Isingeniso se-silicon carbide

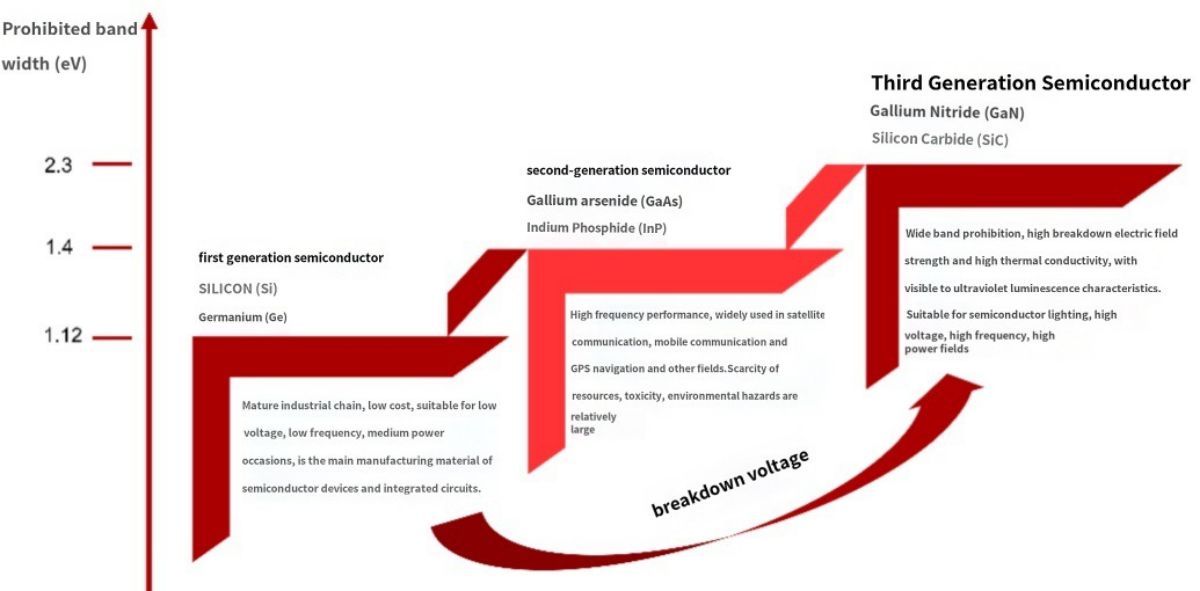

I-Silicon carbide (SiC) iyinhlanganisela ye-semiconductor material eyakhiwe nge-carbon ne-silicon, okungenye yezinto ezikahle zokwenza izinga lokushisa eliphezulu, imvamisa ephezulu, amandla aphezulu kanye namadivayisi aphezulu kagesi. Uma kuqhathaniswa nezinto ezivamile ze-silicon (Si), igebe lebhande le-silicon carbide liphindwe izikhathi ezingu-3 kune-silicon. I-conductivity eshisayo iphindwe izikhathi ezingu-4-5 kune-silicon; I-voltage yokuwohloka iphindwe izikhathi ezingu-8-10 kune-silicon; Izinga le-electronic saturation drift rate liphindwe izikhathi ezingu-2-3 kune-silicon, ehlangabezana nezidingo zemboni yesimanje yamandla aphezulu, i-voltage ephezulu kanye nemvamisa ephezulu. Isetshenziselwa ikakhulukazi ukukhiqizwa kwezingxenye ze-elekthronikhi ezinesivinini esikhulu, imvamisa ephezulu, amandla aphezulu kanye nezikhipha ukukhanya. Izinkambu zesicelo esingezansi zifaka igridi ehlakaniphile, izimoto zamandla amasha, amandla omoya e-photovoltaic, ukuxhumana kwe-5G, njll. Ama-Silicon carbide diode nama-MOSFET asetshenziselwe ukuthengisa.

Ukumelana nokushisa okuphezulu. Ububanzi be-band gap ye-silicon carbide buphindwe izikhathi ezingu-2-3 kune-silicon, ama-electron akulula ukushintshwa emazingeni okushisa aphezulu, futhi angakwazi ukumelana namazinga okushisa aphezulu okushisa, futhi ukushisa okushisayo kwe-silicon carbide kuyizikhathi ezingu-4-5 kune-silicon, okwenza ukushisa kwedivayisi kube lula kanye nomkhawulo wokushisa osebenzayo uphakeme. Ukumelana nezinga lokushisa eliphezulu kungakhuphula kakhulu ukuminyana kwamandla ngenkathi kunciphisa izidingo kusistimu yokupholisa, okwenza itheminali ibe lula futhi ibe ncane.

