Ubuchwepheshe be-wafer dicing, njengesinyathelo esibalulekile enqubweni yokukhiqiza i-semiconductor, buxhumene ngqo nokusebenza kwe-chip, isivuno, kanye nezindleko zokukhiqiza.

#01 Isendlalelo kanye Nokubaluleka Kokudayela Kwe-wafer

1.1 Incazelo ye-Wafer Dicing

I-wafer dicing (eyaziwa nangokuthi i-scribing) isinyathelo esibalulekile ekwenziweni kwe-semiconductor, okuhloswe ngayo ukuhlukanisa amawafa acutshunguliwe abe ama-wafer amaningi. Lezi zifa ngokuvamile ziqukethe ukusebenza kwesekethe ephelele futhi ziyizingxenye ezibalulekile ekugcineni ezisetshenziswa ekukhiqizweni kwemishini kagesi. Njengoba amadizayini ama-chip eba yinkimbinkimbi kakhulu futhi ubukhulu buqhubeka nokuncipha, izimfuneko zokunemba nokusebenza kahle kobuchwepheshe bokudayila ama-wafer ziya ngokuya ziba nzima.

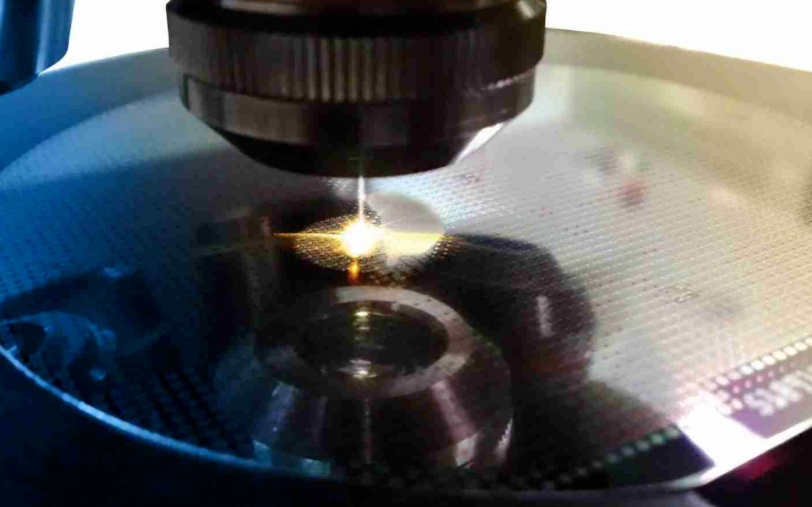

Ekusebenzeni okungokoqobo, ukudayela kwe-wafer ngokuvamile kusebenzisa amathuluzi anemba okuphezulu njengamablade edayimane ukuze kuqinisekiswe ukuthi ukufa ngakunye kuhlala kuphelele futhi kusebenza ngokugcwele. Izinyathelo ezibalulekile zihlanganisa ukulungiselela ngaphambi kokusika, ukulawula okunembile ngesikhathi sokusika, nokuhlolwa kwekhwalithi ngemva kokusika.

Ngaphambi kokusika, i-wafer kufanele imakwe futhi ibekwe ukuze kuqinisekiswe izindlela zokusika ezinembile. Ngesikhathi sokusika, imingcele efana nokucindezela kwamathuluzi kanye nesivinini kufanele ilawulwe ngokuqinile ukuvimbela ukulimala ku-wafer. Ngemuva kokusika, ukuhlolwa kwekhwalithi okuphelele kuyenziwa ukuze kuqinisekiswe ukuthi yonke i-chip ihlangabezana namazinga okusebenza.

Izimiso eziyisisekelo zobuchwepheshe bokudayela nge-wafer ayihlanganisi nje kuphela ukukhethwa kwemishini yokusika kanye nokumiswa kwemingcele yenqubo kodwa futhi nomthelela wezakhiwo zemishini nezici zezinto zokwakha kwikhwalithi yokusika. Isibonelo, ama-wafers e-silicon e-dielectric aphansi-k, ngenxa yezakhiwo zawo eziphansi zemishini, asengozini enkulu ekugxilweni kwengcindezi ngesikhathi sokusika, okuholela ekuhlulekeni okufana nokuqhekeka nokuqhekeka. Ukuqina okuphansi kanye nokuqina kwezinto ezi-low-k kuzenza zithambekele ekulimaleni kwesakhiwo ngaphansi kwamandla omshini noma ingcindezi yokushisa, ikakhulukazi ngesikhathi sokusika. Ukuthintana phakathi kwethuluzi nendawo eyisicwecwana, kuhambisana nezinga lokushisa eliphezulu, kungaqhubeza kubhebhethekise ukugxilwa kwengcindezi.

Ngokuthuthuka kwesayensi yezinto ezibonakalayo, ubuchwepheshe be-wafer dicing buye banda ngaphezu kwama-semiconductors asekelwe ku-silicon ukuze afake izinto ezintsha ezifana ne-gallium nitride (GaN). Lezi zinto ezintsha, ngenxa yokuqina kwazo kanye nezakhiwo zesakhiwo, zibeka izinselele ezintsha zezinqubo zokudayela, ezidinga ukuthuthukiswa okwengeziwe kumathuluzi okusika kanye namasu.

Njengenqubo ebucayi embonini ye-semiconductor, ukudayela kwe-wafer kuyaqhubeka nokuthuthukiswa ngenxa yezidingo eziguqukayo kanye nentuthuko yezobuchwepheshe, ukubeka isisekelo se-microelectronics esizayo kanye nobuchwepheshe besekethe obuhlanganisiwe.

Ukuthuthukiswa kobuchwepheshe be-wafer dicing kudlula ukuthuthukiswa kwezinto ezisizayo namathuluzi. Futhi zihlanganisa ukulungiselelwa kwenqubo, izithuthukisi ekusebenzeni kwemishini, nokulawulwa okunembile kwamapharamitha wokudayela. Lezi ntuthuko zihlose ukuqinisekisa ukunemba okuphezulu, ukusebenza kahle, kanye nokuzinza enqubweni yokudayela ama-wafer, ukuhlangabezana nesidingo semboni ye-semiconductor yobukhulu obuncane, ukuhlanganiswa okuphezulu, kanye nezakhiwo zama-chip eziyinkimbinkimbi.

