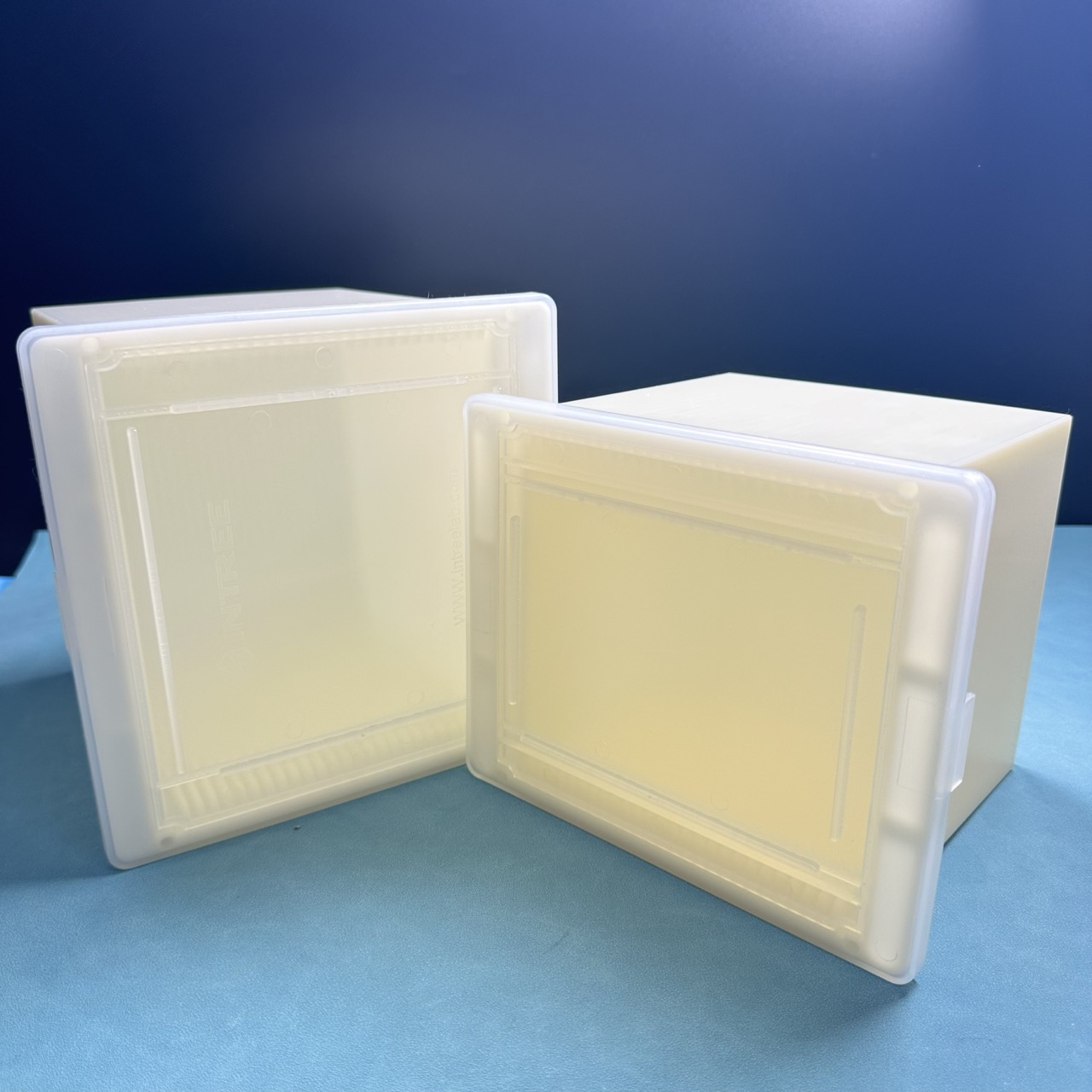

Ibhokisi lezokuthutha lebhokisi lesikwele eliyisikwele lesiqeshana sokuthutha

Izinzuzo zama-wafers wokuthumela emabhokisini okuthumela ayisikwele afaka:

1--Ukusetshenziswa kwesikhala okuphezulu: Amabhokisi okuthumela ayisikwele ngokuvamile aklanyelwe ukuthi aminyene kakhulu, avumela ukusetshenziswa kahle kwendawo yokuthumela neyokugcina kanye nokunciphisa imfucuza.

