Umshini Wokusika we-Diamond Wire Weziteshi Ezintathu Osebenzisa Intambo Eyodwa ye-Si Wafer/Optical Glass Cutting Material Cutting

Isingeniso Somkhiqizo

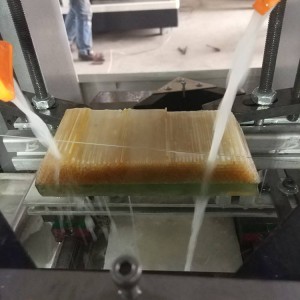

Umshini wokusika we-diamond wire-three-station single-wire cutting umshini wokusika onembile futhi osebenza kahle kakhulu owenzelwe izinto eziqinile neziqinile. Isebenzisa intambo yedayimane njengendawo yokusika futhi ilungele ukucutshungulwa okunembayo kwezinto ezinobulukhuni obuphakeme njengama-silicon wafers, isafire, i-silicon carbide (SiC), i-ceramics, nengilazi yokubona. Ihambisana nomklamo weziteshi ezintathu, lo mshini uvumela ukusika ngesikhathi esisodwa kwezinto zokusebenza eziningi kudivayisi eyodwa, uthuthukise kakhulu ukusebenza kahle kokukhiqiza nokunciphisa izindleko zokukhiqiza.

Isimiso Sokusebenza

- I-Diamond Wire Cutting: Isebenzisa intambo yedayimane ene-electroplated noma ene-resin ukwenza ukusika okusekelwe ekugayeni ngokunyakaza okuphindaphindayo kwesivinini esikhulu.

- I-Three-Station Synchronous Cutting: Ifakwe izindawo zokusebenza ezintathu ezizimele, okuvumela ukusika ngesikhathi esisodwa kwezingcezu ezintathu ukuthuthukisa ukuphuma.

- Ukulawula Ukuqina: Kuhlanganisa isistimu yokulawula ukungezwani okunembayo okuphezulu ukuze kugcinwe ukudonsa kwentambo yedayimane ezinzile ngesikhathi sokusika, iqinisekisa ukunemba.

- Isistimu Yokupholisa Nokugcobisa: Iqasha amanzi enziwe i-deioned noma isipholisi esikhethekile ukuze kuncishiswe umonakalo oshisayo futhi kunwetshwe ukuphila kwezintambo zedayimane.

Izici zezisetshenziswa

- Ukusika Okunembe Kakhulu: Kufeza ukunemba kokusika okungu-±0.02mm, kulungele ukucutshungulwa kwe-wafer encane kakhulu (isb., amawafa e-silicon e-photovoltaic, amawafa we-semiconductor).

- Ukusebenza Okuphakeme Kakhulu: Idizayini yeziteshi ezintathu inyusa ukukhiqiza ngaphezulu kwama-200% uma kuqhathaniswa nemishini yesiteshi esisodwa.

- Ukulahleka Kwezinto Eziphansi: Idizayini ye-kerf emincane (0.1–0.2mm) inciphisa ukumosheka kwezinto.

- I-Automation Ephakeme: Ifaka phakathi ukulayishwa okuzenzakalelayo, ukuqondanisa, ukusika, nokuthulula amasistimu, ukunciphisa ukungenelela okwenziwa ngesandla.

- Ukuguquguquka Okuphezulu: Iyakwazi ukusika izinto ezihlukahlukene eziqinile neziphukayo, okuhlanganisa i-silicon ye-monocrystalline, i-polycrystalline silicon, isafire, i-SiC, nezitsha zobumba.

