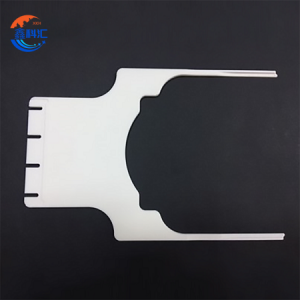

I-Alumina Ceramic End Effector / Fork Arm ye-Wafer kanye nokubamba kwe-Substrate

Umdwebo onemininingwane

Uhlolojikelele lwe-Alumina Ceramic End Effector

I-Alumina Ceramic End Effector, evame ukubizwa ngokuthi i-ceramic fork arm noma i-ceramic gripper, iyithuluzi elibalulekile elisetshenziswa ku-robotic automation kanye nemigqa yokukhiqiza yegumbi lokuhlanza. I-Alumina Ceramic End Effector ifakwe engalweni yerobhothi njengesixhumi esibonakalayo sokugcina somkhiqizo, esibhekele ukucosha, ukubamba, ukuqondanisa, nokudlulisa izingxenye ezizwela kakhulu njengama-silicon wafers, amaphaneli engilazi, noma izingxenye ze-microelectronic.

Ikhiqizwe kusukela ku-ultra-pure alumina ceramic (Al2O3), le ingalo yemfoloko ihlinzeka ngesixazululo esihlanzeke kakhulu nesizinzile sezindawo lapho ukungcoliswa kwensimbi, ukuguqulwa kwepulasitiki, noma ukukhiqizwa kwezinhlayiyana kungenakubekezelelwa.

Izinto ezibonakalayo - Kungani i-Alumina

Mayelana ne-Alumina Ceramic End Effector,Alumina (Al2O3) ingenye esungulwe kakhulu futhi enokwethenjelwa.ubunjiniyela obuphambili be-ceramics. Ibanga esilisebenzisayo (≥99.5% ubumsulwa) linikeza inhlanganisela eyingqayizivele yezimfanelo zomzimba nezamakhemikhali eziyenza ibe yinto yokuzikhethela kuma-semiconductor kanye nezicelo zevacuum:

-

Ukuqina okwedlulele- Ngesilinganiso sokuqina kwe-Mohs esingu-9, sinikeza ukuqina okuhlala isikhathi eside nokumelana nokuklwebheka.

-

Ukukhuthazela okushisayo- Igcina ubuqotho besakhiwo ngaphezu kuka-1600 ° C, insimbi esebenza kahle kakhulu nozakwabo be-polymer.

-

Ukufakwa kukagesi- Iqeda ukwakheka okumile futhi inikeze ukuvikelwa okuphelele kwe-dielectric.

-

Ukuzivikela kwamakhemikhali- Akuthintwa ama-asidi, ama-alkali, amagesi e-plasma, nezixazululo zokuhlanza ezinolaka.

-

Ingozi yokungcola ephansi kakhulu- Indawo engakhiphi, enokungqubuzana okuncane enciphisa ukukhishwa kwezinhlayiyana ezindlini ezihlanzekile.

Lezi zimfanelo zivumela iziphetho ze-alumina ceramic ukuthi zisebenze ngokungenasici ezindaweni ezinokhahlo, ezinembe kakhulu.

Izicelo Eziyinhloko ze-Alumina Ceramic End Effector

Ukuguquguquka kwezingalo ze-alumina ceramic end effectorfork kuzenza zibaluleke ezimbonini eziningi zobuchwepheshe obuphezulu:

-

Amasistimu wokuthutha ama-wafer semiconductor- Ukuhambisa ngokuvikelekile ama-wafers e-silicon ukusuka kunqubo kuya kucutshungulwa ngaphandle kokuklwebheka okuncane.

-

Ukukhiqizwa kwesibonisi sephaneli eyisicaba- Ukuphatha izingxenye zengilazi ezintekenteke zokwenziwa kwe-OLED, i-LCD, noma i-microLED.

-

Ukukhiqizwa kwe-Photovoltaic (PV).- Ukusekela ukulayishwa kwe-wafer yelanga kanye nokuthulula ngaphansi kwemijikelezo yerobhothi enesivinini esikhulu.

-

Ukuhlanganiswa kwengxenye ye-Optical kanye ne-electronic- Ukubamba izingxenye ezithambile njengezinzwa, ama-resistors, nama-chips amancane.

-

I-vacuum ne-cleanroom automation- Ukwenza imisebenzi enembayo ezimeni ezihlanzeke kakhulu, ezilawulwa yizinhlayiyana.

Kuso sonke isimo, i-Alumina Ceramic End Effector inikeza isixhumanisi esibalulekile phakathi kwe-robotic automation kanye nokuhanjiswa komkhiqizo.

Izinketho zokuklama nokwenza ngokwezifiso ze-Alumina Ceramic End Effector

Wonke umugqa wokukhiqiza unezidingo ezihlukile. Ngakho-ke, sihlinzeka ngezixazululo ezenziwe ngomthungo ze-Alumina Ceramic End Effector zosayizi abahlukahlukene wama-wafer, amasistimu wamarobhothi, nezindlela zokubamba:

Ukuhambelana kwe-wafer: Iphatha ama-wafers ukusuka ku-2" kuya ku-12" futhi ingalinganiswa ngezingxenye zangokwezifiso.

Izinketho zejiyomethri: Imfoloko eyodwa, imfoloko ekabili, i-multi-slot, noma umumo wangokwezifiso onezindawo zokuhlala ezihlanganisiwe.

