I-SiC Seed Crystal Substrates Engokwezifiso I-Dia 205/203/208 4H-N Uhlobo Lwezokuxhumana Ngokubona

Imingcele yezobuchwepheshe

Isicwecwana sembewu ye-silicon carbide | |

I-Polytype | 4H |

Iphutha lokuma kobuso | 4° ngase<11-20>±0.5º |

Ukungazweli | ukwenza ngokwezifiso |

Ububanzi | 205±0.5mm |

Ubukhulu | 600±50μm |

Ubulukhuni | I-CMP, Ra≤0.2nm |

I-Micropipe Density | ≤1 i-e/cm2 |

Ukuklwebheka | ≤5, Ubude Obuphelele≤2*Ububanzi |

Ama-Edge chips/ama-indenti | Lutho |

Ukumaka kwe-laser yangaphambili | Lutho |

Ukuklwebheka | ≤2, Ubude Obuphelele≤Ububanzi |

Ama-Edge chips/ama-indenti | Lutho |

Izindawo ze-Polytype | Lutho |

Ukumaka kwe-laser emuva | 1mm (kusukela emaphethelweni aphezulu) |

Umphetho | I-Chamfer |

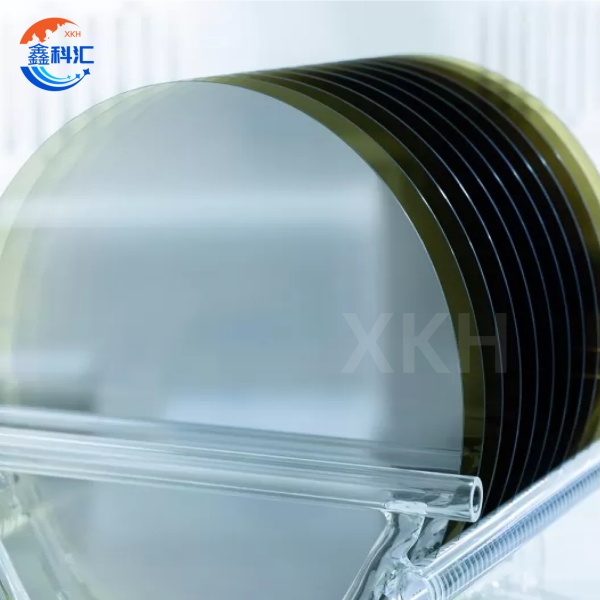

Ukupakisha | Ikhasethi le-multi-wafer |

Izimpawu Ezisemqoka

1. I-Crystal Structure kanye nokusebenza kukagesi

· I-Crystallographic Stability: 100% 4H-SiC polytype dominance, zero multicrystalline inclusions (isb, 6H/15R), ene-XRD rocking curve ububanzi obugcwele ku-half-maximum (FWHM) ≤32.7 arcsec.

· I-High Carrier Mobility: Ukuhamba kwe-Electron okungu-5,400 cm²/V·s (4H-SiC) nokuhamba kwembobo okungu-380 cm²/V·s, okunika amandla amadizayini edivayisi amaza aphezulu.

·Ukuqina Kokushisa: Imelana neradiation ye-neutron engu-1 MeV enomkhawulo womonakalo wokufuduka ongu-1×10¹⁵ n/cm², ilungele i-aerospace nezinhlelo zokusebenza zenuzi.

2. Izakhiwo ezishisayo nezemishini

· I-Exceptional Thermal Conductivity: 4.9 W/cm·K (4H-SiC), kathathu kune-silicon, esekela ukusebenza okungaphezu kuka-200°C.

· I-Coefficient Yokwandisa Okushisayo Ephansi: I-CTE ye-4.0×10⁻⁶/K (25–1000°C), iqinisekisa ukuhambisana nokupakishwa okusekelwe ku-silicon nokunciphisa ukucindezeleka okushisayo.

3. Ukulawula Okungalungile kanye Nokunemba Kokucubungula

· Ukuminyana Kwe-Micropipe: <0.3 cm⁻² (ama-wafers amayintshi angu-8), ukuminyana kokuhlukaniswa <1,000 cm⁻² (kuqinisekiswe nge-KOH etching).

· Ikhwalithi Yokuphezulu: I-CMP-ipholishwe yaba ngu-Ra <0.2 nm, ehlangabezana nezimfuneko ze-EUV lithography-grade flatness.

Izinhlelo zokusebenza ezibalulekile

| Isizinda | I-Application Scenarios | Izinzuzo Technical |

| I-Optical Communications | Ama-lasers angu-100G/400G, amamojula we-silicon photonics hybrid | Ama-substrates embewu ye-InP anika amandla i-bandgap eqondile (1.34 eV) ne-Si-based heteroepitaxy, enciphisa ukulahleka kokuxhumanisa kokubona. |

| Izimoto Ezintsha Zamandla | Ama-inverters angu-800V aphezulu, amashaja angaphakathi (OBC) | Ama-substrates e-4H-SiC amelana > ne-1,200 V, ehlisa ukulahleka kokuqhuba ngo-50% kanye nomthamo wesistimu ngo-40%. |

| I-5G Communications | Imishini ye-Millimeter-wave RF (PA/LNA), izikhulisamandla zamandla esiteshi | Ama-Semi-insulating SiC substrates (ukumelana >10⁵ Ω·cm) anika amandla ukuhlanganiswa kokungenzi lutho kwe-high-frequency (60 GHz+). |

| Izisetshenziswa zezimboni | Izinzwa zokushisa okuphezulu, iziguquli zamanje, iziqaphi ze-nuclear reactor | Ama-substrates embewu ye-InSb (0.17 eV bandgap) aletha ukuzwela kazibuthe kufika ku-300%@10 T. |

