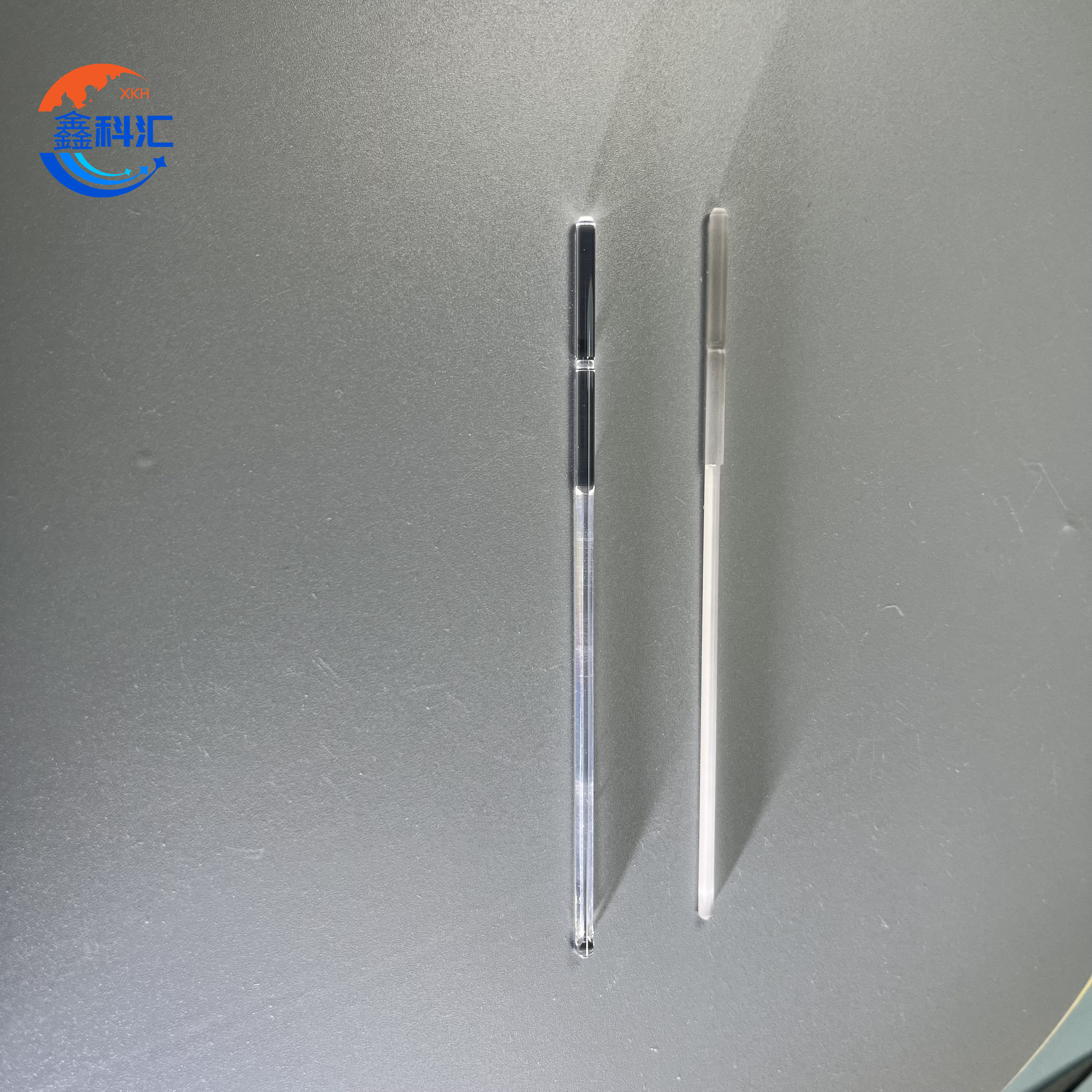

I-Industrial Sapphire Lift Rod and Pin, High Hardness Al2O3 Sapphire Pin for Wafer Handling, Radar System and Semiconductor Processing – Diameter 1.6mm kuya ku-2mm

