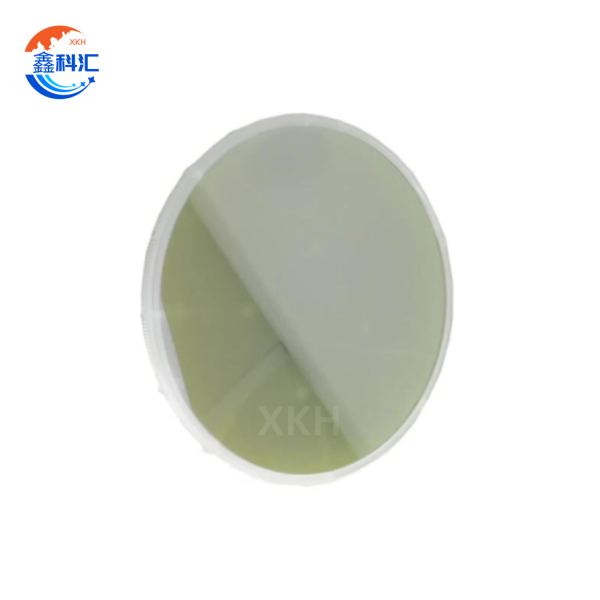

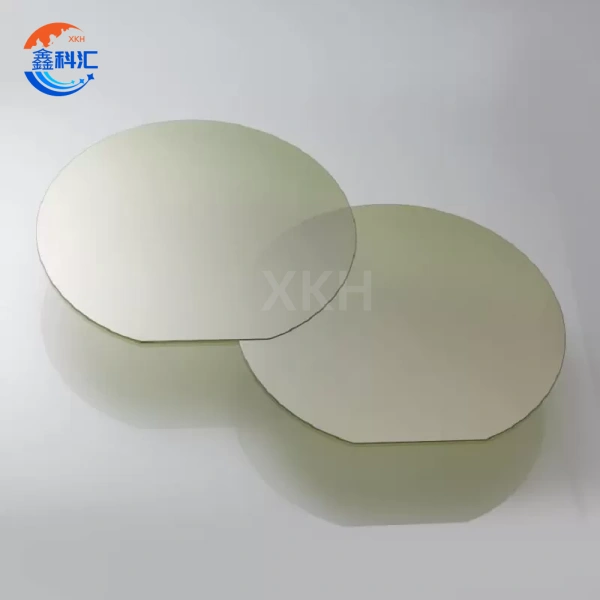

I-N Yangokwezifiso Uhlobo lwe-SiC Seed Substrate Dia153/155mm Yezogesi Zamandla

Ngenisa

Ama-substrates embewu ye-Silicon Carbide (SiC) asebenza njengesisekelo sama-semiconductors esizukulwane sesithathu, ahlukaniswa ngokuguquguquka kwawo okushisayo okuphakeme kakhulu, amandla ensimu kagesi ephukile, kanye nokuhamba kwama-electron aphezulu. Lezi zakhiwo zizenza zibaluleke kakhulu kuma-electronics kagesi, amadivaysi e-RF, izimoto zikagesi (EVs), kanye nezicelo zamandla avuselelekayo. I-XKH igxile kakhulu ku-R&D kanye nokukhiqizwa kwezinga eliphezulu zembewu ye-SiC, isebenzisa amasu athuthukile okukhula kwekristalu njenge-Physical Vapor Transport (PVT) kanye ne-High-Temperature Chemical Vapor Deposition (HTCVD) ukuze kuqinisekiswe ikhwalithi yekristalu ehamba phambili embonini.

