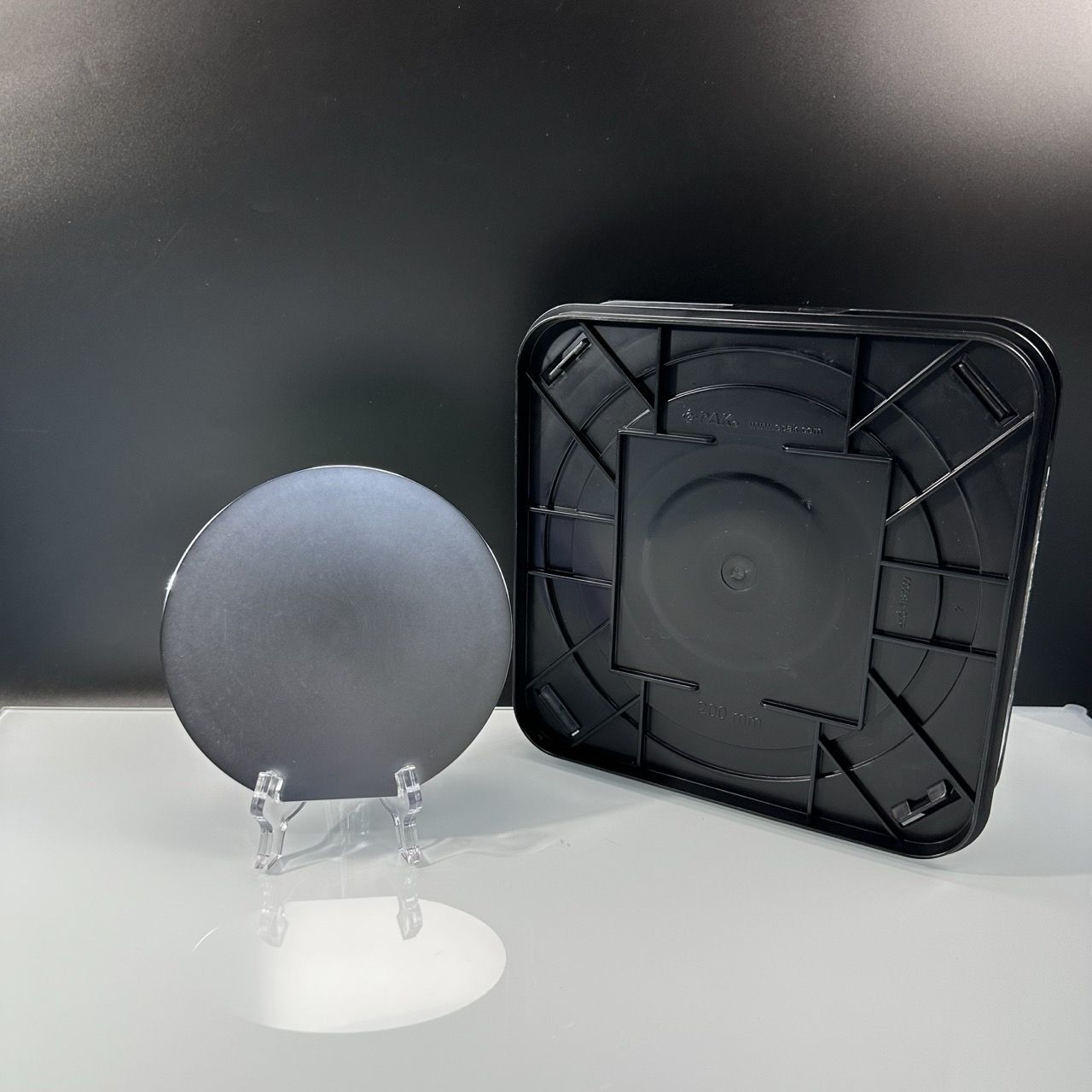

I-Fiber Laser Umaka Ukumaka Okuhle Kakhulu Kwezimpawu Zobucwebe Ze-Electronics

Umdwebo onemininingwane

Uhlolojikelele lwe-Fiber Laser Engraving Machines

Imishini yokuqopha i-fiber laser imelela esinye sezixazululo ezithuthuke kakhulu nezisebenza kahle ezidingweni zokumaka ezimbonini nezohwebo. Ngokungafani namasu okumaka avamile, ama-laser e-fiber ahlinzeka ngendlela yokumaka ehlanzekile, enesivinini esikhulu, futhi ehlala isikhathi eside esebenza kahle kakhulu ezintweni eziqinile nezibonisayo.

