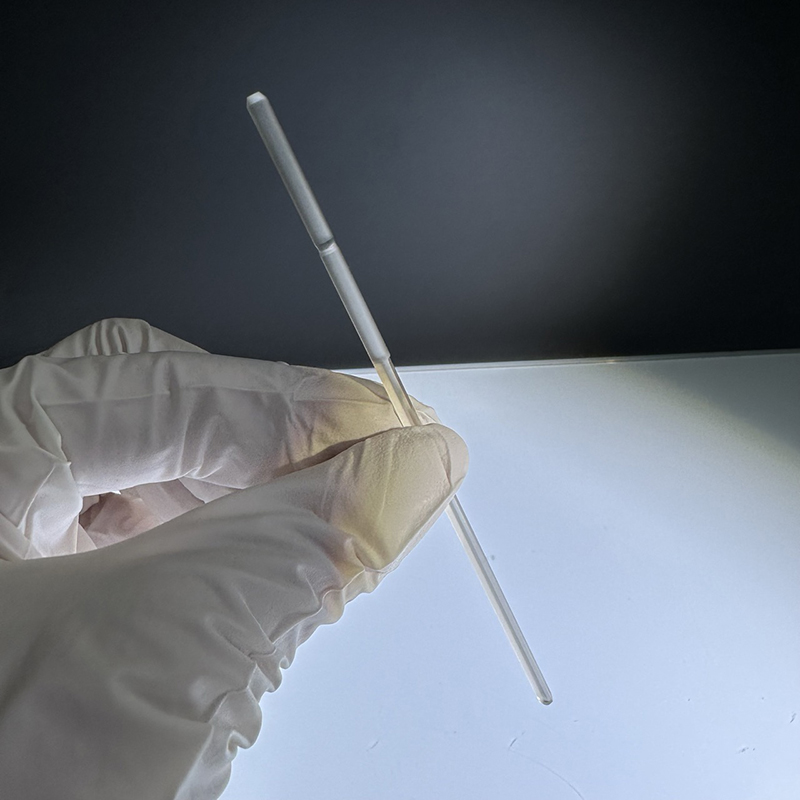

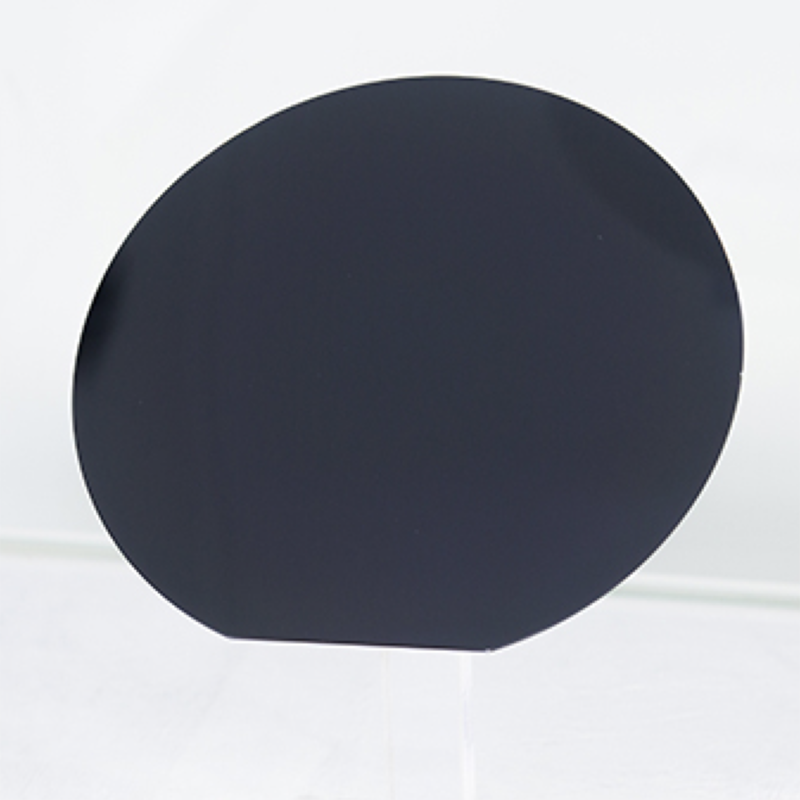

I-wafer yephedi engasheleli ye-bionic ephethe i-vacuum sucker friction pad sucker