| Indawo yokuthuthukisa | Izinyathelo Ezithize | Imiphumela |

| Ukuthuthukisa Inqubo | - Thuthukisa amalungiselelo okuqala, njengokuma kwe-wafer enembe kakhudlwana nokuhlela indlela. | - Yehlisa amaphutha okusika futhi uthuthukise ukuzinza. |

| - Nciphisa amaphutha okusika futhi uthuthukise ukuzinza. | - Yamukela izindlela zokuqapha zesikhathi sangempela kanye nempendulo ukuze ulungise ukucindezela kwamathuluzi, isivinini, nezinga lokushisa. | |

| - Amazinga aphansi okuphuka kwe-wafer futhi athuthukise ikhwalithi ye-chip. | ||

| Ukuthuthukiswa Kokusebenza Kwezisetshenziswa | - Sebenzisa amasistimu emishini anembayo kanye nobuchwepheshe obuthuthukisiwe bokulawula okuzenzakalelayo. | - Thuthukisa ukunemba kokusika futhi unciphise ukumoshwa kwempahla. |

| - Yethula ubuchwepheshe bokusika i-laser obufanele ama-wafers wezinto ezinokuqina okuphezulu. | - Thuthukisa ukusebenza kahle kokukhiqiza futhi unciphise amaphutha enziwa ngesandla. | |

| - Khulisa imishini ezenzakalelayo yokuqapha okuzenzakalelayo nokulungiswa. | ||

| Ukulawulwa Kwepharamitha Okunembile | - Lungisa kahle amapharamitha njengokujula kokusika, isivinini, uhlobo lwamathuluzi, nezindlela zokupholisa. | - Qinisekisa ubuqotho kanye nokusebenza kukagesi. |

| - Yenza ngokwezifiso amapharamitha asuselwa kuzinto eziyisilutshwana, ukujiya, kanye nesakhiwo. | - Khulisa amazinga esivuno, wehlise ukumosha izinto ezibonakalayo, futhi wehlise izindleko zokukhiqiza. | |

| Ukubaluleka Kwamasu | - Qhubeka uhlola izindlela ezintsha zobuchwepheshe, uthuthukise izinqubo, futhi uthuthukise amakhono wemishini ukuze uhlangabezane nezidingo zemakethe. | - Thuthukisa isivuno sokwenza ama-chip nokusebenza, ukusekela ukuthuthukiswa kwezinto ezintsha kanye nemiklamo ethuthukisiwe yama-chip. |

1.2 Ukubaluleka Kokudaya Nge-Wafer

I-wafer dicing idlala indima ebalulekile enqubweni yokukhiqiza i-semiconductor, ibe nomthelela ngokuqondile ezinyathelweni ezilandelayo kanye nekhwalithi nokusebenza komkhiqizo wokugcina. Ukubaluleka kwayo kungachazwa kanjena:

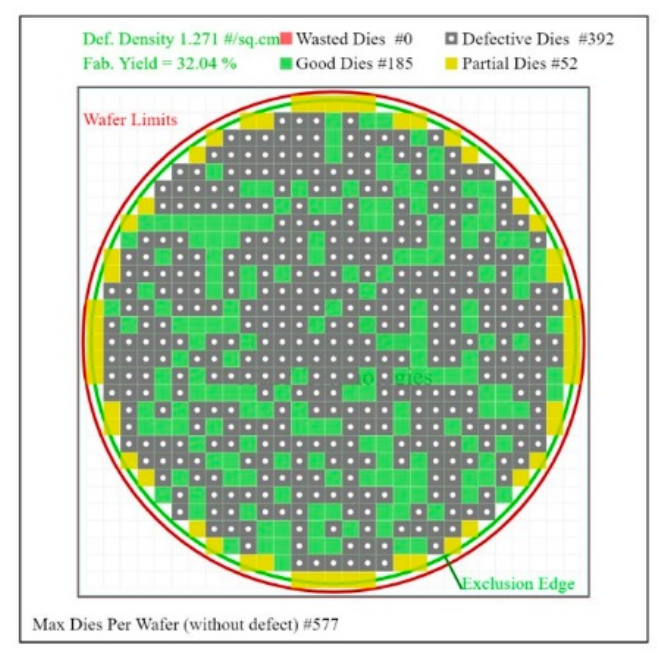

Okokuqala, ukunemba nokuvumelana kokudayela kuyisihluthulelo sokuqinisekisa ukuvunwa kwe-chip nokuthembeka. Ngesikhathi sokukhiqiza, ama-wafers athatha izinyathelo eziningi zokucubungula ukuze akhe izakhiwo zesekethe eziningi eziyinkimbinkimbi, okumele zihlukaniswe ngokunembile zibe ama-chips ngamanye (efa). Uma kukhona amaphutha abalulekile ekuqondaneni noma ekusikeni ngesikhathi senqubo yokudayela, amasekhethi angase alimale, athinte ukusebenza nokuthembeka kwe-chip. Ngakho-ke, ubuchwepheshe bokudayela okunembayo okuphezulu abuqinisekisi nje kuphela ubuqotho be-chip ngayinye kodwa futhi buvimbela ukulimala kumasekhethi angaphakathi, ukuthuthukisa izinga lokukhiqiza jikelele.

Okwesibili, ukudayela kwe-wafer kunomthelela omkhulu ekusebenzeni kahle kokukhiqiza nasekulawuleni izindleko. Njengesinyathelo esibalulekile enqubweni yokukhiqiza, ukusebenza kahle kwayo kuthinta ngqo inqubekelaphambili yezinyathelo ezilandelayo. Ngokulungiselela inqubo yokudayela, ukwandisa amazinga ezishintshayo, kanye nokuthuthukisa isivinini sokusika, ukusebenza kahle kokukhiqiza kukonke kungathuthukiswa kakhulu.

Ngakolunye uhlangothi, ukumosha impahla ngesikhathi sokudayela kuyisici esibalulekile ekulawuleni izindleko. Ukusebenzisa ubuchwepheshe bokudayela okuthuthukisiwe akunciphisi nje kuphela ukulahleka kwempahla okungadingekile phakathi nenqubo yokusika kodwa futhi kukhulisa ukusetshenziswa kwe-wafer, ngaleyo ndlela kwehlise izindleko zokukhiqiza.

Ngokuthuthuka kobuchwepheshe be-semiconductor, ama-wafer diameters ayaqhubeka nokukhula, futhi ukuminyana kwesekethe kukhuphuka ngokufanele, okubeka izidingo eziphakeme kubuchwepheshe bokudayela. Amawafa amakhudlwana adinga ukulawula okunembe kakhudlwana kwezindlela zokusika, ikakhulukazi ezindaweni ezisondelene kakhulu, lapho nokuchezuka okuncane kungenza ama-chips amaningi angasebenzi. Ukwengeza, ama-wafer amakhulu afaka imigqa yokusika eyengeziwe kanye nezinyathelo zenqubo eziyinkimbinkimbi, okudinga ukuthuthukiswa okuqhubekayo ekunembeni, ukungaguquguquki, nokusebenza kahle kobuchwepheshe bokudayela ukuhlangabezana nalezi zinselele.