Le mishini isebenza isebenzisa umthombo we-laser odluliswa ngentambo ye-fiber optic eguquguqukayo, iletha amandla okukhanya agxilile endaweni yokusebenza. Le nsimbi ye-laser egxilile ithungaza into engaphezulu noma ibangele ukusabela kwamakhemikhali ukuze kukhiqizwe izimpawu ezibukhali, ezinomehluko omkhulu. Ngenxa yale ndlela okungeyona yokuxhumana, akukho ukucindezelwa komshini okusetshenziswa entweni emakwayo.

Enye yezinzuzo ezibalulekile ze-fiber laser systems ukuguquguquka kwazo. Bangakwazi ukumaka uhla olukhulu lwezinto ezihlanganisa izinsimbi (ithusi, i-titanium, igolide), amapulasitiki obunjiniyela, ngisho nezinye izinto ezingezona ezensimbi ezinemimbo. Amasistimu ngokuvamile asekela kokubili ukumaka okumile nokushintshayo, okuvumela ukusetshenziswa emigqeni yokukhiqiza ezenzakalelayo.

Ngaphezu kokuguquguquka kwayo, imishini ye-fiber laser iyanconywa ngokuphila isikhathi eside, ukusebenza kahle kwayo, kanye nokugcinwa kwayo okuncane. Amasistimu amaningi apholile emoyeni, awanakho okusebenzisekayo, futhi ayaziqhayisa ngonyawo oluncane, okuwenza alungele ama-workshops nezindawo zokukhiqiza ezinendawo elinganiselwe.

Izimboni ezithembele kakhulu kubuchwepheshe be-fiber laser zifaka phakathi i-precision electronics, amathuluzi ezokwelapha, ukukhiqiza ama-nameplate ensimbi, nokufaka uphawu kwezimpahla zikanokusho. Ngokukhula kwesidingo sezixazululo zokumaka ezinemininingwane, ezihlala njalo, kanye nemvelo, abaqophi be-fiber laser sebeyingxenye ebalulekile yezinqubo zesimanje zokukhiqiza.

Indlela I-Fiber Laser Marking Technology isebenza ngayo

Imishini yokumaka i-fiber laser incike ekusebenzelaneni phakathi kwe-laser egxilile ye-laser kanye nengaphezulu lempahla ukuze ikhiqize amamaki ahlanzekile, ahlala njalo. Indlela yokusebenza eyisisekelo isekelwe ekumunceni amandla nasekuguqukeni kokushisa, lapho okubalulekile kuthola izinguquko zendawo ngenxa yokushisa okukhulu okukhiqizwa i-laser.

Enhliziyweni yalobu buchwepheshe kunenjini ye-fiber laser, ekhiqiza ukukhanya ngokukhishwa okuvuselelwe ku-doped optical fiber, ngokuvamile equkethe i-ytterbium ions. Uma enikwa amandla ama-diode ephampu anamandla amakhulu, ama-ion akhipha i-laser ehambisanayo enobubanzi obuncane be-wavelength—imvamisa ezungeze ama-nanometer angu-1064. Lokhu kukhanya kwe-laser kulungele kahle ukucubungula izinsimbi, amapulasitiki obunjiniyela, nezinto ezimboziwe.

I-laser beam ibe ihanjiswa nge-fiber optics eguquguqukayo iye ezibukweni zokuskena ezinesivinini esikhulu (amakhanda e-galvo) ezilawula ukunyakaza kwe-beam kuyo yonke inkambu yokumaka. I-focal lens (ngokuvamile i-F-theta lens) igxilisa i-beam ibe indawo encane, ephezulu endaweni eqondiwe. Njengoba i-beam ishaya into, idala ukushisa okusheshayo endaweni evalekile, okubangela ukusabela okuhlukahlukene kwendawo kuye ngezakhiwo ezibonakalayo namapharamitha we-laser.

