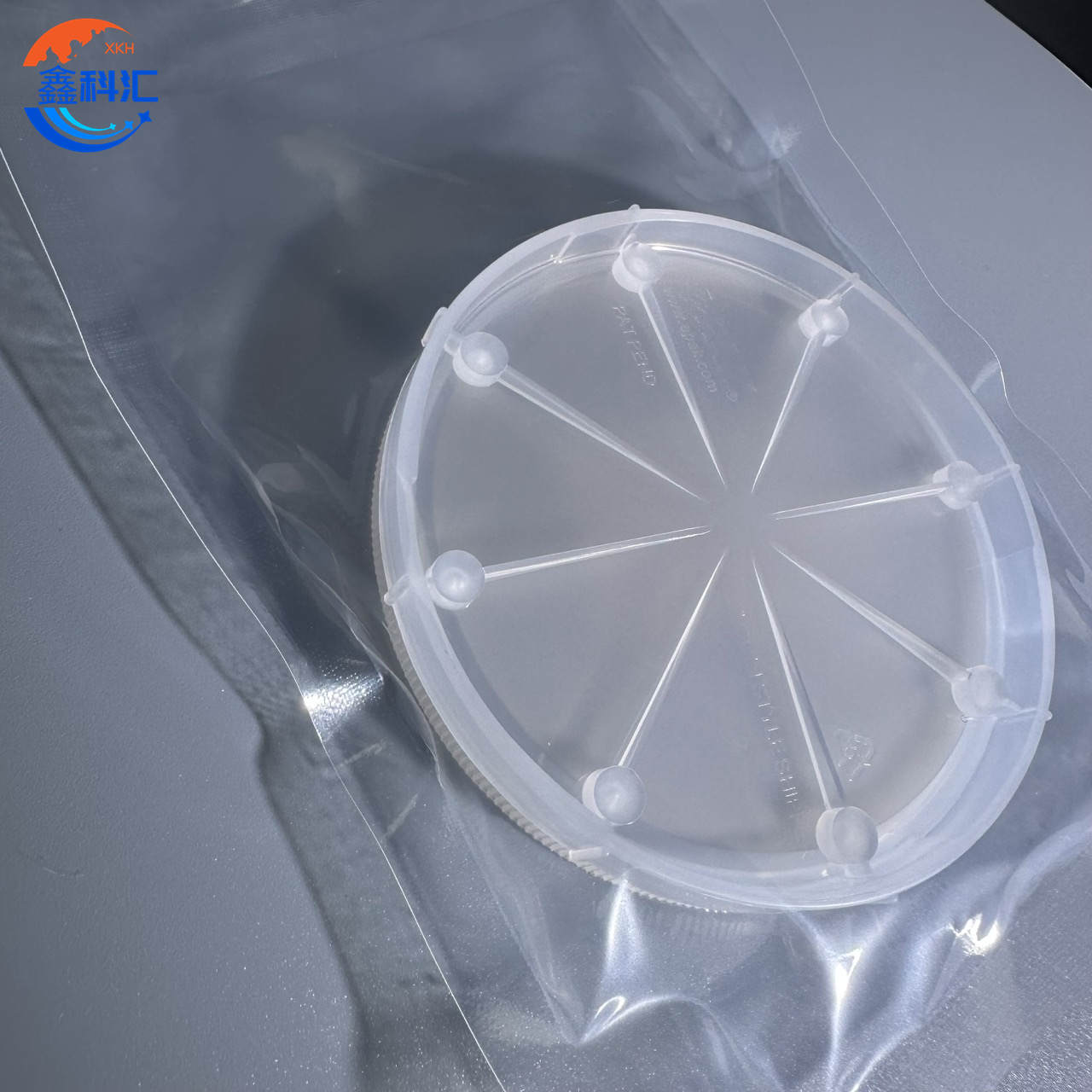

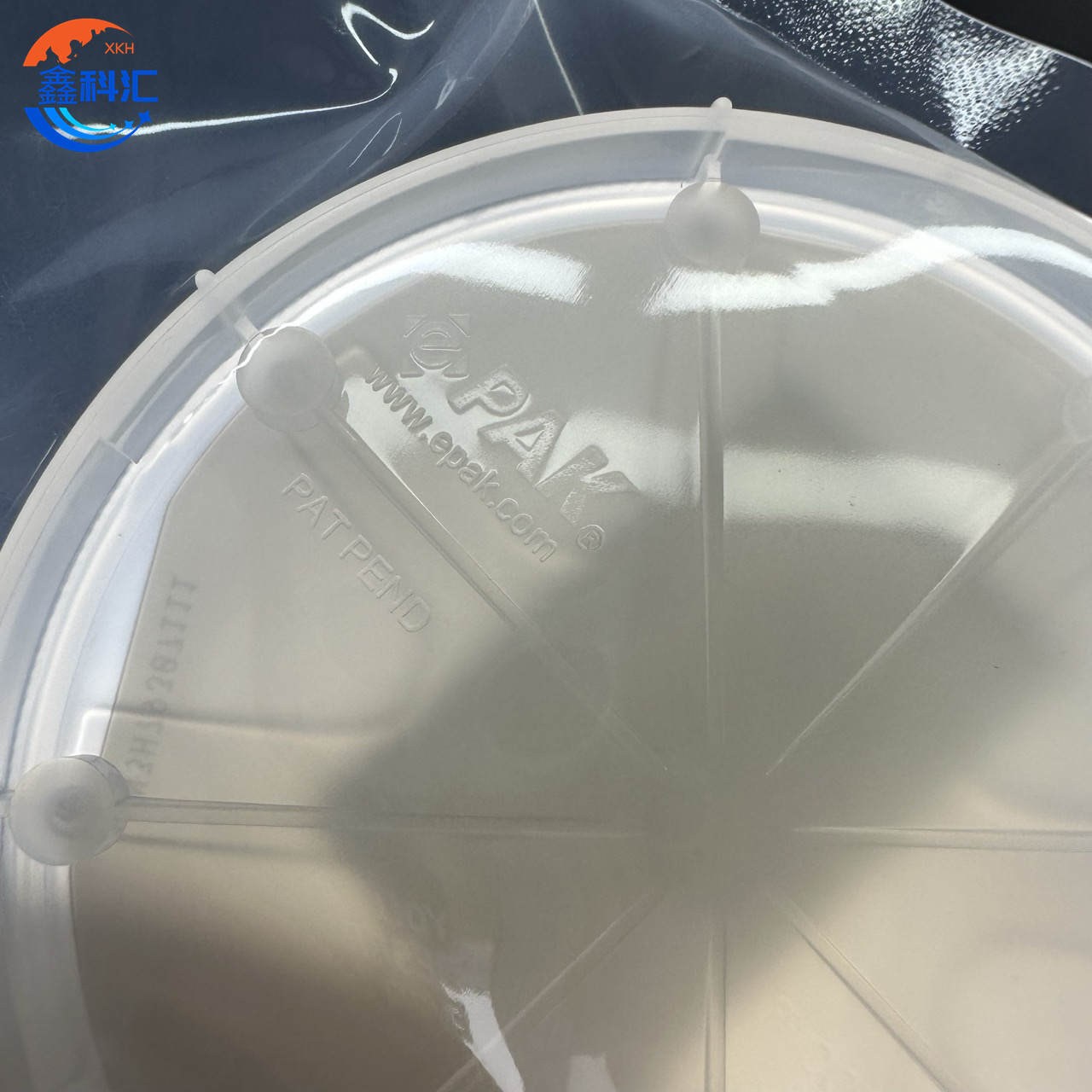

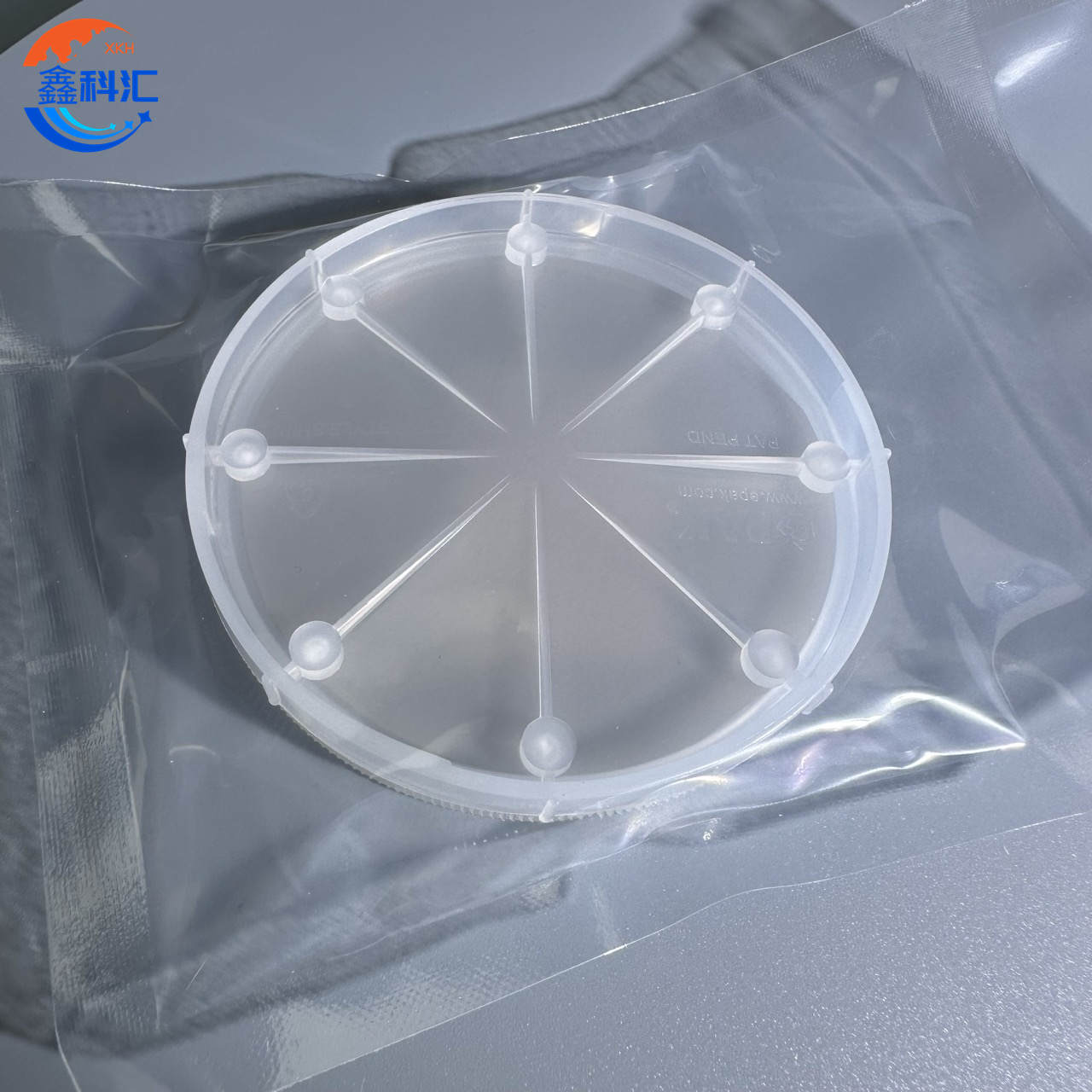

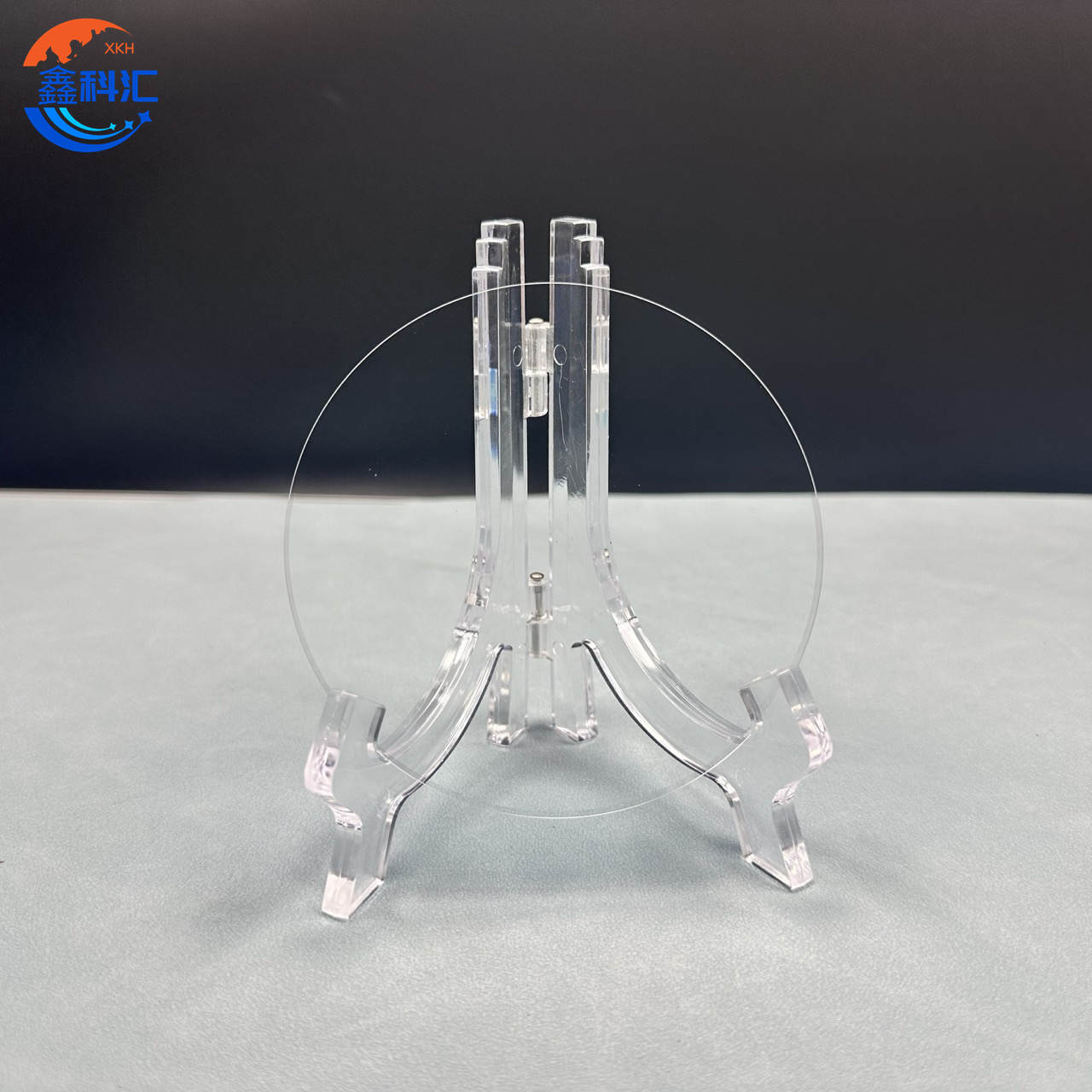

3inch High purity Semi-Insulating (HPSI) SiC wafer 350um Dummy grade Prime grade

Isicelo

Amawafa e-HPSI SiC abalulekile ekuvumelaneni namadivayisi kagesi esizukulwane esilandelayo, asetshenziswa ezinhlotsheni zokusebenza ezisebenza kahle kakhulu:

