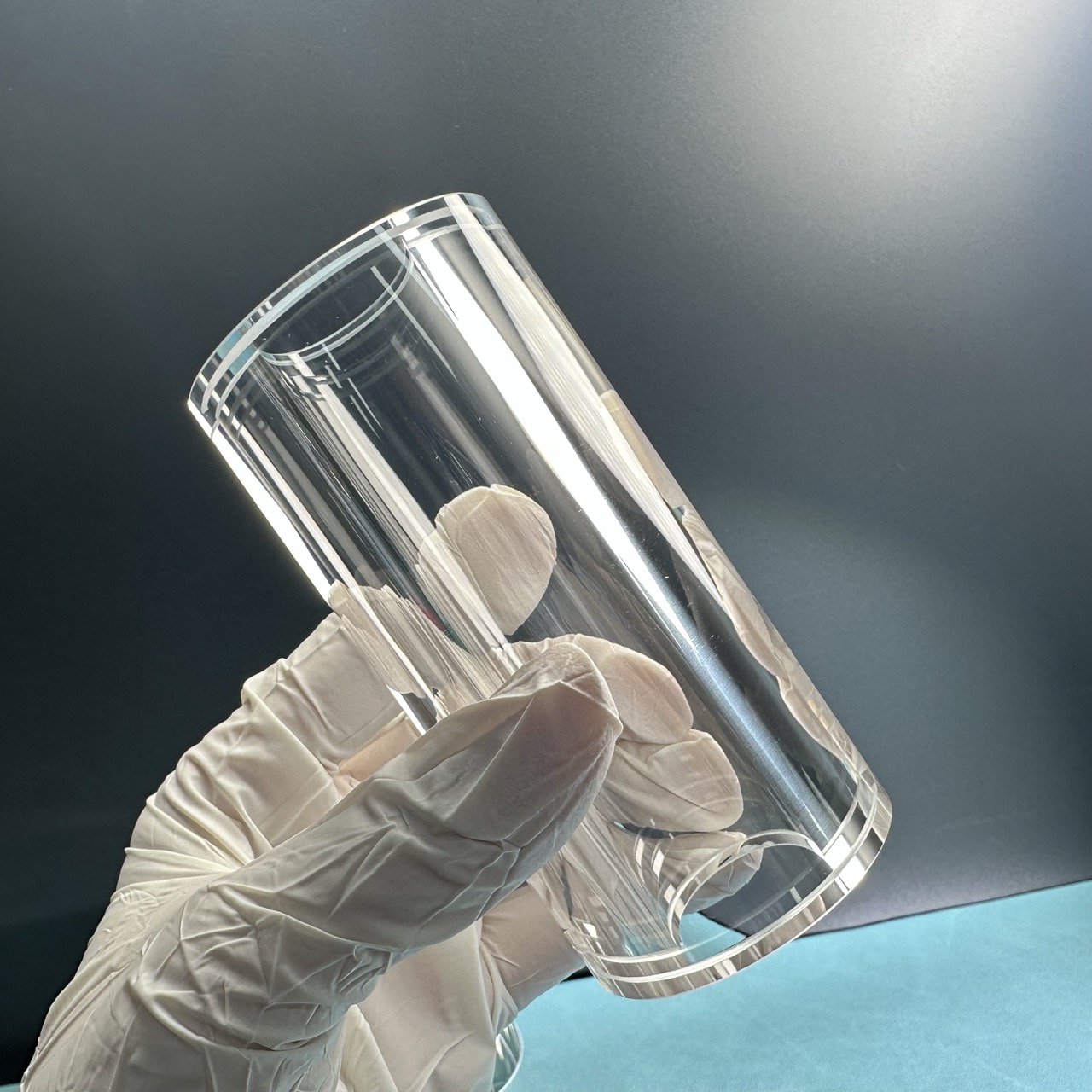

Amawafa e-Quartz aFused High-Purity for Semiconductor, Izicelo ze-Photonics Optical 2″4″6″8″12″

Umdwebo onemininingwane

Uhlolojikelele lwe-Quartz Glass

Amawafa e-quartz akha umgogodla wamadivayisi esimanje amaningi ashayela umhlaba wanamuhla wedijithali. Kusukela ekuzulazuleni ku-smartphone yakho kuya kumgogodla weziteshi eziyisisekelo ze-5G, i-quartz iletha buthule ukuzinza, ukuhlanzeka, nokunemba okudingekayo kuma-electronics asebenza kahle kakhulu nezithombe. Ukuthi isekela ukujikeleza okuvumelana nezimo, ukunika amandla izinzwa ze-MEMS, noma ukwakha isisekelo se-quantum computing, izici ezihlukile ze-quartz ziyenza ibaluleke kakhulu ezimbonini zonkana.

