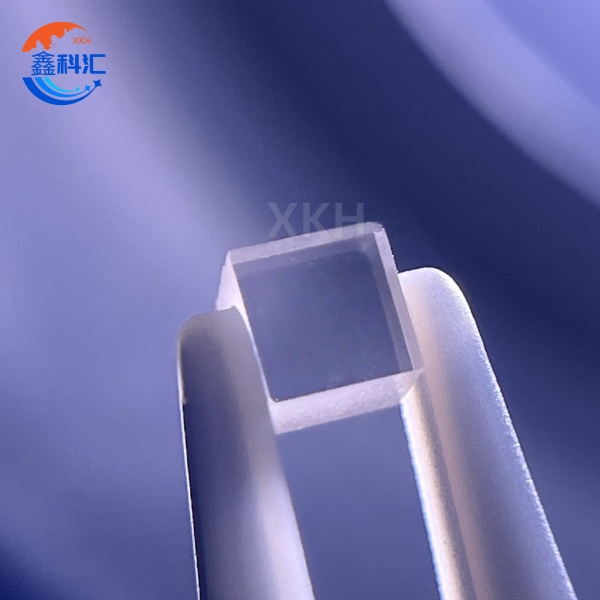

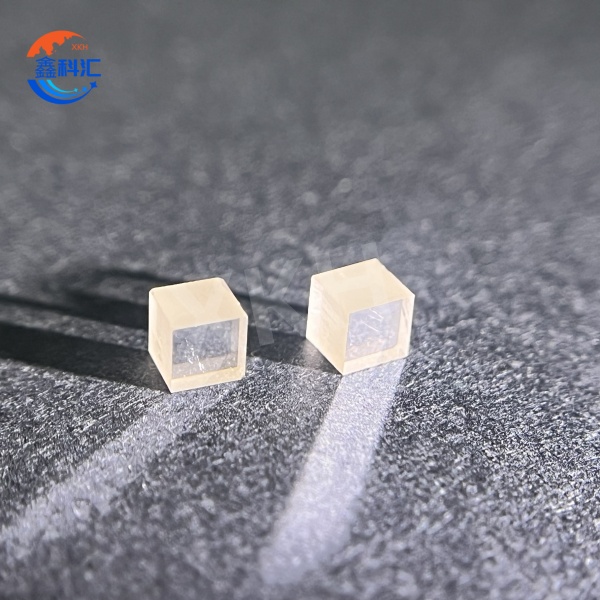

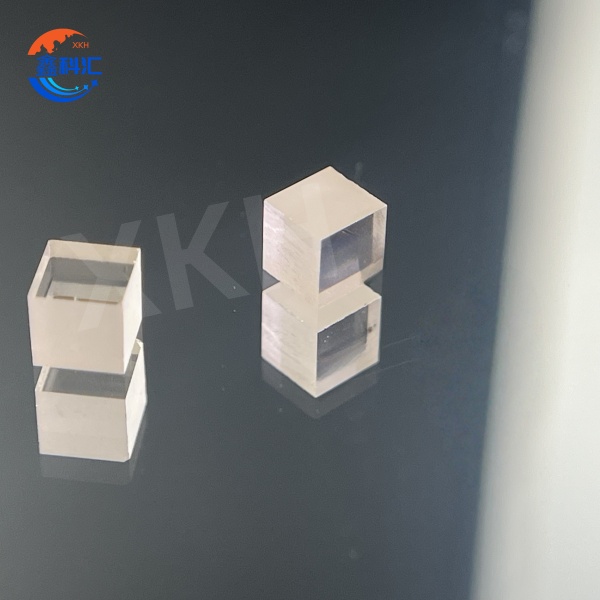

I-High Purity SiC Optical Lens Cubic 4H-semi 6SP Usayizi Owenziwe Ngokwezifiso

Izici ze-SiC Optical Lens

1. Ukuphakama Okubonakalayo

Ukuguquguquka Okudlulele Kwendawo: Imelana nezinga lokushisa >1500°C, ukugqwala kwe-asidi eqinile/i-alkali, nemisebe enamandla amakhulu, ilungele imikhumbi-mkhathi nezindawo zenuzi.