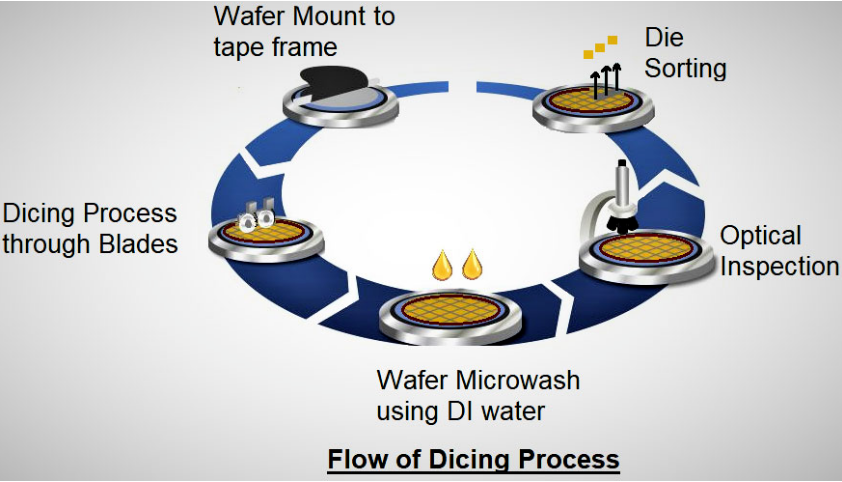

1.3 Inqubo ye-Wafer Dicing

Inqubo ye-wafer dicing ihlanganisa zonke izinyathelo kusukela esigabeni sokulungiselela ukuya ekuhlolweni kwekhwalithi yokugcina, futhi isigaba ngasinye sibalulekile ekuqinisekiseni ikhwalithi nokusebenza kwama-chips adayisi. Ngezansi kunencazelo enemininingwane yesigaba ngasinye.

| Isigaba | Incazelo Eningiliziwe |

| Isigaba Sokulungiselela | -I-Wafer Cleaning: Sebenzisa amanzi ahlanzekile kakhulu kanye nama-agent okuhlanza akhethekile, ahlanganiswe ne-ultrasonic noma mechanical scrubbing, ukususa ukungcola, izinhlayiya, nokungcola, ukuqinisekisa indawo ehlanzekile. -Ukuma Okuqondile: Sebenzisa okokusebenza okunemba okuphezulu ukuze uqinisekise ukuthi isinkwa esilucwecwana sihlukaniswe ngokunembile emigwaqweni yokusika eklanyelwe. -Ukulungiswa kwe-wafer: Vikela i-wafer kuhlaka lwe-tape ukuze ugcine ukuzinza ngesikhathi sokusika, ukuvimbela ukulimala ekudlidlizeni noma ukunyakaza. |

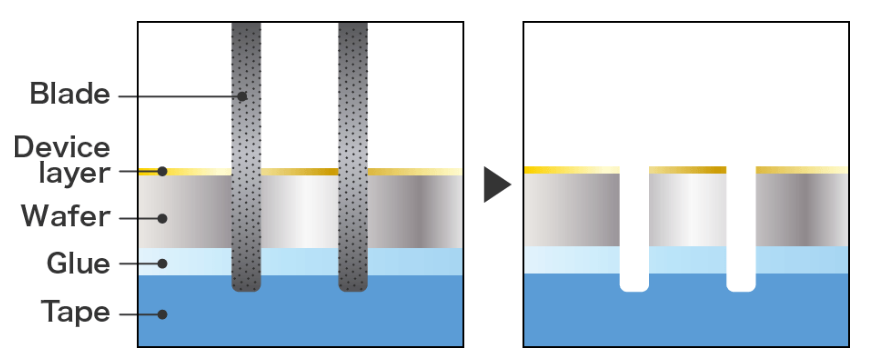

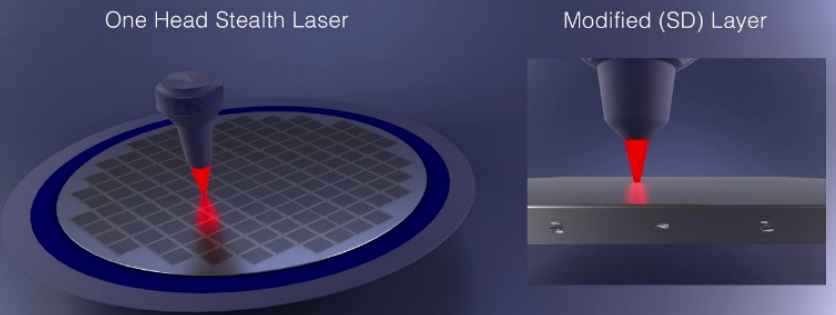

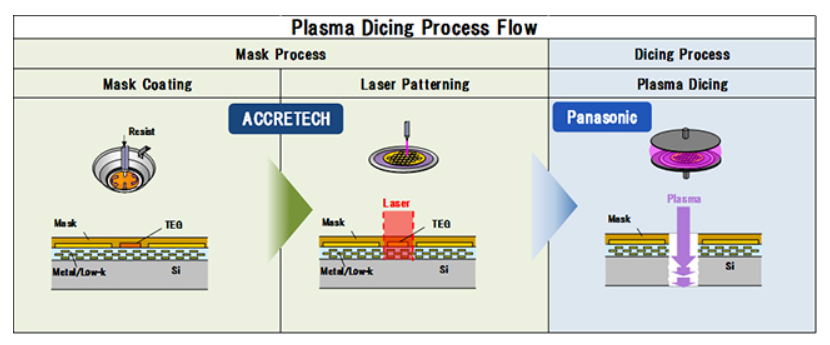

| Isigaba sokusika | -I-Blade Dicing: Sebenzisa izindwani ezinamekwe ngedayimane ezijikelezayo ngesivinini esikhulu ukuze usike ngokomzimba, ezifanele izinto ezisekelwe ku-silicon futhi zingabizi. -I-Laser Dicing: Sebenzisa imishayo ye-laser enamandla kakhulu ekusikeni okungathinteki, ilungele izinto eziphukayo noma ezinokuqina okuphezulu njenge-gallium nitride, enikeza ukunemba okuphezulu nokulahlekelwa okuncane. -New Technologies: Yethula ubuchwepheshe bokusika i-laser ne-plasma ukuze uqhubeke uthuthukisa ukusebenza kahle nokunemba kuyilapho unciphisa izindawo ezithinteke ukushisa. |

| Isigaba sokuhlanza | - Sebenzisa amanzi e-deionized (amanzi e-DI) nama-ejenti okuhlanza akhethekile, ahlanganiswe ne-ultrasonic noma yokuhlanza isifutho, ukususa udoti nothuli olukhiqizwa ngesikhathi sokusika, ukuvimbela izinsalela ukuthi zingathinti izinqubo ezilandelayo noma ukusebenza kukagesi we-chip. - Amanzi e-DI ahlanzekile kakhulu agwema ukuletha ukungcola okusha, aqinisekise indawo ehlanzekile ye-wafer. |

| Isigaba Sokuhlola | -Ukuhlolwa kwe-Optical: Sebenzisa amasistimu okubona amehlo ahlanganiswe nama-algorithms e-AI ukuze uhlonze amaphutha ngokushesha, uqiniseke ukuthi akukho mifantu noma ukuqhekeka kuma-chips adayisi, ukuthuthukisa ukusebenza kahle kokuhlola, nokunciphisa amaphutha abantu. -Ukulinganisa Ubukhulu: Qinisekisa ukuthi ubukhulu be-chip buhlangabezana nokucaciswa kwedizayini. -Ukuhlolwa kokusebenza kukagesi: Qinisekisa ukuthi ukusebenza kukagesi kwama-chips abalulekile kuhlangabezana nezindinganiso, okuqinisekisa ukwethembeka ezinhlelweni zokusebenza ezilandelayo. |

| Isigaba Sokuhlunga | - Sebenzisa izingalo zerobhothi noma izinkomishi zokumunca i-vacuum ukuze uhlukanise ama-chips afanelekayo kuhlaka lwetheyiphu futhi uwahlele ngokuzenzakalelayo ngokusekelwe ekusebenzeni, uqinisekisa ukusebenza kahle kokukhiqiza kanye nokuguquguquka kuyilapho uthuthukisa ukunemba. |