I-"Fused Silica" noma "Fused Quartz" okuyisigaba se-amorphous se-quartz (SiO2). Uma kuqhathaniswa nengilazi ye-borosilicate, i-silica ehlanganisiwe ayinazo izithasiselo; ngakho-ke ikhona ngendlela yayo emsulwa, i-SiO2. I-silica ehlanganisiwe inokudlulisa okuphezulu ku-infrared ne-ultraviolet spectrum uma iqhathaniswa nengilazi evamile. I-silica ehlanganisiwe ikhiqizwa ngokuncibilika futhi iphinde iqinise i-ultrapure SiO2. I-silica ehlanganisiwe yokwenziwa ngakolunye uhlangothi yenziwe ngama-precursors amakhemikhali anothe nge-silicon afana ne-SiCl4 efakwe igesi bese ifakwa i-oxid endaweni ye-H2 + O2. Uthuli lwe-SiO2 olwakhiwe kuleli cala luhlanganiswe ne-silica ku-substrate. Amabhulokhi e-silica ahlanganisiwe asikwa abe ama-wafer emva kwalokho ama-wafers agcina epholishiwe.

Izici Ezibalulekile Nezinzuzo Ze-Quartz Glass Wafer

-

I-Ultra-High Purity (≥99.99% SiO2)

Ilungele i-ultra-clean semiconductor nezinqubo ze-photonics lapho ukungcoliswa kwezinto kufanele kuncishiswe. -

I-Wide Thermal Operating Range

Igcina ubuqotho besakhiwo ukusuka emazingeni okushisa e-cryogenic kuze kufike ngaphezu kuka-1100°C ngaphandle kokungqubuzana noma ukuwohloka. -

I-UV evelele kanye ne-IR Transmission

Iletha ukucaca okuhle kakhulu kokubona okuvela ku-ultraviolet (DUV) ngokusebenzisa i-Near-infrared (NIR), isekela izinhlelo zokusebenza zokubona ezinembayo. -

I-Coefficient Yokunweba Okushisayo Ephansi

Ithuthukisa ukuzinza kwe-dimensional ngaphansi kokuguquguquka kwezinga lokushisa, yehlisa ingcindezi futhi ithuthukise ukwethembeka kwenqubo. -

I-Superior Chemical Resistance

Ingangeni kuma-asidi amaningi, ama-alkali, nezincibilikisi—okuyenza ifaneleke kahle ezindaweni ezinolaka lwamakhemikhali. -

I-Surface Qeda Ukuguquguquka

Itholakala ngeziqephu ezipholishiwe ezibushelelezi, eziwuhlangothi olulodwa noma ezikabili, ezihambisana nezithombe kanye nezidingo ze-MEMS.

Inqubo Yokukhiqiza Ye-Quartz Glass Wafer

Amawafa e-quartz ahlanganisiwe akhiqizwa ngochungechunge lwezinyathelo ezilawulwayo nezinembayo:

-

Ukukhethwa Kwezinto Ezingavuthiwe

Ukukhethwa kwe-quartz yemvelo emsulwa kakhulu noma imithombo yokwenziwa ye-SiO₂. -

Ukuncibilika kanye ne-Fusion

I-quartz incibilika ku-~2000°C ezithandweni zikagesi ngaphansi komkhathi olawulwayo ukuze kuqedwe ukufakwa namabhamuza. -

Block Forming

I-silica encibilikisiwe ipholiswa ibe amabhulokhi aqinile noma ama-ingots. -

I-Wafer Slicing

Idayimane elinembile noma amasaha ocingo asetshenziselwa ukusika ama-ingots abe yizikhala eziyisilutshwana. -

Ukupholisha nokupholisha

Zombili izindawo ezingaphezulu ziyisicaba futhi zipholishiwe ukuze zihlangabezane ncamashi nokucaciswa kokubona, ukujiya, kanye nokumahhadla. -

Ukuhlanza & Ukuhlola

Ama-wafers ahlanzwa kumagumbi ahlanzekile e-ISO Class 100/1000 futhi angaphansi kokuhlolwa okuqinile ukuze athole amaphutha nokuhambisana kobukhulu.

