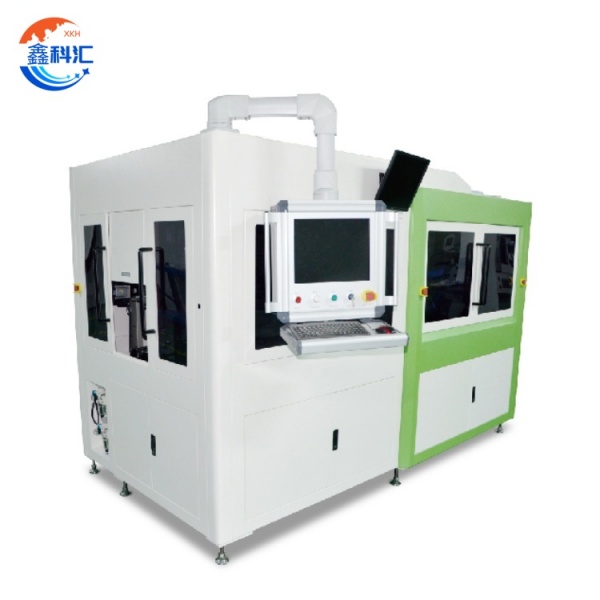

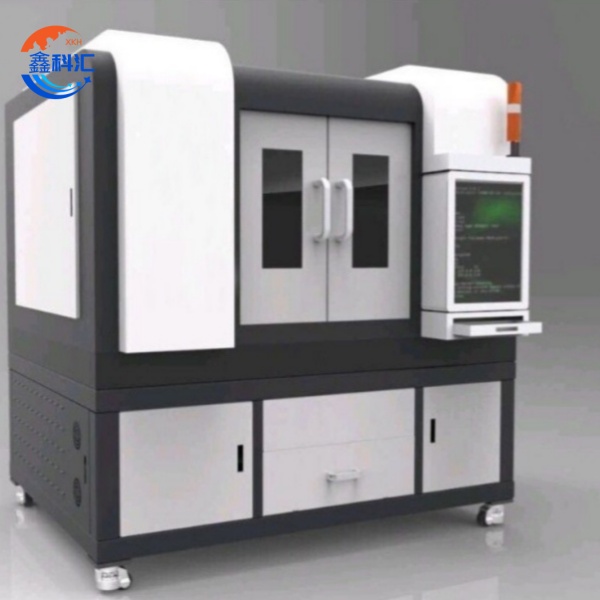

Umshini wokumba we-laser wokunemba okuphezulu we-sapphire ceramic material gem ephethe umbhobho wokumba

Isingeniso Somkhiqizo

Izinto ezisetshenziswayo: Ifanele insimbi yemvelo, insimbi ye-polycrystalline, irubi, isafire, ithusi, i-ceramics, i-rhenium, insimbi engagqwali, i-carbon steel, i-alloy steel nezinye izinto eziqinile, izinto ezimelana nokushisa okuphezulu kobumo obuhlukene, ububanzi, ukujula kanye nokubhola kwe-taper.

Izimo zokusebenza

1. Ilungele ukusebenza ngaphansi kwezinga lokushisa le-ambient elingu-18℃-28℃ kanye nomswakama ohlobene no-30% -60%.

2. Ifanele ukunikezwa kwamandla kwezigaba ezimbili /220V/50HZ/10A.

3. Lungiselela amapulaki ahlangabezana nezidingo zamazinga afanelekile aseShayina. Uma lingekho ipulaki elinjalo, kufanele kuhlinzekwe i-adaptha efanele.

4. Isetshenziswa kakhulu ekudwebeni kwedayimane ngocingo lwedayimane, intambo ehamba kancane, imbobo ye-muffler, imbobo yenaliti, ukuthwala amagugu, umlomo wombhobho nezinye izimboni zokubhoboza.

Imingcele yezobuchwepheshe

| Igama | Idatha | Umsebenzi |

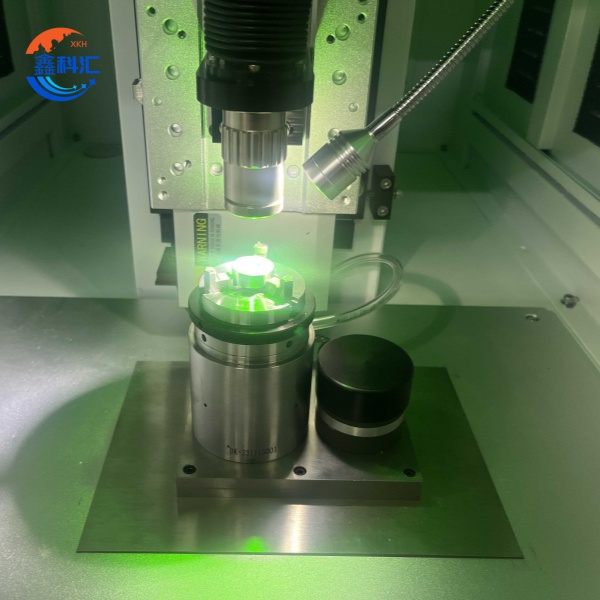

| I-Optical maser wavelength | 354.7nm noma 355nm | Inquma ukusatshalaliswa kwamandla kanye nomthamo wokungena we-laser beam, futhi ithinta izinga lokumuncwa kwezinto kanye nomthelela wokucubungula. |

| Amandla okukhiphayo amaphakathi | 10.0 / 12.0/15.0 w@40khz | Kuthinta ukusebenza kahle kokucubungula kanye nesivinini sokubhoboza, amandla aphezulu, isivinini sokucubungula siyashesha. |

