I-Infrared Picosecond Dual-Platform Laser Cutting imishini yokusika i-Optical Glass/Quartz/Sapphire Processing

Ipharamitha eyinhloko

| Uhlobo lweLaser | I-Infrared Picosecond |

| Usayizi Wenkundla | 700×1200 (mm) |

| 900×1400 (mm) | |

| Ukusika Ukujiya | 0.03-80 (mm) |

| Isivinini sokusika | 0-1000 (mm/s) |

| Cutting Edge Breakage | <0.01 (mm) |

| Qaphela: Usayizi wenkundla ungenziwa ngokwezifiso. | |

Izici Eziyinhloko

1.I-Ultrafast Laser Technology:

· Ama-pulses amafushane eleveli ye-Picosecond (10⁻¹²s) ahlanganiswe nobuchwepheshe bokushuna be-MOPA afinyelela ukuminyana kwamandla aphezulu >10¹² W/cm².

· Ubude beza be-infrared (1064nm) bungena ezintweni ezibonisa ngale ngokumuncwa okungeyona umugqa, kuvimbele ukuphuphuma kwendawo.

· Isistimu ye-optical ye-Proprietary multi-focus ikhiqiza izindawo ezine ezizimele zokucubungula ngesikhathi esisodwa.

2.Isistimu Yokuvumelanisa Yeziteshi Ezimbili:

· Granite-base dual linear motor izigaba (ukunemba kokuma: ±1μm).

· Isikhathi sokushintsha isiteshi <0.8s, esivumela imisebenzi ehambisanayo "yokucubungula-ukulayisha/ukukhipha".

· Ukulawula izinga lokushisa okuzimele (23±0.5°C) esiteshini ngasinye kuqinisekisa ukuzinza kwemishini yesikhathi eside.

3.I-Intelligent Process Control:

· Isizindalwazi esihlanganisiwe sezinto ezibonakalayo (amapharamitha angama-200+) wokufanisa ipharamitha okuzenzakalelayo.

· Ukuqapha kwe-plasma kwesikhathi sangempela kulungisa amandla e-laser (ukulungiswa kokulungiswa: 0.1mJ).

· Ukuvikela amakhethini omoya kunciphisa imifantu emincane (<3μm).

Esimeni sohlelo lokusebenza esivamile esihlanganisa ukudayela kwe-sapphire wafer obukhulu obungu-0.5mm, isistimu ifinyelela isivinini sokusika esingu-300mm/s ngokusika ubukhulu obungu-<10μm, okubonisa ukuthuthukiswa kokusebenza kahle okungu-5x kunezindlela ezivamile.

Ukucubungula Izinzuzo

1.Isistimu ehlanganisiwe yokusika nokuhlukanisa iziteshi ezimbili ukuze kusebenze okuguquguqukayo;

2.Isivinini esikhulu somshini wejometri eyinkimbinkimbi kuthuthukisa ukuguqulwa kwenqubo ukusebenza kahle;

3.Amaphethelo wokusika angenawo ama-taper ane-chipping encane (<50μm) kanye nokubamba okuphephile ko-opharetha;

4.Ushintsho olungenamthungo phakathi kokucaciswa komkhiqizo ngokusebenza okunembile;

5.Izindleko zokusebenza eziphansi, amanani entengo aphezulu, inqubo engathengeki futhi engangcolisi;

6.Ukukhiqizwa okungazero kwe-slag, uketshezi olulahlwayo noma amanzi angcolile anobuqotho obungaphezulu obuqinisekisiwe;

Isibonisi sesampula

Izicelo Ezijwayelekile

1.Ukwenziwa Kwezinto Zogesi Zabathengi:

· Ukusikwa kwekhonta okunembayo kwengilazi yekhava ye-3D ye-smartphone (ukunemba kwe-engeli engu-R: ±0.01mm).

· Ukubhoboza izimbobo ezincane kumalensi wewashi lesafire (ubuncane bembobo: Ø0.3mm).

· Ukuqedwa kwezindawo ezidlulisa ingilazi ezibonakalayo zamakhamera angabonisi kahle.

2.Optical Component Production:

· Ukwenza imishini ye-Microstructure ye-AR/VR lens yamalungu afanayo (usayizi wesici ≥20μm).

· Ukusika okune-angle kwama-quartz prism ama-laser collimators (ukubekezelelana kwe-angular: ±15").

· Ukwakheka kwephrofayili yezihlungi ze-infrared (i-taper yokusika <0.5°).

3.Ukupakishwa kweSemiconductor:

· I-Glass through-via (TGV) icutshungulwa ezingeni le-wafer (i-aspect ratio 1:10).

· Ukufakwa kwe-Microchannel kuma-substrates engilazi ama-microfluidic chips (Ra <0.1μm).

· Ukusikwa kokucushwa kwemvamisa kwamaresonatha equartz e-MEMS.