Amasistimu Okuguqula Amandla: Amawafa e-SiC asebenza njengento eyinhloko yamadivayisi kagesi njengama-MOSFET, ama-diode, nama-IGBT, abalulekile ekuguquleni amandla ngendlela efanele kumasekhethi kagesi. Lezi zingxenye zitholakala kumandla asebenza kahle kakhulu, amadrayivu ezimoto, nama-inverters ezimboni.

Izimoto zikagesi (EVs):Isidingo esikhulayo sezimoto zikagesi sidinga ukusetshenziswa kwamandla kagesi asebenza kahle, futhi ama-wafer e-SiC ahamba phambili kulolu shintsho. Kuma-EV powertrains, lawa mawafa ahlinzeka ngokusebenza kahle okuphezulu namandla okushintsha ngokushesha, anikela ezikhathini zokushaja ngokushesha, ibanga elide, nokusebenza okuthuthukisiwe kukonke kwemoto.

Amandla Avuselelekayo:Ezinhlelweni zamandla avuselelekayo njengamandla elanga nawomoya, amawafa e-SiC asetshenziswa kuma-inverter nama-converter anika amandla ukuthwebula nokusabalalisa amandla asebenza kahle kakhudlwana. I-thermal conductivity ephezulu kanye ne-higher breakdown voltage ye-SiC iqinisekisa ukuthi lezi zinhlelo zisebenza ngokuthembekile, ngisho nangaphansi kwezimo zemvelo ezimbi kakhulu.