Abstract

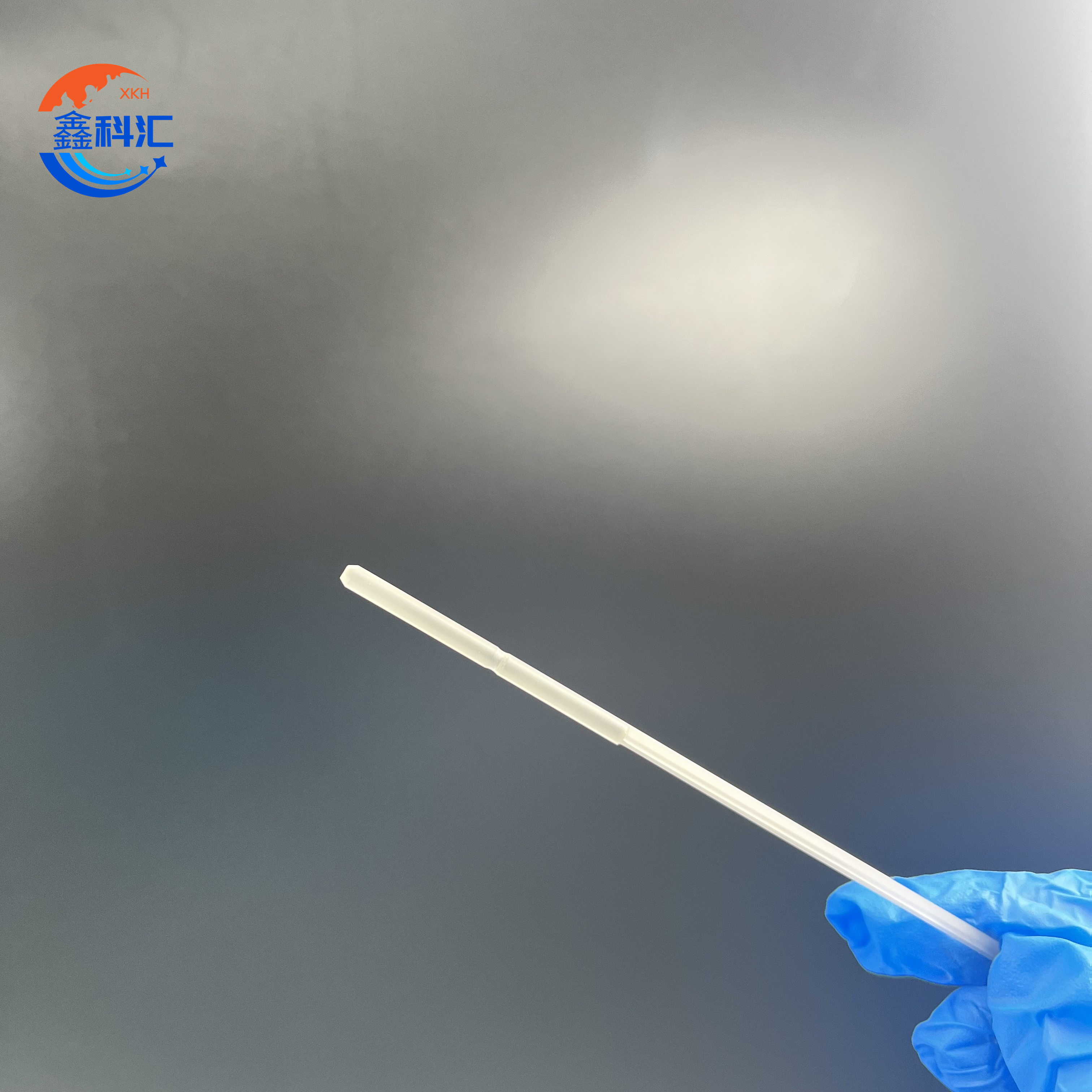

I-Industrial Sapphire Lift Rod kanye nephinikhodi yakhelwe ngokunemba nokuqina kwezinhlelo zokusebenza ezidingeka kakhulu ezifana nokubamba i-wafer, amasistimu e-radar, nokucubungula kwe-semiconductor. Kwenziwe nge-single crystal Al2O3 (sapphire), lezi zikhonkwane zinikeza ubulukhuni obuvelele nokumelana nokushisa. Kutholakala ngobubanzi obusuka ku-1.6mm kuya ku-2mm, lezi zinduku zokuphakamisa nezikhonkwane zingenziwa ngendlela oyifisayo ezidingweni ezikhethekile zezimboni. Banikeza ukumelana nokuklwebheka okuhle kakhulu nokuguga okuphansi, okubenza babe izingxenye ezibalulekile zezinhlelo ezisebenza kahle kakhulu.

