Isisetshenziswa Sokucwebezela Esisohlangothini Olulodwa Esinemba Kakhulu

Ividiyo Yezisetshenziswa Zokupholisha Ezihlangothini Olulodwa

Ukwethulwa Kwezisetshenziswa Zokupholisha Ezihlangothini Olulodwa

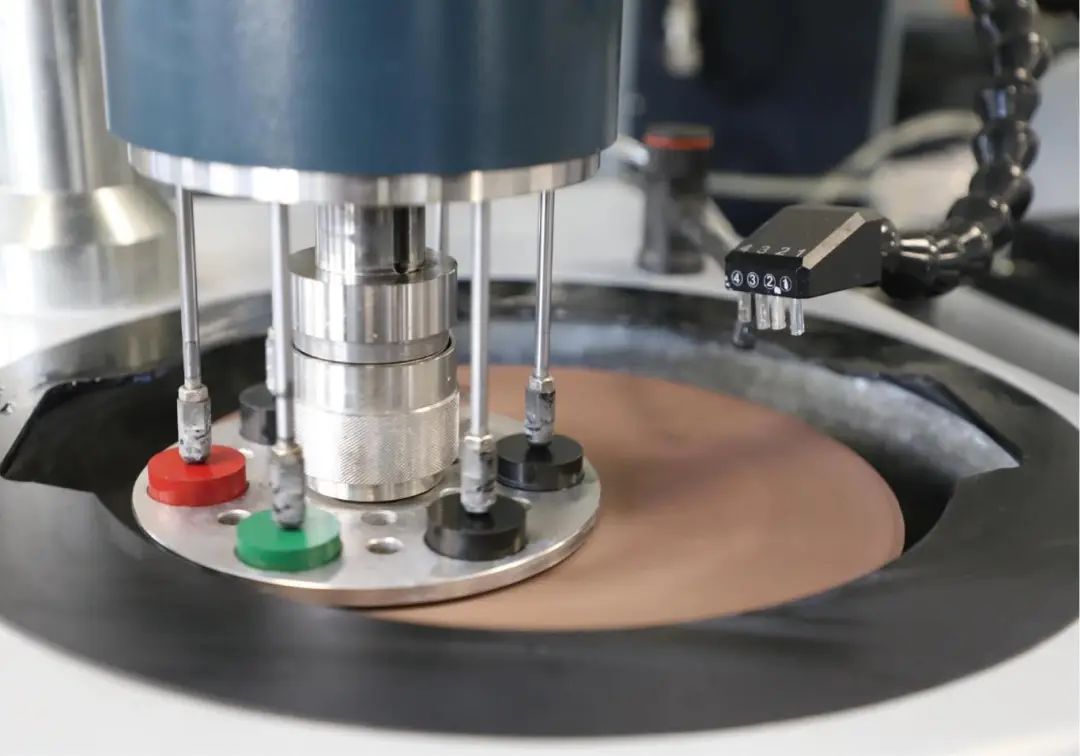

Umshini wokupholisha ohlangothini olulodwa ucezu olukhethekile kakhulu lwemishini eyenzelwe ukuqeda ngokunemba kwezinto eziqinile neziphukayo. Ngokuthuthuka okusheshayo kwemboni ye-semiconductor, i-optoelectronics, i-optical components, kanye nezicelo zezinto ezibonakalayo ezithuthukisiwe, isidingo semishini yokupholisha enembayo ephezulu kanye nesebenza kahle kakhulu sesiya ngokuya siphuthuma. Umshini wokupholisha ohlangothini olulodwa usebenzisa ukunyakaza okuhlobene phakathi kwediski yokupholisha namapuleti e-ceramic ukuze ukhiqize ingcindezi efanayo endaweni yokusebenza, okuvumela ukuhleleka okuhle kakhulu nokuqedwa okufana nesibuko.