Melana nengcindezi ephezulu. Amandla ensimu kagesi ephukile ye-silicon carbide aphindwe ka-10 kune-silicon, ekwazi ukumelana nama-voltage aphezulu futhi ifaneleka kakhulu kumadivayisi asebenzisa amandla kagesi aphezulu.

Ukumelana nemvamisa ephezulu. I-Silicon carbide inesilinganiso sokukhukhuleka se-electron esigcwele esiphindwe kabili kune-silicon, okuholela ekungabibikho komsila wamanje phakathi nenqubo yokuvala shaqa, okungathuthukisa ngempumelelo imvamisa yokushintsha idivayisi futhi ibone ukwenziwa kancane kwedivayisi.

Ukulahlekelwa amandla aphansi. Uma kuqhathaniswa nezinto ze-silicon, i-silicon carbide inokumelana okuphansi kakhulu nokulahlekelwa okuphansi. Ngasikhathi sinye, ububanzi be-band-gap ephezulu ye-silicon carbide kunciphisa kakhulu ukuvuza kwamanje nokulahleka kwamandla. Ngaphezu kwalokho, idivayisi ye-silicon carbide ayinayo into yamanje yokulandela ngesikhathi sokuvala, futhi ukulahlekelwa kokushintsha kuphansi.

I-Silicon carbide industry chain

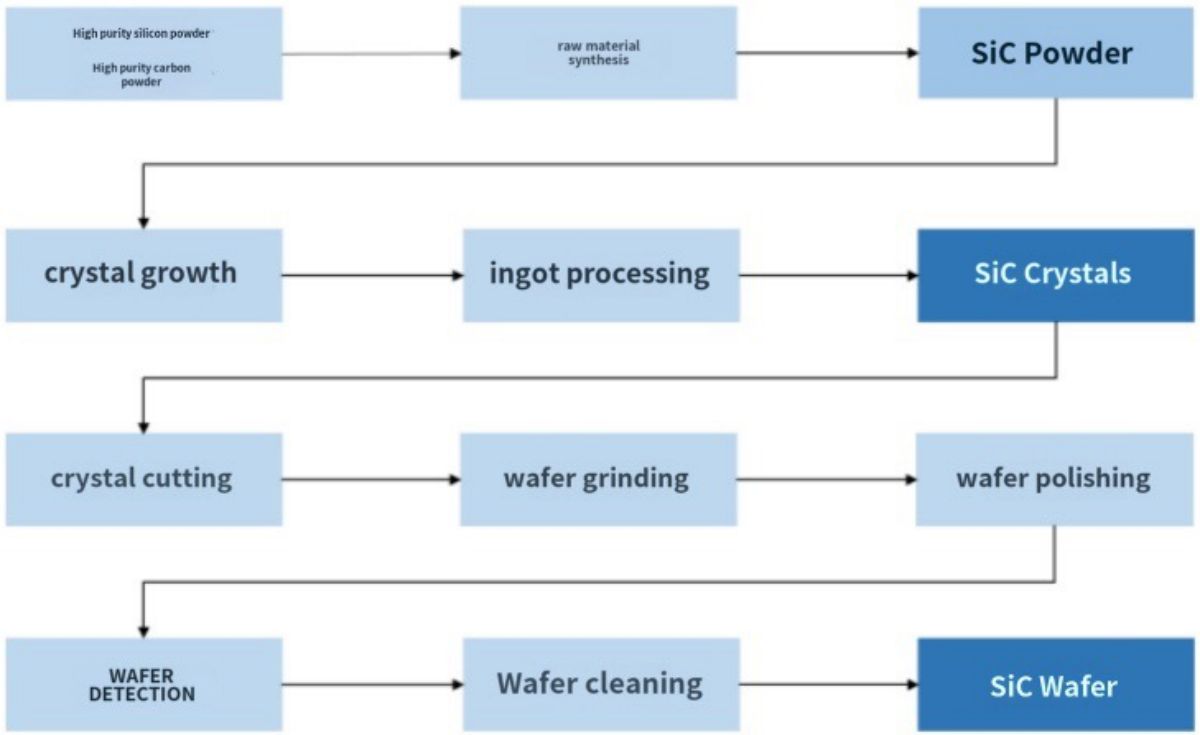

Ihlanganisa ikakhulukazi i-substrate, i-epitaxy, idizayini yedivayisi, ukukhiqiza, ukuvala uphawu nokunye. I-Silicon carbide esuka ezintweni ezibonakalayo kuya kudivayisi yamandla e-semiconductor izobhekana nokukhula kwekristalu eyodwa, ukusika ingot, ukukhula kwe-epitaxial, ukwakheka kwe-wafer, ukukhiqiza, ukupakisha nezinye izinqubo. Ngemuva kokuhlanganiswa kwe-silicon carbide powder, i-silicon carbide ingot yenziwa kuqala, bese i-silicon carbide substrate itholakala ngokusika, ukugaya nokupholisha, futhi ishidi le-epitaxial litholakala ngokukhula kwe-epitaxial. I-wafer ye-epitaxial yenziwe nge-silicon carbide ngokusebenzisa i-lithography, i-etching, i-ion implantation, i-metal passivation nezinye izinqubo, i-wafer iyasikwa ibe yifa, idivayisi iyapakishwa, futhi idivayisi ihlanganiswa ibe igobolondo elikhethekile futhi ihlanganiswe ibe module.