Lokhu kusabela kungase kuhlanganise i-carbonization, ukuncibilika, ukwenza amagwebu, i-oxidation, noma ukuhwamuka kongqimba lwangaphezulu lwento. Umthelela ngamunye ukhiqiza uhlobo oluhlukile lophawu, olufana nokushintsha kombala, ukuqoshwa okujulile, noma ukuthungwa okuphakanyisiwe. Njengoba yonke le nqubo ilawulwa ngedijithali, umshini ungaphinda ngokunembile amaphethini ayinkimbinkimbi, amakhodi esiriyeli, amalogo, namabhakhodi ngokunemba kweleveli ye-micron.

Inqubo yokumaka i-fiber laser ayithinteki, ayihambisani nemvelo, futhi isebenza kahle ngendlela emangalisayo. Ikhiqiza udoti omncane, ayidingi izinto ezisetshenziswayo, futhi isebenza ngesivinini esikhulu nokusebenzisa amandla aphansi. Ukunemba nokuqina kwayo kuyenza ibe indlela ekhethwayo yokuhlonza unomphela nokulandeleka kuyo yonke imikhakha yesimanje yokukhiqiza.

Ukucaciswa kwe-Fiber Laser Marking Machines

| Ipharamitha | Inani |

|---|---|

| Uhlobo lweLaser | I-Fiber Laser |

| Ubude begagasi | 1064nm |

| Ukuphindaphinda Imvamisa | 1.6-1000KHz |

| Amandla Okukhiphayo | 20-50W |

| Ikhwalithi ye-Beam (M²) | 1.2-2 |

| I-Max Single Pulse Energy | 0.8mJ |

| Ukusetshenziswa kwamandla okuphelele | ≤0.5KW |

| Ubukhulu | 795 * 655 * 1520mm |

Izicelo ze-Fiber Laser Marking Machines

Imishini yokumaka ye-fiber laser yamukelwa kabanzi ezimbonini eziningi ngenxa yokuguquguquka kwayo, isivinini, ukunemba, kanye nekhono lokudala amamaki ahlala isikhathi eside, ahluke kakhulu kuhlu olubanzi lwezinto. Ubuchwepheshe babo bokumaka okungeyena othintwayo kanye nezidingo zokunakekelwa okuphansi zibenza bafaneleke ezinhlelweni ezidinga ukukhonjwa unomphela, ukufaka uphawu, nokulandeleka.

1. Imboni Yezimoto:

Emkhakheni wezimoto, omaka be-fiber laser basetshenziswa kakhulu ukuze kuqoshwe izinombolo ze-serial, amakhodi ezingxenye zenjini, ama-VIN (Izinombolo Zokuhlonza Imoto), namalebula okuphepha ezingxenyeni zensimbi ezifana namasistimu amabhuleki, amabhokisi kagiya, amabhulokhi enjini, nezingxenye ze-chassis. Ukuhlala unomphela kanye nokumelana namamaki e-laser kuqinisekisa ukuthi idatha yokuhlonza ebalulekile ihlala ifundeka ngisho nangemva kweminyaka yokusetshenziswa ezindaweni ezinokhahlo.

2. Ama-Electronics namaSemiconductors:

Ukumaka nge-laser enembe kakhulu kubalulekile emkhakheni wezogesi ukuze ulebule ama-PCB (Amabhodi Esifunda Aphrintiwe), ama-capacitor, ama-microchips, nezixhumi. Ikhwalithi yebhimu enhle ivumela ukumakwa okuncane ngaphandle kokulimaza izingxenye ezibucayi, kuyilapho iqinisekisa ukufaneleka okuphezulu kwamakhodi e-QR, amabhakhodi, nezingxenye zezinombolo.

