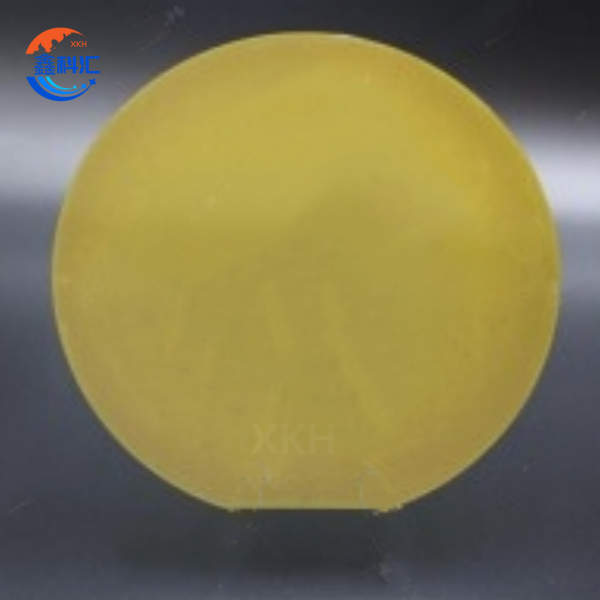

6 intshi Conductive crystal eyodwa SiC on polycrystalline SiC composite substrate Ububanzi 150mm P uhlobo N

Imingcele yezobuchwepheshe

| Usayizi: | 6 intshi |

| Ububanzi: | 150 mm |

| Ubukhulu: | 400-500 μm |

| I-Monocrystalline SiC Film Parameters | |

| I-Polytype: | I-4H-SiC noma i-6H-SiC |

| I-Doping Concentration: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| Ubukhulu: | 5-20 μm |

| Ukumelana Neshidi: | 10-1000 Ω/sq |

| I-Electron Mobility: | 800-1200 cm²/Vs |

| I-Hole Mobility: | 100-300 cm²/Vs |

| I-Polycrystalline SiC Buffer Layer Parameters | |

| Ubukhulu: | 50-300 μm |

| I-Thermal Conductivity: | 150-300 W/m·K |

| I-Monocrystalline SiC Substrate Parameters | |

| I-Polytype: | I-4H-SiC noma i-6H-SiC |

| I-Doping Concentration: | 1×10¹⁴ - 1×10¹⁸ cm⁻³ |

| Ubukhulu: | 300-500 μm |

| Usayizi Wokusanhlamvu: | > 1 mm |

| Ukuqina Kobuso: | <0.3 mm RMS |

| Mechanical & Electrical Properties | |

| Ukuqina: | 9-10 Mohs |

| Amandla Acindezelayo: | 3-4 GPA |

| Amandla Okuqina: | 0.3-0.5 GPA |

| Amandla Enkundla Yokuhlukaniswa: | > 2 MV/cm |

| Isamba Sokubekezelela Umthamo: | > 10 Mr |

| Ukumelana Nomphumela Womcimbi Owodwa: | > 100 MeV·cm²/mg |

| I-Thermal Conductivity: | 150-380 W/m·K |

| I-Operating Temperature Range: | -55 kuya ku-600°C |

Izimpawu Ezisemqoka

I-6-inch conductive monocrystalline SiC ku-polycrystalline SiC composite substrate inikeza ibhalansi eyingqayizivele yesakhiwo sezinto ezibonakalayo nokusebenza, okuyenza ifanelekele indawo yezimboni enenkani:

I-1.Izindleko Ezisebenzayo: Isisekelo se-polycrystalline SiC sinciphisa kakhulu izindleko uma kuqhathaniswa ne-SiC ye-monocrystalline egcwele, kuyilapho isendlalelo esisebenzayo se-monocrystalline SiC siqinisekisa ukusebenza kwebanga ledivayisi, ilungele izinhlelo zokusebenza ezizwelayo ezindleko.

2.Izakhiwo Zikagesi Ezikhethekile: Isendlalelo se-monocrystalline SiC sibonisa ukuhamba kwenkampani yenethiwekhi (>500 cm²/V·s) nokuminyana okunokonakala, okusekela imvamisa ephezulu nokusebenza kwedivayisi yamandla aphezulu.

I-3.Ukuqina Kwezinga Lokushisa Okuphezulu: Ukumelana nokushisa okuphezulu kwe-SiC (> 600 ° C) kuqinisekisa ukuthi i-substrate eyinhlanganisela ihlala izinzile ngaphansi kwezimo ezimbi kakhulu, okwenza ifaneleke izimoto zikagesi kanye nezicelo zezimoto zezimboni.