Inqubo yokusika i-wafer ihlanganisa ukuhlanzwa kwe-wafer, ukubeka, ukusika, ukuhlanza, ukuhlola, nokuhlunga, isinyathelo ngasinye sibalulekile. Ngokuthuthuka kwe-automation, i-laser cutting, kanye nobuchwepheshe bokuhlola i-AI, izinhlelo zesimanje zokusika i-wafer zingafinyelela ukunemba okuphezulu, isivinini, kanye nokulahleka kwempahla ephansi. Ngokuzayo, ubuchwepheshe obusha bokusika obufana ne-laser ne-plasma kancane kancane buzothatha indawo yokusika i-blade yendabuko ukuze kuhlangatshezwane nezidingo zemiklamo eyinkimbinkimbi ye-chip, iqhubekisele phambili ukuthuthukiswa kwezinqubo zokukhiqiza i-semiconductor.

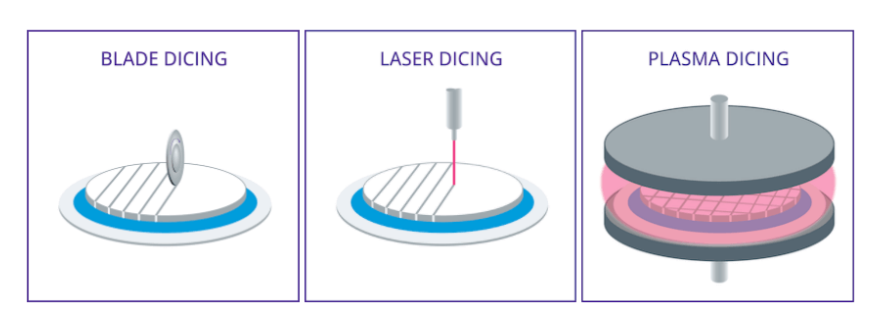

I-Wafer Cutting Technology kanye nezimiso zayo

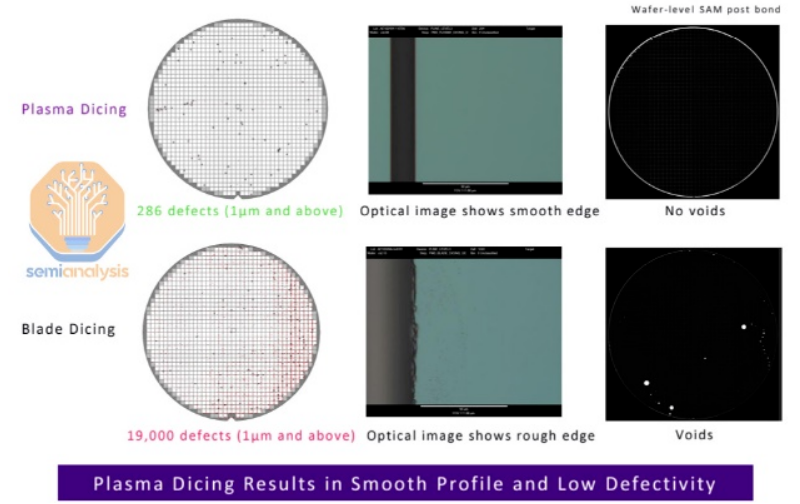

Isithombe sibonisa ubuchwepheshe obuthathu obujwayelekile bokusika ama-wafer:I-Blade Dicing,I-Laser Dicing, futhiI-Plasma Dicing. Ngezansi ukuhlaziya okuningiliziwe kanye nencazelo eyengeziwe yalawa masu amathathu:

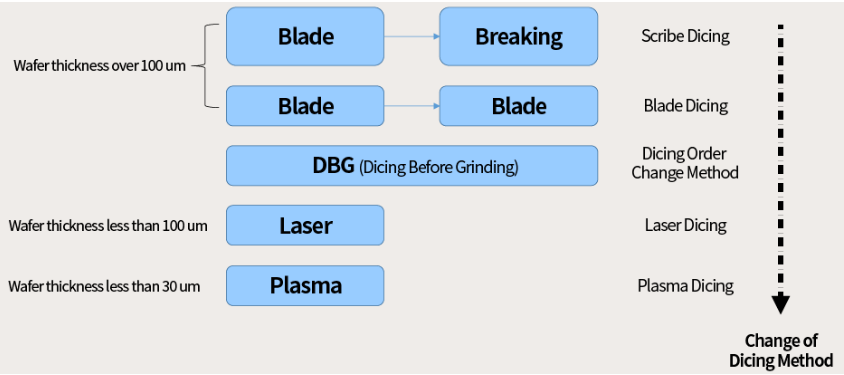

Ekwenziweni kwe-semiconductor, ukusikwa kwe-wafer kuyisinyathelo esibalulekile esidinga ukukhetha indlela yokusika efanele ngokusekelwe kubukhulu be-wafer. Isinyathelo sokuqala ukunquma ubukhulu be-wafer. Uma ubukhulu be-wafer budlula ama-microns ayi-100, ukudayela kwe-blade kungakhethwa njengendlela yokusika. Uma ukudayela kwe-blade kungafanele, indlela yokudayela ngokwehlukana ingasetshenziswa, ehlanganisa kokubili ukusika ababhali kanye namasu okudayela nge-blade.

Uma ubukhulu be-wafer buphakathi kwama-microns angu-30 no-100, indlela ye-DBG (Idayisi Ngaphambi Kokugaya) iyanconywa. Kulesi simo, ukusika ababhali, ukudayela nge-blade, noma ukulungisa ukulandelana kokusika njengoba kudingeka kungakhethwa ukuze kuzuzwe imiphumela engcono kakhulu.

Kumawafa amancane kakhulu anogqinsi olungaphansi kwama-microns angama-30, ukusika nge-laser kuba indlela ekhethwayo ngenxa yekhono lakhona lokusika amawafa amancane ngokunembile ngaphandle kokudala umonakalo omkhulu. Uma ukusika kwe-laser kungakwazi ukuhlangabezana nezidingo ezithile, ukusika kwe-plasma kungasetshenziswa njengenye indlela. Leli shidi lokugeleza linikeza indlela ecacile yokwenza izinqumo ukuze kuqinisekiswe ukuthi ubuchwepheshe obufaneleka kakhulu bokusika ama-wafer bukhethwa ngaphansi kwezimo ezihlukene zokujiya.