Phezulu kochungechunge 1 lwemboni: i-substrate - ukukhula kwekristalu isixhumanisi senqubo eyinhloko

I-Silicon carbide substrate ibalelwa ku-47% wezindleko zamadivayisi e-silicon carbide, izithiyo zobuchwepheshe zokukhiqiza eziphakeme kakhulu, inani elikhulu kunawo wonke, iwumgogodla wezimboni ezinkulu zesikhathi esizayo ze-SiC.

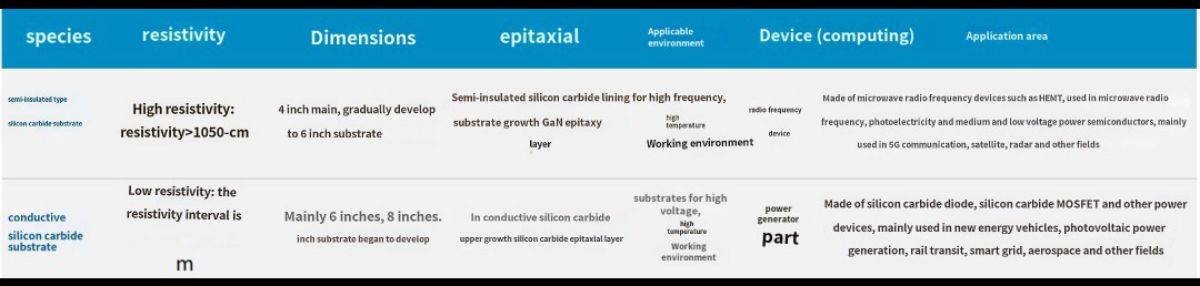

Ngokombono womehluko wezakhiwo ze-electrochemical, izinto ze-silicon carbide substrate zingahlukaniswa zibe ama-conductive substrates (isifunda se-resistivity 15~30mΩ·cm) kanye nama-semi-insulated substrates (ukumelana nokuphezulu kuno-105Ω·cm). Lezi zinhlobo ezimbili zama-substrates zisetshenziselwa ukwakha amadivaysi ahlukene njengamadivayisi kagesi namadivaysi efrikhwensi yomsakazo ngokulandelana kwawo ngemva kokukhula kwe-epitaxial. Phakathi kwazo, i-semi-insulated silicon carbide substrate isetshenziswa ikakhulukazi ekwenzeni amadivayisi we-gallium nitride RF, amadivaysi e-photoelectric nokunye. Ngokukhulisa ungqimba lwe-gan epitaxial ku-semi-insulated SIC substrate, ipuleti le-sic epitaxial liyalungiswa, elingase lilungiswe libe kumadivayisi we-HEMT gan iso-nitride RF. I-conductive silicon carbide substrate isetshenziswa kakhulu ekwenzeni amadivaysi amandla. Ngokungafani nenqubo yendabuko yokukhiqiza idivayisi yamandla e-silicon, idivayisi yamandla e-silicon carbide ayikwazi ukwenziwa ngokuqondile ku-silicon carbide substrate, ungqimba lwe-silicon carbide epitaxial ludinga ukukhuliswa ku-conductive substrate ukuze kutholwe ishidi le-silicon carbide epitaxial, futhi ungqimba lwe-epitaxial lukhiqizwa ku-Schottky diode, i-IGBT yamandla, i-MOS kanye namanye amadivayisi.