Amandla Omshini Akhethekile: Ukuqina kwedayimane eliseduze (Mohs 9.5), amandla aguqukayo >400 MPa, kanye nokumelana nomthelela kuyidlula kude ingilazi evamile yokubona.

Ukuzinza Kwe-Thermal: I-Thermal conductivity engu-100× ephakeme kune-silica ehlanganisiwe, ene-CTE nje engu-1/10 yengilazi evamile, eqinisekisa ukuzinza ngaphansi kokuhamba ngebhayisikili okushisayo okusheshayo.

2. Optical Performance Izinzuzo

Ukudluliswa okubanzi kwe-spectral (0.2-6 μm); okunamathelayo okuyisipesheli kungakhulisa ukuthunyelwa ku>95% kumabhendi athile (isb, 3-5 μm maphakathi ne-IR).

Ukulahleka kokuhlakazeka okuphansi (<0.5%/cm), ukuqeda phezulu kufika ku-10/5 okujwayelekile kokumba, kanye nokucaba kwendawo λ/10@633 nm.

I-high laser-induced damage threshold (LIDT) >15 J/cm² (1064 nm, 10 ns pulses), ilungele amasistimu okugxilisa amandla amakhulu e-laser.

3. Precision Machining Amakhono

Isekela izindawo eziyinkimbinkimbi (i-aspheric, i-freeform) ngokunemba kwefomu <100 nm PV kanye ne-centration <1 arcmin.

Iyakwazi ukwenza amalensi e-SiC amakhulu kakhulu (ububanzi>500 mm) wezibonakude zezinkanyezi kanye ne-space Optics.

Izicelo Eziyinhloko ze-SiC Optical Lens

1. I-Space Optics & Defense

Amalensi enzwa yeremothi yesathelayithi nama-optics ebonakude emkhathini, asebenzisa izici ze-SiC ezingasindi (ukuminyana okungu-3.21 g/cm³) nokumelana nemisebe.

Amawindi abonakalayo okufuna imicibisholo, abekezelela ukushisa kwe-aerodynamic (>1000°C) phakathi nendiza ye-hypersonic.

2. High-Power Laser Systems

Amalensi okugxilisa ingqondo omshini wokusika/wokushisela we-laser yezimboni, agcina ukuchayeka isikhathi eside kumalaser aqhubekayo ekilasi le-kW.

Izinto zokwakheka kwe-Beam kumasistimu we-inertial confinement fusion (ICF), okuqinisekisa ukudluliswa kwe-laser yamandla aphezulu.

3. ISemiconductor & Precision Manufacturing

Ama-SiC mirror substrates we-EUV lithography optics, anokonakala kwe-thermal <1 nm ngaphansi kuka-10 kW/m² ukushisa okuguquguqukayo.

Amalensi kagesi wamathuluzi okuhlola i-e-beam, asebenzisa ukusebenza kwe-SiC yokulawula izinga lokushisa elisebenzayo.

4. Ukuhlolwa Kwezimboni & Amandla

Amalensi e-Endoscope wezithando zokushisa eziphezulu (1500°C ukusebenza okuqhubekayo).

Izingxenye ze-infrared optical zamathuluzi okugawulwa kwemithombo kawoyela, ukumelana nezingcindezi ze-downhole (>100 MPa) kanye nemidiya ebolayo.

Izinzuzo Eziyinhloko Zokuncintisana

1. Ubuholi Bokusebenza Okuphelele

Amalensi e-SiC adlula izinto ezibonwayo zendabuko (i-silica ehlanganisiwe, i-ZnSe) ekuzinzeni kwe-thermal/mechanical/chemical, kanye nezakhiwo zawo "ze-conductivity ephezulu + yokwandisa okuphansi" ezixazulula izinselele zokuwohloka kokushisa kuma-optics amakhulu.