I-Industrial Automation namarobhothi:Ama-electronics asebenza kahle kakhulu ezinhlelweni ezishintshayo zezimboni namarobhothi adinga amadivayisi akwazi ukushintsha ngokushesha, ukuphatha imithwalo emikhulu yamandla, nokusebenza ngaphansi kwengcindezi ephezulu. Ama-semiconductors asuselwa ku-SiC ahlangabezana nalezi zidingo ngokuhlinzeka ngokusebenza kahle nokuqina okuphezulu, ngisho nasezindaweni zokusebenza ezinokhahlo.

Amasistimu ezokuxhumana:Kungqalasizinda yezokuxhumana, lapho ukuthembeka okuphezulu kanye nokuguqulwa kwamandla okusebenzayo kubalulekile, ama-wafers e-SiC asetshenziswa ezintweni zamandla kanye neziguquli ze-DC-DC. Amadivayisi e-SiC asiza ukunciphisa ukusetshenziswa kwamandla futhi athuthukise ukusebenza kwesistimu ezikhungweni zedatha namanethiwekhi okuxhumana.

Ngokuhlinzeka ngesisekelo esiqinile sezinhlelo zokusebenza zamandla aphezulu, iwafa ye-HPSI SiC inika amandla ukuthuthukiswa kwemishini eyonga amandla, isiza izimboni zishintshele ezixazululweni eziluhlaza, ezizinzile.

Izakhiwo

| umsebenzi | Ibanga Lokukhiqiza | IBanga Lokucwaninga | Dummy Grade |

| Ububanzi | 75.0 mm ± 0.5 mm | 75.0 mm ± 0.5 mm | 75.0 mm ± 0.5 mm |

| Ubukhulu | 350 µm ± 25 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| I-Wafer Orientation | Ku-eksisi: <0001> ± 0.5° | Ku-eksisi: <0001> ± 2.0° | Ku-eksisi: <0001> ± 2.0° |

| I-Micropipe Density yama-95% wama-Wafers (MPD) | ≤ 1 cm⁻² | ≤ 5 cm⁻² | ≤ 15 cm⁻² |

| Ukungazweli Kagesi | ≥ 1E7 Ω·cm | ≥ 1E6 Ω·cm | ≥ 1E5 Ω·cm |

| I-Dopant | Kuhlehlisiwe | Kuhlehlisiwe | Kuhlehlisiwe |

| Isisekelo se-Flat Orientation | {11-20} ± 5.0° | {11-20} ± 5.0° | {11-20} ± 5.0° |

| Ubude Befulethi obuyisisekelo | 32.5 mm ± 3.0 mm | 32.5 mm ± 3.0 mm | 32.5 mm ± 3.0 mm |

| Ubude Befulethi besibili | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| I-Flat Orientation yesibili | Ubheke phezulu: 90° CW ukusuka efulethini lokuqala ± 5.0° | Ubheke phezulu: 90° CW ukusuka efulethini lokuqala ± 5.0° | Ubheke phezulu: 90° CW ukusuka efulethini lokuqala ± 5.0° |

| Ukukhishwa komkhawulo | 3 mm | 3 mm | 3 mm |

| LTV/TTV/Bow/Warp | 3 µm / 10 µm / ±30 µm / 40 µm | 3 µm / 10 µm / ±30 µm / 40 µm | 5 µm / 15 µm / ±40 µm / 45 µm |

| Ukuqina Kobuso | Ubuso buka-C: bupholishiwe, ubuso be-Si: CMP | Ubuso buka-C: bupholishiwe, ubuso be-Si: CMP | Ubuso buka-C: bupholishiwe, ubuso be-Si: CMP |

| Imifantu (ihlolwe ngokukhanya okukhulu) | Lutho | Lutho | Lutho |

| I-Hex Plates (ihlolwe ngokukhanya okuphezulu) | Lutho | Lutho | Indawo eqoqiwe 10% |

| Izindawo ze-Polytype (zihlolwe ngokukhanya okukhulu) | Indawo ehlanganisiwe 5% | Indawo ehlanganisiwe 5% | Indawo eqoqiwe 10% |

| Ama-scratches (ahlolwe ngokukhanya okukhulu) | ≤ 5 imihuzuko, ubude obukhulayo ≤ 150 mm | ≤ 10 imihuzuko, ubude obuningi ≤ 200 mm | ≤ 10 imihuzuko, ubude obuningi ≤ 200 mm |

| I-Edge Chipping | Akukho okuvunyelwe ≥ 0.5 mm ububanzi nokujula | 2 okuvunyelwe, ≤ 1 mm ububanzi nokujula | 5 okuvunyelwe, ≤ 5 mm ububanzi nokujula |

| I-Surface Contamination (ihlolwe ngokukhanya okukhulu) | Lutho | Lutho | Lutho |

