Okuqukethwe

1.Izinjongo Ezimqoka Nokubaluleka Kokuhlanza Icwecwe

2. Ukuhlola Ukungcola kanye Namasu Okuhlaziya Athuthukile

3.Izindlela Zokuhlanza Ezithuthukile kanye Nezimiso Zobuchwepheshe

4.Izinto Ezibalulekile Zokusetshenziswa Kobuchwepheshe Nezinqubo Zokulawula

5.Amathrendi Azayo Nezikhombisi-ndlela Ezintsha

6.XKH Izisombululo Zokuphela-kuya-Ekupheleni kanye ne-Service Ecosystem

Ukuhlanzwa kwe-wafer kuyinqubo ebalulekile ekwenziweni kwe-semiconductor, njengoba ngisho nezingcolisi zeleveli ye-athomu zingehlisa isithunzi ukusebenza kwedivayisi noma isivuno. Inqubo yokuhlanza ngokuvamile ihilela izinyathelo eziningi zokususa ukungcola okuhlukahlukene, okufana nezinsalela zezinto eziphilayo, ukungcola kwensimbi, izinhlayiya, nama-oxide omdabu.

1. Izinjongo zokuhlanza i-wafer

- Susa ukungcola kwemvelo (isb, izinsalela ze-photoresist, izigxivizo zeminwe).

- Khipha ukungcola kwensimbi (isb., Fe, Cu, Ni).

- Susa ukungcoliswa kwezinhlayiya (isb, uthuli, izingcezu ze-silicon).

- Susa ama-oxide omdabu (isb., izendlalelo ze-SiO₂ ezakhiwe ngesikhathi sokuchayeka komoya).

2. Ukubaluleka Kokuhlanza Okuqinile Kwe-wafer

- Iqinisekisa ukukhiqiza okuphezulu kwenqubo nokusebenza kwedivayisi.

- Yehlisa ukukhubazeka kanye namazinga e-wafer scrap.

- Ithuthukisa ikhwalithi yobuso nokuvumelana.

Ngaphambi kokuhlanza okujulile, kubalulekile ukuhlola ukungcola okukhona kwendawo. Ukuqonda uhlobo, ukusatshalaliswa kosayizi, kanye nokuhlelwa kwendawo kokungcola endaweni eyiwafa kuthuthukisa ikhemistri yokuhlanza nokokufaka kwamandla okusebenza.

3. Izindlela Zokuhlaziya Ezithuthukile Zokuhlola Ukungcola

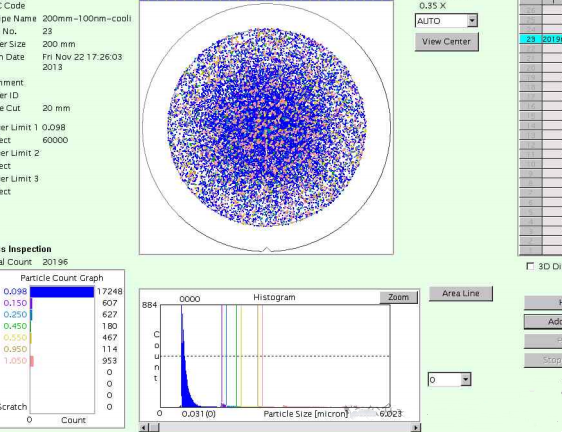

3.1 Ukuhlaziywa kwe-Surface Particle

- Izibali zezinhlayiyana ezikhethekile zisebenzisa i-laser scattering, noma ukubona ngekhompyutha ukubala, usayizi, kanye nemfucumfucu yemephu.

- Amandla okuhlakazeka okukhanyayo ahlotshaniswa nosayizi wezinhlayiyana ezincane njengamashumi ama-nanometers kanye nokuminyana okuphansi njengezinhlayiya ezingu-0.1/cm².

- Ukulinganisa ngezindinganiso kuqinisekisa ukwethembeka kwehadiwe. Izikena zangaphambi nangemuva kokuhlanza ziqinisekisa ukusebenza kahle kokususa, ukuthuthukiswa kwenqubo yokushayela.

3.2 Ukuhlaziywa kwe-Surface Elemental

- Amasu azwelayo ebusweni ahlonza ukwakheka kwezinto.

