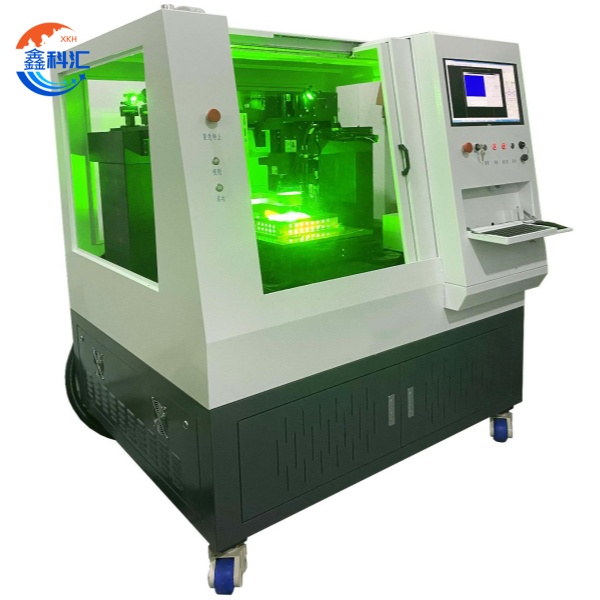

I-Infrared Nanosecond Laser Drilling imishini yokuqina kwe-Glass Drilling≤20mm

Ipharamitha eyinhloko

| Uhlobo lwe-laser | I-infrared nanosecond |

| Usayizi wenkundla | 800*600(mm) |

|

| 2000*1200(mm) |

| Ukuqina kokumba | ≤20(mm) |

| Isivinini sokubhoboza | 0-5000(mm/s) |

| Ukuqhekeka konqenqema lokugaya | <0.5(mm) |

| Qaphela: Usayizi wenkundla ungenziwa ngokwezifiso. | |

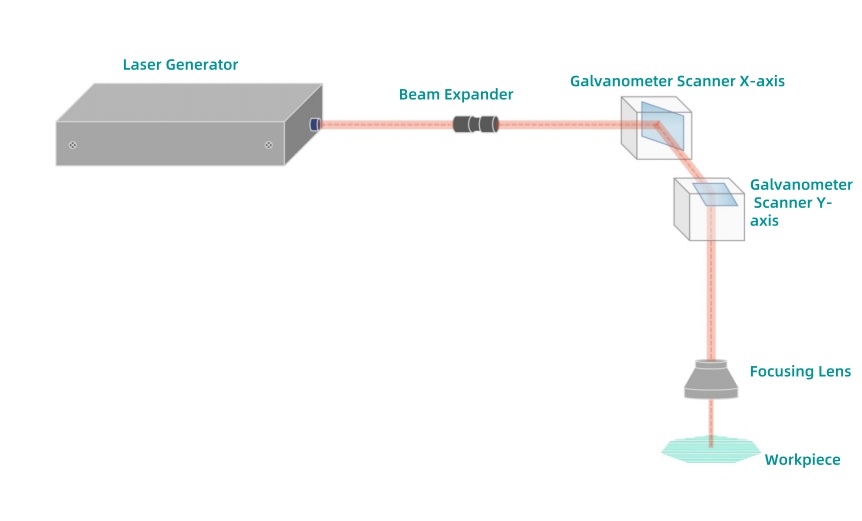

Laser Drilling Isimiso

I-laser beam igxile endaweni efanele uma kuqhathaniswa nogqinsi locezu lokusebenza, bese iskena ezindleleni ezichazwe ngaphambilini ngesivinini esikhulu. Ngokusebenzisana ne-laser enamandla amakhulu, okokusebenza okuqondiwe kukhishwa ungqimba nongqimba ukuze kwakheke amashaneli okusika, kuzuzwe ukubhobozwa okunembile (amajiyometri ayindilinga, ayisikwele, noma ayinkimbinkimbi) ngokuhlukaniswa kwezinto ezilawulwayo.

