Q: Yibuphi ubuchwepheshe obuyinhloko obusetshenziswa ekusikeni nasekucutshungulweni kwe-SiC wafer?

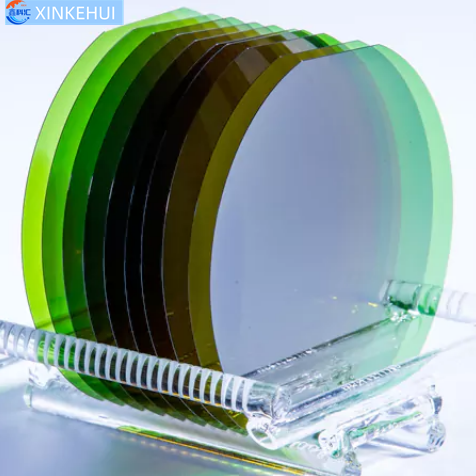

A:I-silicon carbide (I-SiC) inobulukhuni okwesibili kuphela kwedayimane futhi ithathwa njengento eqinile kakhulu futhi ephukayo. Inqubo yokusika, ebandakanya ukusika amakristalu asekhulile abe amawafa amancane, idla isikhathi futhi ijwayele ukucwiywa. Njengesinyathelo sokuqala sokungenaI-SiCukucutshungulwa kwekristalu eyodwa, ikhwalithi yokusika ithonya ngokuphawulekayo ukugaya okulandelayo, ukupholishwa kanye nokuncipha. Ukusika kuvame ukwethula imifantu engaphezulu nendawo engaphansi, kukhuphule izinga lokuqhekeka kwamawafa kanye nezindleko zokukhiqiza. Ngakho-ke, ukulawula ukulimala kokuqhekeka kwendawo ngesikhathi sokusikwa kubalulekile ekuthuthukiseni ukwakhiwa kwedivayisi ye-SiC.

Izindlela zokusika ze-SiC ezibikiwe njengamanje zifaka ukusika okungaguquki, okulimazayo, ukusika i-laser, ukudluliswa kwesendlalelo (ukuhlukaniswa okubandayo), kanye nokusikwa kokukhishwa kukagesi. Phakathi kwalokhu, ukusika kabusha kwezintambo eziningi okunama-abrasive edayimane angashintshi kuyindlela evame ukusetshenziswa kakhulu yokucubungula amakristalu e-SiC eyodwa. Kodwa-ke, njengoba osayizi be-ingot befinyelela amayintshi angu-8 nangaphezulu, ukusaha ngocingo okuvamile kuba kungasebenzi ngenxa yezidingo eziphezulu zemishini, izindleko, nokusebenza kahle okuphansi. Kunesidingo esiphuthumayo sobuchwepheshe bokusika obungabizi kakhulu, obuphansi, obusebenza kahle kakhulu.

Q: Yiziphi izinzuzo zokusika i-laser ngaphezu kokusika okungokwesiko kwezintambo eziningi?

A: I-Traditional wire sawing isikaI-SiC ingoteduze nendawo ethile zibe izingcezu ezingamakhulu ambalwa ama-microns awugqinsi. Izingcezu zibe sezigaywa kusetshenziswa ama-slurries edayimane ukuze kususwe izimpawu zokusaha kanye nomonakalo ongaphansi komhlaba, kulandelwa ukupholisha ngekhemikhali ngomshini (CMP) ukuze kuzuzwe ukuhleleka komhlaba wonke, futhi ekugcineni kuhlanzwe ukuze kutholwe amawafa e-SiC.

Kodwa-ke, ngenxa yokuqina nokuqina okuphezulu kwe-SiC, lezi zinyathelo zingabangela kalula ukungqubuzana, ukuqhekeka, ukukhuphuka kwamazinga okuphuka, izindleko zokukhiqiza eziphakeme, futhi kubangele ukukhahlazeka okuphezulu nokungcola (uthuli, amanzi angcolile, njll.). Ukwengeza, ukusaha ngocingo kuhamba kancane futhi kunesivuno esincane. Izilinganiso zibonisa ukuthi ukusika okuvamile kwezintambo eziningi kuzuza kuphela cishe u-50% wokusetshenziswa kwempahla, futhi kufika ku-75% wezinto ezibonakalayo kulahleka ngemva kokupholishwa nokugaya. Idatha yasekuqaleni yokukhiqiza yangaphandle ibonise ukuthi kungathatha cishe izinsuku ezingu-273 zokukhiqiza okuqhubekayo amahora angu-24 ukukhiqiza ama-wafer angu-10,000—okuthatha isikhathi esiningi kakhulu.