2--Ukuzinza: Amabhokisi okuthumela ayisikwele avamise ukudizayinelwa ukuhlinzeka ngesakhiwo sosekelo esizinzile esiza ukuvikela amawafa ekudlidlizeni nasekushaqekeni.

3--Ukupakisha Okulula: Ngenxa yomumo wamabhokisi okuthumela ayisikwele, ngokuvamile angaqoqwa kalula ndawonye ukuze alondoloze indawo yokugcina neyokuthutha.

4--Ukuphatha kalula okuzenzakalelayo: Umumo nomklamo wamabhokisi okuthumela ayisikwele kuwenza kube lula ukuzijwayeza kumasistimu okubamba azenzakalelayo, akhuphule ukukhiqiza.

Sekukonke, amabhokisi okuthutha ayisikwele ahlinzeka ngokusebenza kahle okukhulu, ukuzinza kanye nokusetshenziswa kwesikhala lapho uthutha ama-wafers, okuwenza abe isitsha esivamile sokuhambisa i-wafer.

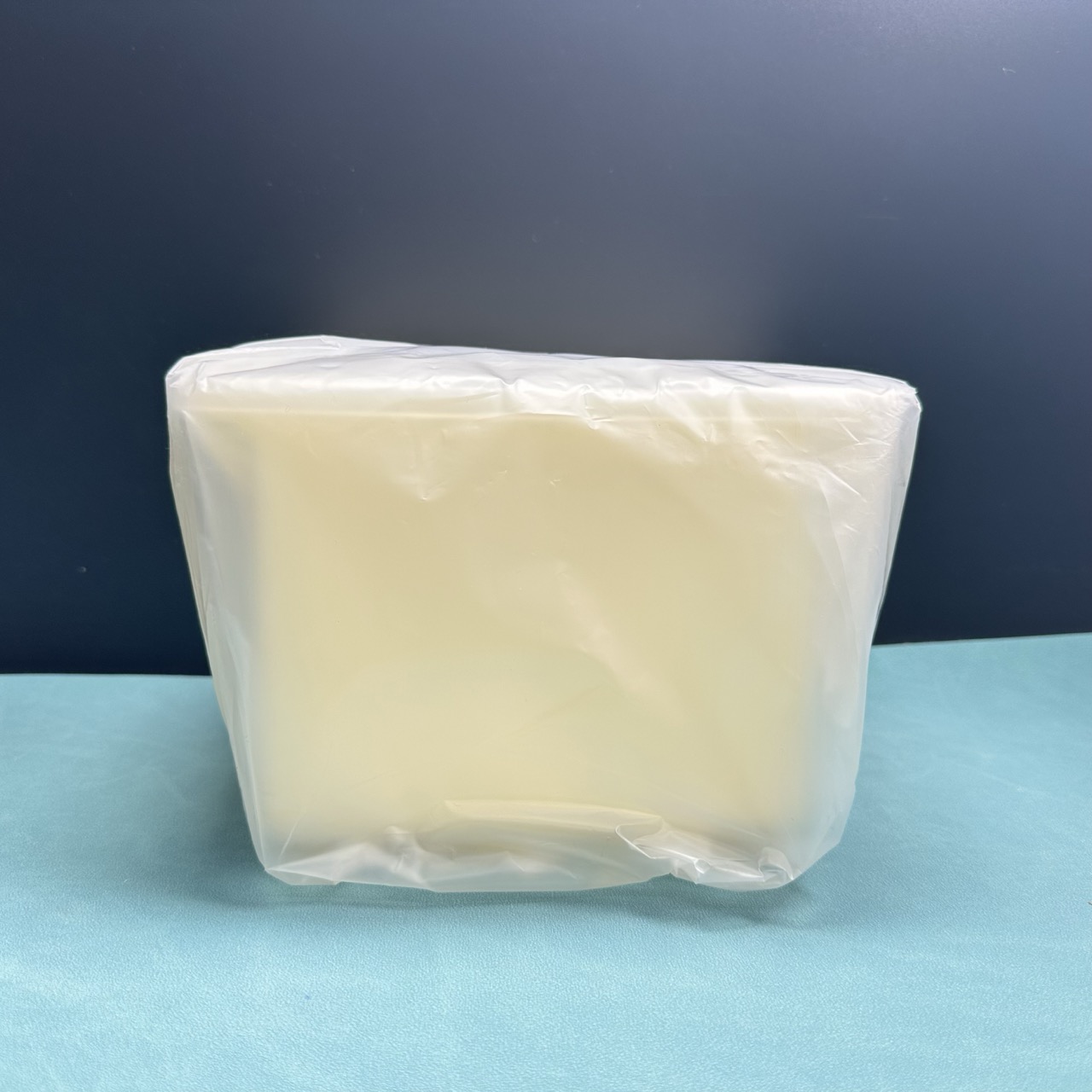

