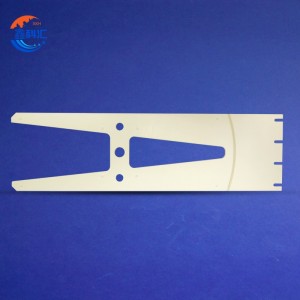

I-High-Performance Alumina Ceramic End Effector (Fork Arm) yeSemiconductor kanye ne-Cleanroom Automation

Umdwebo onemininingwane

Isingeniso Somkhiqizo

I-Alumina Ceramic End Effector, ebizwa nangokuthi ingalo yemfoloko ye-ceramic noma isandla se-robotic ceramic, iyingxenye yokubamba enembayo ephezulu eklanyelwe amasistimu azenzakalelayo ku-semiconductor, photovoltaic, panel display, kanye nezindawo zaselabhorethri ezihlanzeke kakhulu. Yakhelwe ukuhlinzeka ngokuqina okushisayo okukhethekile, ukuqina kwemishini, kanye nokumelana namakhemikhali, enikeza ukuthuthwa okuhlanzekile, okuthembekile, nokuphephile kwezinto ezibucayi njengama-silicon wafers, ama-substrates engilazi, kanye ne-electronic micro-components.

Njengohlobo lwe-robotic end effector, le ngxenye ye-ceramic iyisixhumi esibonakalayo sokugcina phakathi kwesistimu ye-automation kanye nomsebenzi. Idlala indima ebalulekile ekudluliselweni okunembayo, ukuqondanisa, ukulayisha/ukukhipha, kanye nokubeka imisebenzi emagumbini ahlanzekile nasezindaweni ze-vacuum.

Ukubuka konke Kwezinto Ezibalulekile – I-Alumina Ceramic (Al₂O₃)

I-Alumina Ceramic iyimpahla ye-ceramic yobuchwepheshe ezinzile futhi engasebenzi amakhemikhali eyaziwa ngezici zayo ezinhle kakhulu zokumaka kanye nezikagesi. I-high-purity (≥ 99.5%) i-alumina esetshenziswa kulaba benzi bokugcina iqinisekisa:

-

Ukuqina okuphezulu (Mohs 9): Okwesibili kuphela kwedayimane, i-alumina inikeza ukumelana nokugqoka okwedlulele.

-

Amandla okushisa aphezulu: Igcina ubuqotho besakhiwo ngaphezu kuka-1600°C.

-

Ukungabi namandla kwamakhemikhali: Ingazweli kuma-asidi, ama-alkali, izincibilikisi, nezindawo zokunamathisela i-plasma.

-

Ukufakwa kukagesi: Ngamandla aphezulu e-dielectric kanye nokulahlekelwa okuphansi kwe-dielectric.

-

Ukwandiswa kwe-thermal ephansi: Iqinisekisa ukuzinza kwe-dimensional ezindaweni zamabhayisikili ashisayo.

-

Ukukhiqizwa kwezinhlayiyana eziphansi: Ibalulekile ekusebenzisaneni kwe-cleanroom (Ikilasi le-10 ukuya ku-Class 1000).

Lezi zici zenza i-alumina ceramic ilungele ukusebenza okubalulekile kumishini ezimbonini ezizwela ukungcola.

Izinhlelo zokusebenza ezisebenzayo

I-alumina ceramic end effector yamukelwa kabanzi ezinqubweni zezimboni zobuchwepheshe obuphezulu, ikakhulukazi lapho izinto zensimbi noma zepulasitiki zendabuko zihluleka ngenxa yokwanda okushisayo, ukungcoliswa, noma izinkinga zokugqwala. Izinkambu zohlelo lokusebenza eziyinhloko zifaka:

- Ukudluliswa kwe-wafer ye-semiconductor

- I-Photolithography yokulayisha nokukhipha amasistimu

- Ukuphathwa kwe-substrate yengilazi emigqeni ye-OLED ne-LCD

- Ukudluliselwa kwe-crystalline silicon wafer ekukhiqizeni amaseli elanga

- Ukuhlola okuzenzakalelayo kwe-optical noma i-microelectronic

- Isampula yokuthutha kumalebhu okuhlaziya noma e-biomedical

- Vacuum imvelo ezishintshayo izinhlelo

Ikhono layo lokusebenza ngaphandle kokwethula izinhlayiya noma ukushaja okumile kuyenza ibaluleke kakhulu ekusebenzeni kwerobhothi okunembayo ku-cleanroom automation.

Izici Zokuklama nokwenza ngokwezifiso

Isiphetho ngasinye se-ceramic siklanyelwe ukulingana nengalo ethile yerobhothi noma isistimu yokubamba i-wafer. Sisekela ukwenza ngokwezifiso okugcwele okusekelwe kokuthi:

-

Ukuhambisana kosayizi we-wafer: 2", 4", 6", 8", 12" nokunye

-

Slot geometry kanye nesikhala: Ivumela ukubamba konqenqema, ukwesekwa kohlangothi lwangemuva, noma amadizayini angama-wafer anophawu

-

Izimbobo zokudonsa: Izimbobo ze-vacuum ezihlanganisiwe noma iziteshi zokuphatha okungeyena othintana naye

-

Ukulungiselelwa kokukhweza: Izimbobo, izintambo, izikhala eziklanyelwe ithuluzi lokugcina lerobhothi lakho

-

Ukwelashwa kwendawo: Ipholishiwe, igqitshwe, noma isiphetho esiphansi (Ra <0.2 µm etholakalayo)

-

Ukuvikelwa komphetho: Amakhona ayindilinga noma ama-chamfering ukugwema ukulimala kwe-wafer

Ngokusebenzisa imidwebo ye-CAD noma amamodeli e-3D anikezwa amakhasimende, onjiniyela bethu bangakwazi ukuthuthukisa ingalo yemfoloko ngayinye ngesisindo, amandla, kanye nokuhlanzeka.

