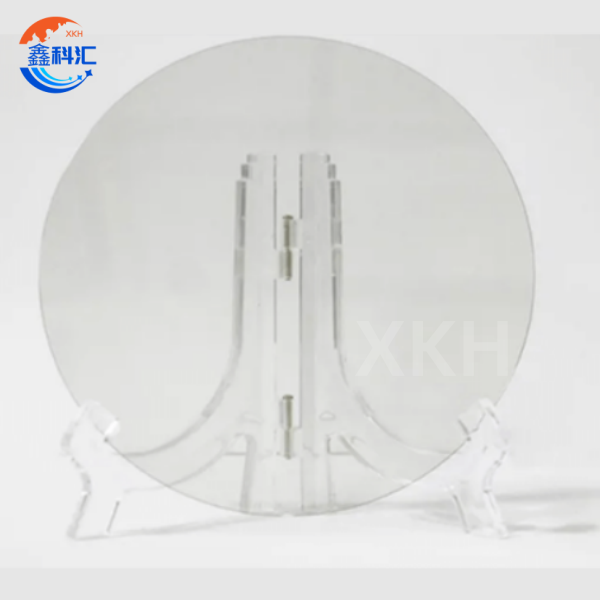

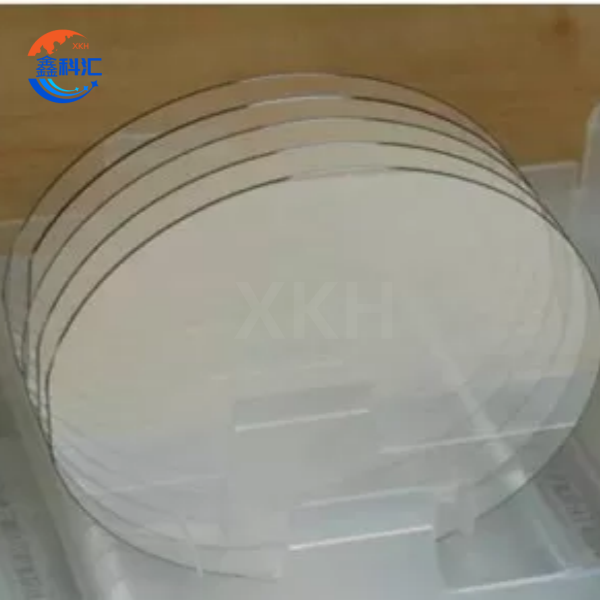

6 Intshi 4H SEMI Uhlobo lwe-SiC eyinhlanganisela ye-substrate Ukuqina 500μm TTV≤5μm MOS ibanga

Imingcele yezobuchwepheshe

| Izinto | Ukucaciswa | Izinto | Ukucaciswa |

| Ububanzi | 150±0.2 mm | Ngaphambili (Si-face) roughness | I-Ra≤0.2 nm (5μm×5μm) |

| I-Polytype | 4H | I-Edge Chip, Scratch, Crack (ukuhlola okubonakalayo) | Lutho |

| Ukungazweli | ≥1E8 Ω·cm | I-TTV | ≤5 μm |

| Dlulisa Ukuqina kwesendlalelo | ≥0.4 μm | I-Wap | ≤35 μm |

| Okungenalutho (2mm>D>0.5mm) | ≤5 i-ea/Wafer | Ubukhulu | 500±25 μm |

Izici Eziyinhloko

1. Ukusebenza Okuphakeme Okujwayelekile

I-substrate eyinhlanganisela ye-SiC eyi-6-inch semi-insulating semi-insulating isebenzisa ukwakheka kwesendlalelo se-dielectric esesigabeni, iqinisekisa ukuhlukahluka okungaguquki kwe-dielectric engu-<2% ku-Ka-band (26.5-40 GHz) futhi ithuthukisa ukungaguquguquki kwesigaba ngo-40%. Ukwenyuka ngo-15% ekusebenzeni kahle kanye no-20% wokusetshenziswa kwamandla okuphansi kumamojula we-T/R kusetshenziswa le substrate.

2. Ukuphathwa kwe-Thermal Breakthrough

Isakhiwo esiyinhlanganisela "yebhuloho elishisayo" esiyingqayizivele sinika amandla ukuhanjiswa kwe-thermal okungemuva okungu-400 W/m·K. Kumamojula we-PA esisekelo se-28 GHz 5G, izinga lokushisa le-junction likhuphuka ngo-28 ° C kuphela ngemva kwamahora angu-24 wokusebenza okuqhubekayo-50 ° C ngaphansi kunezixazululo ezivamile.

3. Superior Wafer Quality

Ngokusebenzisa indlela ye-Physical Vapor Transport (PVT) ethuthukisiwe, sifinyelela ukuminyana kokugudluzwa okungu-<500/cm² kanye Nokwehluka Kokuqina Kwengqikithi (TTV) <3 μm.