2. Ukuphumelela Kwezindleko Zomjikelezo Wokuphila

Nakuba izindleko zokuqala ziphakeme, impilo yesevisi eyandisiwe yamalensi e-SiC (5-10× ingilazi evamile) kanye nokusebenza ngaphandle kokulungisa kunciphisa ngokuphawulekayo izindleko eziphelele zobunikazi (TCO).

3. Inkululeko Yokuklama

Izinqubo ze-Reaction-bonded noma ze-CVD zinika amandla i-SiC optical structures engasindi (i-honeycomb cores), ifinyelela ukuqina okungenakuqhathaniswa kwesisindo.

XKH Amakhono Esevisi

1. Izinsizakalo Zokukhiqiza Ngokwezifiso

Izixazululo ezisuka ekupheleni zisuka kumklamo wokubona (ukulingiswa kwe-Zemax/Code V) kuya ekulethweni kokugcina, okusekela izindawo ezikhululekile ze-aspheric/off-axis parabolic.

Izindwangu ezikhethekile: i-anti-reflection (AR), ikhabhoni efana nedayimane (LIDT>50 J/cm²), i-ITO eqhubayo, njll.

2. Izinhlelo Zokuqinisekisa Ikhwalithi

Imishini ye-Metrology ehlanganisa ama-interferometer e-4D namaphrofayili akhanyayo amhlophe aqinisekisa ukunemba kwe-λ/20 kwendawo.

I-QC yeleveli ebalulekile: Ukuhlaziywa kwe-XRD crystallographic orientation yayo yonke i-SiC engenalutho.

3. Amasevisi Angezwe Ivalue

Ukuhlaziywa kwe-Thermo-structural coupling (i-ANSYS simulation) yokuqagela ukusebenza.

Idizayini edidiyelwe yokukhweza amalensi e-SiC.

Isiphetho

Amalensi e-SiC achaza kabusha imikhawulo yokusebenza yesistimu yokubona enembayo ephezulu ngokusebenzisa izakhiwo zawo ezingenakuqhathaniswa. Amandla ethu ahlanganiswe aqonde ekuhlanganiseni kwezinto ze-SiC, ukunemba kwemishini, kanye nokuhlola kuletha izixazululo zenguquko ezibonakalayo ze-aerospace kanye nemikhakha yokukhiqiza ethuthukisiwe. Ngokuthuthuka ekukhuleni kwekristalu ye-SiC, intuthuko yesikhathi esizayo izogxila ekuvuleni okukhulu (>1m) kanye namajiyometri angaphezulu ayinkimbinkimbi (ama-arrays akhululekile).

Njengomkhiqizi ohamba phambili wezingxenye ze-optical ezithuthukisiwe, i-XKH igxile ezintweni ezisebenza kahle kakhulu ezihlanganisa isafire, i-silicon carbide (SiC), nama-silicon wafers, enikeza izixazululo zokuphela kusukela ekucutshungulweni kwempahla eluhlaza kuya ekuqedeni okunembayo. Ubuchwepheshe bethu buhlanganisa:

1. Ukwenziwa Ngokwezifiso: Ukwenziwa ngokunemba kwejometri eyinkimbinkimbi (i-aspheric, i-freeform) enokubekezelela ukuya ku-±0.001mm

2. I-Material Versanity: Icubungula isafire (amawindi e-UV-IR), i-SiC (i-high-power optics), ne-silicon (IR/micro-optics)

3. Amasevisi Angezwe Ivelu:

Ama-anti-reflective/ahlala isikhathi eside (UV-FIR)

Isiqiniseko sekhwalithi esisekelwa yi-Metrology (λ/20 flatness)

Ukuhlanganiswa kwegumbi elihlanzekile kwezinhlelo zokusebenza ezizwela ukungcola

Sisebenzela i-aerospace, i-semiconductor, nezimboni ze-laser, sihlanganisa ubuchwepheshe besayensi yezinto ezibonakalayo nokukhiqiza okuthuthukisiwe ukuze silethe izinto zokubona ezimelana nezimo ezibucayi kuyilapho sithuthukisa ukusebenza kokubona.