I-silicon carbide powder yahlanganiswa kusukela ekuhlanzekeni okuphezulu kwe-carbon powder kanye nokuhlanzeka okuphezulu kwe-silicon powder, futhi osayizi abahlukene be-silicon carbide ingot bakhuliswa ngaphansi kwenkambu yokushisa ekhethekile, kwase kuthi i-silicon carbide substrate yakhiqizwa ngezinqubo eziningi zokucubungula. Inqubo eyinhloko ihlanganisa:

Ukwenziwa kwe-Raw material: I-silicon powder + ye-toner ehlanzekile kakhulu ixubene ngokwefomula, futhi ukusabela kwenziwa ekamelweni lokusabela ngaphansi kwezimo zokushisa ezingaphezulu kuka-2000 ° C ukuze kuhlanganiswe izinhlayiya ze-silicon carbide ngohlobo oluthile lwekristalu nosayizi wezinhlayiyana. Bese ngokusebenzisa ukuchotshozwa, ukuhlolwa, ukuhlanza nezinye izinqubo, ukuhlangabezana nezidingo zokuhlanzeka okuphezulu kwe-silicon carbide powder izinto zokusetshenziswa.

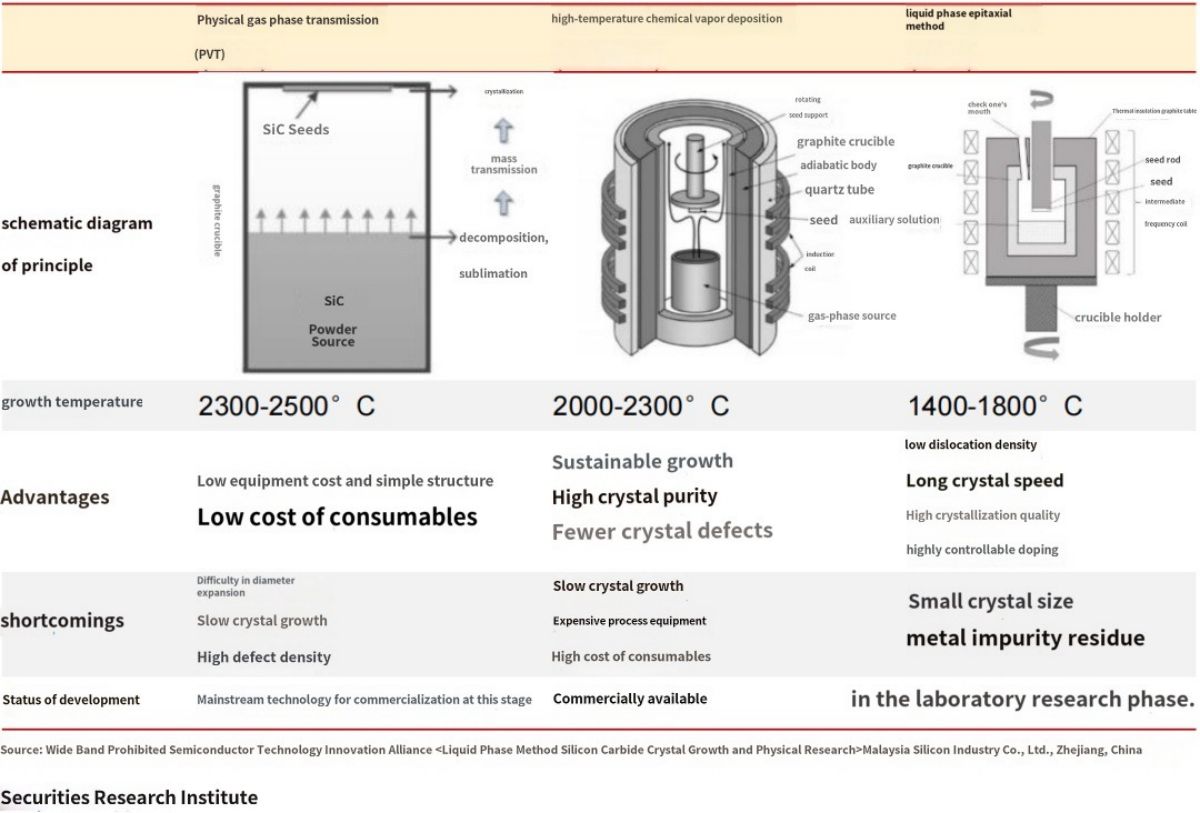

Ukukhula kwekristalu kuyinqubo ewumgogodla wokwenziwa kwe-silicon carbide substrate, enquma izakhiwo zikagesi ze-silicon carbide substrate. Njengamanje, izindlela eziyinhloko zokukhula kwekristalu ukudluliswa komhwamuko obonakalayo (PVT), izinga lokushisa eliphakeme lokubeka umhwamuko wamakhemikhali (HT-CVD) kanye ne-liquid phase epitaxy (LPE). Phakathi kwazo, indlela ye-PVT iyindlela evamile yokukhula kwezentengiselwano ye-SiC substrate okwamanje, ngokuvuthwa okuphezulu kakhulu kwezobuchwepheshe kanye nesetshenziswa kakhulu kwezobunjiniyela.