Ngaphakathi, izinkampani eziningi ezikhulayo ze-SiC crystal zigxile ekwandiseni umthamo wesithando somlilo. Kodwa-ke, esikhundleni sokwandisa umkhiqizo kuphela, kubaluleke kakhulu ukucabangela indlela yokunciphisa ukulahlekelwa-ikakhulukazi lapho isivuno sokukhula kwekristalu singakafiki kahle.

Imishini yokusika i-laser inganciphisa kakhulu ukulahleka kwezinto futhi ithuthukise isivuno. Isibonelo, usebenzisa i-single 20 mmI-SiC ingot:Ukusaha ngocingo kungakhiqiza cishe amawafa angama-30 anogqinsi luka-350 μm. Ukusika nge-laser kungaveza amawafa angaphezu kuka-50. Uma ugqinsi lwewafer lwehliswa lube ama-200 μm, amawafa angaphezu kuka-80 angakhiqizwa ku-ingot efanayo.Ngenkathi ukusaha ngocingo kusetshenziswa kabanzi kuma-wafers ama-wafers amancane ama-intshi angu-6 amasentimitha angu-6 amasentimitha Izinsuku ezingu-10-15 ngezindlela zendabuko, ezidinga imishini ephezulu kanye nezindleko eziphezulu ngokusebenza kahle okuphansi. Ngaphansi kwalezi zimo, izinzuzo ze-laser slicing ziba sobala, okwenza kube ubuchwepheshe besikhathi esizayo obujwayelekile bamawafa angu-8 intshi.

Ngokusikwa kwe-laser, isikhathi sokusika iwafa ngayinye engama-intshi angu-8 singaba ngaphansi kwamaminithi angu-20, nokulahlekelwa kwempahla ngewafa ngayinye ngaphansi kuka-60 μm.

Kafushane, uma kuqhathaniswa nokusika kwezintambo eziningi, ukusika i-laser kunikeza isivinini esiphezulu, isivuno esingcono, ukulahleka kwempahla ephansi, nokucubungula okuhlanzekile.

Q: Yiziphi izinselelo zobuchwepheshe eziyinhloko ekusikeni kwe-laser ye-SiC?

A:Inqubo yokusika i-laser ibandakanya izinyathelo ezimbili ezibalulekile: ukuguqulwa kwe-laser nokuhlukaniswa kwe-wafer.

Umnyombo wokuguqulwa kwe-laser ukubunjwa kwe-beam kanye nokwenza kahle kwepharamitha. Amapharamitha anjengamandla e-laser, ububanzi bendawo, kanye nesivinini sokuskena konke kuthinta ikhwalithi yokukhishwa kwezinto ezibonakalayo kanye nempumelelo yokuhlukaniswa kwe-wafer okulandelayo. Ijiyomethri yendawo eguquliwe inquma ubulukhuni bobuso kanye nobunzima bokuhlukaniswa. Ukumahhadla okuphezulu kwenza kube nzima ukugaya kamuva futhi kwandisa ukulahleka kwempahla.

Ngemuva kokulungiswa, ukuhlukaniswa kwe-wafer ngokuvamile kufinyelelwa ngokusebenzisa amandla okugunda, njengokuphuka okubandayo noma ingcindezi yokusebenza. Ezinye izinhlelo ezifuywayo zisebenzisa ama-transducer e-ultrasonic ukuze zenze ukudlidliza ukuze kuhlukaniswe, kodwa lokhu kungabangela ukukhubazeka nokuphuka, ukwehlisa isivuno sokugcina.