I-Laser Drilling Izinzuzo

· Ukuhlanganiswa okuzenzakalelayo okuphezulu nokusetshenziswa kwamandla okuncane nokusebenza okulula;

· Ukucutshungulwa okungekona othintana naye kuvumela iphethini yejometri engakhawulelwe ngaphezu kwezindlela ezijwayelekile;

· Ukusebenza kwamahhala okuthengayo kunciphisa izindleko zokusebenza futhi kuthuthukise ukusimama kwemvelo;

· Ukunemba okuphezulu ngokuchotshozwa okuncane konqenqema kanye nokuqedwa komonakalo wengxenye yesibili yokusebenza;

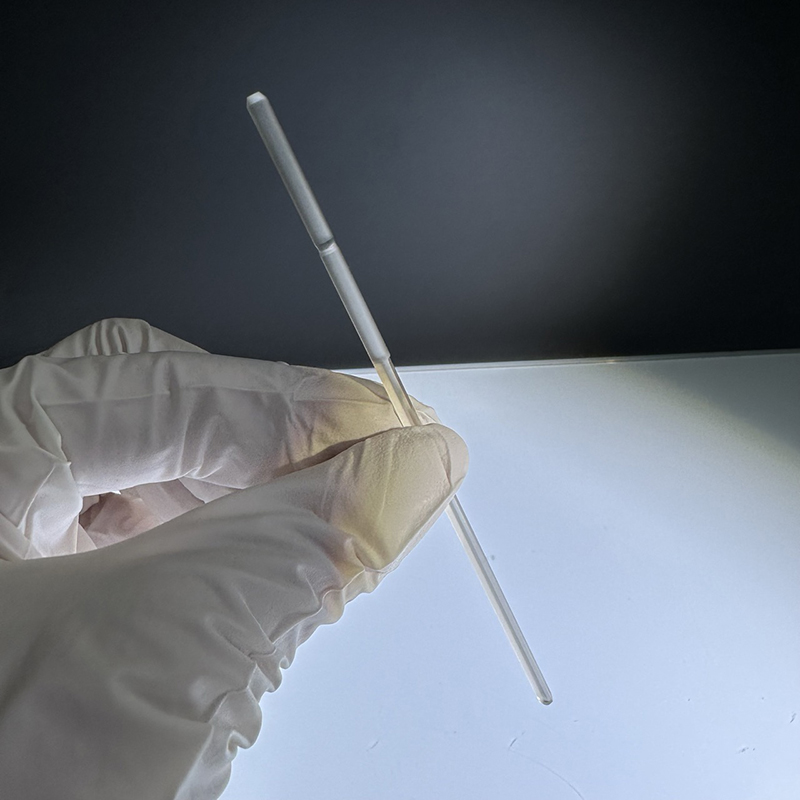

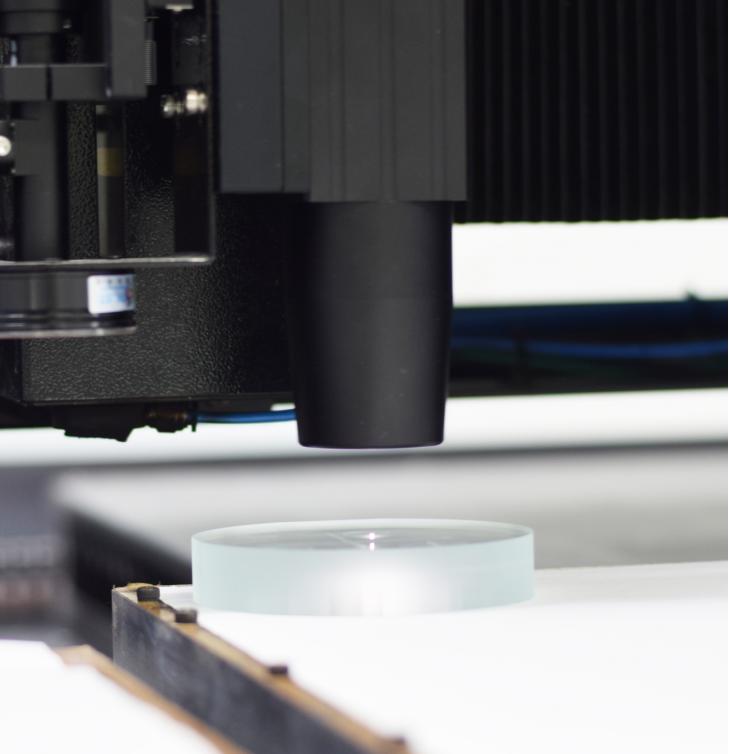

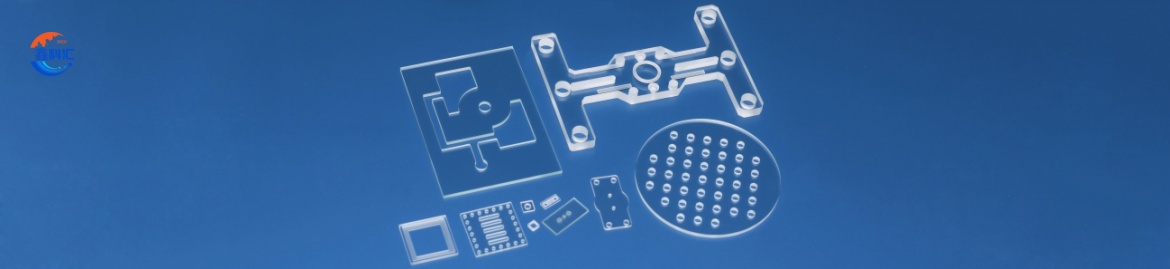

Isibonisi sesampula

Lungiselela Izicelo

Isistimu yakhelwe ukucutshungulwa okunembayo kwezinto ezi-brittle/eziqinile ezihlanganisa ukubhoboza, ukugoba, ukususwa kwefilimu, nokuthumela umbhalo ngaphezulu. Izinhlelo zokusebenza ezijwayelekile zifaka:

1. Ukubhoboza kanye nokubhala izingxenye zeminyango yeshawa

2. Ukubhobozwa ngokunemba kwamaphaneli engilazi kagesi

3. Iphaneli yelanga ngokubhoboza

4. Ukubhobozwa kwepuleti lekhava yesokhethi/sokhethi

5. Ukukhishwa kwe-Mirror enamathela ngokubhoboza