- I-X-ray Photoelectron Spectroscopy (XPS/ESCA): Ihlaziya izimo zamakhemikhali ezingaphezulu ngokufaka i-wafer ngama-X ray kanye nokulinganisa ama-electron akhishiwe.

- I-Glow Discharge Optical Emission Emission Spectroscopy (GD-OES): I-Sputters izendlalelo zomhlaba ezizacile kakhulu ngokulandelana ngenkathi ihlaziya i-spectra ekhishiwe ukuze kutholwe ukwakheka kwezinto ezincike ekujuleni.

- Imikhawulo yokutholwa ifinyelela izingxenye ngesigidi (ppm)), eqondisa ukukhethwa kwamakhemikhali okuhlanza okufanelekile.

3.3 Ukuhlaziywa kwe-Morphological Contamination

- Iskena i-Electron Microscopy (SEM)izimbamba ecacileyo ephezulu iveza umumo wokungcola kanye lokulinganiswa kwesici, okubonisa izindlela zokunamathela (ikhemikhali uma iqhathaniswa nemishini).

- I-Atomic Force Microscopy (AFM): I-Maps nanoscale topography ukuze kulinganise ubude bezinhlayiyana kanye nezakhiwo zomshini.

- I-Focused Ion Beam (FIB) Milling + Transmission Electron Microscopy (TEM): Inikeza ukubukwa kwangaphakathi kokungcola okungcwatshiwe.

4. Izindlela Zokuhlanza Ezithuthukile

Nakuba ukuhlanzwa kwe-solvent kususa ngokuphumelelayo ukungcola kwezinto eziphilayo, amasu athuthukile engeziwe ayadingeka ezinhlayiyeni ze-inorganic, izinsalela zensimbi, nokungcola kwe-ionic:

.

4.1 Ukuhlanza i-RCA

- Ithuthukiswe yi-RCA Laboratories, le ndlela isebenzisa inqubo yokugeza kabili ukuze isuse ukungcola kwe-polar.

- I-SC-1 (I-Standard Clean-1): Isusa ukungcola okuphilayo nezinhlayiya kusetshenziswa ingxube ye-NH₄OH, H₂O₂, ne-H₂O(isb, 1:1:5 isilinganiso esingu-~20°C). Yakha ungqimba oluncane lwe-silicon dioxide.

- I-SC-2 (I-Standard Clean-2): Isusa ukungcola kwensimbi isebenzisa i-HCl, H₂O₂, ne-H₂O (isb, 1:1:6 isilinganiso ku-~80°C). Ishiya indawo engashintshiwe.

- Ibhalansisa ukuhlanzeka nokuvikelwa kwendawo.

.

4.2 Ukuhlanzwa kwe-Ozone

- Icwilisa ama-wafer emanzini agcwele i-ozone-saturated deionized (O₃/H₂O)).

- I-oxidize futhi isuse i-organic ngaphandle kokulimaza i-wafer, ishiya indawo engasetshenziswanga ngamakhemikhali.

.