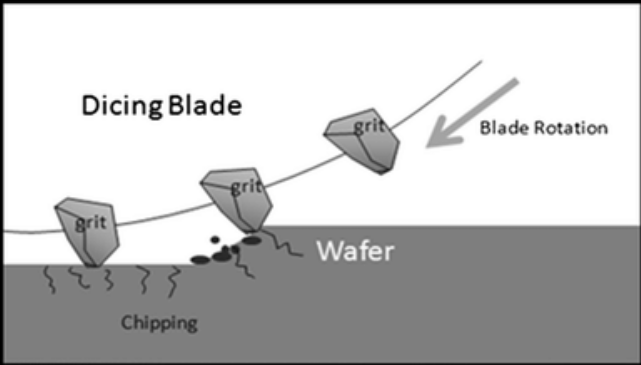

2.1 I-Mechanical Cutting Technology

Ubuchwepheshe bokusika bemishini buyindlela yendabuko yokudayela kwe-wafer. Umgomo oyinhloko uwukusebenzisa isondo lokugaya idayimane eligijima ngesivinini esikhulu njengethuluzi lokusika ukuze usike isinkwa esilucwecwana. Izinto ezisetshenziswayo ezibalulekile zihlanganisa isondo lokuphotha eliphethe umoya, elishayela ithuluzi lesondo lokugaya idayimane ngesivinini esikhulu ukuze lisike ngokunembile noma ligwebe endleleni yokusika echazwe ngaphambilini. Lobu buchwepheshe busetshenziswa kakhulu embonini ngenxa yezindleko zabo eziphansi, ukusebenza kahle okuphezulu, nokusebenza okubanzi.

Izinzuzo

Ukuqina okuphezulu nokumelana nokugqokwa kwamathuluzi amasondo okugaya idayimane kwenza ubuchwepheshe bokusika imishini bukwazi ukuzivumelanisa nezidingo zokusika zezinto eziyisinkwa esincanyana, kungakhathaliseki ukuthi yizinto zendabuko ezisekelwe ku-silicon noma ama-semiconductors amasha. Ukusebenza kwayo kulula, kunezidingo zobuchwepheshe eziphansi, okuqhubekisela phambili ukuthandwa kwayo ekukhiqizeni ngobuningi. Ukwengeza, uma kuqhathaniswa nezinye izindlela zokusika njengokusika kwe-laser, ukusika ngomshini kunezindleko ezilawulekayo, okuyenza ifanele izidingo zokukhiqiza umthamo omkhulu.

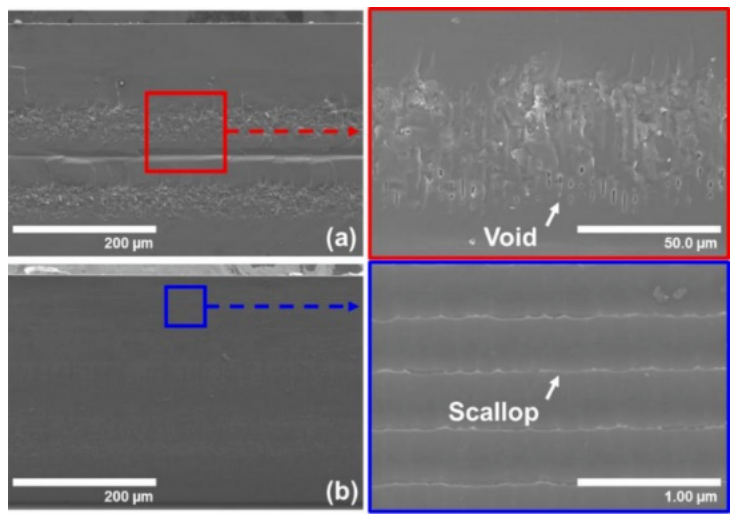

Ukulinganiselwa

Naphezu kwezinzuzo zayo eziningi, ubuchwepheshe bokusika bemishini bubuye bube nemingcele. Okokuqala, ngenxa yokuthintana ngokomzimba phakathi kwethuluzi nesinkwa esilucwecwana, ukunemba kokusika kunomkhawulo, ngokuvamile okuholela ekuchezukeni kwe-dimensional okungathinta ukunemba kokupakishwa nokuhlolwa kwe-chip okulandelayo. Okwesibili, amaphutha afana nokuqhekeka nokuqhekeka kungenzeka kalula phakathi nenqubo yokusika imishini, engathinti nje kuphela izinga lesivuno kodwa futhi engaba nomthelela omubi ekuthembekeni nasekuphileni kwama-chips. Ukulimala komshini okubangelwa ingcindezi kuyingozi kakhulu ekwenzeni ama-chip asondelene kakhulu, ikakhulukazi lapho kusikwa izinto eziphukayo, lapho lezi zinkinga zigqama kakhulu.

Ukuthuthukiswa Kwezobuchwepheshe

Ukuze banqobe le mikhawulo, abacwaningi baqhubeka bethuthukisa inqubo yokusika ngomshini. Ukuthuthukiswa okubalulekile kufaka phakathi ukuthuthukisa ukwakheka nokukhethwa kwezinto ezibonakalayo zamasondo okugaya ukuze kuthuthukiswe ukunemba kokusika nokuqina. Ukwengeza, ukwenza kahle ukwakheka kwesakhiwo kanye nezinhlelo zokulawula zemishini yokusika kuye kwathuthukisa ukuzinza kanye nokuzenzakalela kwenqubo yokusika. Le ntuthuko inciphisa amaphutha enziwa ukusebenza kwabantu futhi ithuthukise ukuvumelana kokusikeka. Ukwethulwa kokuhlolwa okuthuthukisiwe kanye nobuchwepheshe bokulawula ikhwalithi ukuze kuqashwe ngesikhathi sangempela izinto ezididayo phakathi nenqubo yokusika kuthuthukise kakhulu ukwethembeka nokukhiqiza.

Ukuthuthukiswa Kwekusasa kanye Nobuchwepheshe obusha

Nakuba ubuchwepheshe bokusika ngomshini busabambe isikhundla esibalulekile ekusikeni kwe-wafer, ubuchwepheshe obusha bokusika buthuthuka ngokushesha njengoba izinqubo ze-semiconductor zishintsha. Isibonelo, ukusetshenziswa kwe-thermal laser cutting technology kunikeza izixazululo ezintsha ezindabeni zokunemba kanye nesici ekusikeni komshini. Le ndlela yokusika engathinteki inciphisa ukucindezelwa komzimba ku-wafer, yehlisa kakhulu izehlakalo zokuqhekeka nokuqhekeka, ikakhulukazi uma kusikwa izinto eziphukayo. Esikhathini esizayo, ukuhlanganiswa kobuchwepheshe bokusika imishini namasu okusika abasafufusa kuzohlinzeka ngokukhiqiza kwe-semiconductor ngezinketho eziningi nokuguquguquka, kuqhubeke kuthuthukise ukusebenza kahle kokukhiqiza kanye nekhwalithi ye-chip.

