Ama-Wafer Substrates Njengezinto Ezibalulekile kumadivayisi we-Semiconductor

Ama-wafer substrates abathwali abaphathekayo bamadivayisi we-semiconductor, futhi izakhiwo zawo ezibonakalayo zinquma ngokuqondile ukusebenza kwedivayisi, izindleko, nezinkambu zohlelo lokusebenza. Ngezansi kunezinhlobo eziyinhloko zama-wafer substrates kanye nezinzuzo kanye nokubi:

-

Ukwabelana Kwemakethe:Ibalelwa ngaphezu kwama-95% emakethe ye-semiconductor yomhlaba.

-

Izinzuzo:

-

Izindleko eziphansi:Izinto zokusetshenziswa eziningi (i-silicon dioxide), izinqubo zokukhiqiza ezivuthiwe, nomnotho oqinile wesikali.

-

Ukuhambisana kwenqubo ephezulu:Ubuchwepheshe be-CMOS buvuthwe kakhulu, busekela ama-node athuthukile (isb, i-3nm).

-

Ikhwalithi yekristalu enhle kakhulu:Ama-wafer anobubanzi obukhulu (ikakhulukazi ama-intshi angu-12, amayintshi angu-18 ngaphansi kokuthuthukiswa) anobunzima obuncane obuncane angatshalwa.

-

Izakhiwo ezizinzile zemishini:Kulula ukusika, ukupholisha, nokubamba.

-

-

Ububi:

-

I-bandgap emincane (1.12 eV):Ukuvuza okuphezulu kwamanje emazingeni okushisa aphakeme, kukhawulela ukusebenza kahle kwedivayisi yamandla.

-

I-bandgap engaqondile:Ukusebenza kahle kokukhipha ukukhanya okuphansi kakhulu, akufanelekile kumadivayisi e-optoelectronic njengama-LED nama-lasers.

-

Ukuhamba kwama-electron okulinganiselwe:Ukusebenza kwe-high-frequency ephansi uma kuqhathaniswa nama-semiconductors ahlanganisiwe.

-

-

Izicelo:Imishini ye-RF ye-high-frequency (5G/6G), amadivaysi e-optoelectronic (ama-lasers, amaseli elanga).

-

Izinzuzo:

-

Ukuhamba kwe-electron ephezulu (5–6× okwe-silicon):Ifanele ukusetshenziswa kwesivinini esikhulu, imvamisa ephezulu njengokuxhumana kwegagasi lemilimitha.

-

I-bandgap eqondile (1.42 eV):Ukuguqulwa kwe-photoelectric okusebenza kahle kakhulu, isisekelo samalaser e-infrared nama-LED.

-

Izinga lokushisa eliphezulu nokumelana nemisebe:Ifanele i-aerospace kanye nezindawo ezinokhahlo.

-

-

Ububi:

-

Izindleko eziphezulu:Izinto eziyivelakancane, ukukhula kwekristalu okunzima (okujwayele ukugudluka), usayizi we-wafer olinganiselwe (ikakhulukazi amayintshi angu-6).

-

I-Brittle mechanics:Ijwayele ukuphuka, okuholela ekukhiqizeni okuphansi kokucubungula.

-

Ubuthi:I-Arsenic idinga ukuphathwa okuqinile kanye nokulawulwa kwemvelo.

-

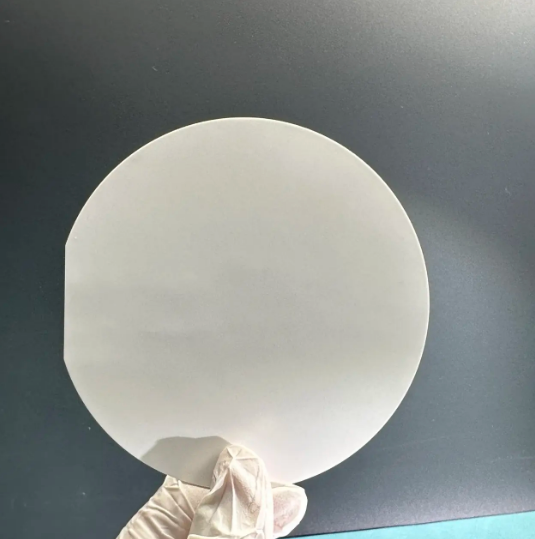

3. I-Silicon Carbide (SiC)

-

Izicelo:Amadivayisi anamandla okushisa aphezulu nanamandla kagesi aphezulu (ama-inverter e-EV, iziteshi zokushaja), i-aerospace.