4. Ukukhiqiza-Ukucubungula Okunobungane

Inqubo yethu yokuhlanganisa i-laser annealing eklanyelwe ngokukhethekile inxanxathela eyinhlanganisela ye-SiC engu-6-inch semi-insulating inciphisa ukuminyana kwendawo ngama-oda amabili obukhulu ngaphambi kwe-epitaxy.

Izicelo Eziyinhloko

1. I-5G Base Station Core Components

Kuma-antenna amakhulu we-MIMO, amadivayisi we-GaN HEMT kuma-substrates ayinhlanganisela ye-SiC eyinhlanganisela engu-6-intshi athola amandla okukhipha angu-200W kanye > nokusebenza kahle okungu-65%. Ukuhlolwa kwenkundla ku-3.5 GHz kubonise ukukhuphuka okungama-30% kwirediyasi yokukhava.

2. Amasistimu Wokuxhumana Ngesathelayithi

Ama-transceivers wesathelayithi e-Low-Earth (LEO) asebenzisa le substrate abonisa i-EIRP engu-8 dB ephakeme ku-Q-band (40 GHz) kuyilapho ehlisa isisindo ngo-40%. Amatheminali e-SpaceX Starlink ayamukele ukuze akhiqizwe ngobuningi.

3. I-Military Radar Systems

Amamojula we-radar ye-Phased-array T/R kule substrate afinyelela umkhawulokudonsa ongu-6-18 GHz kanye nenani lomsindo eliphansi njengo-1.2 dB, andisa ububanzi bokutholwa ngo-50 km kumasistimu e-radar axwayisayo.

4. I-Automotive Millimeter-Wave Radar

79 GHz ama-radar chips ezimoto asebenzisa le substrate athuthukisa ukulungiswa kwe-angular ukuya ku-0.5°, ahlangabezana nezimfuneko zokushayela okuzenzakalelayo kwe-L4.

Sinikeza isixazululo esibanzi sesevisi esenziwe ngokwezifiso sama-substrates ayinhlanganisela ye-SiC eyi-6-inch semi-insulating. Mayelana nokwenza ngendlela oyifisayo amapharamitha wento, sisekela ukulawulwa okunembile kokumelana phakathi kwebanga elingu-10⁶-10¹⁰ Ω·cm. Ikakhulukazi ezinhlelweni zempi, singanikeza inketho yokumelana nokuphakama okuphezulu kakhulu >10⁹ Ω·cm. Inikeza ukucaciswa kogqinsi okuthathu okungu-200μm, 350μm kanye no-500μm ngesikhathi esisodwa, nokubekezelelana okulawulwa ngokuqinile ngaphakathi kuka-±10μm, kuhlangabezana nezidingo ezihlukene kusukela kumadivayisi anemvamisa ephezulu kuya kuzinhlelo zokusebenza zamandla aphezulu.

Ngokuphathelene nezinqubo zokwelashwa kwendawo, sinikeza izixazululo ezimbili zobungcweti: I-Chemical Mechanical Polishing (CMP) ingafinyelela ukucaba kwendawo ye-athomu nge-Ra<0.15nm, ehlangabezana nezidingo ezidinga kakhulu zokukhula kwe-epitaxial; Ubuchwepheshe bokwelapha obulungile be-epitaxial bezidingo zokukhiqiza ngokushesha bungahlinzeka ngezindawo ezibushelelezi ezino-Sq<0.3nm kanye nogqinsi lwe-oxide eyinsalela engu-<1nm, okwenza kube lula inqubo yokwelapha kusengaphambili ekupheleni kweklayenti.

I-XKH ihlinzeka ngezixazululo eziphelele ezenziwe ngokwezifiso zama-SiC ahlanganisiwe ayizingxenye ezingaphansi eziyi-6-intshi

1. Ukwenza Ngokwezifiso Ipharamitha Yezinto

Sinikeza ukushuna okunembile kokumelana nokumelana phakathi kwebanga elingu-10⁶-10¹⁰ Ω·cm, ngezinketho ezikhethekile zokumelana nokuphakama okuphezulu >10⁹ Ω·cm ezitholakalayo ezinhlelweni zempi/ze-aerospace.

2. Ukujiya Imininingwane

Izinketho ezintathu zobukhulu obujwayelekile:

· 200μm (elungiselelwe amadivayisi anemvamisa ephezulu)

· 350μm (ukucaciswa okujwayelekile)

· 500μm (yenzelwe izinhlelo zokusebenza zamandla aphezulu)

· Zonke izinhlobo zigcina ukubekezelela ukujiya okuqinile okungu-±10μm.

3. Ama-Surface Treatment Technologies

I-Chemical Mechanical Polishing (CMP): Ifinyelela izinga le-atomic flat surface nge-Ra<0.15nm, ihlangabezana nezidingo eziqinile zokukhula kwe-epitaxial ze-RF namadivayisi kagesi.

4. I-Epi-Ready Surface Processing

· Iletha izindawo ezibushelelezi ezinobukhulu obungu-Sq<0.3nm

· Ilawula ukujiya kwe-oxide yemvelo kuya ku-<1nm

· Isusa kuze kufike ku-3 izinyathelo zokucubungula ngaphambilini ezikhungweni zamakhasimende