4.6-intshi Usayizi We-wafer Ojwayelekile: Uma kuqhathaniswa nama-substrate avamile angu-4-intshi we-SiC, ifomethi engu-6-intshi inyusa isivuno se-chip ngaphezu kuka-30%, kunciphisa izindleko zeyunithi ngayinye.

I-5.Idizayini Yokuqhuba: Izendlalelo zohlobo lwe-N-doped ngaphambili noma uhlobo lwe-P zinciphisa izinyathelo zokufakelwa kwe-ion ekukhiqizeni idivayisi, ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nesivuno.

6.Ukuphathwa Okushisayo Okuphezulu: I-polycrystalline SiC base base-thermal conductivity (~120 W/m·K) isondela kuleyo ye-monocrystalline SiC, ibhekana ngokuphumelelayo nezinselele zokulahla ukushisa kumadivayisi anamandla amakhulu.

Lezi zici zibeka i-6-inch conductive monocrystalline SiC ku-polycrystalline SiC composite substrate njengesixazululo sokuncintisana sezimboni ezifana namandla avuselelekayo, ezokuthutha ngesitimela, kanye ne-aerospace.

Izicelo Eziyinhloko

I-6-inch conductive monocrystalline SiC ku-polycrystalline SiC composite substrate isetshenziswe ngempumelelo emikhakheni eminingana edingeka kakhulu:

I-1.Electric Vehicle Powertrains: Isetshenziswa kuma-SiC MOSFET ane-voltage ephezulu kanye nama-diode ukuze kuthuthukiswe ukusebenza kahle kwe-inverter nokwelula ububanzi bebhethri (isb, amamodeli we-Tesla, we-BYD).

2.Ama-Industrial Motor Drives: Inika amandla amamojula wamandla aphezulu, ukushintsha-imvamisa ephezulu, ukunciphisa ukusetshenziswa kwamandla emishinini esindayo kanye nezinjini zomoya.

I-3.Ama-Photovoltaic Inverters: Amadivayisi we-SiC athuthukisa ukusebenza kahle kokuguqulwa kwelanga (>99%), kuyilapho i-substrate ehlanganisiwe inciphisa kakhulu izindleko zesistimu.

4.Ezokuthutha Ngojantshi: Kusetshenziswa kuziguquli zokudonsa kumzila wesitimela wesivinini esikhulu kanye nezinhlelo zesitimela esihamba ngaphansi komhlaba, ezinikeza ukumelana nogesi ophezulu (>1700V) nezici zefomu elihlangene.

5.I-Aerospace: Ilungele izinhlelo zamandla wesathelayithi namasekhethi okulawula injini yendiza, ekwazi ukumelana nezinga lokushisa elidlulele kanye nemisebe.

Ekwenziweni okungokoqobo, i-6-inch conductive monocrystalline SiC ku-polycrystalline SiC composite substrate ihambisana ngokugcwele nezinqubo ezijwayelekile zedivayisi ye-SiC (isb, i-lithography, i-etching), ayidingi ukutshalwa kwezimali okungeziwe.

Izinsizakalo ze-XKH

I-XKH ihlinzeka ngokusekelwa okuphelele kwe-6-inch conductive monocrystalline SiC ku-polycrystalline SiC composite substrate, ehlanganisa i-R&D ekukhiqizeni ngobuningi:

1.Ukwenza ngendlela oyifisayo: Ugqinsi lwesendlalelo se-monocrystalline olulungisekayo (5–100 μm), ukugxiliswa kwe-doping (1e15–1e19 cm⁻³), nokuma kwekristalu (4H/6H-SiC) ukuze kuhlangatshezwane nezidingo zedivayisi ezihlukahlukene.