Ngokungafani nemishini yokupholisha ezinhlangothini ezimbili, umshini wokupholisha ohlangothini olulodwa unikeza ukuguquguquka okukhulu ekuphatheni osayizi abahlukene nobukhulu bamawafa noma ama-substrates. Lokhu kuyenza ifaneleke ikakhulukazi ukucubungula izinto ezifana nama-silicon wafers, i-silicon carbide, isafire, i-gallium arsenide, ama-germanium flakes, i-lithium niobate, i-lithium tantalate, nengilazi yokubona. Ukunemba okufinyelelwe ngalolu hlobo lwemishini kuqinisekisa ukuthi izingxenye ezicutshunguliwe zihlangabezana nezidingo eziqinile zama-microelectronics, ama-substrates e-LED, nama-optics asebenza kahle kakhulu.

Inzuzo Yezisetshenziswa Zokupholisha Ezihlangothini Olulodwa

Ifilosofi yokuklama yomshini wokupholisha ohlangothini olulodwa igcizelela ukuzinza, ukunemba, nokusebenza kahle. Umzimba oyinhloko womshini ngokuvamile wenziwe ngensimbi ekhonjiwe kanye ne-forged, ehlinzeka ngokuzinza okuqinile komshini futhi inciphise ukudlidliza ngesikhathi sokusebenza. Izingxenye zamazwe ngamazwe ezisezingeni eliphezulu zemukelwe ezinhlelweni ezibalulekile ezifana nedrayivu yokuzungezisa, ukudluliswa kwamandla, kanye nesistimu yokulawula, ukuqinisekisa ukusebenza okuthembekile nempilo ende yesevisi.

Enye inzuzo eyinhloko ilele kusixhumi esibonakalayo sokusebenza komuntu. Imishini yesimanje yokupholisha ohlangothini olulodwa ifakwe amaphaneli okulawula ahlakaniphile, avumela opharetha ukuthi balungise ngokushesha imingcele yenqubo efana nesivinini sokupholisha, ingcindezi, nezinga lokuzungezisa. Lokhu kuvumela izimo zokucubungula ezikwazi ukukhiqizwa kabusha, okubalulekile ezimbonini lapho ukuhambisana kubaluleke kakhulu.

Ngokombono wenqubo eguquguqukayo, okokusebenza kungakwazi ukuthwala izinhlobonhlobo zosayizi bemishini, ngokuvamile ukusuka ku-50mm ukuya ku-200mm noma ngaphezulu, kuye ngemodeli. Izinga lokuzungezisa kwediski yokupholisha ngokuvamile liwela phakathi kuka-50 kuya ku-80 rpm, kuyilapho isilinganiso samandla sihluka ukusuka ku-11kW ukuya phezu kuka-45kW. Ngohlu olubanzi kangaka lokucushwa, abasebenzisi bangakhetha imodeli efanelana kangcono nezidingo zabo zokukhiqiza, noma ngabe amalabhorethri esilinganiso socwaningo noma ukukhiqizwa kwezimboni ezinkulu.

Ngaphezu kwalokho, amamodeli athuthukile afaka amakhanda amaningi okupholisha, avunyelaniswe amasistimu okulawula ama-servo electronic. Lokhu kuqinisekisa ukuthi wonke amakhanda okupholisha agcina isivinini esingaguquki ngesikhathi sokusebenza, ngaleyo ndlela kuthuthukisa kokubili izinga lokucubungula kanye nesivuno. Ngaphezu kwalokho, izinhlelo zokupholisa nokulawula izinga lokushisa ezihlanganiswe emshinini ziqinisekisa ukuzinza kokushisa, okuyisici esibalulekile lapho usebenza nezinto ezizwela ukushisa.

Umshini wokupholisha ohlangothini olulodwa umele ucezu olubalulekile lwemishini yokukhiqiza enkathini yesimanje yobuchwepheshe obuphezulu. Inhlanganisela yayo yomklamo oqinile wemishini, ukulawula okukhaliphile, ukuhambisana kwezinto eziningi, nokusebenza okuphakeme kokuqeda ingaphezulu kuyenza ibe ithuluzi elibalulekile ezinkampanini nezikhungo zocwaningo ezidinga ukulungiswa okuphezulu kokunemba kwezinto eziphambili.

Izici Zomkhiqizo Zesisetshenziswa Sokupholisha Sihlangothi Olulodwa

-

Ukuzinza okuphezulu: Umzimba womshini uyaphonswa futhi uyakhiwe ukuze kuqinisekiswe ukuqina kwesakhiwo kanye nokuzinza okuhle kakhulu kokusebenza.

