I-Microjet Water-Guided Laser Cutting System Yezinto Ezithuthukile

Izinzuzo eziphezulu

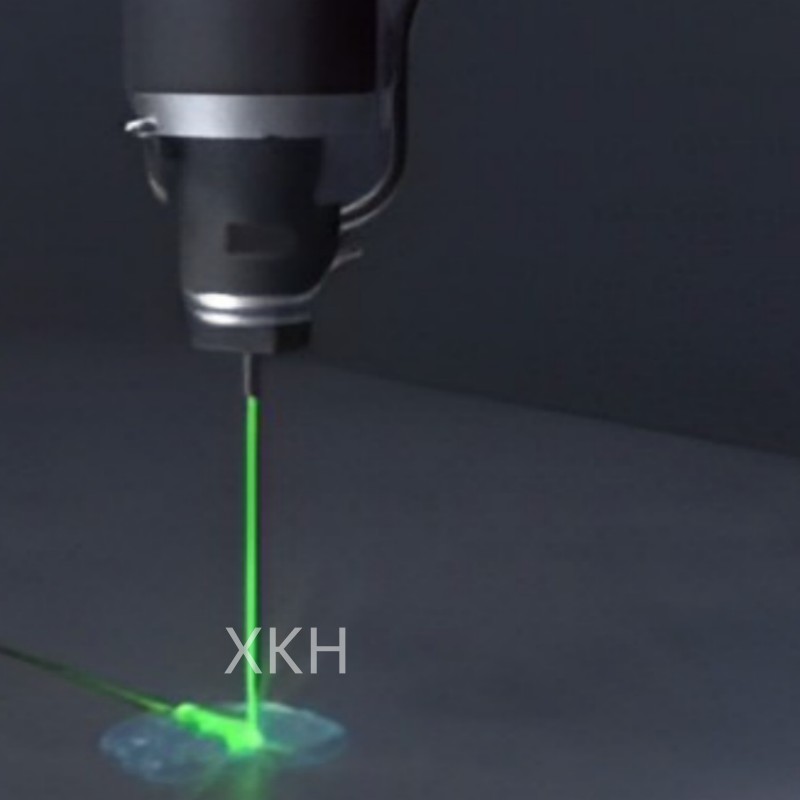

1. Ukugxila Kwamandla Okungenakuqhathaniswa Ngesiqondiso Samanzi

Ngokusebenzisa ijethi lamanzi elicindezelwe kahle njenge-laser waveguide, isistimu iqeda ukuphazamiseka komoya futhi iqinisekisa ukugxila kwe-laser okugcwele. Umphumela uba ububanzi bokusika obuncane kakhulu—buncane njengo-20μm—obunamaphethelo acijile, ahlanzekile.

2. I-Minimal Thermal Footprint

Ukulawulwa kokushisa kwesikhathi sangempela kwesistimu kuqinisekisa ukuthi indawo ethinteke ukushisa ayilokothi idlule u-5μm, okubalulekile ekulondolozeni ukusebenza kwempahla nokugwema ama-microcracks.

3. Ukuhambisana Okubanzi Kwezinto

Okuphumayo kwe-wavelength ekabili (532nm/1064nm) kunikeza ukushuna okuthuthukisiwe, okwenza umshini ukwazi ukujwayelana nama-substrates ahlukahlukene, kusukela kumakristalu abonakalayo kuya kuma-opaque ceramics.

4. High-Speed, High-Precision Motion Control

Ngezinketho zamamotho alayini kanye namadrayivu aqondile, isistimu isekela izidingo zokuphumelela okuphezulu ngaphandle kokuphazamisa ukunemba. Ukunyakaza kwe-axis emihlanu kuqhubekela phambili kunika amandla ukwakhiwa kwephethini eyinkimbinkimbi kanye nokusikeka okunezinhlangothi eziningi.

5. Idizayini ye-Modular ne-Scalable

Abasebenzisi bangakwazi ukuhlela ukulungiselelwa kwesistimu ngokusekelwe kuzidingo zohlelo lokusebenza—kusuka ku-prototyping esekelwe elebhu kuya ekusetshenzisweni kwesikali sokukhiqiza—okuyenza ifaneleke kuzo zonke izizinda ze-R&D nezimboni.