Ukulungiswa kwe-substrate ye-SiC kunzima, okuholela entengo yayo ephezulu

Ukulawula insimu yokushisa kunzima: Ukukhula kwe-crystal rod kudinga kuphela i-1500 ℃, kuyilapho i-SiC crystal rod idinga ukukhuliswa ezingeni lokushisa eliphezulu elingaphezu kuka-2000 ℃, futhi kukhona ama-isomers we-SiC angaphezu kuka-250, kodwa isakhiwo esiyinhloko se-crystal ye-4H-SiC sokukhiqiza amadivayisi wamandla, uma kungenjalo ukulawulwa okuqondile, kuzothola ezinye izakhiwo zekristalu. Ngaphezu kwalokho, i-gradient yokushisa ku-crucible inquma izinga lokudluliswa kwe-SiC sublimation kanye nemodi yokuhlela nokukhula kwama-athomu egesi ku-interface ye-crystal, ethinta izinga lokukhula kwekristalu nekhwalithi ye-crystal, ngakho-ke kuyadingeka ukwakha ubuchwepheshe obuhlelekile bokulawula insimu yokushisa. Uma kuqhathaniswa nezinto zokwakha ze-Si, umehluko ekukhiqizeni kwe-SiC futhi usezinkambisweni zokushisa okuphezulu njengokufakwa kwe-ion yokushisa ephezulu, i-oxidation yokushisa ephezulu, ukusebenza kokushisa okuphezulu, kanye nenqubo ye-mask enzima edingwa yilezi zinqubo zokushisa okuphezulu.

Ukukhula kancane kwekristalu: izinga lokukhula kwe-Si crystal rod lingafinyelela ku-30 ~ 150mm/h, futhi ukukhiqizwa kwe-1-3m silicon crystal rod kuthatha cishe usuku olulodwa kuphela; I-SiC crystal rod enendlela ye-PVT njengesibonelo, izinga lokukhula lingaba ngu-0.2-0.4mm / h, izinsuku ezingu-7 ukuze zikhule ngaphansi kuka-3-6cm, izinga lokukhula lingaphansi kwe-1% yezinto ze-silicon, amandla okukhiqiza alinganiselwe kakhulu.

Imingcele yomkhiqizo ophezulu kanye nesivuno esincane: imingcele eyinhloko ye-SiC substrate ihlanganisa ukuminyana kwe-microtubule, ukuminyana kwe-dislocation, resistivity, i-warpage, i-surface roughness, njll. Kuwubunjiniyela besistimu eyinkimbinkimbi yokuhlela ama-athomu ekamelweni elivaliwe lokushisa eliphezulu kanye nokukhula okuphelele kwe-crystal, ngenkathi ilawula izinkomba zepharamitha.

Impahla inobunzima obuphezulu, i-brittleness ephezulu, isikhathi eside sokusika nokugqoka okuphezulu: Ukuqina kwe-SiC Mohs ye-9.25 okwesibili kuphela kwedayimane, okuholela ekwandeni okuphawulekayo kobunzima bokusika, ukugaya nokupholisha, futhi kuthatha cishe amahora angu-120 ukusika izingcezu ezingu-35-40 ze-ingot engu-3cm ewugqinsi. Ngaphezu kwalokho, ngenxa yokuqina okuphezulu kwe-SiC, ukugqokwa kwe-wafer processing kuzoba ngaphezulu, futhi isilinganiso sokuphumayo singama-60% kuphela.

Umkhuba wokuthuthuka: Ukwenyuka kosayizi + ukwehla kwentengo

Imakethe yomhlaba wonke yeSiC ulayini wokukhiqiza umthamo wamayintshi angu-6 uyakhula, futhi izinkampani ezihamba phambili sezingene emakethe engama-intshi angu-8. Amaphrojekthi okuthuthukiswa kwasekhaya ikakhulukazi ama-intshi angu-6. Njengamanje, nakuba izinkampani eziningi ezifuywayo zisasekelwe emigqeni yokukhiqiza engu-4-intshi, kodwa imboni ikhula kancane kancane ibe yi-intshi engu-6, ngokuvuthwa kobuchwepheshe bemishini yokusekela engu-6-intshi, ubuchwepheshe be-SiC substrate basekhaya buthuthukisa kancane kancane umnotho wesilinganiso semigqa yokukhiqiza emikhulu izobonakala, futhi igebe lamanje lesikhathi sokukhiqiza elingu-6 intshi liye lehla laya eminyakeni engu-7. Usayizi we-wafer omkhulu ungaletha ukwanda kwenani lama-chips angawodwa, uthuthukise izinga lokukhiqiza, futhi unciphise ingxenye yama-chips onqenqemeni, futhi izindleko zocwaningo nokuthuthukiswa nokulahlekelwa kwesivuno zizogcinwa cishe ku-7%, ngaleyo ndlela kuthuthukiswe ukusetshenziswa kwe-wafer.