Izici ze-Bionic anti-slip pad:

• Ukusetshenziswa kobunjiniyela obukhethekile bezinto ezihlanganisiwe ze-elastomer, ukuze kungabi nazinsalela, umphumela ohlanzekile wokulwa nokushushuluza ongenakungcola, olungele izidingo zemvelo yokukhiqiza i-semiconductor.

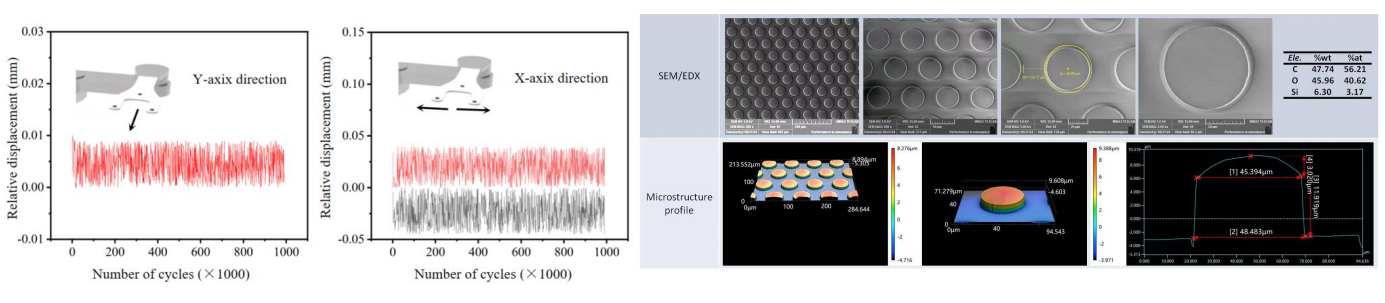

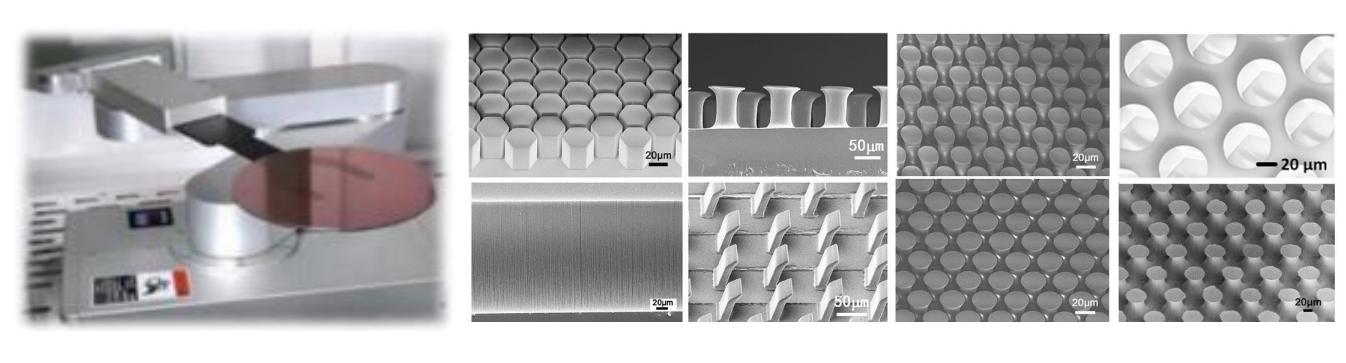

• Ngokunemba kwe-micro-nano structure array design, ukulawula okuhlakaniphile kwezici zokungqubuzana kwendawo, kuyilapho kugcinwa i-coefficient ephezulu yokungqubuzana kuyilapho kuzuzwa ukunamathela okuphansi kakhulu.