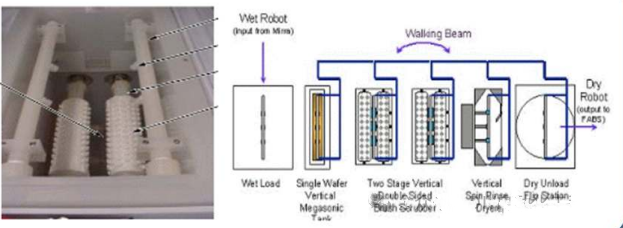

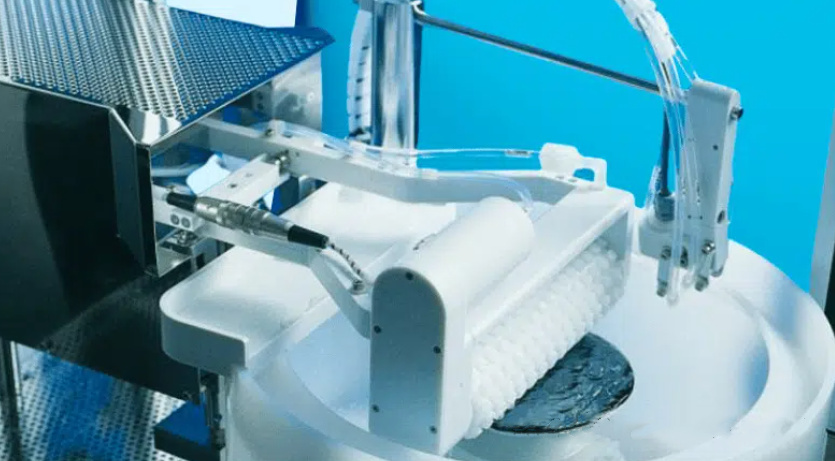

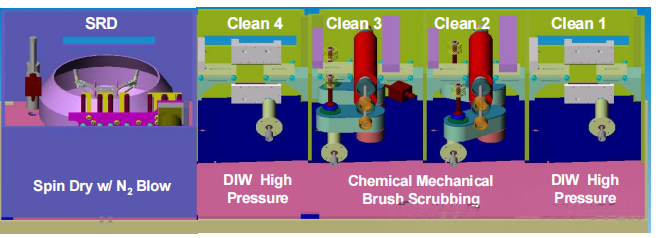

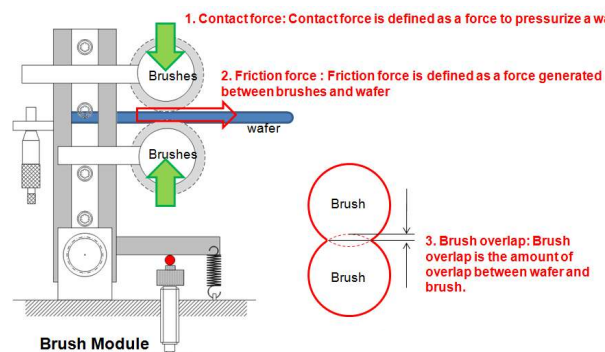

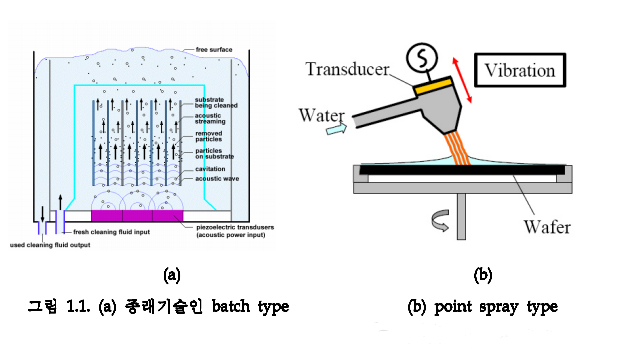

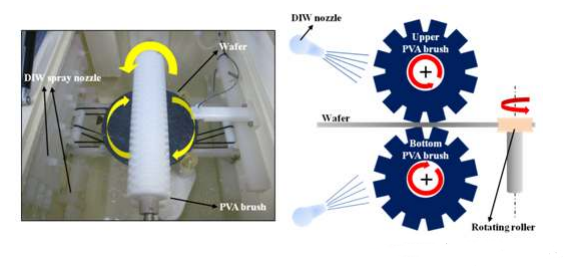

4.3 I-Megasonic Cleaning.

- Isebenzisa amandla e-ultrasonic avamile (imvamisa engu-750–900 kHz) ahlanganiswe nezixazululo zokuhlanza.

- Ikhiqiza amabhamuza e-cavitation akhipha ukungcola. Ingena kumajiyometri ayinkimbinkimbi kuyilapho inciphisa umonakalo ezakhiweni ezintekenteke.

4.4 I-Cryogenic Cleaning

- Ipholisa ngokushesha ama-wafers emazingeni okushisa e-cryogenic, angcolisana.

- Ukuhlanza okulandelayo noma ukuxubha ngobumnene kususa izinhlayiya ezixegisiwe. Ivimbela ukungcoliswa kabusha nokusabalalisa endaweni.

- Inqubo esheshayo, eyomile esebenzisa amakhemikhali amancane.