Kusenobunzima obuningi ekwakhiweni kwedivayisi

Ukuthengiswa kwe-SiC diode kuyathuthukiswa kancane kancane, okwamanje, inani labakhiqizi basekhaya baklame imikhiqizo ye-SiC SBD, imikhiqizo ye-SiC SBD yamandla aphakathi nendawo aphezulu inokuqina okuhle, emotweni ye-OBC, ukusetshenziswa kwe-SiC SBD+SI IGBT ukuze kuzuzwe ukuminyana kwamanje okuzinzile. Njengamanje, azikho izithiyo ekwakhiweni kwelungelo lobunikazi kwemikhiqizo ye-SiC SBD e-China, futhi igebe emazweni angaphandle lincane.

I-SiC MOS isenobunzima obuningi, lisekhona igebe phakathi kwe-SiC MOS nabakhiqizi baphesheya kwezilwandle, futhi inkundla yokukhiqiza efanele isakhiwa. Njengamanje, i-ST, i-Infineon, i-Rohm kanye nezinye i-600-1700V SiC MOS ziye zazuza ukukhiqizwa ngobuningi futhi zasayinwa futhi zathunyelwa nezimboni eziningi zokukhiqiza, kuyilapho umklamo wamanje we-SiC MOS wasekhaya usuqediwe ngokuyisisekelo, inani labakhiqizi bokuklama basebenza ngezindwangu esiteji sokugeleza kwe-wafer, futhi kamuva ukuqinisekiswa kwamakhasimende kusadinga isikhathi esithile, ngakho-ke kusekhona isikhathi eside sokuhweba.

Njengamanje, ukwakheka kwepulani kuyisinqumo esivamile, futhi uhlobo lomsele lusetshenziswa kakhulu emkhakheni wengcindezi ephezulu esikhathini esizayo. Isakhiwo se-Plalar SiC MOS abakhiqizi abaningi, isakhiwo se-planar akulula ukukhiqiza izinkinga zokuwohloka kwendawo uma kuqhathaniswa ne-groove, okuthinta ukuzinza komsebenzi, emakethe engaphansi kwe-1200V inenani elibanzi lenani lesicelo, futhi isakhiwo se-planar silula ekugcineni kokukhiqiza, ukuhlangabezana nokulawulwa kokwenziwa nokulawula izindleko izici ezimbili. Idivayisi ye-groove inezinzuzo ze-inductance ye-parasitic ephansi kakhulu, isivinini sokushintsha ngokushesha, ukulahlekelwa okuphansi nokusebenza okuphezulu uma kuqhathaniswa.

2--SiC wafer izindaba

Ukukhiqizwa kwemakethe ye-silicon carbide kanye nokukhula kokuthengisa, naka ukungalingani kwesakhiwo phakathi kokunikezwa kanye nesidingo

Ngokukhula okusheshayo kwesidingo semakethe yama-elekthronikhi anemvamisa ephezulu namandla amakhulu, umkhawulo ongokomzimba wemishini ye-semiconductor esekwe ku-silicon uye wabonakala kancane kancane, futhi izinto zesizukulwane sesithathu ze-semiconductor ezimelwe yi-silicon carbide (SiC) kancane kancane ziye zaba yizimboni. Ngokombono wokusebenza kwezinto ezibonakalayo, i-silicon carbide ine-silicon carbide izikhathi ezingu-3 ububanzi begebe le-band yezinto ze-silicon, izikhathi ezingu-10 ukuwohloka okubalulekile kwamandla kagesi, izikhathi ezi-3 ukuqhutshwa kwe-thermal, ngakho-ke amadivaysi kagesi e-silicon carbide afaneleka imvamisa ephezulu, ukucindezela okuphezulu, izinga lokushisa eliphezulu nezinye izinhlelo zokusebenza, zisiza ukuthuthukisa ukusebenza kahle namandla okuminyana kwamandla kagesi amasistimu.