-

Izingxenye Zokunemba: Ama-bearings asezingeni lomhlaba wonke, amamotho, namayunithi okulawula ama-elekthronikhi aqinisekisa impilo ende yesevisi nokusebenza okuthembekile.

-

Amamodeli Aguquguqukayo: Itholakala ngochungechunge oluningi (305, 36D, 50D, 59D, kanye ne-X62 S59D-S) ukuze kuhlangatshezwane nezidingo ezihlukahlukene zokukhiqiza.

-

I-Humanized Interface: Iphaneli yokusebenza okulula ukuyisebenzisa enezilungiselelo zedijithali zamapharamitha wokupholisha, evumela ukulungiswa kweresiphi esheshayo.

-

Ukupholisa Okusebenzayo: Izinhlelo ezihlanganisiwe zokupholisa amanzi ezinezinzwa zokushisa ezinembayo ukuze kugcinwe izimo zokupholisha ezizinzile.

-

Ukuvumelanisa Okuningi Kwekhanda: Ukulawulwa kwe-elekthronikhi kwe-Servo kuqinisekisa isivinini esivumelanisiwe samakhanda amaningi okupholisha ukuze uthole imiphumela engaguquki.

Ukucaciswa Kwezobuchwepheshe Kwezisetshenziswa Zokupholisha Ezihlangothini Olulodwa

| Isigaba | Into | 305 Uchungechunge | 36D Series | 50D Series | 59D Series |

|---|---|---|---|---|---|

| Icwecwe lokupholisha | Ububanzi | 820 mm | 914 mm | 1282 mm | 1504 mm |

| Izingcwecwe zeCeramic | Ububanzi | 305 mm | 360 mm | 485 mm | 576 mm |

| I-Optimum Machining | Usayizi Womsebenzi | 50-100 mm | 50-150 mm | 150-200 mm | 200 mm |

| Amandla | I-Main Motor | 11kw | 11kw | 18.5 kW | 30 kW |

| Isilinganiso Sokuzungezisa | Icwecwe lokupholisha | 80 rpm | 65 rpm | 65 rpm | 50 rpm |

| Ubukhulu (L×W×H) | - | 1920×1125×1680 mm | 1360×1330×2799 mm | 2334×1780×2759 mm | 1900×1900×2700 mm |

| Isisindo Somshini | - | 2000 kg | 3500 kg | 7500 kg | 11826 kg |

| Into | Ipharamitha | Okubalulekile |

|---|---|---|

| Ububanzi be-Main Polishing Disc | Φ1504 × 40 mm | I-SUS410 |

| Ububanzi beDiski yokupholisha (Ikhanda) | Φ576 × 20 mm | I-SUS316 |

| Isivinini esikhulu se-Main Polishing Disc | 60 rpm | - |

| Isivinini esikhulu sekhanda eliphonsa phezulu | 60 rpm | - |

| Inombolo Yamakhanda Apholishayo | 4 | - |

| Ubukhulu (L×W×H) | 2350 × 2250 × 3050 mm | - |

| Isisindo Sezisetshenziswa | 12 t | - |

| I-Max Pressure Range | 50-500 ± kg | - |

| Amandla Aphelele Omshini Wonke | 45kw | - |

| Ilayisha Amandla (ikhanda ngalinye) | 8 h/φ 150 mm (6”) noma 5 h/φ 200 mm (8”) | - |

Uhla Lokusebenza Lwezisetshenziswa Zokupholisha Ezihlangothini Olulodwa

Umshini uklanyelweukupholisha ohlangothini olulodwayezinhlobonhlobo zezinto eziqinile neziqinile, okuhlanganisa:

-

Ama-silicon wafers wamadivayisi we-semiconductor

-

I-silicon carbide yama-electronics amandla kanye nama-substrates e-LED

-

Ama-sapphire wafers we-optoelectronics namakristalu wewashi

-

I-Gallium arsenide yezinhlelo zokusebenza ze-elekthronikhi ze-high-frequency

-

Ama-flakes e-Germannium we-infrared optics

-

I-Lithium niobate ne-lithium tantalate yezingxenye ze-piezoelectric

-

I-Glass substrates ye-optics enembayo namadivayisi okuxhumana

Imibuzo Evame Ukubuzwa (FAQ) Yezisetshenziswa Zokupholisha Ezihlangothini Olulodwa

Q1: Yiziphi izinto ezingenziwa inqubo yomshini wokupholisha ohlangothini olulodwa?