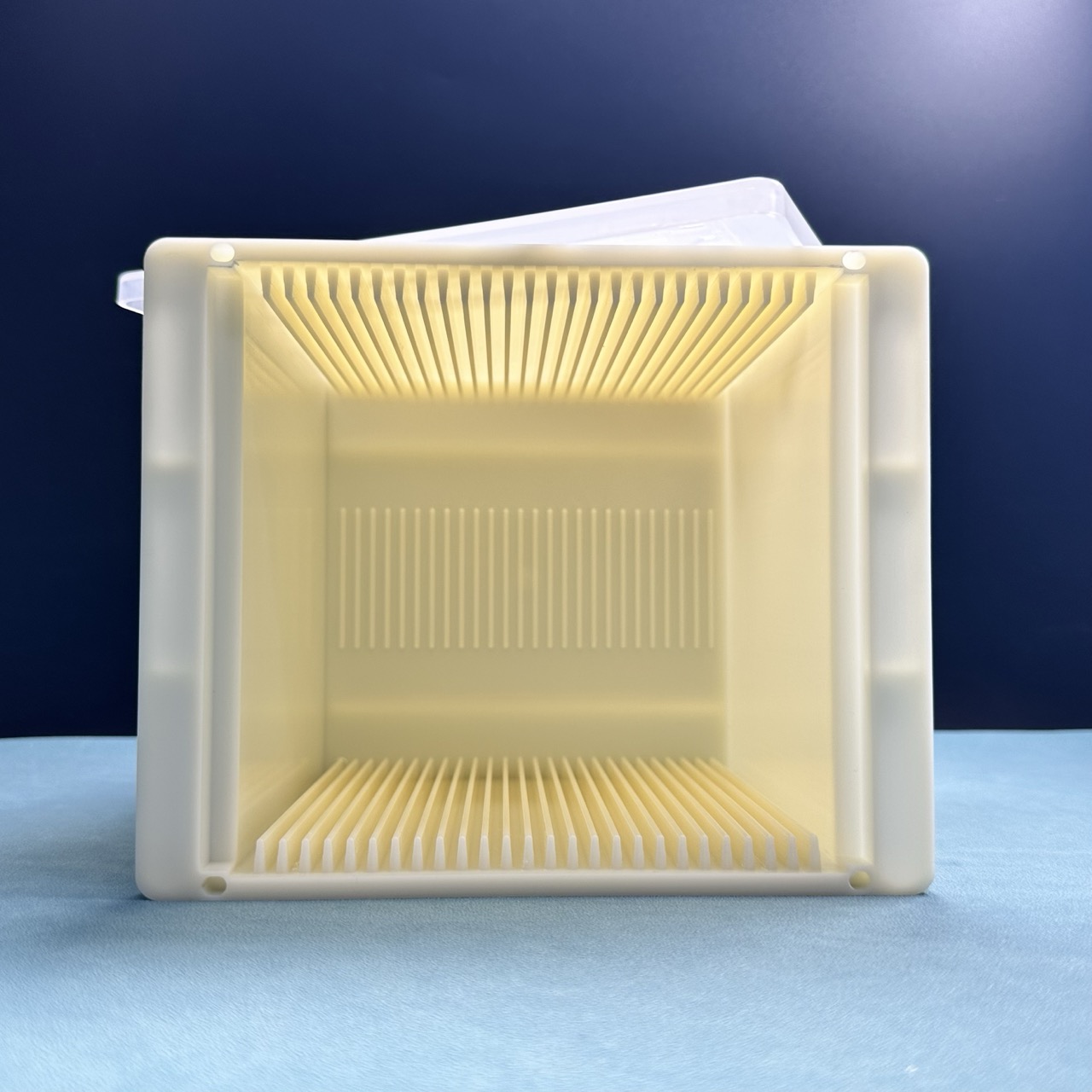

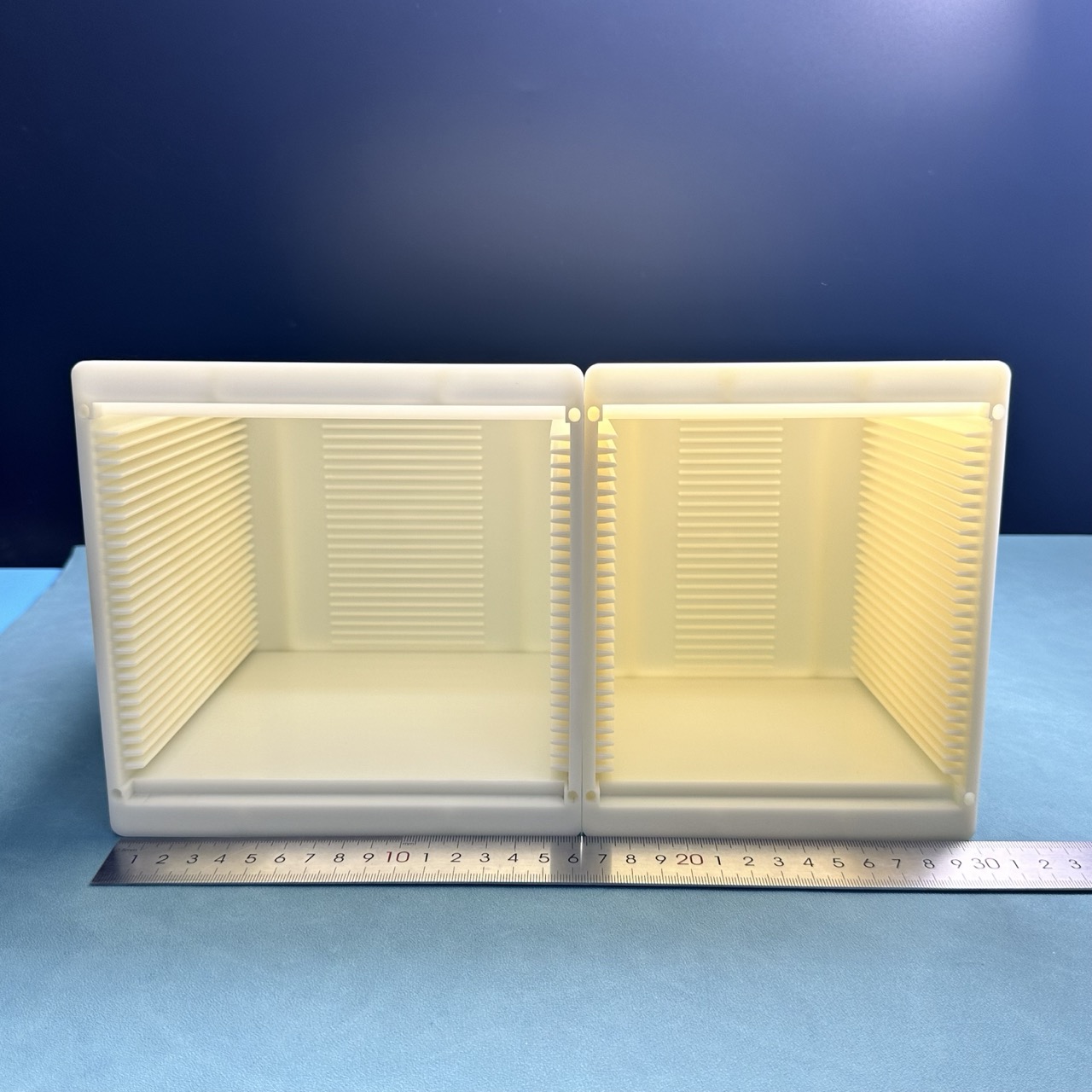

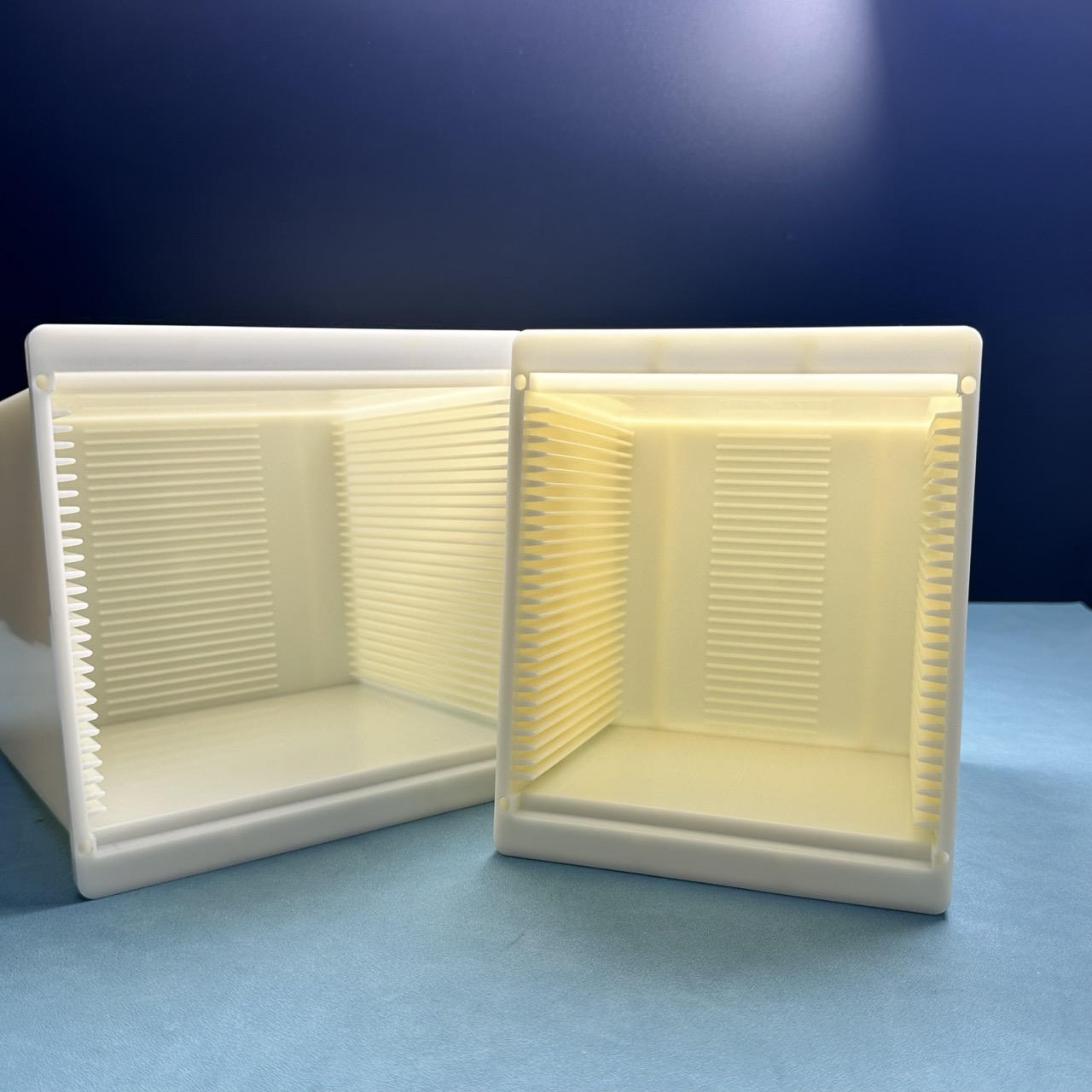

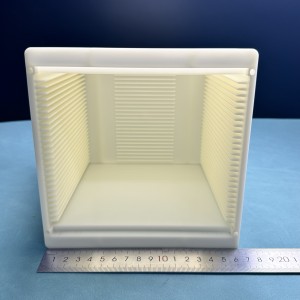

Akhiwe ngezinto eziqinile ze-ABS futhi anezikhala ezingu-25, la mabhokisi okugcina anikeza isikhala esanele sokuhlela nokuvikela amawafa ngesikhathi sokuphatha nokuthutha. Ngokwakhiwa kwawo okumazombezombe kanye nedizayini enembile, amabhokisi ethu okuthumela ama-wafer aqinisekisa ukuthi ama-wafer ahanjiswa ngokuphepha lapho aya khona, agcina ubuqotho kanye nekhwalithi kulo lonke uhambo lwawo. Ilungele izikhungo zokukhiqiza ama-semiconductor namalebhu ocwaningo, la mabhokisi okugcina ahlinzeka ngesixazululo esithembekile sokugcina nokuthutha ama-wafers kalula futhi kalula.

Umdwebo onemininingwane