Njengamanje, ama-SiC diode nama-SiC MOSFET athuthela kancane kancane emakethe, futhi kunemikhiqizo evuthiwe eyengeziwe, phakathi kwayo ama-SiC diode asetshenziswa kakhulu esikhundleni se-silicon-based diode kweminye imikhakha ngenxa yokuthi ayinayo inzuzo yokukhokhiswa kokuhlehlisa kabusha; I-SiC MOSFET iphinde isetshenziswe kancane kancane kwezezimoto, ukugcinwa kwamandla, inqwaba yokushaja, i-photovoltaic nezinye izinkambu; Emkhakheni wezicelo zezimoto, ukuthambekela kwe-modularization kuya ngokuya kugqama, ukusebenza okuphezulu kwe-SiC kudinga ukuncika ezinqubweni zokupakisha ezithuthukisiwe ukuze kuzuzwe, ngokobuchwepheshe ngokuvalwa kwegobolondo okuvuthiwe njengokujwayelekile, ikusasa noma ekuthuthukisweni kokufakwa uphawu kwepulasitiki, izici zayo zokuthuthuka ezenziwe ngokwezifiso zifaneleka kakhulu kumamojula we-SiC.

Ijubane lentengo ye-silicon carbide liyancipha noma ngaphezu komcabango

Ukusetshenziswa kwamadivayisi we-silicon carbide kunqunyelwe kakhulu izindleko eziphezulu, intengo ye-SiC MOSFET ngaphansi kwezinga elifanayo iphakeme izikhathi ezi-4 kune-Si-based IGBT, lokhu kungenxa yokuthi inqubo ye-silicon carbide iyinkimbinkimbi, lapho ukukhula kwe-crystal eyodwa kanye ne-epitaxial kungekona nje kuphela imvelo, kodwa futhi izinga lokukhula lihamba kancane, futhi ukucutshungulwa kwekristalu eyodwa kufanele kudlule inqubo yokusika i-crystal te encane. Ngokusekelwe ezicini zayo ezibonakalayo kanye nobuchwepheshe bokucubungula okungavuthiwe, isivuno se-substrate yasekhaya singaphansi kwama-50%, futhi izici ezihlukahlukene ziholela emananini aphezulu e-substrate kanye ne-epitaxial.

Kodwa-ke, ukwakheka kwezindleko zamadivayisi e-silicon carbide kanye namadivayisi asekelwe ku-silicon kuphambene kakhulu, izindleko ze-substrate kanye ne-epitaxial ye-akhawunti yesiteshi sangaphambili ngama-47% no-23% wayo yonke idivayisi ngokulandelanayo, isamba esingaba ngu-70%, umklamo wedivayisi, izixhumanisi zokukhiqiza nokuvala i-akhawunti yesiteshi esingemuva ngama-30% kuphela, izindleko zokukhiqizwa kwemishini yokukhiqiza e-silicon esekelwe ngokuyinhloko imayelana nokukhiqizwa kwe-silicon-based 50%, kanti izindleko ze-substrate zenza u-7% kuphela. Isimo senani le-silicon carbide industry sibheke phansi sisho ukuthi abakhiqizi be-epitaxy ye-upstream substrate banelungelo eliyinhloko lokukhuluma, okuwukhiye wesakhiwo samabhizinisi asekhaya nawangaphandle.

Ngokombono oguquguqukayo emakethe, ukunciphisa izindleko ze-silicon carbide, ngaphezu kokuthuthukisa inqubo ye-silicon carbide crystal ende kanye nenqubo yokusika, ukwandisa usayizi we-wafer, okubuye kube yindlela evuthiwe yokuthuthukiswa kwe-semiconductor esikhathini esidlule, idatha ye-Wolfspeed ibonisa ukuthi i-silicon carbide substrate ithuthukisa isuka ku-6 amayintshi ukuya kuma-intshi angu-8 kuya ku-80% wokukhiqiza, ingasiza ekukhiqizeni ama-intshi angu-8 kuya kwangu-8. ngcono isivuno. Inganciphisa izindleko zeyunithi ehlanganisiwe ngo-50%.

I-2023 yaziwa ngokuthi "unyaka wokuqala we-8-inch SiC", kulo nyaka, abakhiqizi be-silicon carbide basekhaya nabangaphandle basheshisa ukwakheka kwe-silicon carbide engu-8-intshi, njengokutshalwa kwe-Wolfspeed crazy yama-dollar ayizigidi eziyizinkulungwane ezingu-14.55 ukuze kwandiswe ukukhiqizwa kwe-silicon carbide, okuyingxenye ebalulekile yokwakhiwa kwesitshalo sensimbi esingu-8-inch Ukuqinisekisa ukuhlinzekwa kwensimbi okuzayo kwe-SiC 0. ezinkampanini eziningi; I-Domestic Tianyue Advanced kanye no-Tianke Heda nabo basayine izivumelwano zesikhathi eside ne-Infineon zokuhlinzeka ngama-8-inch silicon carbide substrates esikhathini esizayo.