Ekuphetheni, nakuba ubuchwepheshe bokusika bemishini bunezithiyo ezithile, ukuthuthukiswa okuqhubekayo kwezobuchwepheshe kanye nokuhlanganiswa kwayo nezindlela ezintsha zokusika kuvumela ukuthi kusabambe iqhaza elibalulekile ekukhiqizeni kwe-semiconductor nokugcina ukuncintisana kwayo ezinkambisweni zesikhathi esizayo.

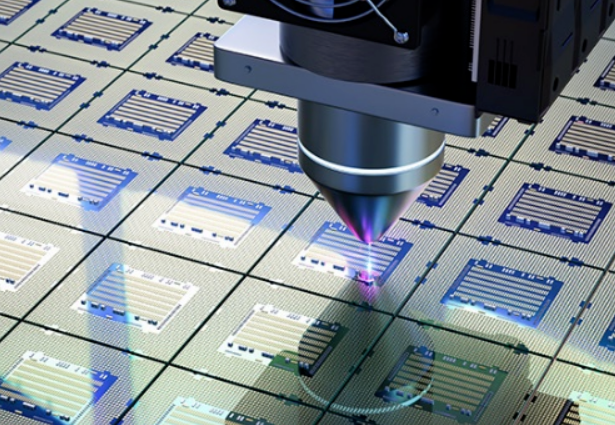

2.2 I-Laser Cutting Technology

Ubuchwepheshe bokusika i-laser, njengendlela entsha yokusika i-wafer, kancane kancane buye bathola ukunakwa okubanzi embonini ye-semiconductor ngenxa yokunemba kwayo okuphezulu, ukuntuleka kokulimala komshini wokuxhumana, kanye nekhono lokusika ngokushesha. Lobu buchwepheshe busebenzisa ukuminyana okukhulu kwamandla nekhono lokugxila le-laser ukuze kwakhe indawo encane ethinteke ekushiseni endaweni yezinto eziyisicwecwana. Lapho i-laser beam isetshenziswa ku-wafer, ingcindezi eshisayo ekhiqizwayo ibangela ukuthi impahla iphuke endaweni ebekiwe, kuzuzwe ukusikwa okunembile.

Izinzuzo Laser Cutting Technology

• Ukunemba okuphezulu: Ikhono lokuma elinembile le-laser livumela ukunemba kokusika kweleveli ye-nanometer, ehlangabezana nezimfuneko zesimanje zokwenziwa kwesekethe ehlanganisiwe enokuminyana okuphezulu.

• Akekho Othintana Nomshini: Ukusika i-laser kugwema ukuthintana ngokomzimba nesinkwa esilucwecwana, kuvimbela izinkinga ezivamile ekusikeni komshini, njengokuchopha nokuqhekeka, kuthuthukisa kakhulu izinga lokukhiqiza nokuthembeka kwama-chips.

• Fast Cutting Speed: Isivinini esikhulu sokusika i-laser sinomthelela ekwandiseni ukusebenza kahle kokukhiqiza, okuyenza ifaneleke ikakhulukazi izimo zokukhiqiza ezinkulu, ezinesivinini esikhulu.

Izinselele Okubhekana Nazo

• Izindleko Eziphakeme Zezisetshenziswa: Ukutshalwa kwezimali kokuqala kwemishini yokusika i-laser kuphezulu, okwethula ingcindezi yezomnotho, ikakhulukazi kumabhizinisi amancane naphakathi nendawo.

• Ukulawula Inqubo Eyinkimbinkimbi: Ukusika i-laser kudinga ukulawula okunembile kwemingcele eminingana, okuhlanganisa ukuminyana kwamandla, indawo yokugxila, kanye nesivinini sokusika, okwenza inqubo ibe yinkimbinkimbi.

• Izinkinga Zendawo Ethinteke Ukushisa: Nakuba imvelo yokungathintani ye-laser yehlisa ukulimala kokusebenza, ukucindezelwa okushisayo okubangelwa indawo ethinteke ukushisa (HAZ) kungaba nomthelela ongemuhle ezimpahleni ze-wafer material. Ukwenziwa ngcono okwengeziwe kwenqubo kuyadingeka ukuze kuncishiswe lo mphumela.

Iziqondiso Zokuthuthukiswa Kwezobuchwepheshe

Ukuze kubhekwane nalezi zinselelo, abacwaningi bagxile ekwehliseni izindleko zemishini, ukuthuthukisa ukusebenza kahle kokusika, kanye nokwenza kahle ukugeleza kwenqubo.

• Ama-Lasers asebenzayo nama-Optical Systems: Ngokuthuthukisa ama-lasers asebenza kahle kakhulu kanye nezinhlelo ezithuthukisiwe ze-optical, kungenzeka ukwehlisa izindleko zemishini ngenkathi kuthuthukiswa ukunemba nokusheshisa kokusika.

• Ukuthuthukisa Amapharamitha Enqubo: Ucwaningo olujulile mayelana nokusebenzisana phakathi kwama-lasers nezinto eziyisicwecwana zenziwa ukuze kuthuthukiswe izinqubo ezinciphisa indawo ethinteke ukushisa, ngaleyo ndlela kuthuthukiswe ikhwalithi yokusika.

• Amasistimu Okulawula Ahlakaniphile: Ukuthuthukiswa kobuchwepheshe bokulawula okuhlakaniphile kuhloswe ukwenza ngokuzenzakalelayo kanye nokwandisa inqubo yokusika i-laser, ukuthuthukisa ukuzinza nokuvumelana kwayo.

Ubuchwepheshe bokusika i-laser busebenza kakhulu kuma-wafers amancane kakhulu kanye nezimo zokusika ezinembayo. Njengoba ama-wafer osayizi akhula futhi ukuminyana kwesekethe kukhuphuka, izindlela zokusika zemishini zendabuko ziyazabalaza ukuhlangabezana nezidingo ezinembayo nezisebenza kahle kakhulu zokukhiqiza i-semiconductor yesimanje. Ngenxa yezinzuzo zayo eziyingqayizivele, ukusika kwe-laser kuba yisixazululo esithandwayo kule mikhakha.

Nakuba ubuchwepheshe bokusika i-laser busabhekene nezinselele ezifana nezindleko eziphezulu zemishini kanye nobunkimbinkimbi benqubo, izinzuzo zabo eziyingqayizivele ngokunemba okuphezulu kanye nokulimala okungathinteki kukwenza kube isiqondiso esibalulekile sokuthuthukiswa ekukhiqizeni kwe-semiconductor. Njengoba ubuchwepheshe be-laser nezinhlelo zokulawula ezihlakaniphile ziqhubeka nokuthuthuka, ukusika kwe-laser kulindeleke ukuthi kuthuthukise ukusebenza kahle kwe-wafer nokusika ikhwalithi, kuqhubekisele phambili intuthuko eqhubekayo yemboni ye-semiconductor.