3. Amadivayisi Ezokwelapha Nokuhlinza:

Ukumakwa kwe-fiber laser kuyindlela ekhethwayo yokuhlonza amathuluzi okuhlinza, izimila, nezinye izisetshenziswa zezokwelapha. Ihlangabezana nezindinganiso eziqinile zokulawula (isb, i-UDI - Ukuhlonza Idivayisi Eyingqayizivele) edingekayo emkhakheni wezokunakekelwa kwempilo. Amamaki ayahambelana ne-biocompatible, amelana nokugqwala, futhi angakwazi ukumelana nezinqubo zokuvala inzalo.

4. I-Aerospace kanye Nokuvikela:

Ekwenziweni kwe-aerospace, izingxenye kufanele zilandeleke, ziqinisekiswe, futhi zikwazi ukumelana nezimo ezimbi kakhulu. Ama-fiber lasers asetshenziselwa ukumaka unomphela ama-turbine blades, izinzwa, izingxenye ze-airframe, nomaka bokuhlonza abanedatha ebalulekile yokuthobelana nokulandelela ukuphepha.

5. Ubucwebe Nezimpahla zikanokusho:

Ukumaka nge-laser kuvame ukusetshenziswa ekubekweni uphawu nokwenza ngokwezifiso amawashi, izindandatho, amasongo, nezinye izinto zenani eliphezulu. Inikeza ukuqoshwa okunembayo nokuhlanzekile ezinsimbini ezifana negolide, isiliva, ne-titanium, esekela izidingo zokulwa nomgunyathi nezomuntu siqu.

6. Amathuluzi Emboni kanye Nezisetshenziswa:

Abakhiqizi bamathuluzi basebenzisa amasistimu e-fiber laser ukuze baqophe izikali zokulinganisa, amalogo, nama-ID ayingxenye kuma-wrenches, caliper, drill, nezinye izinsimbi. Izimpawu zimelana nokungqubuzana, ukuguga, nokuchayeka kumafutha namakhemikhali.

7. Ukupakishwa kanye Nezimpahla Zabathengi:

Ama-fiber lasers angamaka amadethi, izinombolo zeqoqo, kanye nolwazi lomkhiqizo ekupakishweni komkhiqizo okwenziwe ngensimbi, ipulasitiki, noma izindawo ezimboziwe. Lawa mamaki asekela izinhlelo zokusebenza, ukuthobela, kanye nezinhlelo zokulwa nokukhwabanisa.

Ngekhwalithi yayo ephakeme ye-beam, isivinini esikhulu sokumaka, nokulawulwa kwesofthiwe eguquguqukayo, ubuchwepheshe bokumaka be-fiber laser buyaqhubeka nokwandisa indima yabo ekukhiqizeni kwesimanje kanye nezinhlelo zokulawula ikhwalithi.

Umshini Wokumaka we-Fiber Laser - Imibuzo Ejwayelekile Nezimpendulo Eziningiliziwe

1. Yiziphi izimboni ezivame ukusebenzisa ubuchwepheshe bokumaka i-fiber laser?

Ukumakwa kwe-fiber laser kusetshenziswa kakhulu emikhakheni efana nokukhiqiza izimoto, i-aerospace, i-electronics, ukukhiqizwa kwemishini yezokwelapha, ukusebenza kwensimbi, kanye nezimpahla zikanokusho. Isivinini sayo, ukunemba, nokuqina kwayo kuyenza ilungele ukumaka izinombolo ze-serial, amabhakhodi, amalogo, nolwazi lokulawula.

2. Ingakwazi ukumaka kokubili izinsimbi nezingezona izinsimbi?

Ngokuyinhloko yakhelwe ukumaka insimbi, ama-fiber lasers asebenza kahle kakhulu ngensimbi engagqwali, i-aluminium, insimbi, ithusi, nezinsimbi eziyigugu. Ezinye izinto ezingezona ezensimbi—njengepulasitiki ebunjiniyela, izindawo ezimboziwe, nezinye izinto zobumba—zingamakwa, kodwa izinto ezifana nengilazi, iphepha, nokhuni zifaneleka kangcono kumalaser e-CO₂ noma e-UV.