Izakhiwo ze-Quartz Glass wafer

| spec | iyunithi | 4" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|---|

| Ububanzi / usayizi (noma isikwele) | mm | 100 | 150 | 200 | 250 | 300 |

| Ukubekezelela (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Ubukhulu | mm | 0.10 noma ngaphezulu | 0.30 noma ngaphezulu | 0.40 noma ngaphezulu | 0.50 noma ngaphezulu | 0.50 noma ngaphezulu |

| Ifulethi eliyinkomba eliyinhloko | mm | 32.5 | 57.5 | I-semi-notch | I-semi-notch | I-semi-notch |

| I-LTV (5mm×5mm) | μm | <0.5 | <0.5 | <0.5 | <0.5 | <0.5 |

| I-TTV | μm | < 2 | <3 | <3 | <5 | <5 |

| Khothama | μm | ±20 | ±30 | ±40 | ±40 | ±40 |

| I-Wap | μm | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 50 | ≤ 50 |

| I-PLTV (5mm×5mm) <0.4μm | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| I-Edge Rounding | mm | Ihambisana ne-SEMI M1.2 Standard / bhekisa ku-IEC62276 | ||||

| Uhlobo Lobuso | Uhlangothi Olulodwa Olupholishiwe / Izinhlangothi Ezikabili Ziphucuziwe | |||||

| Uhlangothi olupholishiwe u-Ra | nm | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Imibandela Yokubheka Emuva | μm | jikelele 0.2-0.7 noma ngokwezifiso | ||||

I-Quartz vs. Okunye Okubalulekile Okungafihli

| Impahla | I-Quartz Glass | Ingilazi ye-Borosilicate | Isafire | Ingilazi ejwayelekile |

|---|---|---|---|---|

| I-Max Operating Temp | ~ 1100°C | ~500°C | ~2000°C | ~200°C |

| Ukudluliswa kwe-UV | Kuhle kakhulu (JGS1) | Impofu | Kuhle | Impofu kakhulu |

| Ukumelana Kwamakhemikhali | Kuhle kakhulu | Kuphakathi | Kuhle kakhulu | Impofu |

| Ubumsulwa | Iphakeme kakhulu | Kuphansi ukuya kumaphakathi | Phezulu | Phansi |

| Ukunwetshwa kwe-Thermal | Iphansi kakhulu | Kuphakathi | Phansi | Phezulu |

| Izindleko | Kuphakathi kuya phezulu | Phansi | Phezulu | Iphansi kakhulu |

I-FAQ ye-Quartz Glass Wafer

Q1: Uyini umehluko phakathi kwe-quartz ehlanganisiwe ne-silica ehlanganisiwe?

Nakuba zombili kuyizinhlobo ze-amorphous ze-SiO₂, i-quartz ehlanganisiwe ngokuvamile isuka emithonjeni ye-quartz yemvelo, kuyilapho i-silica ehlanganisiwe ikhiqizwa ngokwenziwa. Ngokusebenza, banikeza ukusebenza okufanayo, kodwa i-silica ehlanganisiwe ingase ibe nokuhlanzeka okuthe xaxa kanye ne-homogeneity.

I-Q2: Ingabe ama-wafers e-quartz ahlanganisiwe angasetshenziswa ezindaweni ezine-vacuum ephezulu?

Yebo. Ngenxa yezakhiwo eziphansi zokukhipha umoya kanye nokumelana nokushisa okuphezulu, amawafa e-quartz ahlanganisiwe angcono kakhulu kumasistimu we-vacuum kanye nezicelo ze-aerospace.

Q3: Ingabe lawa mawafa alungele izinhlelo zokusebenza ze-laser ejulile ye-UV?

Nakanjani. I-quartz ehlanganisiwe inokudlulisa okuphezulu okufika ku-~185 nm, okuyenza ifaneleke ku-DUV optics, imaski ye-lithography, namasistimu e-excimer laser.

Q4: Ingabe uyakweseka ukwenziwa kwe-wafer yangokwezifiso?

Yebo. Sinikeza ukwenza ngokwezifiso okugcwele okuhlanganisa ububanzi, ukujiya, ikhwalithi yendawo ephezulu, amaflethi/amanotshi, kanye nephethini ye-laser, ngokusekelwe kuzidingo zakho zohlelo lokusebenza.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.