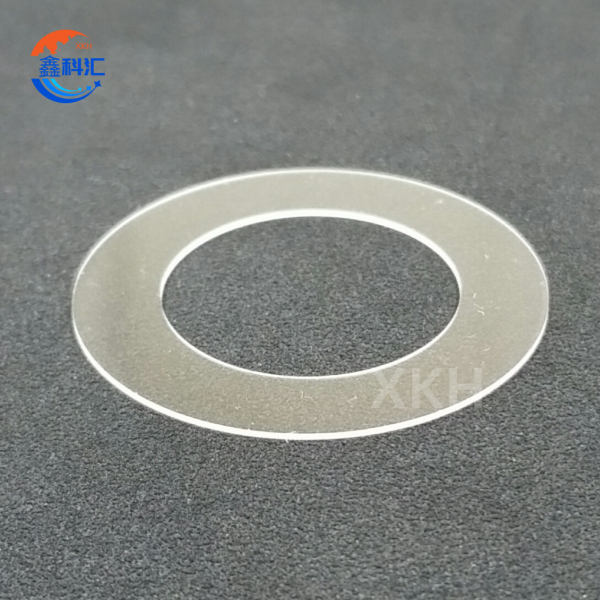

Izingxenye Ze-Windows Sapphire Ezenziwe Ngokwezifiso Ezinomumo We-Sapphire Optical Nge-Precision Polishing

Imingcele yezobuchwepheshe

| Iwindi lesafire | |

| Ubukhulu | 8-400mm |

| Ukubekezelela Dimensional | +0/-0.05mm |

| Ikhwalithi yobuso (ukuklwebha nokumba) | 40/20 |

| Ukunemba kobuso | λ/10per@633nm |

| Imbobo ecacile | >85%, 90% |

| Ukubekezelelana kwe-Parallelism | ±2''-±3'' |

| Bevel | 0.1-0.3mm |

| Ukugqoka | AR/AF/ngesicelo sekhasimende |

Izici Eziyinhloko

1.Ubukhulu Bezinto

· Izici Zokushisa Ezithuthukisiwe: Ibonisa ukusebenza kokushisa okungu-35 W/m·K (ku-100°C), nge-coefficient ephansi yokwandisa okushisayo (5.3×10⁻⁶/K) evimbela ukuhlanekezelwa kokubona ngaphansi kokuhamba ngebhayisikili okusheshayo. Izinto ezisetshenziswayo zigcina ubuqotho besakhiwo ngisho nangesikhathi sokushintsha kokushaqeka okushisayo ukusuka ku-1000°C kuya kuzinga lokushisa legumbi ngemizuzwana.

· Ukuzinza Kwekhemikhali: Kubonisa ukuwohloka okuyiziro lapho kuchayeke kuma-acids agxilile (i-HF ikhishiwe) kanye nama-alkali (pH 1-14) isikhathi eside, okuyenza ifaneleke imishini yokucubungula amakhemikhali.

· I-Optical Refinement: Ngokukhula okuthuthukisiwe kwekristalu ye-C-axis, ifinyelela >85% yokudlulisela ku-spectrum ebonakalayo (400-700nm) ngokulahleka kwe-scatter ngaphansi kuka-0.1%/cm.

· Ukupholisha kwe-hyper-hemispherical ongakukhetha kunciphisa ukuboniswa kwendawo kufinyelele ku-<0.2% endaweni ngayinye ku-1064nm.

2.Amakhono Obunjiniyela Anembile

· I-Nanoscale Surface Control: Ukusebenzisa i-magnetorheological finishing (MRF), ifinyelela ubulukhuni obungaphezulu kwe-<0.3nm Ra, ibalulekile ezinhlelweni ze-laser zamandla aphezulu lapho i-LIDT idlula u-10J/cm² ku-1064nm, ama-pulses angu-10ns.

· I-Complex Geometry Fabrication: Ihlanganisa i-5-axis ultrasonic machining yokudala iziteshi ze-microfluidic (50μm wide tolerance) kanye ne-diffractive optical elements (DOE) ene-<100nm isici sokuxazulula.

· I-Metrology Integration: Ihlanganisa i-interferometry yokukhanya okumhlophe kanye ne-atomic force microscopy (AFM) yezinhlamvu ezingaphezulu ze-3D, iqinisekisa ukunemba kwefomu <100nm PV kuwo wonke ama-substrates angu-200mm.