Izinzuzo Ceramic End Effectors

| Isici | Zuza |

|---|---|

| High Mechanical Rigidity | Igcina ukunemba kwe-dimensional ngaphansi kwamandla okulayisha amarobhothi |

| Ukusebenza okuhle kakhulu kwe-Thermal | Isebenza ngendlela enokwethenjelwa endaweni enezinga eliphezulu lokushisa noma ku-plasma |

| I-Zero Metal Contamination | Ayikho ingozi yokungcoliswa kwe-ion ekucubunguleni okubalulekile kwe-semiconductor |

| I-Low Friction Surface | Yehlisa ingozi yokuklwebheka kuma-wafer noma ama-glass substrates |

| I-Anti-Static ne-Non-Magnetic | Ayihehi uthuli noma ithinte izingxenye ezizwela kazibuthe |

| Impilo Emide Yenkonzo | Ukumelana nokugqoka okuphezulu emijikelezweni ephindaphindwayo yesivinini esikhulu ezishintshayo |

| Ukuhambisana Okuhlanzekile Kakhulu | Ifanele amagumbi okuhlanza e-ISO 14644 (Ikilasi le-100 nangaphansi) |

Uma kuqhathaniswa nezingalo zepulasitiki noma ze-aluminium, i-alumina ceramic inikeza ukuqina okuthuthukisiwe kwamakhemikhali nokomzimba kanye nezidingo zokunakekelwa okuncane.

| Impahla | Ingalo Yensimbi | Ingalo yePlastiki | I-Alumina Ceramic Arm |

|---|---|---|---|

| Ukuqina | Kuphakathi | Phansi | Phezulu kakhulu (Mohs 9) |

| Ukuzinza Okushisayo | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Ukumelana Kwamakhemikhali | Kuphakathi | Impofu | Kuhle kakhulu |

| Ukufaneleka Kwegumbi Lokuhlanza | Maphakathi | Phansi | Phezulu kakhulu |

| Gqoka Ukumelana | Maphakathi | Phansi | Okuvelele |

| Amandla e-Dielectric | Phansi | Maphakathi | Phezulu |

| Ukunemba Kwemishini Yangokwezifiso | Inomkhawulo | Kuphakathi | Phezulu (±0.01mm kungenzeka) |

Imininingwane Yezobuchwepheshe

| Ipharamitha | Inani |

|---|---|

| Okubalulekile | I-High-purity Alumina (≥ 99.5%) |

| Izinga Lokushisa Lokusebenza | Kufika ku-1600°C |

| Ukuqina Kobuso | I-Ra ≤ 0.2 µm (uma uthanda) |

| Amasayizi we-wafer ahambisanayo | 2" kuya ku-12" noma ngokwezifiso |

| Ukubekezelelana kwe-Flatness | ±0.01 mm (kuncike kuhlelo lokusebenza) |

| I-Vacuum Suction Support | Iziteshi ozikhethela zona |

| Izinketho zokukhweza | I-Bolt-through, i-flange, izimbobo ezifakiwe |

Imibuzo Evame Ukubuzwa (FAQ)

Q1: Ingabe umphumela wokugcina ungahlanganiswa ezinhlelweni ezikhona zamarobhothi?

A1:Yebo. Sisekela ukwenza ngokwezifiso okusekelwe kusixhumi esibonakalayo serobhothi. Ungasithumela umdwebo we-CAD noma ubukhulu be-flange ukuze uzivumelanise nezimo ngokuqondile.

Q2: Ingabe izingalo ze-ceramic zizophuka kalula ngesikhathi sokusetshenziswa?

A2:Nakuba i-ceramic ibuthakathaka ngokwemvelo, imiklamo yethu isebenzisa i-geometry ethuthukisiwe ukunciphisa ukugxila kwengcindezi. Ngaphansi kwezimo ezifanele zokusetshenziswa, zinikeza impilo yesevisi ende kakhulu kunensimbi noma ipulasitiki.

Q3: Kungenzeka yini ukusebenzisa lokhu ku-vacuum ephezulu kakhulu noma emakamelweni e-plasma etching?

A3:Yebo. I-alumina ceramic ayikhiphi ngaphandle, izinzile ngokushisa, futhi imelana nokugqwala—ifaneleka ngokuphelele indawo enevacuum ephezulu, igesi esebenzayo, noma indawo ye-plasma.

Q4: Lezi zingxenye zihlanzwa noma zigcinwe kanjani?

A4:Angahlanzwa kusetshenziswa amanzi e-DI, utshwala, noma okokuhlanza okuhambisana negumbi. Akukho ukulungiswa okukhethekile okudingekayo ngenxa yokuzinza kwawo kwamakhemikhali kanye ne-inert surface.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.