Izinzuzo Eziyinhloko

Ukusebenza Okushisayo Okuphezulu: I-Thermal conductivity ephezulu ye-SiC iqinisekisa ukuchithwa kokushisa okusebenzayo kumadivayisi kagesi, okuwavumela ukuthi asebenze kumazinga aphezulu wamandla namaza ngaphandle kokushisisa ngokweqile. Lokhu kuhumusha kumasistimu amancane, asebenza kahle kakhulu kanye nempilo ende yokusebenza.

I-High Breakdown Voltage: Nge-bandgap ebanzi uma iqhathaniswa ne-silicon, ama-wafers e-SiC asekela izinhlelo zokusebenza ezinamandla kagesi, okuzenza zilungele izingxenye ze-elekthronikhi ezidinga ukumelana nokuqhekeka okuphezulu, njengasezimotweni zikagesi, amasistimu wamandla egridi, nezinhlelo zamandla avuselelekayo.

Ukulahleka Kwamandla Okuncishisiwe: Ukumelana okuphansi nesivinini sokushintsha ngokushesha samadivayisi we-SiC siphumela ekulahlekelweni kwamandla okuncishisiwe phakathi nokusebenza. Lokhu akuthuthukisi ukusebenza kahle kuphela kodwa futhi kuthuthukisa ukonga konke kwamandla kwezinhlelo ezisetshenziswa kuzo.

Ukwethenjwa Okuthuthukisiwe Ezindaweni Eziqinile: Izakhiwo ze-SiC eziqinile ziyivumela ukuthi isebenze ezimweni ezimbi kakhulu, njengamazinga okushisa aphezulu (afika ku-600°C), ama-voltage aphezulu, namaza aphezulu. Lokhu kwenza ama-wafer e-SiC afanelekele izicelo zezimboni, ezezimoto, namandla.

Ukusebenza Kahle Kwezamandla: Amadivayisi e-SiC anikeza ukuminyana kwamandla okuphezulu kunamadivayisi endabuko asekelwe ku-silicon, ehlisa usayizi nesisindo sezinhlelo zikagesi zamandla kuyilapho ethuthukisa ukusebenza kahle kwawo konke. Lokhu kuholela ekongeni kwezindleko kanye nokuma kwezemvelo okuncane ezinhlelweni ezinjengamandla avuselelekayo kanye nezimoto zikagesi.

Ukunwebeka: Ububanzi obungu-3-intshi nokubekezelela okunembayo kokukhiqiza kwewafa ye-HPSI SiC kuqinisekisa ukuthi ingakaleka ekukhiqizeni ngobuningi, ihlangabezana kokubili nezidingo zocwaningo nezohwebo.

Isiphetho

Iwafa ye-HPSI SiC, enobubanzi bayo obungu-3-intshi nogqinsi olungu-350 µm ± 25 µm, iyinto efanelekile yesizukulwane esilandelayo samadivayisi kagesi asebenza kahle kakhulu. Inhlanganisela yayo eyingqayizivele ye-thermal conductivity, i-voltage ephezulu yokuphuka, ukulahlekelwa kwamandla amancane, nokuthembeka ngaphansi kwezimo ezimbi kakhulu kuyenza ibe yingxenye ebalulekile yezinhlelo zokusebenza ezihlukahlukene ekuguquleni amandla, amandla avuselelekayo, izimoto zikagesi, izinhlelo zezimboni, kanye nezokuxhumana.

Le wafer ye-SiC ifanele ikakhulukazi izimboni ezifuna ukuzuza ukusebenza kahle okuphezulu, ukonga amandla amakhulu, nokuthembeka kwesistimu okuthuthukisiwe. Njengoba ubuchwepheshe bama-electronics buqhubeka nokuvela, i-wafer ye-HPSI SiC ihlinzeka ngesisekelo sokuthuthukiswa kwesizukulwane esilandelayo, izixazululo ezonga amandla, okuqhubekisela phambili uguquko lwekusasa elizinzile, elinekhabhoni ephansi.

Umdwebo onemininingwane