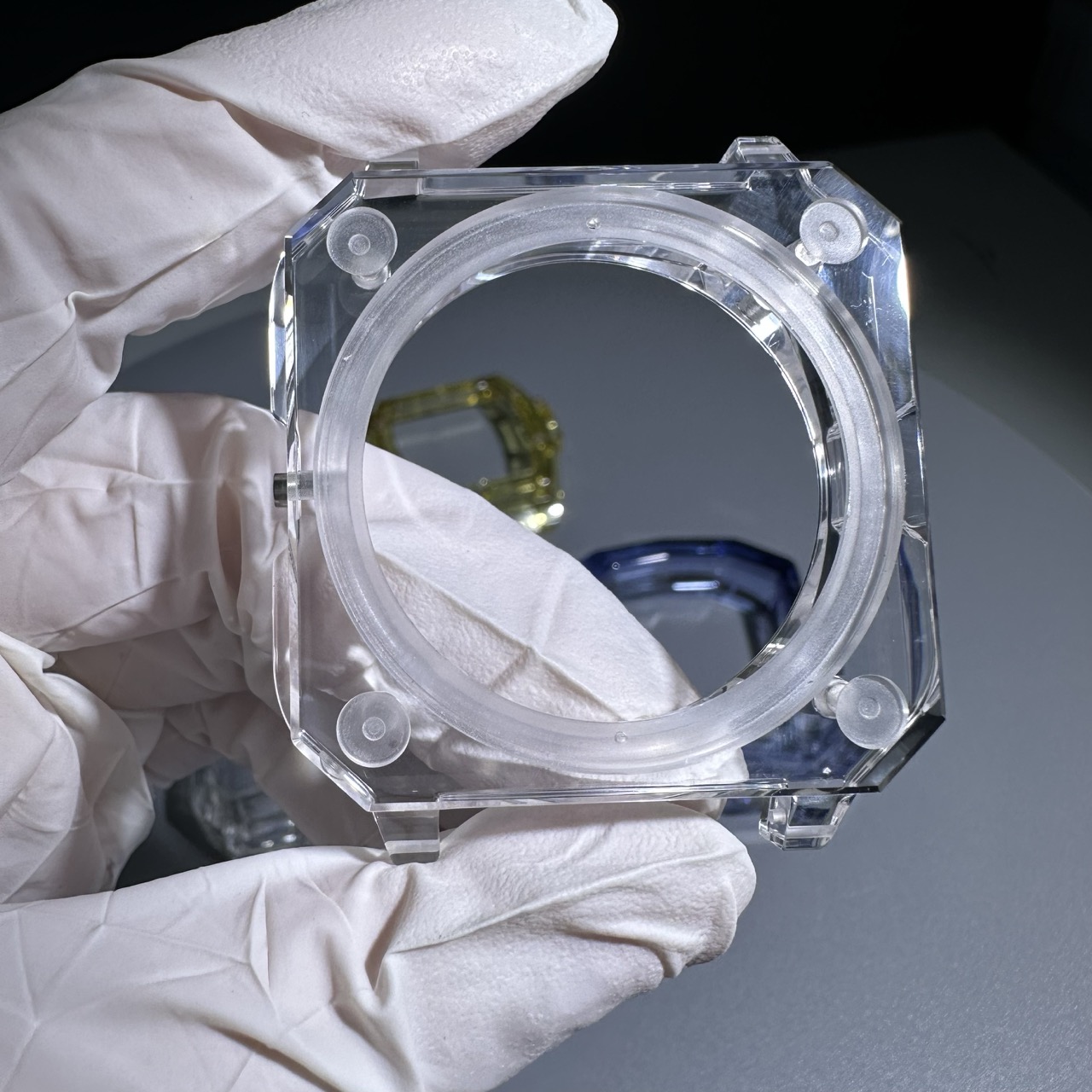

I-2.Wafer Processing: Ukunikezwa kwenqwaba yama-substrates angu-6-intshi anokunciphisa ingemuva kanye nezinsizakalo ze-metallization zokuhlanganiswa kwepulaki nokudlala.

3.Ukuqinisekisa Kobuchwepheshe: Kufaka phakathi ukuhlaziywa kwe-XRD crystallinity, ukuhlolwa komthelela wehholo, kanye nesilinganiso sokumelana nokushisa ukuze kusheshiswe ukufaneleka kokubalulekile.

I-4.I-Prototyping esheshayo: amasampula angu-2 kuya kwangu-4-intshi (inqubo efanayo) ukuze izikhungo zocwaningo zisheshise imijikelezo yokuthuthukiswa.

5.Ukuhlaziywa Kokwehluleka Nokuthuthukisa: Izisombululo zezinga lezinto ezibonakalayo zokucubungula izinselele (isb, amaphutha e-epitaxial layer).

Umgomo wethu ukusungula i-6-inch conductive monocrystalline SiC ku-polycrystalline SiC composite substrate njengesixazululo esikhethwayo sokusebenza kwezindleko zama-SiC power electronics, sinikeza ukusekelwa kokuphela kusukela ku-prototyping kuya ekukhiqizweni kwevolumu.

Isiphetho

I-6-inch conductive monocrystalline SiC ku-polycrystalline SiC composite substrate ifinyelela ibhalansi ephumelelayo phakathi kokusebenza nezindleko ngesakhiwo sayo esixubile se-mono/polycrystalline. Njengoba izimoto zikagesi zanda futhi i-Industrial 4.0 ithuthuka, le substrate inikeza isisekelo esithembekile sezinto zikagesi zesizukulwane esilandelayo. I-XKH iyakwamukela ukusebenzisana ukuze kuqhutshekwe nokuhlola amandla obuchwepheshe be-SiC.