Nakuba lezi zinyathelo ezimbili azinzima ngokwemvelo, ukungahambisani nekhwalithi ye-crystal-ngenxa yezinqubo ezihlukene zokukhula, amazinga e-doping, nokusabalalisa kokucindezeleka kwangaphakathi-kuthinta kakhulu ubunzima bokusika, isivuno, nokulahlekelwa kwezinto ezibonakalayo. Ukukhomba izindawo eziyinkinga nokulungisa izindawo zokuskena nge-laser kungase kungayithuthukisi kakhulu imiphumela.

Isihluthulelo sokwamukelwa okusabalele silele ekuthuthukiseni izindlela ezintsha nemishini engakwazi ukuzivumelanisa nezinhlobonhlobo zezimfanelo zekristalu ezivela kubakhiqizi abahlukahlukene, ukwenza ngcono imingcele yenqubo, nokwakha amasistimu okusika i-laser ngokusebenza kwendawo yonke.

Umbuzo: Ingabe ubuchwepheshe bokusika i-laser bungasetshenziswa kwezinye izinto ze-semiconductor ngaphandle kwe-SiC?

A: Ubuchwepheshe bokusika i-laser ngokomlando bebusetshenziswa ezinhlobonhlobo zezinto. Kuma-semiconductors, ekuqaleni ibisetshenziselwa ukudayela kwe-wafer futhi kusukela ngaleso sikhathi inwetshiwe ekusikeni amakristalu enqwaba eyodwa.

Ngale kwe-SiC, ukusika nge-laser kungabuye kusetshenziselwe ezinye izinto eziqinile noma eziphukayo njengedayimane, i-gallium nitride (GaN), ne-gallium oxide (Ga₂O₃). Izifundo zokuqala ngalezi zinto ezisetshenziswayo zibonise ukuba nokwenzeka kanye nobuhle bokusikwa kwe-laser ezinhlelweni ze-semiconductor.

Q: Ingabe okwamanje ikhona imikhiqizo yemishini yokusika i-laser evuthiwe yasekhaya? Ucwaningo lwakho lukusiphi isigaba?

A:Imishini yokusika i-laser ye-SiC enobubanzi obukhulu ibhekwa kabanzi njengethuluzi eliyinhloko lekusasa lokukhiqizwa kwe-wafer ye-SiC engu-8-intshi. Njengamanje, yiJapan kuphela engahlinzeka ngezinhlelo ezinjalo, futhi ziyabiza futhi zingaphansi kwemikhawulo yokuthumela ngaphandle.

Isidingo sasekhaya se-laser slicing/thinning systems silinganiselwa cishe kumayunithi ayi-1,000, ngokusekelwe ezinhlelweni zokukhiqiza ze-SiC namandla esaha ezintambo ezikhona. Izinkampani ezinkulu zasekhaya zitshale imali eningi ekuthuthukisweni, kodwa azikho izisetshenziswa zasekhaya ezivuthiwe, ezitholakala ngokuthengiswa ezingakafinyeleli ekusetshenzisweni kwezimboni.