6. Umbhalo owenziwe ngokwezifiso wangaphezulu kanye nokugxusha emikhiqizweni ekhethekile

Ukucubungula Izinzuzo

1. Inkundla yefomethi enkulu ithatha ubukhulu bemikhiqizo ehlukahlukene kuzo zonke izimboni

2. I-complex contour drilling efinyelelwe ekusebenzeni kwe-single-pass

3. Ukucupha unqenqema oluncane ngokuqedwa kwengaphezulu (Ra <0.8μm)

4. Ushintsho olungenamthungo phakathi kokucaciswa komkhiqizo ngokusebenza okunembile

5. Ukusebenza ngendlela eyongayo okufaka:

· Amazinga esivuno esiphezulu (>99.2%)

· Ukucubungula kwamahhala

· Ukukhishwa okungcolile kwe-Zero

I-6.Ukucubungula okungathintana naye kuqinisekisa ukulondolozwa kobuqotho obungaphezulu

Izici Eziyinhloko

1. I-Precision Thermal Management Technology:

· Isebenzisa inqubo yokumba eqhubekayo ene-multi-pulse enamandla ashintshwayo e-single-pulse (0.1–50 mJ)

· Uhlelo olusha lokuvikela ikhethini lomoya lwangemuva luhlanganisa indawo ethinteke ukushisa ibe phakathi kuka-10% wobubanzi bembobo

· Imoduli yokuqapha izinga lokushisa le-infrared yesikhathi sangempela inxephezela ngokuzenzakalelayo amapharamitha wamandla (±2% ukuzinza)