Ngokwenziwa kwewindi le-LiDAR optical yezimoto, isistimu inika amandla ukusika i-contour yengilazi yequartz engu-2mm enogqinsi olusikiwe lwe-89.5±0.3°, ehlangabezana nezidingo zokuhlolwa kokudlidliza kwebanga lezimoto.

Lungiselela Izicelo

Iklanyelwe ngokukhethekile ukusikwa okunembayo/okuqinile okuhlanganisa:

1.Ingilazi ejwayelekile & izibuko zamehlo (BK7, silica ehlanganisiwe);

2. Amakristalu e-quartz nama-sapphire substrates;

3. Ingilazi eshisayo nezihlungi zamehlo

4. I-Mirror substrates

Iyakwazi kokubili ukusika i-contour kanye nokunemba kokumba imbobo yangaphakathi (ubuncane be-Ø0.3mm)

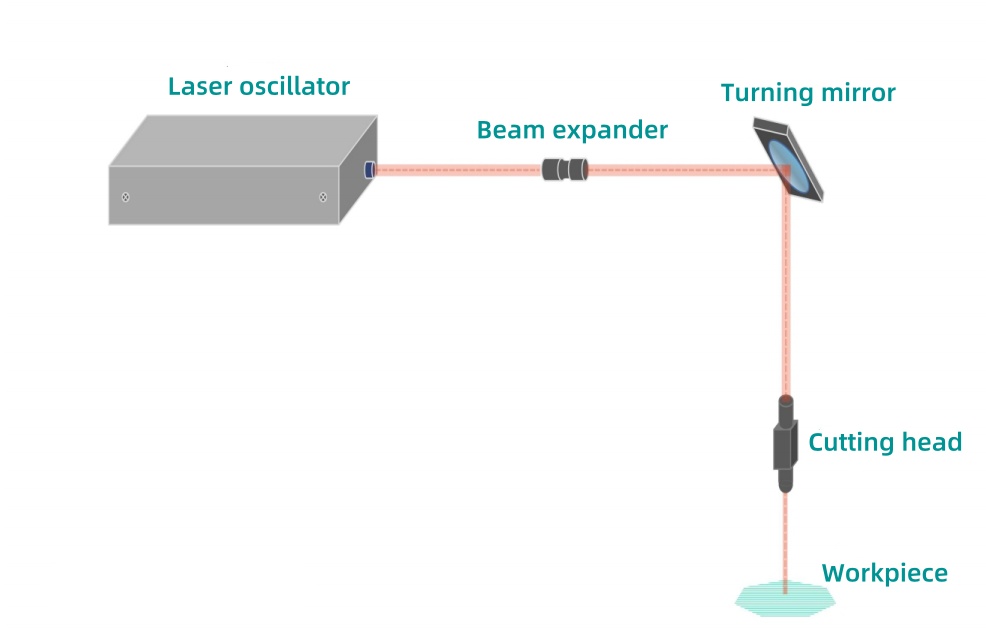

Laser Cutting Isimiso

I-laser ikhiqiza ama-ultrashort pulses anamandla aphezulu kakhulu asebenzisana nesiqeshana somsebenzi phakathi kwezilinganiso zezikhathi ze-femtosecond-to-picosecond. Ngesikhathi sokusakazwa ngempahla, i-beam iphazamisa isakhiwo sayo sokucindezeleka ukuze yenze izimbobo ze-micron-scale filamentation. Isikhala sezimbobo esithuthukisiwe sidala imifantu emincane elawulwayo, ehlangana nobuchwepheshe bokuhlukanisa ukuze kutholakale ukuhlukana okunembayo.

Laser Cutting Izinzuzo

I-1.Ukuhlanganiswa okuzenzakalelayo okuphezulu (ukusebenza okuhlanganisiwe kokusika / ukusika) nokusetshenziswa kwamandla okuphansi nokusebenza okulula;

2.Ukucubungula okungekona othintana naye kwenza amakhono ayingqayizivele angafinyeleleki ngezindlela ezijwayelekile;

3.Ukusebenza kwamahhala okuthengayo kunciphisa izindleko zokusebenzisa futhi kuthuthukisa ukusimama kwemvelo;

4.Ukunemba okuphezulu nge-engeli ye-taper eyiziro kanye nokuqedwa komonakalo wengxenye yokusebenza yesibili;

I-XKH ihlinzeka ngezinsizakalo eziphelele zokwenza ngokwezifiso zezinhlelo zethu zokusika i-laser, okuhlanganisa ukucushwa kweplathifomu eyenzelwe wena, ukuthuthukiswa kwepharamitha yenqubo ekhethekile, nezixazululo eziqondene nohlelo lokusebenza ukuze kuhlangatshezwane nezidingo ezihlukile zokukhiqiza kuzo zonke izimboni ezihlukahlukene.