-

Izinzuzo:

-

I-bandgap ebanzi (3.26 eV):Amandla okuphuka okuphezulu (10× awe-silicon), ukubekezelela izinga lokushisa eliphezulu (izinga lokushisa elisebenzayo>200 °C).

-

Ukusebenza okuphezulu kwe-thermal (≈3× i-silicon):Ukukhipha ukushisa okuhle kakhulu, okuvumela ukuminyana kwamandla esistimu ephezulu.

-

Ukulahlekelwa kokushintsha okuphansi:Ithuthukisa ukusebenza kahle kokuguqulwa kwamandla.

-

-

Ububi:

-

Ukulungiswa kwe-substrate okuyinselele:Ukukhula kwekristalu okuhamba kancane (> 1 isonto), ukulawulwa kokukhubazeka okunzima (ama-micropipe, ukuhlukaniswa), izindleko eziphezulu kakhulu (5-10× silicon).

-

Usayizi omncane we-wafer:Ikakhulukazi amayintshi angu-4–6; 8-intshi isathuthukiswa.

-

Kunzima ukucubungula:Kunzima kakhulu (Mohs 9.5), okwenza ukusika nokupholisha kudle isikhathi.

-

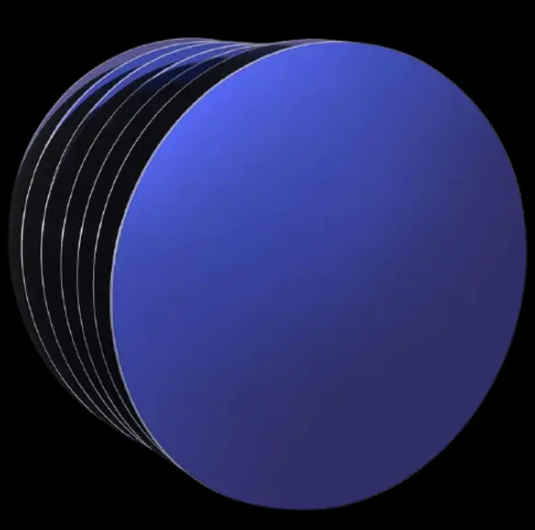

4. I-Gallium Nitride (GaN)

-

Izicelo:Imishini yamandla emvamisa ephezulu (ukushaja okusheshayo, iziteshi eziyisisekelo ze-5G), ama-LED/ama-lasers aluhlaza.

-

Izinzuzo:

-

Ukuhamba kwe-electron ephezulu kakhulu + i-bandgap ebanzi (3.4 eV):Ihlanganisa imvamisa ephezulu (>100 GHz) nokusebenza kwevoltage ephezulu.

-

Ukumelana okuphansi:Yehlisa ukulahleka kwamandla edivayisi.

-

I-Heteroepitaxy iyahambisana:Ivame ukutshalwa ku-silicon, isafire, noma i-SiC substrates, kunciphisa izindleko.

-

-

Ububi:

-

Ukukhula kwekristalu eyodwa kunzima:I-Heteroepitaxy ijwayelekile, kodwa ukungafani kwe-lattice kubangela ukukhubazeka.

-

Izindleko eziphezulu:Ama-substrates omdabu we-GaN abiza kakhulu (i-wafer engu-2-intshi ingabiza izinkulungwane ezimbalwa zama-USD).

-

Izinselelo zokuthembeka:Izenzakalo ezifana nokuwa kwamanje zidinga ukuthuthukiswa.

-

5. I-Indidium Phosphide (InP)

-

Izicelo:Ukuxhumana okushesha kakhulu kwe-optical (ama-lasers, ama-photodetectors), amadivaysi e-terahertz.

-

Izinzuzo:

-

Ukuhamba kwama-electron aphezulu kakhulu:Isekela ukusebenza kwe->100 GHz, okudlula ama-GaAs.

-

I-bandgap eqondile enobude be-wavelength:Okubalulekile kokuxhumana okungu-1.3–1.55 μm kwefiber optical.

-

-

Ububi:

-

I-brittle futhi ibiza kakhulu:Izindleko ze-substrate zidlula i-silicon engu-100×, osayizi be-wafer abalinganiselwe (amayintshi angu-4–6).