Izici

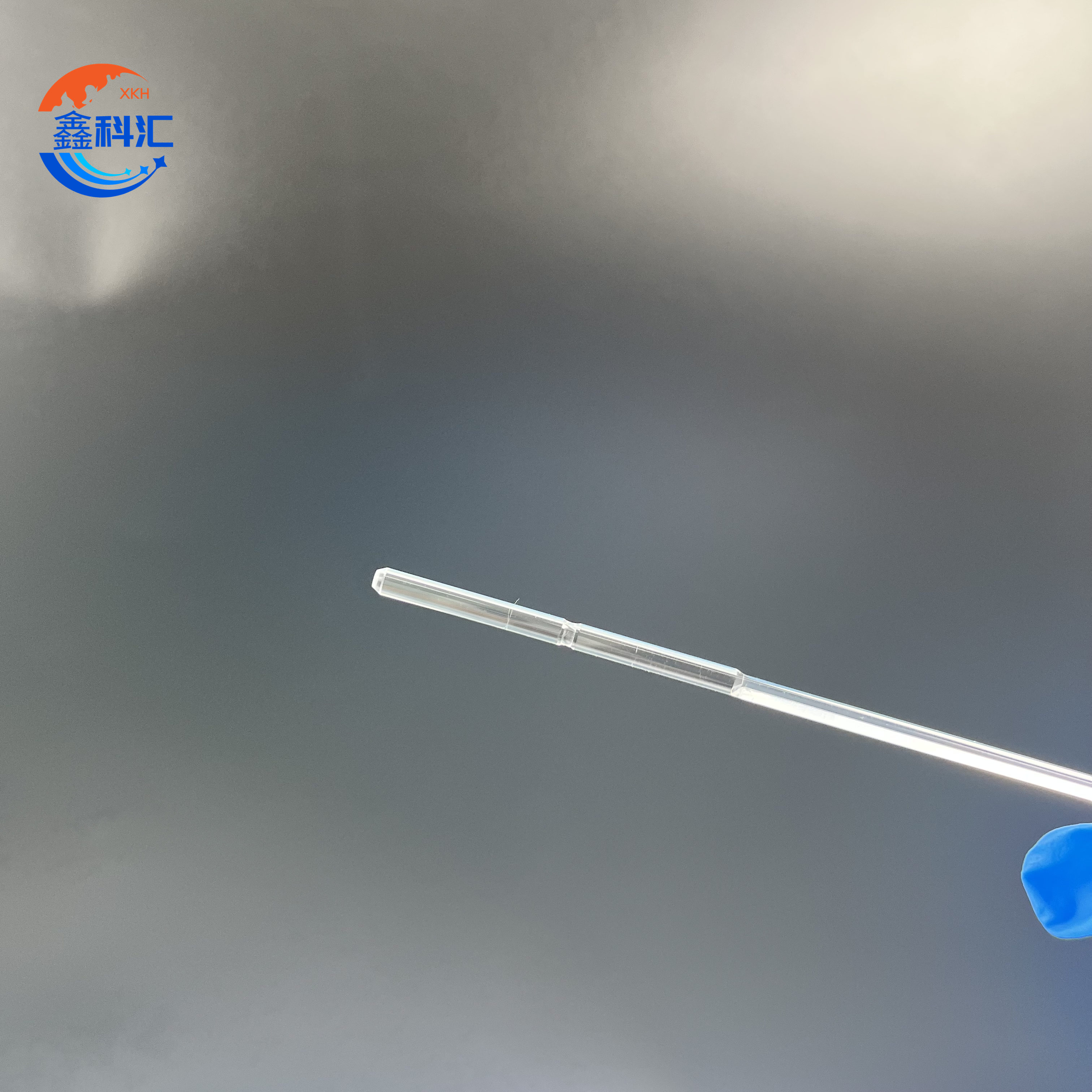

●Ukuqina Okuphezulu Nokuqina:Ngobunzima be-Mohs obungu-9, lawa maphini nezinduku amelana nokuklwebheka, okuqinisekisa ukusebenza okuhlala isikhathi eside kuzinhlelo zokusebenza zokugqoka okuphezulu.