Izinzuzo Zobuchwepheshe

| Inzuzo

| Incazelo

|

| I-Multi-Station Synchronous Cutting

| Iziteshi ezintathu ezilawulwa ngokuzimela zinika amandla ukusika ama-workpiece anobukhulu obuhlukile noma izinto zokwakha, ukuthuthukisa ukusetshenziswa kwemishini.

|

| Intelligent Tension Control

| Ukulawulwa kwe-loop evaliwe ngama-servo motors kanye nezinzwa kuqinisekisa ukudonsa okungaguquki kwezintambo, ukuvimbela ukuphuka noma ukusika ukuchezuka.

|

| High-Rigidity Isakhiwo

| Imihlahlandlela yomugqa enembayo ephezulu nezinhlelo ezishayelwa yi-servo ziqinisekisa ukusika okuzinzile futhi kunciphise imiphumela yokudlidliza.

|

| Ukusebenza kahle kwamandla kanye ne-Eco-Friendliness

| Uma kuqhathaniswa nokusikwa kwe-slurry evamile, ukusika izintambo zedayimane akungcolisi, futhi into epholile ingagaywa kabusha, kwehlise izindleko zokuhlanza imfucuza.

|

| Intelligent Monitoring

| Ifakwe i-PLC kanye nezinhlelo zokulawula isikrini esithintwayo zokuqapha ngesikhathi sangempela isivinini sokusika, ukushuba, izinga lokushisa, nezinye izinhlaka, ezisekela ukulandelelwa kwedatha. |

Ukucaciswa Kwezobuchwepheshe

| Imodeli | Umshini wokusika umugqa owodwa wedayimane wesiteshi ezintathu |

| Ubukhulu bosayizi wocezu lokusebenza | 600*600mm |

| Isivinini sokugijima kwentambo | 1000 (MIX) m/min |

| Idayimane yentambo yedayimane | 0.25-0.48mm |

| Umthamo wokugcina ulayini wesondo lokunikezela | 20km |

| Ukusika ububanzi ububanzi | 0-600mm |

| Ukusika ukunemba | 0.01mm |

| I-stroke yokuphakamisa eqondile yendawo yokusebenza | 800mm |

| Indlela yokusika | Impahla imile, futhi ucingo lwedayimane luyanyakaza lwehle |

| Ukusika isivinini sokuphakelayo | 0.01-10mm/min (Ngokwezinto ezibonakalayo nokuqina) |

| Ithangi lamanzi | 150L |

| Ukusika uketshezi | Uketshezi olunqamula ukugqwala olusebenza kahle kakhulu |

| Swing angle | ±10° |

| Isivinini sokushwiba | 25°/s |

| Ukucindezela okukhulu kokusika | 88.0N (Setha ubuncane beyunithi0.1n) |

| Ukujula kokusika | 200 ~ 600mm |

| Yenza amapuleti ahambisanayo ahambisanayo ngokwebanga lokusika lekhasimende | - |

| Indawo yokusebenza | 3 |

| Ukunikezwa kwamandla kagesi | Izigaba ezintathu zezintambo ze-AC380V/50Hz |

| Amandla aphelele wethuluzi lomshini | ≤32kw |

| Injini eyinhloko | 1*2kw |

| I-Wiring motor | 1*2kw |

| I-workbench swing motor | 0.4*6kw |

| I-tension control motor | 4.4*2kw |

| Ukukhishwa kwentambo kanye nemoto yokuqoqa | 5.5*2kw |

| Ubukhulu bangaphandle (ngaphandle kwebhokisi lengalo ye-rocker) | 4859*2190*2184mm |

| Ubukhulu bangaphandle (kuhlanganise nebhokisi lengalo ye-rocker) | 4859*2190*2184mm |

| Isisindo somshini | 3600ka |

Izinkambu Zokusebenza

- Imboni ye-Photovoltaic: Ukusika ingots ye-silicon ye-monocrystalline ne-polycrystalline ukuze kuthuthukiswe isivuno se-wafer.

- Imboni ye-Semiconductor: Ukusikwa ngokunemba kwama-wafers we-SiC ne-GaN.

- Imboni ye-LED: Ukusika ama-sapphire substrates okukhiqiza ama-chip e-LED.

- I-Ceramics Ethuthukisiwe: Ukwakha nokusika izitsha zobumba ezisebenza kahle njenge-alumina ne-silicon nitride.

- I-Optical Glass: Ukucutshungulwa okunembayo kwengilazi ezacile kakhulu yamalensi ekhamera namafasitela e-infrared.