-

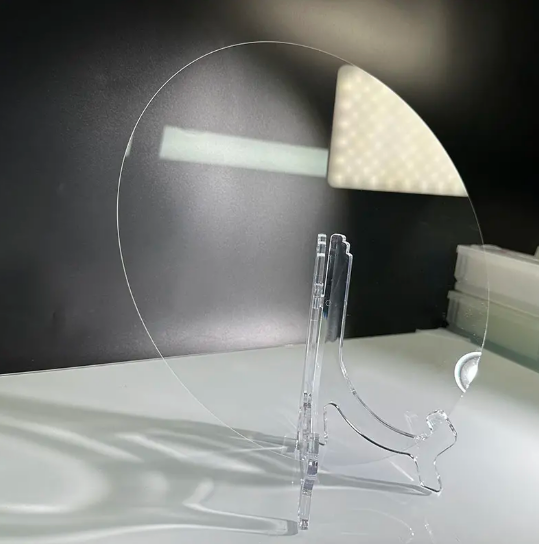

6. I-Sapphire (Al₂O₃)

-

Izicelo:Ukukhanyisa kwe-LED (i-GaN epitaxial substrate), ingilazi yekhava ye-electronics yabathengi.

-

Izinzuzo:

-

Izindleko eziphansi:Kushibhe kakhulu kune-SiC/GaN substrates.

-

Ukuzinza kwamakhemikhali okuhle kakhulu:Imelana nokugqwala, i-insulating kakhulu.

-

Ukubonisa ngale:Ifanele izakhiwo ze-LED eziqondile.

-

-

Ububi:

-

Ukungafani kwe-lattice enkulu ne-GaN (>13%):Idala ukuminyana kokukhubazeka okuphezulu, idinga izendlalelo zebhafa.

-

I-thermal conductivity engalungile (~1/20 ye-silicon):Ikhawulela ukusebenza kwama-LED anamandla amakhulu.

-

7. Ama-Ceramic Substrates (AlN, BeO, njll.)

-

Izicelo:Izisakazeli zokushisa zamamojula wamandla aphezulu.

-

Izinzuzo:

-

I-insulating + high conductivity thermal (AlN: 170–230 W/m·K):Ifanele ukupakishwa okuphezulu kwabantu.

-

-

Ububi:

-

I-Non-single-crystal:Ayikwazi ukusekela ngokuqondile ukukhula kwedivayisi, esetshenziswa kuphela njengama-substrates okupakisha.

-

8. Ama-substrates akhethekile

-

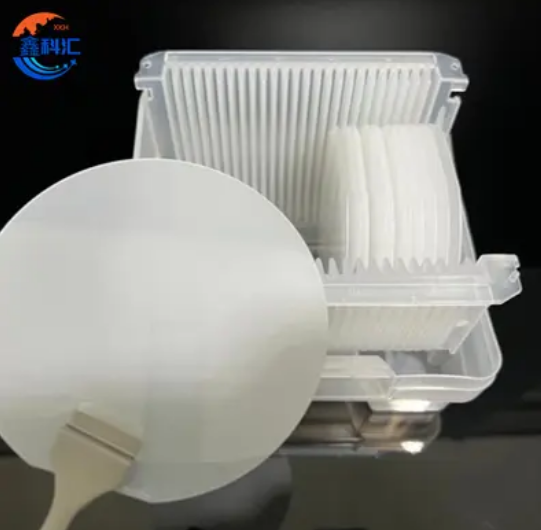

I-SOI (I-Silicon ku-Insulator):

-

Isakhiwo:Isemishi le-silicon/SiO₂/silicon.

-

Izinzuzo:Yehlisa i-parasitic capacitance, i-radiation-hardened, ukucindezelwa kokuvuza (okusetshenziswe ku-RF, MEMS).

-

Ububi:I-30-50% ibiza kakhulu kune-silicon eyinqwaba.

-

-

I-Quartz (SiO₂):Isetshenziswa kuma-photomasks kanye ne-MEMS; ukumelana nokushisa okuphezulu kodwa kuyaphuka kakhulu.

-

Idayimane:I-substrate ye-thermal conductivity ephezulu kakhulu (>2000 W/m·K), ngaphansi kwe-R&D yokulahla ukushisa okudlulele.