Izindawo Zokufaka Isicelo

AmaSemiconductors esizukulwane sesithathu:

Ilungele amawafa e-SiC ne-GaN, isistimu yenza ukudayela, ukugoqa, nokusika ngobuqotho obukhethekile bonqenqema.

Idayimane ne-Oxide Semiconductor Machining:

Isetshenziselwa ukusika nokumba izinto ezinokuqina okuphezulu njengedayimane lekristalu elilodwa ne-Ga₂O₃, ngaphandle kwe-carbonization noma ukuguqulwa kwe-thermal.

Izingxenye ze-Aerospace ezithuthukisiwe:

Isekela ukubunjwa kwesakhiwo sezinhlanganisela ze-ceramic eziqine kakhulu kanye nama-superalloy enjini yejethi nezingxenye zesathelayithi.

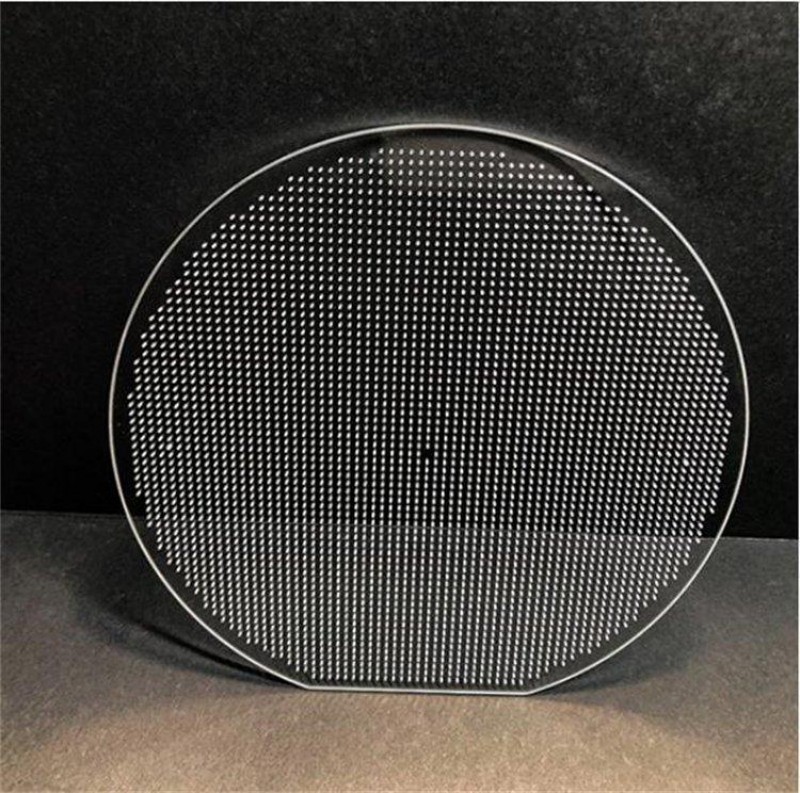

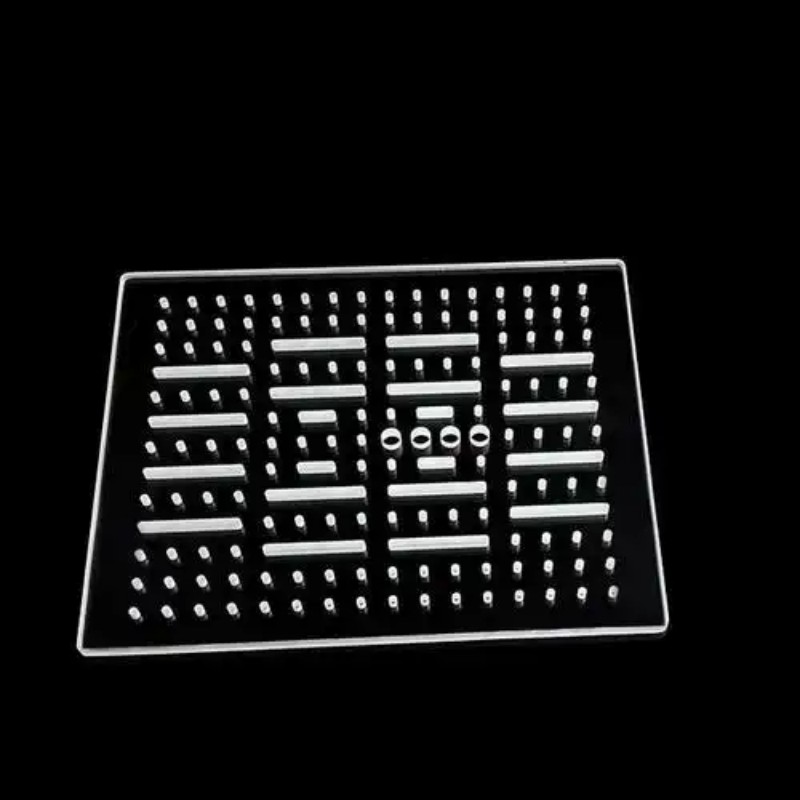

Ama-Photovoltaic kanye ne-Ceramic Substrates:

Inika amandla ukusikwa okungana-burr kwama-wafer azacile nama-substrates e-LTCC, okufaka phakathi izimbobo nokugaywa kwesikhala kokuxhumanisa.

Ama-scintillators kanye ne-Optical Components:

Igcina ukushelela kwendawo kanye nokudluliselwa kwezinto ezibonakalayo ezintekenteke njenge-Ce:YAG, LSO, nezinye.

Ukucaciswa

| Isici | Ukucaciswa |

| Umthombo we-Laser | I-DPSS Nd:YAG |

| Izinketho ze-Wavelength | 532nm / 1064nm |

| Amazinga Amandla | 50/100/200 Watts |

| Ukunemba | ±5μm |

| Sika Ububanzi | Njengoba imincane njengoba 20μm |

| Indawo Ethintekile Ukushisa | ≤5μm |

| Uhlobo Lokunyakaza | I-Linear / Direct Drive |

| Izinto Ezisekelwe | I-SiC, i-GaN, iDayimane, i-Ga₂O₃, njll. |