2. I-Intelligent Processing Platform:

· Ifakwe isiteji senjini esinembayo esiphezulu (phinda ukunemba kokuma: ±2 μm)

· Isistimu yokuqondanisa umbono ehlanganisiwe (5-megapixel CCD, ukunemba kokuqaphela: ±5 μm)

· Isizindalwazi senqubo esilayishwe ngaphambili esinamapharamitha alungiselelwe wezinhlobo ezingama-50+ zezinto zengilazi

3. Idizayini Yokukhiqiza Esebenza Kakhulu:

· Imodi yokusebenza eshintshashintshayo yeziteshi ezimbili enesikhathi sokushintsha kwezinto ≤3 amasekhondi

· Umjikelezo wokucubungula ojwayelekile wembobo engu-1/0.5 isekhondi (Φ0.5 mm ngokusebenzisa imbobo)

· Idizayini ye-modular inika amandla ukushintshana okusheshayo kokuhlanganisa amalensi okugxilisa ingqondo (ububanzi bokucubungula: Φ0.1–10 mm)

Izicelo Zokucubungula Okuqinile Kwe-Brittle

| Uhlobo Lwezinto | Isicelo Scenario | Icubungula Okuqukethwe |

| Ingilazi ye-soda-lime | Iminyango yeshawa | Ukukhweza izimbobo namashaneli okudonsa amanzi |

| Amaphaneli okulawula izinto zikagesi | Izimbobo zokudonsa amanzi | |

| Ingilazi Epholile | Amawindi wokubuka i-oven | Izimbobo zokungenisa umoya |

| Iziqalo zokupheka zokungeniswa | Iziteshi zokupholisa ezinama-engeli | |

| Ingilazi ye-Borosilicate | Amaphaneli elanga | Izimbobo ezifakwayo |

| I-glassware yelabhorethri | Iziteshi zokukhipha amanzi ngokwezifiso | |

| Ingilazi-ceramic | Indawo yokupheka | Izimbobo zokubeka i-Burner |

| Ama-induction cookers | Amalungu afanayo embobo yenzwa yokukhweza | |

| Isafire | Amakhava edivayisi ehlakaniphile | Izimbobo zokungenisa umoya |

| Izikhumulo zokubuka zezimboni | Izimbobo eziqinisiwe | |

| Ingilazi Ehlanganisiwe | Izibuko zasendlini yokugezela | Izimbobo ezifakwayo (ukususwa kwe-coating + ukubhoboza) |

| Izindonga zamakhethini | Ingilazi ye-Low-E efihle izimbobo zokudonsa amanzi | |

| Ingilazi yeCeramicized | Shintsha/amakhava esokhethi | Izikhala zokuphepha + izimbobo zezintambo |

| Imigoqo yomlilo | Izimbobo zokukhulula ingcindezi yesimo esiphuthumayo |

I-XKH ihlinzeka ngosekelo oluphelele lobuchwepheshe kanye nezinsizakalo ezingeziwe ze-value yemishini yokumba ingilazi ye-infrared nanosecond ukuze kuqinisekiswe ukusebenza okuphelele kuwo wonke umjikelezo wempilo wemishini. Sihlinzeka ngezinsizakalo zokuthuthukisa inqubo engokwezifiso lapho ithimba lethu lonjiniyela lisebenzisana eduze namakhasimende ukuze lisungule imitapo yolwazi yepharamitha ethize, okuhlanganisa nezinhlelo ezikhethekile zokumba izinto eziyinselele ezifana nesafire nengilazi epholile enokwehluka kogqinsi ukusuka ku-0.1mm kuye ku-20mm. Ukuze kuthuthukiswe ukukhiqiza, senza ukulinganisa kwemishini ekusayithi kanye nokuhlolwa kokuqinisekisa ukusebenza, siqinisekisa amamethrikhi abalulekile njengokubekezelela kobubanzi bembobo (±5μm) nekhwalithi yomphetho (Ra<0.5μm) ahlangabezana namazinga omkhakha.