Izinzuzo Eziyinhloko

Ama-SiC (silicon carbide) ama-crystal substrates embewu aletha ukusebenza okungenakuqhathaniswa ne-4.9 W/cm·K conductivity eshisayo, amandla enkambu yokuhlukaniswa kwe-2–4 MV/cm, kanye ne-bandgap ebanzi engu-3.2 eV, evumela ukusetshenziswa kwamandla aphezulu, imvamisa ephezulu, kanye nezinga eliphezulu lokushisa. Ifaka ukuminyana kwe-micropipe enguziro kanye nokuminyana kokugudluka okungu-<1,000 cm⁻², lawa ma-substrates aqinisekisa ukwethembeka ezimeni ezimbi kakhulu. I-inertness yabo yamakhemikhali kanye nezindawo ezihambisana ne-CVD (Ra <0.2 nm) zisekela ukukhula kwe-heteroepitaxial okuthuthukisiwe (isb, i-SiC-on-Si) ye-optoelectronics kanye nezinhlelo zamandla ze-EV.

Izinsizakalo ze-XKH:

1. Ukukhiqiza Ngokwezifiso

· Amafomethi we-Wafer Flexible: Ama-wafer angu-2–12-intshi anesiyingi, unxande, noma ukusikeka okumise okwezifiso (±0.01 mm ukubekezelelana).

· Ukulawula I-Doping: I-nitrogen enembile (N) ne-aluminium (Al) doping nge-CVD, ukufeza amabanga wokuphikiswa asuka ku-10⁻³ kuya ku-10⁶ Ω·cm.

2. I-Advanced Process Technologies.

· I-Heteroepitaxy: I-SiC-on-Si (ihambisana nemigqa ye-silicon yamayintshi angu-8) kanye ne-SiC-on-Diamond (i-thermal conductivity >2,000 W/m·K).

· Ukunciphisa Ukukhubazeka: Ukufakwa kwe-Hydrogen kanye nokudonsa ukuze kuncishiswe ukukhubazeka kwe-micropipe/ukuminyana, ukuthuthukisa isivuno se-wafer sibe >95%.

3. Izinhlelo Zokuphatha Ikhwalithi.

· Ukuhlolwa kokuphela kuya ekupheleni: I-Raman spectroscopy (ukuqinisekiswa kwe-polytype), i-XRD (crystallinity), ne-SEM (ukuhlaziywa kokukhubazeka).

· Izitifiketi: Ithobelana ne-AEC-Q101 (yezimoto), i-JEDEC (JEDEC-033), kanye ne-MIL-PRF-38534 (ibanga lezempi).

4. Global Supply Chain Support.

· Amandla Okukhiqiza: Okukhiphayo nyanga zonke >10,000 wafers (60% 8-intshi), nokulethwa kwezimo eziphuthumayo amahora angu-48.

· Inethiwekhi Yezinhlelo Zokusebenza: Isebenza e-Europe, eNyakatho Melika, nase-Asia-Pacific ngempahla yomoya/yasolwandle enamaphakheji alawulwa izinga lokushisa.

5. I-Technical Co-Development.

· Amalebhu Ahlanganyelwe E-R&D: Hlanganyela ekuthuthukisweni kokupakishwa kwemojula yamandla e-SiC (isb., ukuhlanganiswa kwe-DBC substrate).

· Ilayisense ye-IP: Nikeza ilayisense yobuchwepheshe bokukhula kwe-GaN-on-SiC RF ukuze wehlise izindleko ze-R&D zeklayenti.

Isifinyezo

I-SiC (silicon carbide) seed crystal substrates, njengento esetshenziswayo, ibumba kabusha amaketanga ezimboni zomhlaba wonke ngokusebenzisa impumelelo ekukhuleni kwekristalu, ukulawulwa kokukhubazeka, nokuhlanganiswa okuhlukahlukene. Ngokuqhubeka nokuthuthukisa ukuncishiswa kokukhubazeka kwe-wafer, ukukala ukukhiqizwa okungamayintshi angu-8, nokwandisa amapulatifomu e-heteroepitaxial (isb, i-SiC-on-Diamond), i-XKH iletha izixazululo ezinokwethenjelwa okuphezulu, ezibiza izindleko ze-optoelectronics, amandla amasha, nokukhiqiza okuthuthukile. Ukuzibophezela kwethu ekusunguleni izinto ezintsha kuqinisekisa ukuthi amaklayenti ahola ekungathathi hlangothi kwekhabhoni nasezinhlelweni ezihlakaniphile, okuqhuba inkathi elandelayo ye-wide-bandgap semiconductor ecosystems.