●Osayizi abenziwa ngokwezifiso:Itholakala ngobubanzi obusuka ku-1.6mm ukuya ku-2mm, nenketho yobukhulu bangokwezifiso ukuhlangabezana nezidingo ezithile zohlelo lokusebenza.

●Ukumelana nokushisa:Indawo yokuncibilika ephezulu ye-Sapphire (2040°C) iqinisekisa ukuthi lawa maphini angakwazi ukumelana nezimo zezinga lokushisa eliphezulu ngaphandle kokuwohloka.

●Izici Ezinhle Kakhulu Zokubona:Ukucaca okungokwemvelo kwe-Sapphire kwenza lawa maphini okuphakamisa afanelekele ukusetshenziswa kumasistimu okubona kanye namadivayisi anembayo.

●I-Low Friction and Wear:Indawo ebushelelezi yesafire inciphisa ukuguga kukho kokubili iphini lokuphakamisa kanye nezinto zokusebenza, kunciphisa izindleko zokuyilungisa.

Izinhlelo zokusebenza

●Ukuphatha i-Wafer:Isetshenziswa ekucubunguleni i-semiconductor ukuze kusetshenziswe i-wafer ethambile.

● Amasistimu e-Radar:Izikhonkwane ezisebenza kahle kakhulu ezisetshenziswa ezinhlelweni ze-radar ukuqina nokunemba kwazo.

● Ukucutshungulwa kweSemiconductor:Iphelele ekuphatheni ama-wafers nezinye izingxenye ezinkambisweni zokukhiqiza ze-semiconductor ezisezingeni eliphezulu.

●Izinhlelo zezimboni:Ifanele izinhlelo zokusebenza ezihlukene zezimboni ezidinga ukuqina okuphezulu nokunemba.

Amapharamitha womkhiqizo

| Isici | Ukucaciswa |

| Okubalulekile | I-Single Crystal Al2O3 (Sapphire) |

| Ukuqina | umh 9 |

| Ibanga Lobubanzi | 1.6mm ukuze 2mm |

| I-Thermal Conductivity | 27 W·m^-1·K^-1 |

| I-Melting Point | 2040°C |

| Ukuminyana | 3.97g/cc |

| Izinhlelo zokusebenza | Ukuphatha i-Wafer, Amasistimu we-Radar, Ukucutshungulwa kweSemiconductor |

| Ukwenza ngokwezifiso | Itholakala Ngosayizi Wangokwezifiso |

I-Q&A (Imibuzo Evame Ukubuzwa)

Q1: Kungani isafire iyinto enhle yezikhonkwane zokuphakamisa esetshenziswa ekuphathweni kwe-wafer?

A1: Isafire iphezulu kakhuluukumelana nokuklwebhekafuthi has aizinga eliphezulu lokuncibilika, okwenza kube yinto enhle kakhulu yokusebenza okubucayi njengeukuphathwa kwe-wafer, lapho ukunemba nokuqina kuyisihluthulelo.

Q2: Iyini inzuzo yokwenza ngokwezifiso usayizi wezikhonkwane zokuphakamisa isafire?

I-A2: Osayizi bangokwezifiso bavumela lezi zikhonkwane zokuphakamisa ukuthi zenziwe ngendlela efanele ukuze zilingane nezinhlelo zokusebenza ezithile, kuqinisekiswe ukusebenza kahle kumasistimu ahlukahlukene, okuhlanganisaukucubungula kwe-semiconductorfuthiizinhlelo ze-radar.

Q3: Ingabe izikhonkwane zokuphakamisa isafire zingasetshenziswa ezinhlelweni zokushisa eziphezulu?

A3: Yebo,isafireunayo aizinga eliphezulu lokuncibilikakwe2040°C, okwenza ilungele ukusetshenziswa ezindaweni ezinezinga lokushisa eliphezulu.

Umdwebo onemininingwane