Kungani Khetha Lolu hlelo?

● Iqeda izinkinga ezijwayelekile zemishini ye-laser njengokuqhekeka okushisayo nokusika umphetho

● Ithuthukisa isivuno nokuvumelana kwezinto ezibiza kakhulu

● Ijwayela kokubili ukulinga-scale kanye nokusetshenziswa ezimbonini

● Inkundla yobufakazi besikhathi esizayo yesayensi yezinto eziguqukayo

Q&A

Q1: Yiziphi izinto ezingenziwa lolu hlelo lokusebenza?

A: Uhlelo luklanyelwe ngokukhethekile izinto ezinenani eliphakeme eziqinile neziphukayo. Ingakwazi ukucubungula ngempumelelo i-silicon carbide (SiC), i-gallium nitride (GaN), idayimane, i-gallium oxide (Ga₂O₃), ama-substrates e-LTCC, ama-aerospace composite, ama-wafers e-photovoltaic, namakristalu e-scintillator afana ne-Ce: YAG noma i-LSO.

Q2: Ngabe ubuchwepheshe belaser obuqondiswa ngamanzi busebenza kanjani?

IMP: Isebenzisa i-microjet yamanzi enengcindezi ephezulu ukuze iqondise i-laser beam ngokubonisa okuphelele kwangaphakathi, ihambisa kahle amandla e-laser ngokuhlakazeka okuncane. Lokhu kuqinisekisa ukugxila okuhle kakhulu, umthwalo oshisayo ophansi, nokusikeka okunembayo ngobubanzi belayini kuze kufike ku-20μm.

I-Q3: Yiziphi izilungiselelo zamandla we-laser ezitholakalayo?

A: Amakhasimende angakhetha kusukela ku-50W, 100W, kanye nezinketho zamandla we-laser angu-200W kuye ngesivinini sabo sokucubungula nezidingo zokuxazulula. Zonke izinketho zigcina ukuzinza okuphezulu kwe-beam nokuphindaphinda.