Ukubamba i-vacuum: Iziteshi ozikhethela zokudonsa i-vacuum ukuze uthole ukwesekwa kwe-wafer ngaphandle kokuthinta.

Izixhumi ezibonakalayo ezikhuphukayo: Izimbobo zamabhawodi ngokwezifiso, ama-flange, noma amadizayini afakiwe ukuze alingane nanoma iyiphi ingalo yerobhothi.

Ukuqedwa kobuso: Indawo epholishiwe noma eqedelwe kakhulu (yehlele ku-Ra <0.15 μm).

Amaphrofayili e-Edge: Imiphetho e-Chamfered noma eyindilinga ukuze kuvikeleke i-wafer ephezulu.

Ithimba lethu lobunjiniyela be-Alumina Ceramic End Effector lingasebenza ngemidwebo ye-CAD yekhasimende noma izingxenye zesampula, liqinisekise ukuhlanganiswa okungenamthungo ezinhlelweni ezizenzakalelayo ezikhona.

Izinzuzo Eziyinhloko Ze-Alumina Ceramic End Effecters

| Isici | Kungani Kubalulekile? |

|---|---|

| Ukunemba kwe-Dimensional | Igcina ukuqondana okuphelele ngisho nasemijikelezweni enesivinini esikhulu, ephindaphindayo. |

| Ayingcolisi | Ayikhiqizi nhlobo izinhlayiya, ihlangabezana nezidingo eziqinile zegumbi lokuhlanza. |

| Ubufakazi bokushisa nokugqwala | Ibekezelela izinyathelo zokucubungula ezinolaka kanye nokushaqeka okushisayo. |

| Ayikho inkokhiso emile | Ivikela amawafa azwelayo nezingxenye engozini ye-electrostatic. |

| Ilula kodwa iqinile | Inikeza ukuqina okuphezulu ngaphandle kokubeka engcupheni umthwalo wengalo yerobhothi. |

| Impilo yesevisi enwetshiwe | Idlula izingalo zensimbi neze-polymer esikhathini sokuphila nokuthembeka. |

Ukuqhathaniswa Okubalulekile kwe-Alumina Ceramic End Effector

| Isibaluli | Plastic Fork Arm | I-Aluminium/Metal Fork Arm | I-Alumina Ceramic Fork Arm |

|---|---|---|---|

| Ukuqina | Phansi | Maphakathi | Phezulu kakhulu |

| I-Thermal Range | ≤ 150°C | ≤ 500°C | Kufika ku-1600°C |

| Ukuzinza Kwamakhemikhali | Impofu | Kuphakathi | Kuhle kakhulu |

| Isilinganiso segumbi lokuhlanza | Phansi | Isilinganiso | Ilungele Ikilasi 100 noma okungcono |

| Gqoka Ukumelana | Inomkhawulo | Kuhle | Okuvelele |

| Ileveli yokwenza ngokwezifiso | Kuphakathi | Inomkhawulo | Okubanzi |

Imibuzo Evame Ukubuzwa (FAQ) Ye-Alumina Ceramic End Effector

Q1: Yini eyenza i-alumina ceramic end effector ihluke kweyensimbi?

A1:Ngokungafani nezingalo ze-aluminium noma zensimbi, i-alumina ceramic ayigqwali, yonakali, noma yethula ama-ion ensimbi kuzinqubo ze-semiconductor. Ihlala izinzile ngaphansi kwezimo ezimbi kakhulu futhi ayikhiphi nhlobo izinhlayiya.

Q2: Ingabe lezi ze-Alumina Ceramic End Effect zingasetshenziswa emakamelweni ane-vacuum ephezulu kanye ne-plasma?

A2:Yebo. I-Alumina Ceramic injalookungakhiphifuthi imelana ne-plasma, eyenza ibe yinto ekhethwayo yokucubungula i-vacuum kanye nemishini yokufaka.

Q3: Zingenziwa kanjani ngokwezifiso lezi zingalo zemfoloko ze-Alumina Ceramic End Effector?

A3:Wonke amayunithi angabangokwezifiso ngokugcwele—okuhlanganisa umumo, izikhala, izimbobo zokudonsa, isitayela sokukhweza, kanye nokuqedwa konqenqema—ukuze kufane nezidingo zesistimu yakho yerobhothi.

Q4: Ingabe zintekenteke?

A4:Ngenkathi i-ceramic inobukhazikhazi bemvelo, ubunjiniyela bethu bokuklama basabalalisa umthwalo ngokulinganayo futhi bunciphise amaphuzu okucindezeleka. Uma iphathwa ngendlela efanele, impilo yesevisi ivame ukudlula leyo yensimbi noma enye ye-polymer.

Mayelana NATHI

I-XKH igxile ekuthuthukisweni kobuchwepheshe obuphezulu, ukukhiqiza, nokudayiswa kwengilazi ekhethekile yokubona nezinto ezintsha zekristalu. Imikhiqizo yethu isebenza ngogesi obonakalayo, ugesi wabathengi, kanye nezempi. Sinikezela ngezinto ezibonakalayo ze-Sapphire, izembozo zamalensi omakhalekhukhwini, i-Ceramics, i-LT, i-Silicon Carbide SIC, i-Quartz, namawafa ekristalu e-semiconductor. Ngobungcweti abanamakhono nemishini esezingeni eliphezulu, sihamba phambili ekucutshungulweni komkhiqizo okungajwayelekile, sihlose ukuba yibhizinisi elihamba phambili le-optoelectronic materials high-tech.