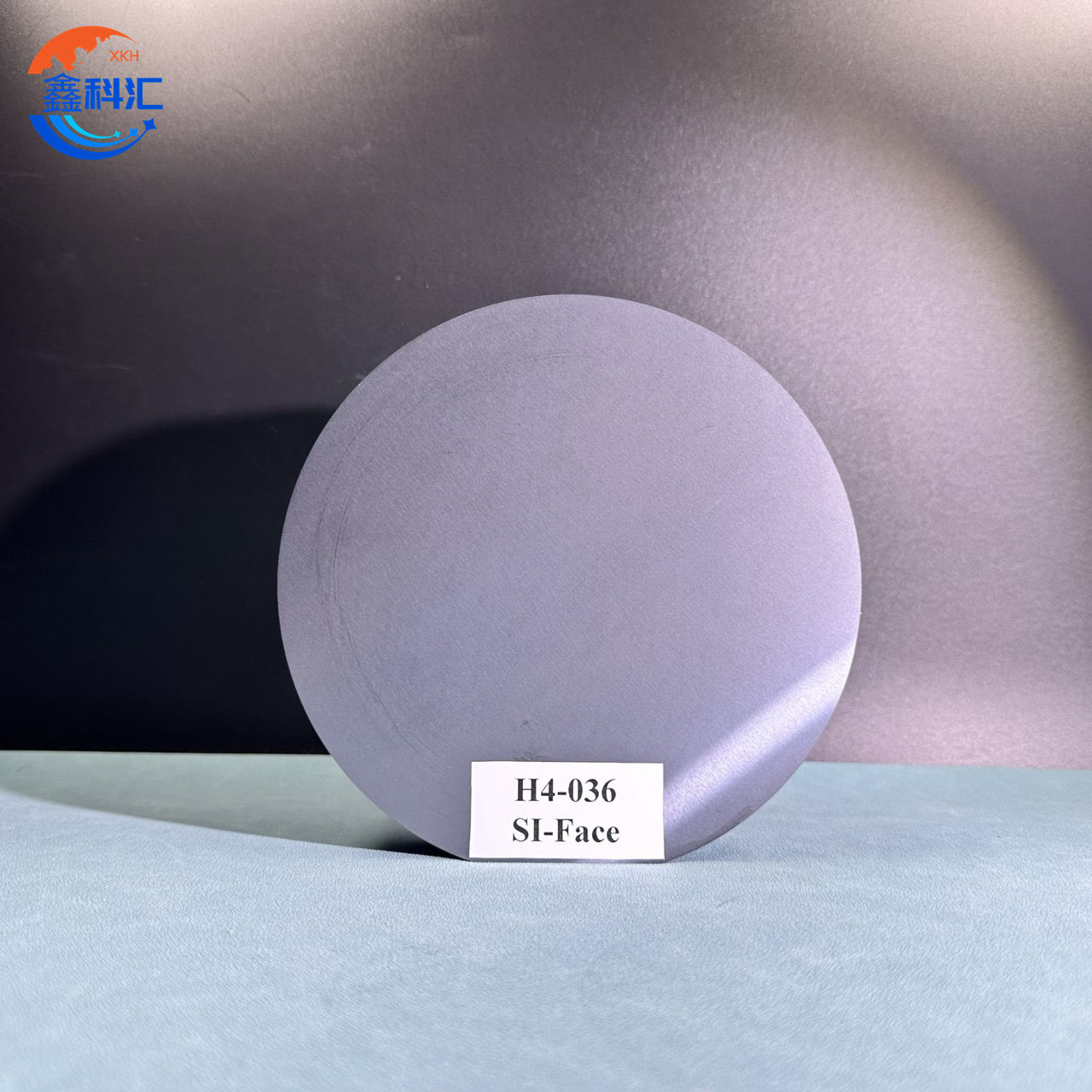

Amaqembu ocwaningo abelokhu ethuthukisa ubuchwepheshe bobunikazi bokuphakamisa i-laser kusukela ngo-2001 futhi manje aselule lokhu ekusikeni nasekunciphiseni i-laser ye-SiC enobubanzi obukhulu. Bakhe uhlelo lwe-prototype kanye nezinqubo zokusika ezikwazi:Ukusika nokuphungula ama-SiC ama-intshi angama-4–6 ama-semi-insulating ama-wafers ama-SiC ama-intshi angu-6–8 amayintshi aqhuba i-SiC ingotsAmabhentshimakhi okusebenza:6–8 inch semi-insulating SiC: isikhathi sokusika imizuzu eyi-10–15/i-wafer; ukulahlekelwa kwempahla <30 μm6–8 inch conductive SiC: isikhathi sokusika 14–20 imizuzu/wafer; ukulahlekelwa kwempahla <60 μm

Isilinganiso sesivuno se-wafer sikhuphuke ngaphezu kuka-50%

Ngemuva kokusika, ama-wafers ahlangabezana nezindinganiso zikazwelonke zejometri ngemva kokugaya nokupholishwa. Ucwaningo luphinde lubonise ukuthi imiphumela yokushisa eyenziwe nge-laser ayithinti kakhulu ingcindezi noma ijometri kumawafa.

Imishini efanayo iphinde yasetshenziswa ukuze kuqinisekiswe ukuthi kungenzeka yini ukusika idayimane, i-GaN, nekristalu eyodwa ye-Ga₂O₃.

Isikhathi sokuthumela: May-23-2025