Izicelo Eziyinhloko

1.Ukuthuthukiswa Kwezinhlelo Zokuvikela

· I-Hypersonic Vehicle Domes: Iklanyelwe ukumelana ne-Mach 5+ imithwalo ye-aerothermal ngenkathi igcina ukudluliswa kwe-MWIR kumakhanda afunayo. Izigxivizo ezikhethekile ze-nanocomposite ezinqenqemeni zivimbela ukuchithwa ngaphansi kwemithwalo yokudlidliza engu-15G.

· Ama-Quantum Sensing Platform: Izinguqulo ze-Ultra-low birefringence (<5nm/cm) zinika amandla i-magnetometry enembile kumasistimu okuthola umkhumbi ongaphansi kolwandle.

2.I-Industrial Process Innovation

· I-Semiconductor Extreme UV Lithography: Amawindi aphucuziwe weBanga AA anobunzima obungu-<0.01nm obuphezulu bunciphisa ukulahlekelwa okuhlakazekayo kwe-EUV (13.5nm) kumasistimu anyathelayo.

· Ukuqapha kwe-Nuclear Reactor: Okuhlukile kwe-Neutron-transparent (Al₂O₃ isotopically purified) kunikeza ukuqapha okubonakalayo kwesikhathi sangempela kuma-Gen IV reactor cores.

3.Emerging Technology Integration

· I-Space-Based Optical Comms: Izinguqulo eziqiniswe yi-radiation (ngemuva kokuchayeka kwe-gamma engu-1Mrad) zigcina >80% ukudluliselwa kwe-LEO satellite laser crosslinks.

· I-Biophotonics Interfaces: Ukwelashwa kwe-Bio-inert surface kunika amandla amafasitela e-Raman spectroscopy afakelwayo ukuze aqaphe ushukela.

4.Amasistimu Amandla Athuthukile

· I-Fusion Reactor Diagnostics: I-Multi-layer conductive coatings (ITO-AlN) inikeza kokubili ukubuka kwe-plasma kanye nokuvikela kwe-EMI ekufakweni kwe-tokamak.

· Ingqalasizinda ye-Hydrogen: Izinguqulo ze-Cryogenic-grade (ezivivinywe ku-20K) zivimbela ukukhishwa kwe-hydrogen ezindaweni zokubuka eziwuketshezi ze-H₂.

Izinsizakalo ze-XKH & Namakhono Wokunikezela

1.Izinkonzo Zokukhiqiza Ngokwezifiso

· Ukwenza Ngokwezifiso Okusekelwe Kumdwebo: Isekela imiklamo engajwayelekile (ubukhulu obungu-1 mm ukuya ku-300 mm), ukulethwa okusheshayo kwezinsuku ezingu-20, kanye nokwenza i-prototyping okokuqala ngqa phakathi kwamaviki angu-4.

· Izixazululo Zokuhlanganisa: I-Anti-reflection (AR), i-anti-fouling (AF), ne-wavelength-specific coatings (UV/IR) ukuze kuncishiswe ukulahlekelwa kokubonisa.

· Ukupholisha Okunembayo Nokuhlola: Ukupholisha kwezinga le-athomu kufinyelela u-≤0.5 nm obumahwashana obuphezulu, nge-interferometry eqinisekisa ukuthobela okungu-λ/10.

2.Supply Chain & Technical Support

· Ukuhlanganiswa Okuma mpo: Ukulawula inqubo egcwele kusukela ekukhuleni kwekristalu (indlela ye-Czochralski) ukuya ekusikeni, ukupholishwa, nokunamathiswa, okuqinisekisa ukuhlanzeka kwempahla (okungenalutho-/okungenayo imingcele) kanye nokuvumelana kwenqwaba.

· Ukusebenzisana Kwezimboni: Kugunyazwe osonkontileka basemkhathini; isebenzisana ne-CAS ukuthuthukisa i-superlattice heterostructures esikhundleni sasekhaya.

3.Iphothifoliyo Yomkhiqizo & Logistics

· I-inventory evamile: amafomethi angama-intshi angu-6 kuya kwangu-12-intshi; intengo yeyunithi ukusuka ku-43to82 (usayizi/incike ekunambeni), ngokuthunyelwa kosuku olufanayo.

· Ukubonisana nobuchwepheshe mayelana nemiklamo eqondene nohlelo oluthile (isb., amafasitela anezitebhisi zamakamelo okuhlanza, izakhiwo ezimelana nokushaqeka).