2.3 I-Plasma Cutting Technology

Ubuchwepheshe bokusika i-Plasma, njengendlela yokudayela eyisicwecwana esafufusayo, buthole ukunakwa okubalulekile eminyakeni yamuva nje. Lobu buchwepheshe busebenzisa imishayo ye-plasma enamandla amakhulu ukusika amawafa ngokunembile ngokulawula amandla, isivinini, kanye nendlela yokusika ye-plasma beam, kuzuzwe imiphumela emihle yokusika.

Isimiso Sokusebenza Nezinzuzo

Inqubo yokusika i-plasma incike emazingeni okushisa aphezulu, i-high-energy plasma beam ekhiqizwa imishini. Le nsimbi ingashisisa iwafer endaweni yayo yokuncibilika noma yokuhwamuka ngesikhathi esifushane kakhulu, okuvumela ukusika ngokushesha. Uma kuqhathaniswa nokusika kwemishini yendabuko noma nge-laser, ukusika kwe-plasma kuyashesha futhi kukhiqiza indawo encane ethinteke ekushiseni, kunciphisa ngempumelelo ukuvela kokuqhekeka nokulimala ngesikhathi sokusika.

Ekusetshenzisweni okungokoqobo, ubuchwepheshe bokusika i-plasma bunekhono ikakhulukazi ekuphatheni ama-wafers anezimo eziyinkimbinkimbi. Uthango lwalo olunamandla amakhulu, olulungisekayo lwe-plasma lungasika kalula amawafa amise ngendlela engavamile ngokunemba okuphezulu. Ngakho-ke, ekukhiqizeni ama-microelectronics, ikakhulukazi ekukhiqizeni okwenziwe ngokwezifiso kanye nenqwaba yama-chips aphezulu, lobu buchwepheshe bubonisa isithembiso esihle sokusetshenziswa kabanzi.

Izinselelo Nemikhawulo

Naphezu kwezinzuzo eziningi zobuchwepheshe bokusika i-plasma, iphinde ibhekane nezinselele ezithile.

• Inqubo Eyinkimbinkimbi: Inqubo yokusika i-plasma iyinkimbinkimbi futhi idinga imishini yokunemba okuphezulu kanye nabaqhubi abanolwazi ukuze baqinisekiseukunemba nokuzinza ekusikeni.

• Ukulawula Imvelo Nokuphepha: Izinga lokushisa eliphezulu, imvelo yamandla aphezulu we-plasma beam idinga ukulawulwa kwemvelo okuqinile kanye nezinyathelo zokuphepha, okwandisa ubunkimbinkimbi nezindleko zokuqalisa.

Iziqondiso Zokuthuthukiswa Kwekusasa

Ngokuthuthuka kwezobuchwepheshe, izinselelo ezihlobene nokusikwa kwe-plasma kulindeleke ukuthi zinqotshwe kancane kancane. Ngokuthuthukisa imishini yokusika ehlakaniphile futhi ezinzile, ukuncika ekusebenzeni kwezandla kungancishiswa, ngaleyo ndlela kuthuthukiswe ukusebenza kahle kokukhiqiza. Ngasikhathi sinye, ukwenza ngcono imingcele yenqubo kanye nendawo yokusika kuzosiza ukunciphisa izingozi zokuphepha kanye nezindleko zokusebenza.

Embonini ye-semiconductor, ukuthuthukiswa kobuchwepheshe bokusika ama-wafer kanye nokudayela kubalulekile ekuqhubekiseni intuthuko yemboni. Ubuchwepheshe bokusika i-Plasma, nobunemba bayo obuphezulu, ukusebenza kahle, kanye nekhono lokuphatha izimo eziyinkimbinkimbi zama-wafer, buye bavela njengomdlali omusha obalulekile kulo mkhakha. Nakuba ezinye izinselele zisekhona, lezi zinkinga zizoxazululwa kancane kancane ngokusungulwa kwezobuchwepheshe okuqhubekayo, okuletha amathuba amaningi kanye namathuba okukhiqiza ama-semiconductor.

Amathemba okusetshenziswa kobuchwepheshe bokusika i-plasma makhulu, futhi kulindeleke ukuthi abambe iqhaza elibaluleke kakhulu ekukhiqizeni ama-semiconductor esikhathini esizayo. Ngokuqhubeka nokusungula izinto ezintsha kanye nokwenza kahle, ukusika i-plasma ngeke kubhekane nezinselele ezikhona kuphela kodwa futhi kuzoba umshayeli onamandla wokukhula kwemboni ye-semiconductor.

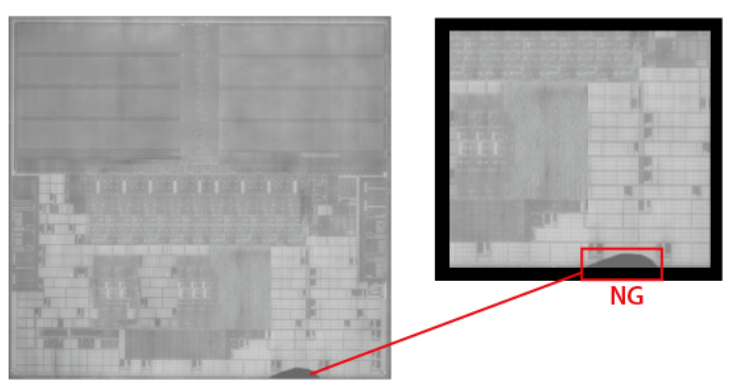

2.4 Ukusika Ikhwalithi kanye Nezici Ezinomthelela

Ikhwalithi yokusika i-wafer ibalulekile ekupakishweni kwe-chip, ukuhlolwa, kanye nokusebenza kukonke kanye nokuthembeka komkhiqizo wokugcina. Izinkinga ezijwayelekile okuhlangatshezwana nazo ngesikhathi sokusika zifaka ukuqhekeka, ukuqhekeka, nokuchezuka kokusika. Lezi zinkinga zithonywa izici eziningana ezisebenza ndawonye.

| Isigaba | Okuqukethwe | Umthelela |

| Amapharamitha okucubungula | Ijubane lokusika, izinga lokuphakelayo, nokujula kokusika kuthinta ngokuqondile ukuzinza nokunemba kwenqubo yokusika. Izilungiselelo ezingalungile zingaholela ekugxilweni kwengcindezi nendawo ethinteke kakhulu ukushisa, okuholela ekuqhekekeni nokuqhekeka. Ukulungisa amapharamitha ngokufanele ngokusekelwe ezintweni eziyisicwecwana, ukujiya, kanye nezidingo zokusika kuyisihluthulelo sokuzuza imiphumela yokusika oyifunayo. | Imingcele yenqubo efanele iqinisekisa ukusika okunembile futhi inciphisa ubungozi bokulimala njengokuqhekeka nokuqhekeka. |

