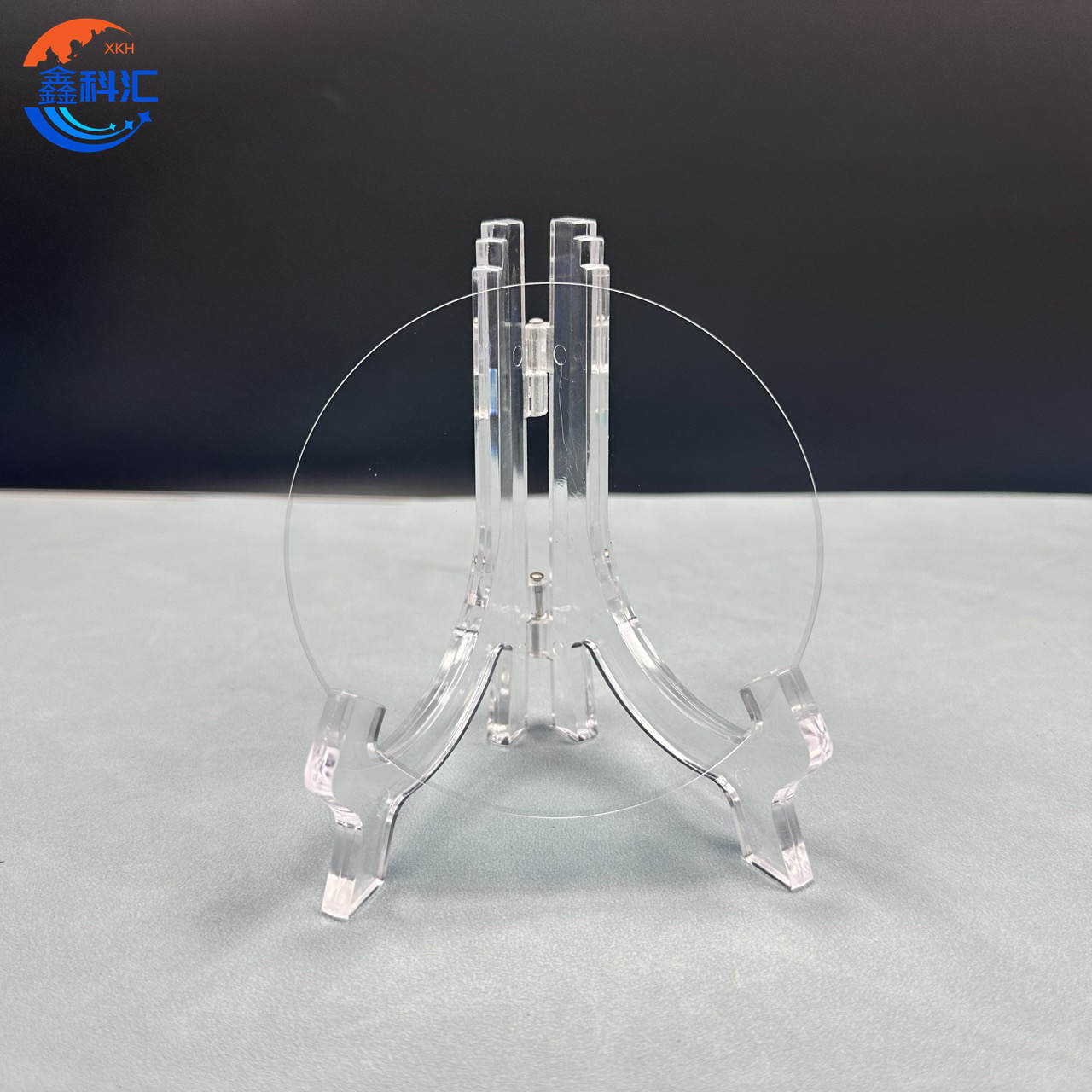

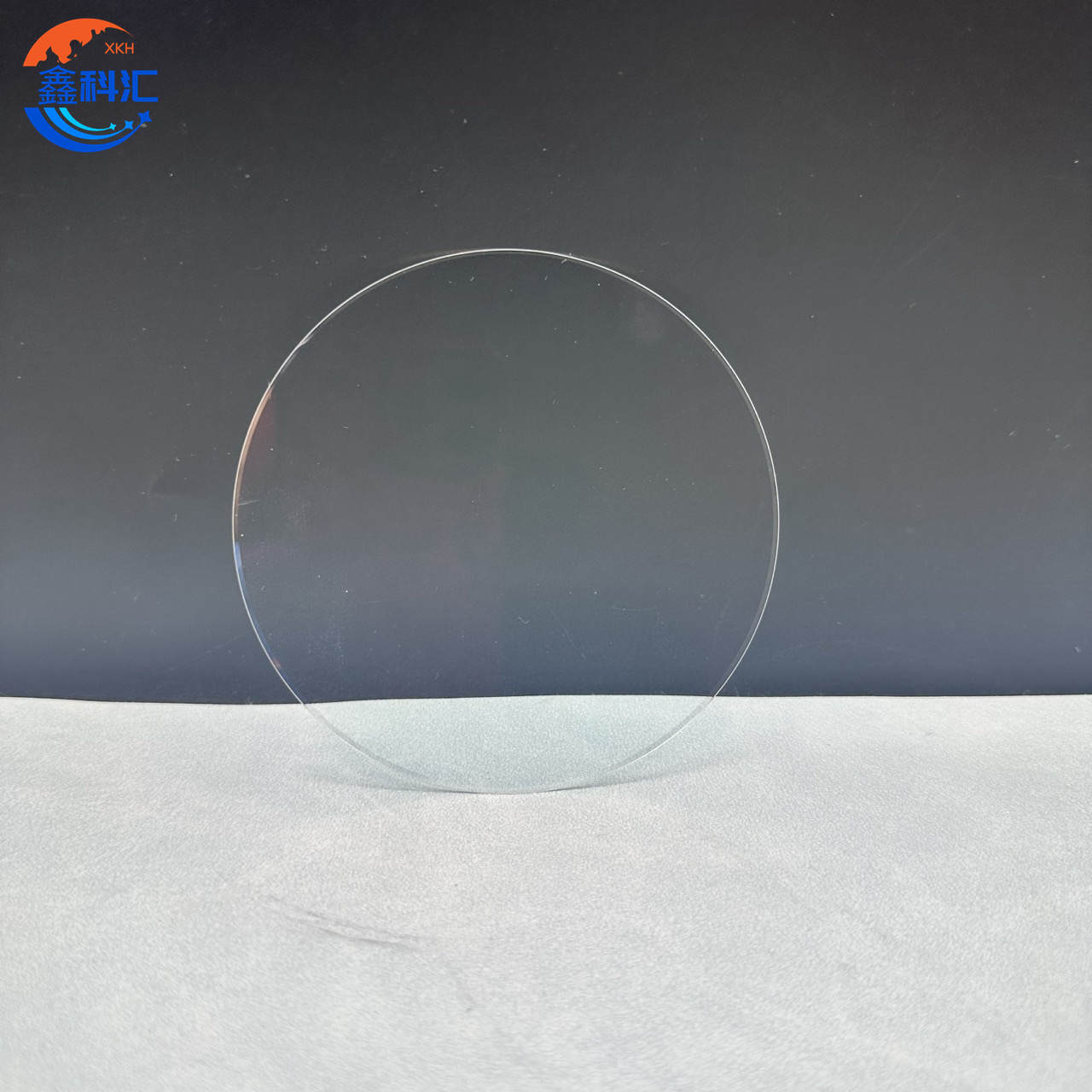

I-HPSI SiC wafer dia:3inch ukujiya:350um± 25 µm ye-Power Electronics

Isicelo

Ama-wafer we-HPSI SiC asetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza zamandla kagesi, okuhlanganisa:

Ama-Semiconductors Amandla:Ama-wafers e-SiC avame ukusetshenziswa ekukhiqizeni amandla e-diode, ama-transistors (ama-MOSFET, ama-IGBT), nama-thyristors. Lawa ma-semiconductors asetshenziswa kakhulu ezinhlelweni zokuguqula amandla ezidinga ukusebenza kahle okuphezulu nokuthembeka, njengakumadrayivu ezimoto zezimboni, izinsiza zikagesi, nama-inverter wezinhlelo zamandla avuselelekayo.

Izimoto zikagesi (EVs):Kuma-powertrains emoto kagesi, amadivaysi kagesi asuselwa ku-SiC ahlinzeka ngesivinini sokushintsha ngokushesha, ukusebenza kahle kwamandla okuphezulu, kanye nokuncipha kokulahlekelwa kwezinga lokushisa. Izingxenye ze-SiC zilungele izinhlelo zokusebenza ezinhlelweni zokuphatha ibhethri (i-BMS), ingqalasizinda yokushaja, namashaja angaphakathi ebhodini (ama-OBC), lapho ukunciphisa isisindo nokwandisa ukusebenza kahle kokuguqulwa kwamandla kubalulekile.

Amasistimu Amandla Avuselelekayo:Ama-wafer e-SiC asetshenziswa kakhulu kuma-solar inverters, amajeneretha enjini yomoya, nezinhlelo zokugcina amandla, lapho ukusebenza kahle okuphezulu nokuqina kubalulekile. Izingxenye ezisekelwe ku-SiC zinika amandla ukuminyana kwamandla aphezulu kanye nokusebenza okuthuthukisiwe kulezi zinhlelo zokusebenza, ukuthuthukisa ukusebenza kahle kokuguqulwa kwamandla.

I-Industrial Power Electronics:Ezinhlelweni zokusebenza zezimboni ezisebenza kahle kakhulu, ezinjengokushayela kwezimoto, amarobhothi, kanye nempahla yamandla amakhulu, ukusetshenziswa kwama-wafers e-SiC kuvumela ukusebenza okuthuthukisiwe mayelana nokusebenza kahle, ukwethembeka, nokuphatha okushisayo. Amadivayisi we-SiC angakwazi ukuphatha amaza okushintshashintsha aphezulu kanye namazinga okushisa aphezulu, awenze afanelekele izindawo ezifunayo.