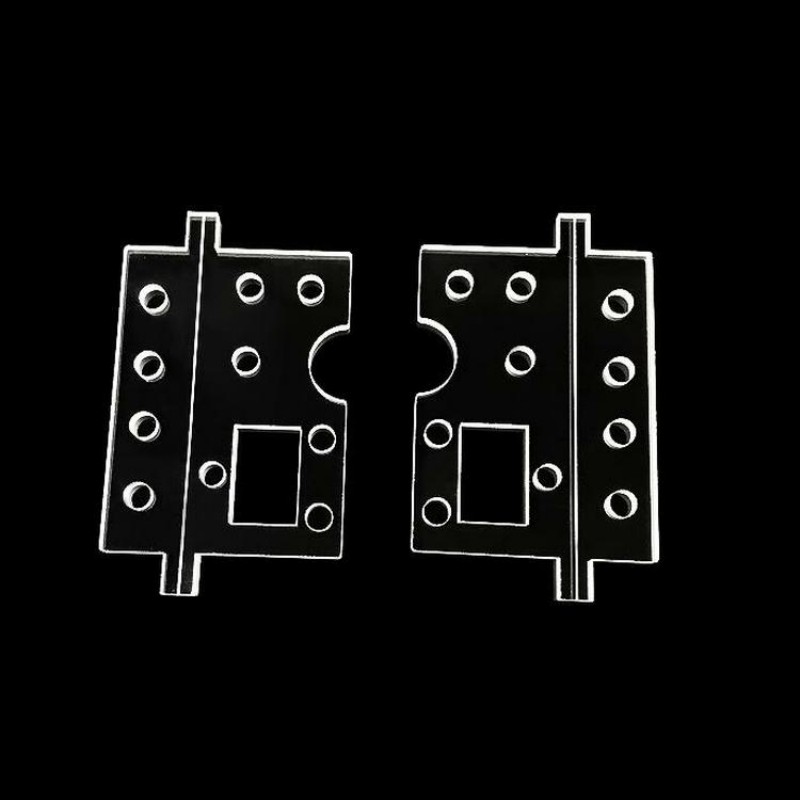

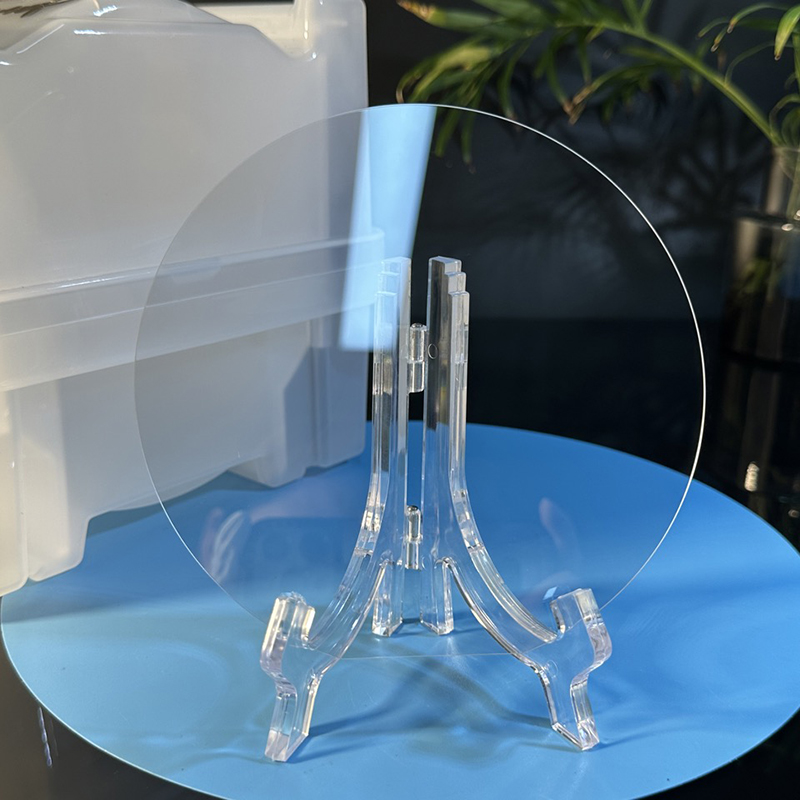

Umdwebo onemininingwane