Kusukela kulo nyaka, i-silicon carbide izokhula ngesivinini isuka ku-6 amayintshi iye ku-8 amayintshi, iWolfspeed ilindele ukuthi ngo-2024, izindleko zeyunithi ye-chip engu-8 amayintshi substrate uma kuqhathaniswa nezindleko zeyunithi ye-chip engu-6 amayintshi substrate ngo-2022 zizoncishiswa ngaphezu kuka-60%, futhi ukwehla kwezindleko kuzovula imakethe ye-Consul. Isabelo semakethe samanje semikhiqizo engama-intshi angu-8 singaphansi kuka-2%, kanti isabelo semakethe kulindeleke ukuthi sikhule sifinyelele cishe ku-15% ngo-2026.

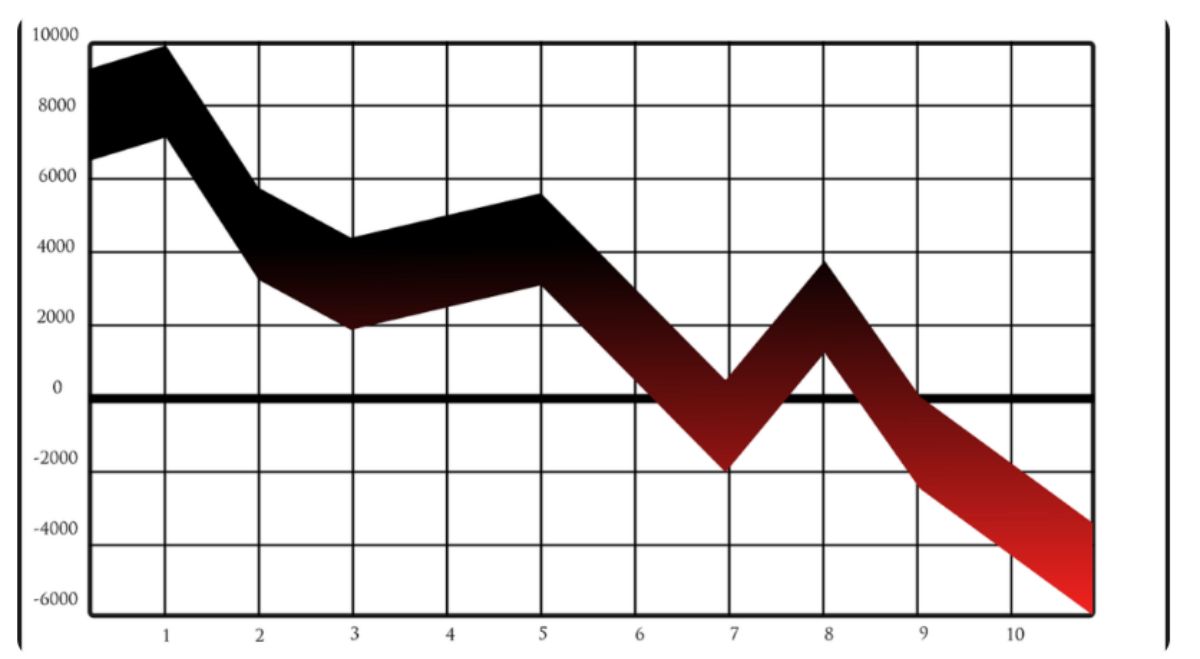

Eqinisweni, izinga lokwehla kwenani le-silicon carbide substrate lingase lidlule umcabango wabantu abaningi, ukunikezwa kwemakethe kwamanje kwe-6-intshi substrate kungu-4000-5000 yuan / ucezu, uma kuqhathaniswa nokuqala konyaka kuwile kakhulu, kulindeleke ukuba kuwele ngaphansi kwama-yuan angama-4000 ngonyaka ozayo, kufanele kuqashelwe ukuthi umugqa wemakethe unciphise abakhiqizi kuqala, intengo ephansi iphansi. imodeli yempi yamanani, egxile kakhulu ekunikezeni kwe-silicon carbide substrate iye yanele emkhakheni we-voltage ephansi, abakhiqizi basekhaya nabangaphandle bakhulisa ngamandla umthamo wokukhiqiza, noma bavumele isiteji se-silicon carbide substrate sigcwale ngaphambi kwalokho obekucatshangwa.

Isikhathi sokuthumela: Jan-19-2024