Ithebula Elifingqiwe Lokuqhathanisa

| I-substrate | I-Bandgap (eV) | I-Electron Mobility (cm²/V·s) | I-Thermal Conductivity (W/m·K) | Usayizi we-Wafer oyinhloko | Izicelo Eziyinhloko | Izindleko |

|---|---|---|---|---|---|---|

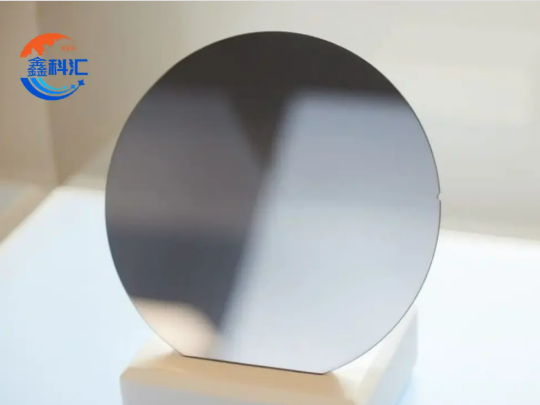

| Si | 1.12 | ~1,500 | ~ 150 | 12-intshi | I-Logic / Memory Chips | Okuphansi kakhulu |

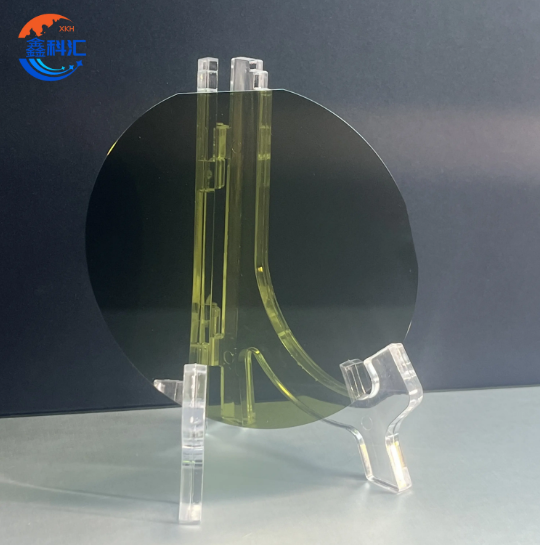

| I-GaAs | 1.42 | ~8,500 | ~55 | 4-6 amayintshi | I-RF / Optoelectronics | Phezulu |

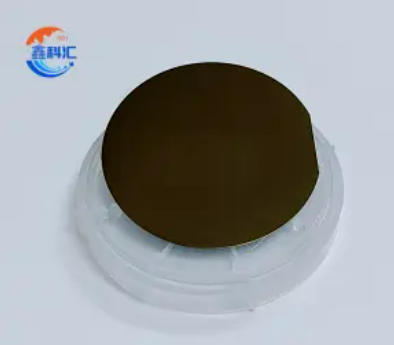

| I-SiC | 3.26 | ~900 | ~ 490 | 6-intshi (8-intshi R&D) | Amadivayisi kagesi / EV | Phezulu kakhulu |

| I-GaN | 3.4 | ~2,000 | ~130–170 | 4–6 amayintshi (heteroepitaxy) | Ukushaja okusheshayo / RF / LEDs | Phezulu (i-heteroepitaxy: okumaphakathi) |

| I-InP | 1.35 | ~5,400 | ~70 | 4-6 amayintshi | Ukuxhumana okubonakalayo / THz | Phezulu Kakhulu |

| Isafire | 9.9 (isivikelo) | - | ~40 | 4-8 amayintshi | Ama-substrates e-LED | Phansi |

Izinto Ezibalulekile Zokukhetha I-substrate

-

Izidingo zokusebenza:I-GaAs/InP ye-high-frequency; I-SiC ye-high-voltage, izinga lokushisa eliphezulu; I-GaAs/InP/GaN ye-optoelectronics.

-

Imikhawulo yezindleko:I-electronics yabathengi ithanda i-silicon; Izinkambu ezisezingeni eliphezulu zingathethelela amaphrimiyamu e-SiC/GaN.

-

Ukuhlanganisa inkimbinkimbi:I-Silicon ihlala ingenakushintshwa ukuze ihambisane ne-CMOS.

-

Ukuphathwa kokushisa:Izinhlelo zokusebenza zamandla aphezulu zikhetha i-SiC noma i-GaN esekelwe idayimane.

-

Ukuvuthwa kochungechunge lokuhlinzeka:Si > Sapphire > GaAs > SiC > GaN > InP.

Ikusasa Trend

Ukuhlanganiswa okuhlukahlukene (isb., i-GaN-on-Si, i-GaN-on-SiC) izobhalansisa ukusebenza nezindleko, ukuthuthukiswa kokushayela ku-5G, izimoto zikagesi, kanye ne-quantum computing.

Isikhathi sokuthumela: Aug-21-2025