Izikhungo Zezokuxhumana Nedatha:I-SiC isetshenziswa ezintweni zikagesi kumishini yezokuxhumana kanye nezikhungo zedatha, lapho ukuthembeka okuphezulu nokuguqulwa kwamandla okusebenzayo kubalulekile. Amadivayisi kagesi asekelwe ku-SiC anika amandla ukusebenza kahle okuphezulu kumasayizi amancane, okuhumushela ekusetshenzisweni kwamandla okuncishisiwe kanye nokusebenza kahle kokupholisa okungcono kungqalasizinda yezinga elikhulu.

I-voltage ephezulu yokuphuka, ukumelana okuphansi, kanye nokuhamba kahle kokushisayo kwamawafa e-SiC kuwenza abe i-substrate efanelekile yalezi zinhlelo zokusebenza ezithuthukisiwe, okuvumela ukuthuthukiswa kwesizukulwane esilandelayo sama-electronics awonga amandla.

Izakhiwo

| Impahla | Inani |

| I-Wafer Diameter | 3 amayintshi (76.2 mm) |

| Ubukhulu be-Wafer | 350 µm ± 25 µm |

| I-Wafer Orientation | <0001> ku-eksisi ± 0.5° |

| I-Micropipe Density (MPD) | ≤ 1 cm⁻² |

| Ukungazweli Kagesi | ≥ 1E7 Ω·cm |

| I-Dopant | Kuhlehlisiwe |

| Isisekelo se-Flat Orientation | {11-20} ± 5.0° |

| Ubude Befulethi obuyisisekelo | 32.5 mm ± 3.0 mm |

| Ubude Befulethi besibili | 18.0 mm ± 2.0 mm |

| I-Flat Orientation yesibili | Ubheke phezulu: 90° CW ukusuka efulethini lokuqala ± 5.0° |

| Ukukhishwa komkhawulo | 3 mm |

| LTV/TTV/Bow/Warp | 3 µm / 10 µm / ±30 µm / 40 µm |

| Ukuqina Kobuso | Ubuso buka-C: bupholishiwe, ubuso be-Si: CMP |

| Imifantu (ihlolwe ngokukhanya okukhulu) | Lutho |

| I-Hex Plates (ihlolwe ngokukhanya okuphezulu) | Lutho |

| Izindawo ze-Polytype (zihlolwe ngokukhanya okukhulu) | Indawo ehlanganisiwe 5% |

| Ama-scratches (ahlolwe ngokukhanya okukhulu) | ≤ 5 imihuzuko, ubude obukhulayo ≤ 150 mm |

| I-Edge Chipping | Akukho okuvunyelwe ≥ 0.5 mm ububanzi nokujula |

| I-Surface Contamination (ihlolwe ngokukhanya okukhulu) | Lutho |

Izinzuzo Eziyinhloko

High Thermal Conductivity:Ama-wafer e-SiC aziwa ngekhono lawo eliyingqayizivele lokuqeda ukushisa, okuvumela amadivayisi kagesi ukuthi asebenze ngendlela esezingeni eliphezulu futhi aphathe imisinga ephakeme ngaphandle kokushisisa ngokweqile. Lesi sici sibalulekile kuma-electronics wamandla lapho ukuphathwa kokushisa kuyinselele enkulu.

I-Voltage Yokuhlukaniswa Okuphezulu:I-bandgap ebanzi ye-SiC yenza amadivaysi akwazi ukubekezelela amazinga kagesi aphezulu, okuwenza alungele ukusetshenziswa kwamandla kagesi aphezulu njengamagridi kagesi, izimoto zikagesi, nemishini yezimboni.

Ukusebenza Okuphezulu:Inhlanganisela yamafrikhwensi okushintsha okuphezulu kanye nokumelana okuphansi kuholela emishinini elahlekelwa amandla aphansi, ithuthukisa ukusebenza kahle kukonke kokuguqulwa kwamandla kanye nokunciphisa isidingo samasistimu okupholisa ayinkimbinkimbi.

Ukwethenjwa Ezimweni Ezinzima:I-SiC iyakwazi ukusebenza emazingeni okushisa aphezulu (kufika ku-600°C), okuyenza ifanelekele ukusetshenziswa ezindaweni ezingalimaza izinto zendabuko ezisekelwe ku-silicon.

Ukonga Amandla:Amadivayisi kagesi e-SiC athuthukisa ukusebenza kahle kokuguqulwa kwamandla, okubalulekile ekwehliseni ukusetshenziswa kwamandla, ikakhulukazi ezinhlelweni ezinkulu ezifana neziguquli zamandla ezimboni, izimoto zikagesi, nengqalasizinda yamandla avuselelekayo.

Umdwebo onemininingwane