3. Ishesha kangakanani inqubo yokumaka?

Ukumakwa kwe-fiber laser kuyashesha kakhulu—amanye amasistimu angafinyelela isivinini esingaphezu kuka-7000 mm/s, kuye ngokuklama nokuba yinkimbinkimbi kokuqukethwe. Umbhalo olula namakhodi kungamakwa ngengxenyana yesekhondi, kuyilapho amaphethini e-vector ayinkimbinkimbi angase athathe isikhathi eside.

4. Ingabe ukumaka nge-laser kuyawathinta amandla ezinto ezibonakalayo?

Ezimweni eziningi, ukumaka nge-laser kubangela umthelela omncane noma ongabikho kubuqotho besakhiwo sento. Ukumakwa kwendawo, ukuhunyushwa, noma ukushumeka kokukhanya kushintsha kuphela ungqimba oluncane, okwenza inqubo iphephe ezingxenyeni ezisebenzayo neziwumshini.

5. Ingabe isofthiwe yokumaka i-laser kulula ukuyisebenzisa?

Yebo, amasistimu we-fiber laser yesimanje ngokuvamile afika nezixhumi zesofthiwe ezisebenziseka kalula ezisekela izilungiselelo zezilimi eziningi, ukubuka kuqala kwezithombe, namathuluzi okuklama ukudonsa nokuwisa. Abasebenzisi bangangenisa izithombe, bachaze okuguquguqukayo kokumaka inqwaba, futhi bazenzele ngokuzenzakalelayo ukukhiqizwa kwekhodi ye-serial.

6. Uyini umehluko phakathi kokumaka, ukuqopha, nokunamathisela?

Ukumakangokuvamile isho izinguquko zombala noma zokuqhathanisa endaweni ngaphandle kokujula okubalulekile.

Ukuqophakuhlanganisa ukususwa kwezinto ukuze kudaleke ukujula.

Etchingngokuvamile ibhekisela ekuqoshweni okungashoni kusetshenziswa amandla aphansi.

Amasistimu we-fiber laser angakwazi ukwenza konke okuthathu ngokusekelwe esimisweni samandla kanye nobude be-pulse.

7. I-laser mark ingaba nembe futhi inemininingwane kangakanani?

Amasistimu we-fiber laser angamaka ngokulungiswa okuhle njengama-microns angama-20, okuvumela imininingwane enembe kakhulu, okuhlanganisa umbhalo omncane, amakhodi amancane e-QR, namalogo ayinkimbinkimbi. Lokhu kubaluleke kakhulu ezimbonini lapho ukufaneleka nokunemba kubaluleke kakhulu.

8. Ingabe izinhlelo ze-fiber laser zingamaka ezintweni ezihambayo?

Yebo. Amanye amamodeli athuthukile afaka amakhanda okumaka ashukumisayo nezinhlelo zokuvumelanisa ezivumela ukumaka lapho undiza, okuwenza afanelekele imigqa yokuhlanganisa enesivinini esikhulu kanye nokugeleza komsebenzi okuqhubekayo kokukhiqiza.

9. Ingabe kukhona ukucatshangelwa kwemvelo?

Ama-laser we-fiber abhekwa njengenganeno imvelo. Ayikhiphi intuthu enobuthi, ayiwasebenzisi amakhemikhali, futhi ikhipha udoti omncane. Ezinye izinhlelo zokusebenza zingase zidinge amasistimu okukhipha intuthu, ikakhulukazi uma kumaka izindawo ezinamekwe noma zepulasitiki.

10. Isiphi isilinganiso samandla okufanele ngisikhethe kuhlelo lwami lokusebenza?

Ngokumaka ukukhanya ezinsimbi namapulasitiki, imishini engu-20W noma engu-30W yanele ngokujwayelekile. Ngokuqoshwa okujulile noma ukuphuma okusheshayo, amamodeli angu-50W, 60W, noma angu-100W angase anconywe. Inketho engcono kakhulu incike ohlotsheni lwempahla, ukujula kokumaka okufunayo, kanye nezidingo zesivinini.