Isiphetho:

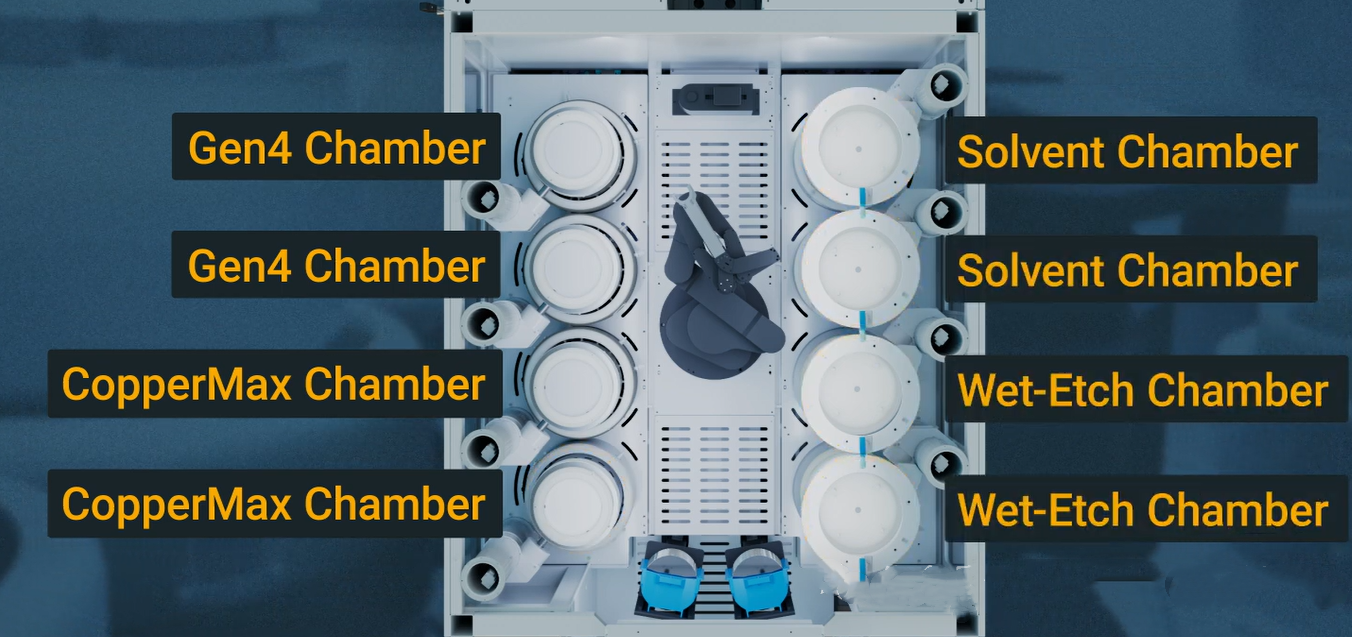

Njengomhlinzeki wezixazululo ze-semiconductor yochungechunge olugcwele olugcwele, i-XKH iqhutshwa ukuqanjwa kabusha kwezobuchwepheshe futhi ikhasimende lidinga ukuletha i-ecosystem yesevisi yokugcina-esekupheleni, ehlanganisa ukuhlinzekwa kwemishini ephezulu, ukwakhiwa kwe-wafer, nokuhlanza ngokunemba. Asihlinzeki nje kuphela ngezinto ezisetshenziswa emhlabeni wonke ze-semiconductor (isb., imishini ye-lithography, amasistimu e-etching) anezixazululo eziklanyelwe kodwa futhi nobuchwepheshe bobunikazi obuphayona—okuhlanganisa ukuhlanzwa kwe-RCA, ukuhlanzwa kwe-ozone, nokuhlanza okukhulu—ukuqinisekisa ukuhlanzeka kwezinga le-athomu—ukukhiqiza ama-wafer, okuthuthukisa ngokuphawulekayo ukuvunwa kwamaklayenti. Ngokusebenzisa amaqembu asendaweni asabela ngokushesha, kanye namanethiwekhi esevisi ahlakaniphile, sinikeza ukwesekwa okuphelele kusukela ekufakweni kwemishini nokwenza ngcono inqubo ukuya ekulungiseni okubikezelwayo, sinikeza amaklayenti amandla okunqoba izinselele zobuchwepheshe futhi athuthukele ekunembeni okuphezulu nasekuthuthukisweni kwe-semiconductor eqhubekayo. Sikhethele i-synergy yokuwina okukabili kochwepheshe bezobuchwepheshe kanye nenani lezentengiso.

Isikhathi sokuthumela: Sep-02-2025