• Idizayini yemishini yokusetshenziswa kubonwa inika amandla ukusebenza okuhle kakhulu kwakho kokubili ukungqubuzana okuphezulu kwe-tangential (μ>2.5) nokunamathela okujwayelekile okuphansi (<0.1N/cm²).

• Izinto ze-polymer ezithuthukiswe ngokukhethekile imboni ye-semiconductor, efinyelela ukusebenza okuzinzile ngaphandle kokuncishiswa kokuphinda kusetshenziswe okungu-100,000 ngobuchwepheshe bokukhiqiza obuncane kanye ne-nano.

Isicelo se-Bionic anti-slip pad:

(1) Imboni ye-semiconductor

1. Ukwenziwa kwe-wafer:

· Ukuma okungasheleli ngesikhathi sokudlulisa amawafa amancane kakhulu afika kumayintshi angu-12 (50-300μm)

· Ukulungiswa okunembile kwesithwali esilucwecwana somshini we-lithography

· I-wafer non-slip liner yemishini yokuhlola

2. Ukuhlolwa kwephakheji:

· Ukulungiswa okungabhubhisi kwamadivayisi wamandla we-silicon carbide/gallium nitride

· Isibavi se-anti-slip ngesikhathi sokufakwa kwe-chip

· Hlola ukushaqeka nokushelela kwetafula lokuhlola

(2) Imboni ye-Photovoltaic

1. I-Silicon wafer processing:

· Ukulungiswa okungasheleli ngesikhathi sokusika induku ye-silicon ye-monocrystalline

· Iwafa ye-silicon encane kakhulu (<150μm) engasheleli

· I-Silicon wafer positioning yomshini wokuphrinta isikrini

2. Ukuhlanganiswa kwengxenye:

· Indiza yangemuva yengilazi elaminethiwe ngokungasheleli

· Ukubekwa kozimele

· Ibhokisi lokubopha lilungisiwe

(3) imboni yezithombe zikagesi

1. Iphaneli yokubonisa:

· Inqubo engasheleli yengilazi ye-OLED/LCD

· Ukuma okunembile kokulingana kwe-polarizer

· Imishini yokuhlola i-Shock-proof kanye ne-skid-proof

2. Izingxenye ze-Optical:

· Ukuhlanganisa imojuli yelensi ngokungasheleli

· Ukulungiswa kweprism/isibuko

· Uhlelo lwe-laser optical olushaqisayo

(4) Amathuluzi anembile

1. Inkundla yokunemba yomshini we-lithography iphikisana nokushelela

2. Ithebula lokulinganisa lemishini yokuhlonza alikwazi ukushaqeka

3. Imishini ezenzakalelayo ingalo engasheleli

Idatha yobuchwepheshe:

| Ukwakheka kwezinto: | C, O, Si |

| Ukuqina kogu (A) : | 50 ~ 55 |

| I-Elastic recovery coefficient: | 1.28 |

| Izinga lokushisa eliphezulu lokubekezelela: | 260℃ |

| I-friction coefficient: | 1.8 |

| Ukumelana ne-PLASMA: | Ukubekezelelana |

Izinsizakalo ze-XKH:

I-XKH ihlinzeka ngezinsizakalo ezigcwele zenqubo yokwenza ngokwezifiso umata we-bionic anti-slip, okuhlanganisa ukuhlaziywa kwesidingo, ukwakheka kwesikimu, ukuqinisekisa okusheshayo nokusekelwa kokukhiqiza ngobuningi. Ithembele kubuchwepheshe bokukhiqiza i-micro kanye ne-nano, i-XKH inikeza izixazululo ezichwepheshile zokulwa nokushelela kwezimboni ze-semiconductor, photovoltaic kanye ne-photoelectric, futhi isize ngempumelelo amakhasimende ukuba afinyelele imiphumela ebalulekile efana nokwehliswa kwezinga lemfucumfucu ukuya ku-0.005% kanye nokwenyuka kwesivuno ngo-15%.

Umdwebo onemininingwane