Umshini ulungele ama-silicon wafers, isafire, i-silicon carbide, i-gallium arsenide, ingilazi, nezinye izinto eziphukayo.(Amagama angukhiye: umshini wokupholisha, izinto eziphukayo)

Q2: Yimaphi amasayizi wediski wokupholisha atholakalayo?

Ngokuya ngochungechunge, ama-disc wokupholisha asukela ku-820 mm kuya ku-1504 mm ububanzi.(Amagama angukhiye: idiski yokupholisha, usayizi womshini)

I-Q3: Iyini izinga lokujikeleza kwediski yokupholisha?

Izinga lokujikeleza liyahlukahluka kusuka ku-50 kuye ku-80 rpm, kuye ngemodeli.(Amagama angukhiye: izinga lokuphenduka, isivinini sokupholisha)

I-Q4: Isistimu yokulawula ithuthukisa kanjani ikhwalithi yokupholisha?

Umshini usebenzisa isilawuli se-electronic se-servo sokujikeleza kwekhanda okuvumelanisiwe, ukuqinisekisa ingcindezi efanayo kanye nemiphumela ezinzile.(Amagama angukhiye: uhlelo lokulawula, ikhanda lokupholisha)

Q5: Siyini isisindo kanye nezinyathelo zomshini?

Izisindo zomshini zisuka kumathani ama-2 kuye kwayi-12, ezinezinyathelo eziphakathi kuka-1360×1330×2799 mm no-2350×2250×3050 mm.(Amagama angukhiye: isisindo somshini, ubukhulu)

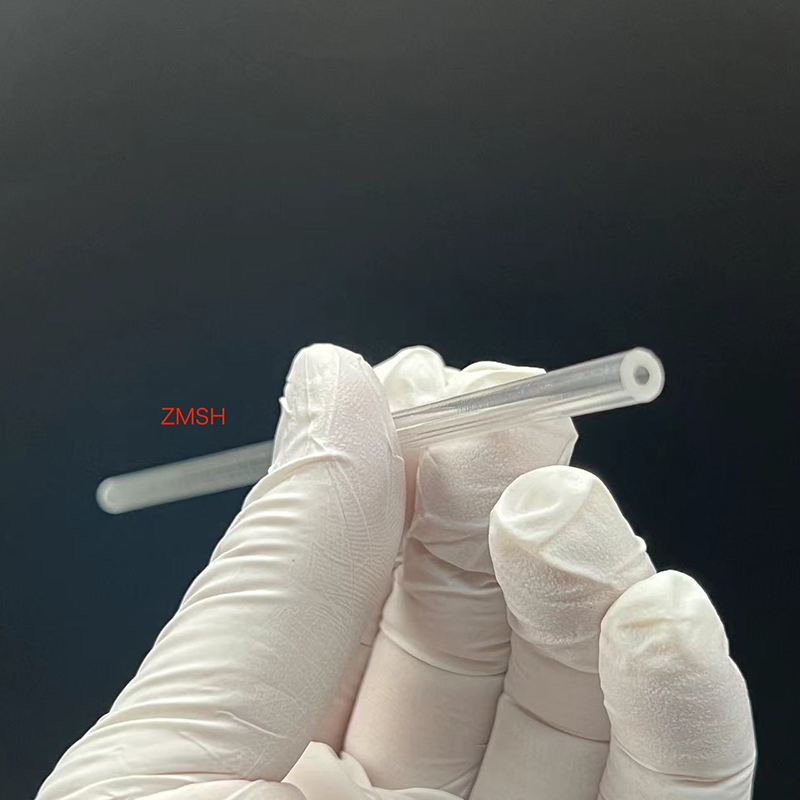

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.