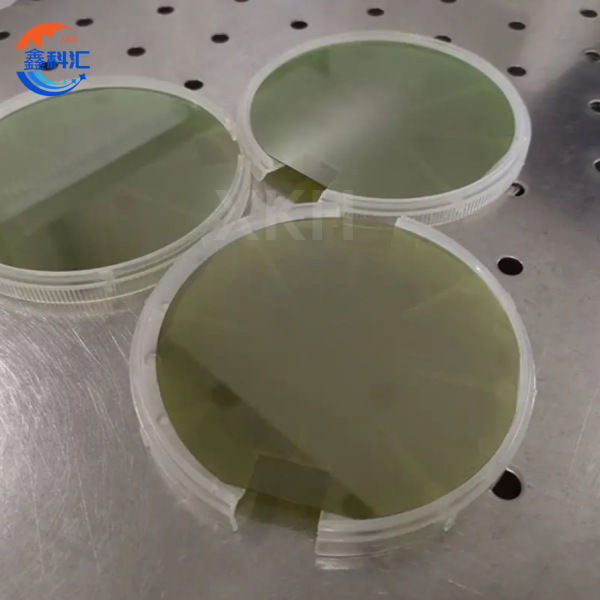

I-XKH inikela ngama-intshi angu-4, angu-6-intshi, kanye nama-intshi angu-8-inch embewu ye-SiC ene-doping eyenziwe ngokwezifiso yohlobo lwe-N/P, efinyelela amazinga okumelana angu-0.01-0.1 Ω·cm nokuminyana kokugudluzwa ngaphansi kuka-500 cm⁻², okuwenza alungele ukukhiqiza ama-MOSFET, i-Schottky Barriers Digital Inqubo yethu yokukhiqiza ehlanganiswe iqonde ihlanganisa ukukhula kwekristalu, ukusikwa kwe-wafer, ukupholisha, nokuhlolwa, okunamandla okukhiqiza anyanga zonke angaphezu kuka-5,000 wama-wafer ukuze kuhlangatshezwane nezidingo ezihlukahlukene zezikhungo zocwaningo, abakhiqizi be-semiconductor, nezinkampani zamandla avuselelekayo.

Ukwengeza, sinikeza izixazululo ezenziwe ngokwezifiso, okuhlanganisa:

Ukwenza ngokwezifiso i-Crystal orientation (4H-SiC, 6H-SiC)

I-Doping ekhethekile (i-Aluminium, i-nitrogen, i-Boron, njll.)

Ukupholisha okubushelelezi (Ra <0.5 nm)

I-XKH isekela ukucubungula okusekelwe kusampula, ukubonisana nobuchwepheshe, kanye ne-prototyping yeqoqwana elincane ukuze ilethe izixazululo ze-SiC substrate ezithuthukisiwe.

Imingcele yezobuchwepheshe

| Isicwecwana sembewu ye-silicon carbide | |

| I-Polytype | 4H |

| Iphutha lokuma kobuso | 4° ngase<11-20>±0.5º |

| Ukungazweli | ukwenza ngokwezifiso |

| Ububanzi | 205±0.5mm |

| Ubukhulu | 600±50μm |

| Ubulukhuni | I-CMP, Ra≤0.2nm |

| I-Micropipe Density | ≤1 i-e/cm2 |

| Ukuklwebheka | ≤5, Ubude Obuphelele≤2*Ububanzi |

| Ama-Edge chips/ama-indent | Lutho |

| Ukumaka kwe-laser yangaphambili | Lutho |

| Ukuklwebheka | ≤2, Ubude Obuphelele≤Ububanzi |

| Ama-Edge chips/ama-indent | Lutho |

| Izindawo ze-Polytype | Lutho |

| Ukumaka kwe-laser emuva | 1mm (kusukela emaphethelweni aphezulu) |

| Umphetho | I-Chamfer |

| Ukupakisha | Ikhasethi le-multi-wafer |

I-SiC Seed Substrates - Izimpawu Ezisemqoka

1. Izakhiwo Ezingokoqobo Ezingavamile

· I-thermal conductivity ephezulu (~490 W/m·K), idlula ngokuphawulekayo i-silicon (Si) ne-gallium arsenide (GaAs), okuyenza ifaneleke ukupholisa idivayisi yamandla aphezulu.

· Amandla enkambu yokuhlukaniswa (~3 MV/cm), evumela ukusebenza okuzinzile ngaphansi kwezimo ze-voltage ephezulu, okubalulekile kuma-inverter e-EV namamojula wamandla ezimboni.

· I-Wide bandgap (3.2 eV), inciphisa ukuvuza kwemisinga emazingeni okushisa aphezulu futhi ithuthukisa ukwethembeka kwedivayisi.

2. Superior Crystalline Quality

· Ubuchwepheshe bokukhula obuxubile be-PVT + HTCVD bunciphisa ukukhubazeka kwe-micropipe, igcine ukuminyana kokususwa kungaphansi kuka-500 cm⁻².

· I-wafer bow/warp < 10 μm kanye nobulukhuni bobuso i-Ra < 0.5 nm, iqinisekisa ukuhambisana ne-lithography enembayo ephezulu kanye nezinqubo zokubeka ifilimu elincanyana.

3. Izinketho Ezihlukahlukene Zokudotshwa

·N-uhlobo (i-Nitrogen-doped): Ukumelana okuphansi (0.01-0.02 Ω·cm), okulungiselelwe amadivayisi e-RF anemvamisa ephezulu.

· Uhlobo lwe-P (i-Aluminium-doped): Ilungele amandla ama-MOSFET nama-IGBT, ithuthukisa ukuhamba kwenkampani yenethiwekhi.

· I-Semi-insulating SiC (Vanadium-doped): Ukumelana > 10⁵ Ω·cm, yakhelwe amamojula angaphambili e-5G RF.

4. Ukuzinza Kwemvelo

· Ukumelana nezinga lokushisa eliphezulu (>1600°C) nokuqina kwemisebe, kulungele i-aerospace, izinto zokusebenza zenuzi, nezinye izindawo eziyingozi kakhulu.

