalithi yendawo, lapho ukulawulwa okucaba nokumahhadla kubalulekile kuso sonke isigaba.

Ukucubungula Ubuchwepheshe

Ngesikhathi sesiteji sokugaya i-wafer, i-diamond slurry enobukhulu bezinhlayiyana ezihlukene isetshenziselwa ukugaya i-wafer ukuze ibe flatness edingekayo kanye nokuqina kwendawo. Lokhu kulandelwa ukupholisha, kusetshenziswa amasu womabili ama-mechanical and chemical mechanical polishing (CMP) ukuze kukhiqizwe amawafa e-silicon carbide (SiC) angenakonakala.

Ngemva kokupholishwa, ama-wafer e-SiC ahlolwa ngokucophelela ikhwalithi kusetshenziswa amathuluzi afana nama-optical microscopes nama-X-ray diffractometers ukuze kuqinisekiswe ukuthi yonke imingcele yobuchwepheshe ihlangabezana namazinga adingekayo. Okokugcina, ama-wafer aphucuziwe ahlanzwa kusetshenziswa ama-agent akhethekile okuhlanza namanzi ahlanzekile ukuze kukhishwe ukungcola okungaphezulu. Bese zomiswa kusetshenziswa i-ultra-high purerity nitrogen gas nama-spin dryers, kuphothula yonke inqubo yokukhiqiza.

Ngemuva kweminyaka yokuzama, inqubekelaphambili enkulu yenziwe ekucutshungulweni kwekristalu eyodwa ye-SiC ngaphakathi kweChina. Ngaphakathi, amakristalu angama-4H-SiC ane-doped semi-insulating angu-100 mm athuthukiswe ngempumelelo, futhi amakristalu angama-n-type 4H-SiC kanye ne-6H-SiC manje angakhiqizwa ngamaqoqo. Izinkampani ezifana ne-TankeBlue ne-TYST sezivele zenze amakristalu awodwa angu-150 mm SiC.

Ngokobuchwepheshe bokucubungula i-SiC wafer, izikhungo zasekhaya ziye zahlola izimo zenqubo kanye nemizila yokusikwa kwekristalu, ukugaya, nokupholisha. Bayakwazi ukukhiqiza amasampula ahlangabezana nezidingo zokwenziwa kwedivayisi. Kodwa-ke, uma kuqhathaniswa namazinga omhlaba, ikhwalithi yokucubungula indawo yama-wafers asekhaya isasilele emuva kakhulu. Kunezinkinga ezimbalwa:

Imibono ye-SiC yamazwe ngamazwe kanye nobuchwepheshe bokucubungula kuvikelwe ngokuqinile futhi akufinyeleleki kalula.

Kunokuntuleka kocwaningo lwethiyori nokwesekwa kokuthuthukiswa kwenqubo nokwenza kahle.

Izindleko zokungenisa impahla kanye nezingxenye zangaphandle ziphezulu.

Ucwaningo lwasekhaya lokuklanywa kwemishini, ukunemba kokucubungula, nezinto zokwakha zisabonisa izikhala ezinkulu uma kuqhathaniswa namazinga omhlaba.

Njengamanje, amathuluzi amaningi anembe kakhulu asetshenziswa e-China angenisiwe. Imishini yokuhlola kanye nezindlela nazo zidinga ukuthuthukiswa okwengeziwe.

Ngokuthuthuka okuqhubekayo kwama-semiconductors esizukulwane sesithathu, ububanzi be-SiC single crystal substrates bukhula kancane, kanye nezidingo eziphakeme zekhwalithi yokucubungula indawo. Ubuchwepheshe bokucubungula i-wafer buye baba ngesinye sezinyathelo eziyinselele kakhulu ngemuva kokukhula kwekristalu eyodwa ye-SiC.

Ukuze kubhekwane nezinselele ezikhona ekucutshungulweni, kubalulekile ukuqhubeka nokufunda izindlela ezihilelekile ekusikeni, ekugayeni, nasekupholishweni, kanye nokuhlola izindlela ezifanelekile nezindlela zokukhiqiza ama-wafer e-SiC. Ngesikhathi esifanayo, kuyadingeka ukufunda kubuchwepheshe bokucubungula obusezingeni eliphezulu bamazwe ngamazwe futhi usebenzise amasu emishini esezingeni eliphezulu nenemba kakhulu ukuze kukhiqizwe ama-substrates ekhwalithi ephezulu.

Njengoba usayizi we-wafer ukhula, ubunzima bokukhula kwekristalu nokucubungula nakho kuyakhuphuka. Kodwa-ke, ukusebenza kahle kokukhiqizwa kwamadivaysi angaphansi komfula kuba ngcono kakhulu, futhi izindleko zeyunithi ziyancipha. Njengamanje, abahlinzeki abakhulu be-SiC wafer emhlabeni jikelele bahlinzeka ngemikhiqizo esukela kumayintshi angu-4 ukuya kumayintshi angu-6 ububanzi. Izinkampani ezihamba phambili ezifana neCree ne-II-VI seziqalile ukuhlela ukwakhiwa kwemigqa yokukhiqiza ye-SiC yama-wafer engu-8 inch.

Isikhathi sokuthumela: May-23-2025