| Ububanzi be-Pulse | Ngaphansi kuka-20ns@40KHz | Ububanzi be-pulse obufushane bunciphisa indawo ethintekile ekushiseni, buthuthukisa ukunemba komshini, futhi bugwema ukulimala okushisayo kwento. |

| Izinga lokuphindaphinda kwe-Pulse | 10 ~ 200KHz | Nquma imvamisa yokudlulisela nokusebenza kahle kokubhoboza kwe-laser beam, ukuphakama kwefrikhwensi, isivinini sokubhoboza sishesha. |

| ikhwalithi ye-optical beam | M²<1.2 | Imishayo yekhwalithi ephezulu iqinisekisa ukunemba kokumba kanye nekhwalithi yomphetho, inciphisa ukulahleka kwamandla. |

| Ububanzi bebala | 0.8±0.1mm | Thola ukuvuleka okuncane nokunemba kwemishini, indawo encane, imbobo encane, iphezulu ukunemba. |

| i-angle ye-beam-divergence | Ngaphezulu kuka-90% | Ikhono lokugxila nokujula kokubhoboza kwe-laser beam kuyathinteka. Uma i-engeli yokuhluka incane, ikhono lokugxila liqina. |

| I-beam ellipality | Ngaphansi kuka-3% RMS | Okuncane kwe-ellipticity, ukusondela kokuma kwembobo kuyindilinga, kuphakama ukunemba kwemishini. |

Umthamo wokucubungula

Imishini yokumba i-laser enembayo ephezulu inamandla okucubungula anamandla futhi ingamba izimbobo ukusuka kuma-microns ambalwa ukuya kumamilimitha ambalwa ububanzi, futhi ukwakheka, usayizi, indawo kanye ne-Engeli yezimbobo kungalawulwa ngokunembile. Ngasikhathi sinye, imishini isekela ukumba okuyindilinga okungu-360-degree, okungahlangabezana nezidingo zokubhoboza ubujamo obuhlukahlukene obuyinkimbinkimbi nezakhiwo. Ngaphezu kwalokho, umshini wokubhoboza we-laser onembayo ophezulu nawo unekhwalithi ephezulu kakhulu yonqenqema nokuqedwa kwangaphezulu, izimbobo ezicutshunguliwe azikho i-burr, azincibiliki onqenqemeni, futhi ingaphezulu lembobo libushelelezi futhi liyisicaba.

Ukusetshenziswa komshini wokubhoboza we-laser wokunemba okuphezulu:

1. Imboni yezogesi:

Ibhodi lesekethe eliphrintiwe (PCB) : lisetshenziselwa ukucubungula ama-microhole ukuhlangabezana nezidingo zokuxhumanisa okukhulu.

Ukupakishwa kweSemiconductor: Punch izimbobo kumawafa nezinto zokupakisha ukuze uthuthukise ukuminyana kwephakheji nokusebenza.

2. Umkhathi:

Izimbobo zokupholisa ze-blade yenjini: Izimbobo zokupholisa ezincane zenziwa ngomshini ngama-superalloy blade ukuze kuthuthukiswe ukusebenza kahle kwenjini.

Ukucutshungulwa kwe-Composite: Ukuze kubhojwe ngokunemba okuphezulu kwezinhlanganisela ze-carbon fiber ukuze kuqinisekiswe amandla esakhiwo.

3. Izinto Zokwelashwa:

Amathuluzi okuhlinza ahlasela kancane: Ukwenza ama-microholes kumathuluzi okuhlinza ukuze kuthuthukiswe ukunemba nokuphepha.

Uhlelo lokulethwa kwezidakamizwa: Gubha izimbobo kudivayisi yokulethwa kwezidakamizwa ukuze ulawule izinga lokukhululwa kwezidakamizwa.

4. Ukukhiqiza Izimoto:

Isistimu yomjovo kaphethiloli: Ukwenza izimbobo ezincane ku-nozzle yomjovo kaphethiloli ukuze kuthuthukiswe umphumela we-atomization kaphethiloli.

Ukukhiqizwa kwezinzwa: Ukubhoboza izimbobo kusici senzwa ukuthuthukisa ukuzwela kwayo nesivinini sokuphendula.

5. Imishini yokubona:

Isixhumi se-fiber optical: Ukwenza ama-microholes kusixhumi se-fiber optical ukuze kuqinisekiswe ikhwalithi yokudluliswa kwesignali.

Isihlungi se-Optical: Punch izimbobo kusihlungi se-optical ukuze uthole ukukhetha okukhethekile kobude beza.

6. Imishini enembayo:

Isikhunta esinembayo: Ukwenza ama-microholes esibunjeni ukuthuthukisa ukusebenza nempilo yesevisi yesikhunta.

Izingxenye ezincane: Punch izimbobo ezingxenyeni ezincane ukuze uhlangabezane nezidingo zokuhlanganisa okunembe kakhulu.

I-XKH ihlinzeka ngohlu olugcwele lwezinsizakalo zemishini yokumba ye-laser enembayo ephezulu, okuhlanganisa ukuthengiswa kwemishini, ukwesekwa kobuchwepheshe, izixazululo ezenziwe ngokwezifiso, ukufakwa kanye nokugunyazwa, ukuqeqeshwa kokusebenza kanye nokugcinwa kokunakekelwa ngemva kokuthengisa, njll., ukuze kuqinisekiswe ukuthi amakhasimende ekusebenziseni ukusekelwa kochwepheshe, okuphumelelayo nokuphelele.

Umdwebo onemininingwane