I-SiC Seed Substrates - Izicelo Eziyinhloko

1. Amandla kagesi

· Izimoto zikagesi (ama-EV): Asetshenziswa kumashaja angaphakathi ebhodini (OBC) nama-inverter ukuze kuthuthukiswe ukusebenza kahle nokunciphisa izimfuno zokulawula ukushisa.

· I-Industrial Power Systems: Ithuthukisa ama-inverters e-photovoltaic namagridi ahlakaniphile, kuzuzwe >99% ukusebenza kahle kokuguqulwa kwamandla.

2. Amadivayisi e-RF

· I-5G Base Stations: Ama-Semi-insulating SiC substrates anika amandla izikhulisamandla zamandla e-GaN-on-SiC RF, ezisekela imvamisa ephezulu, ukudluliswa kwesignali yamandla aphezulu.

Ukuxhumana Kwesathelayithi: Izici zokulahlekelwa okuphansi ziyenza ifaneleke kumadivayisi we-millimeter-wave.

3. Amandla Avuselelekayo Nesitoreji Samandla

· Amandla Elanga: Ama-SiC MOSFET athuthukisa ukusebenza kahle kokuguqulwa kwe-DC-AC kuyilapho ehlisa izindleko zesistimu.

· I-Energy Storage Systems (ESS): Ithuthukisa iziguquli eziqondiswe kabili futhi inwebe ubude bebhethri.

4. Defense & Aerospace

· I-Radar Systems: Amadivayisi e-SiC anamandla aphezulu asetshenziswa kumarada e-AESA (Active Electronically Scanned Array).

· Ukuphatha Amandla Emikhumbi-mkhathi: Ama-substrates e-SiC amelana nemisebe abalulekile ohambweni lwasemkhathini ojulile.

5. Ucwaningo & Emerging Technologies

· I-Quantum Computing: I-High-purity SiC inika amandla ucwaningo lwe-spin qubit.

· Izinzwa Ezinokushisa Okuphezulu: Zitshalwe ekuhloleni uwoyela kanye nokuqapha kwe-nuclear reactor.

I-SiC Seed Substrates - Izinsizakalo ze-XKH

1. Izinzuzo ze-Supply Chain

· Ukukhiqiza okuhlanganisiwe okuqondile: Ukulawula okugcwele kusuka kumpushana ye-SiC ehlanzekile kakhulu kuya kumawafa aqediwe, okuqinisekisa izikhathi zokuhola zamaviki angu-4-6 ngemikhiqizo evamile.

· Ukuncintisana kwezindleko: Umnotho wesilinganiso uvumela amanani aphansi ngo-15-20% kuneziqhudelana naye, ngokusekelwa Kwezivumelwano Zesikhathi Eside (ama-LTA).

2. Amasevisi Okwenza ngokwezifiso

· I-Crystal orientation: 4H-SiC (ejwayelekile) noma i-6H-SiC (izinhlelo zokusebenza ezikhethekile).

· Ukwenza ngcono i-Doping: Izakhiwo ezihlanganisiwe zohlobo lwe-N/P/ezivikela kancane.

· Ukupholishwa okuthuthukisiwe: Ukupholishwa kwe-CMP nokwelashwa kwendawo elungele i-epi (Ra <0.3 nm).

3. Ukusekelwa Kwezobuchwepheshe

· Ukuhlolwa kwamahhala kwesampula: Kufaka i-XRD, i-AFM, nemibiko yokulinganisa umphumela weHholo.

· Usizo lokulingisa idivayisi: Isekela ukukhula kwe-epitaxial nokuthuthukiswa kwedizayini yedivayisi.

4. Ukusabela Ngokushesha

· I-prototyping enevolumu ephansi: I-oda elincane lama-wafers ayi-10, elethwa phakathi kwamaviki ama-3.

· Ukuphathwa kwempahla yomhlaba wonke: Ubambiswano ne-DHL kanye ne-FedEx ekulethweni kwendlu ngendlu.

5. Ukuqinisekisa Ikhwalithi

· Ukuhlolwa kwenqubo egcwele: Kumboza i-X-ray topography (XRT) kanye nokuhlaziywa kokuminyana kokukhubazeka.

· Izitifiketi zamazwe ngamazwe: Ithobelana ne-IATF 16949 (izinga lezimoto) kanye namazinga e-AEC-Q101.

Isiphetho

I-XKH's SiC seed substrates ihamba phambili ngekhwalithi yecrystalline, ukuzinza kwe-supply chain, kanye nokuguquguquka ngokwezifiso, inikezela ngama-electronics amandla, ukuxhumana kwe-5G, amandla avuselelekayo, nobuchwepheshe bokuvikela. Siyaqhubeka nokuqhubekisela phambili ubuchwepheshe bokukhiqiza ngobuningi be-SiC engu-8-intshi ukuze siqhubekisele phambili imboni ye-semiconductor yesizukulwane sesithathu.