| Izinsiza kanye Nezici Zento | -Ikhwalithi yeBlade: Izinto ezibonakalayo, ubulukhuni, nokumelana nokugqoka kwe-blade kuthonya ukushelela kwenqubo yokusika kanye nokucaba kwendawo yokusika. Ama-blade ekhwalithi engeyinhle akhuphula ukungqubuzana kanye nengcindezi yokushisa, okungase kuholele ekuqhekekeni noma ekuqhekekeni. Ukukhetha impahla ye-blade efanele kubalulekile. -Ukusebenza Okupholile: Izinto ezipholile zisiza ukunciphisa izinga lokushisa lokusika, ukunciphisa ukungqubuzana, nokusula imfucumfucu. Ukupholisa okungasebenzi kahle kungaholela emazingeni okushisa aphezulu kanye nokunqwabelana kwemfucumfucu, kuthinte ikhwalithi yokusika nokusebenza kahle. Ukukhetha izinto zokupholisa ezisebenza kahle nezingayingeni imvelo kubalulekile. | Ikhwalithi ye-blade ithinta ukunemba nokushelela kokusikwa. Isibandisi esingasebenzi kahle singase sibe nekhwalithi ephansi yokusika nokusebenza kahle, okugqamisa isidingo sokusebenzisa okupholisa kahle. |

| Ukulawulwa Kwenqubo kanye Nokuhlolwa Kwekhwalithi | -Ukulawulwa Kwenqubo: Ukuqapha kwesikhathi sangempela nokulungiswa kwemingcele yokusika ukhiye ukuze kuqinisekiswe ukuzinza nokuvumelana enqubweni yokusika. -Ukuhlolwa Kwekhwalithi: Ukuhlola ukubukeka kwangemva kokusika, izilinganiso zobukhulu, nokuhlolwa kokusebenza kukagesi kusiza ukuhlonza nokubhekana nezinkinga zekhwalithi ngokushesha, ukuthuthukisa ukunemba nokuvumelana. | Ukulawula inqubo efanele kanye nokuhlolwa kwekhwalithi kusiza ukuqinisekisa imiphumela engaguquki, yokusika yekhwalithi ephezulu kanye nokutholwa kusenesikhathi kwezinkinga ezingaba khona. |

Ukuthuthukisa Ikhwalithi Yokusika

Ukuthuthukisa ikhwalithi yokusika kudinga indlela ebanzi ecabangela imingcele yenqubo, okokusebenza kanye nokukhethwa kwempahla, ukulawula inqubo, nokuhlolwa. Ngokuqhubeka nokucwenga ubuchwepheshe bokusika kanye nezindlela zenqubo yokuthuthukisa, ukunemba nokuzinza kokusikwa kwe-wafer kungathuthukiswa, kuhlinzekwe ukwesekwa okuthembekile kwezobuchwepheshe embonini yokukhiqiza i-semiconductor.

#03 Ukuphatha Nokuhlola Ngemva Kokusika

3.1 Ukuhlanza Nokomisa

Izinyathelo zokuhlanza nokomisa ngemva kokusikwa kwe-wafer zibalulekile ekuqinisekiseni ikhwalithi ye-chip nokuqhubeka kahle kwezinqubo ezilandelayo. Ngalesi sigaba, kubalulekile ukususa ngokuphelele izinsalela ze-silicon, izinsalela ezipholile, nokunye ukungcola okukhiqizwa ngesikhathi sokusika. Kubalulekile ngokufanayo ukuqinisekisa ukuthi ama-chips awonakaliswa ngesikhathi sokuhlanza, futhi ngemva kokoma, qinisekisa ukuthi akukho mswakamo ohlala endaweni ye-chip ukuvimbela izinkinga ezinjengokugqwala noma ukukhishwa kwe-electrostatic.

Ukuphatha Ngemva Kokusika: Inqubo Yokuhlanza Nokomisa

| Isinyathelo Sokucubungula | Okuqukethwe | Umthelela |

| Ukuhlanza Inqubo | -Indlela: Sebenzisa ama-agent okuhlanza akhethekile namanzi ahlanzekile, ahlanganiswe nezindlela zokuxubha ze-ultrasonic noma zemishini zokuhlanza. | Iqinisekisa ukususwa ngokuphelele kokungcola futhi ivimbele ukulimala kwama-chips ngesikhathi sokuhlanza. |

| -Ukukhethwa kwe-ejenti yokuhlanza: Khetha ngokusekelwe kumpahla ye-wafer kanye nohlobo olungcolile ukuze uqinisekise ukuhlanza okuphumelelayo ngaphandle kokulimaza i-chip. | Ukukhetha kahle i-ejenti kuyisihluthulelo sokuhlanza okusebenzayo nokuvikela i-chip. | |

| -Ukulawula Ipharamitha: Lawula ngokuqinile izinga lokushisa lokuhlanza, isikhathi, kanye nokugxilwa kwesisombululo sokuhlanza ukuze uvimbele izinkinga zekhwalithi ezibangelwa ukuhlanza okungalungile. | Izilawuli zisiza ukugwema ukulimaza i-wafer noma ukushiya ukungcola ngemuva, ukuqinisekisa ikhwalithi engaguquki. | |

| Inqubo Yokomisa | -Izindlela Zendabuko: Ukomiswa komoya kwemvelo nokomisa komoya oshisayo, okunokusebenza kahle okuphansi futhi kungaholela ekwakhekeni kukagesi omile. | Kungase kubangele ezikhathini zokomisa kancane kanye nezinkinga ezingaba khona ezimile. |

| -I-Modern Technologies: Sebenzisa ubuchwepheshe obuthuthukisiwe obufana nokumisa i-vacuum nokomisa nge-infrared ukuze uqinisekise ukuthi ama-chips oma ngokushesha futhi ugweme imiphumela eyingozi. | Inqubo yokomisa esheshayo nesebenza kahle kakhudlwana, enciphisa ingcuphe yokukhipha i-static noma izinkinga ezihlobene nomswakama. | |

| Ukukhethwa Kwezisetshenziswa Nokunakekelwa | -Ukukhethwa Kwezisetshenziswa: Imishini yokuhlanza neyomisa esebenza kahle kakhulu ithuthukisa ukusebenza kahle kokucubungula futhi ilawule kahle izinkinga ezingase zibe khona ngesikhathi sokuphatha. | Imishini yekhwalithi ephezulu iqinisekisa ukucubungula okungcono futhi inciphisa amathuba okuba namaphutha ngesikhathi sokuhlanza nokomisa. |

| -Ukugcinwa Kwezisetshenziswa: Ukuhlolwa njalo nokunakekelwa kwemishini kuqinisekisa ukuthi ihlala isesimweni esikahle sokusebenza, kuqinisekisa ikhwalithi ye-chip. | Ukunakekelwa okufanele kuvimbela ukwehluleka kwemishini, kuqinisekisa ukucubungula okuthembekile nokusezingeni eliphezulu. |

Ukuhlanza Nokomisa Ngemva Kokusika

Izinyathelo zokuhlanza nokomisa ngemva kokusikwa kwe-wafer ziyizinqubo eziyinkimbinkimbi futhi ezibucayi ezidinga ukucatshangelwa ngokucophelela kwezinto eziningi ukuze kuqinisekiswe umphumela wokugcina wokucubungula. Ngokusebenzisa izindlela zesayensi kanye nezinqubo eziqinile, kungenzeka ukuqinisekisa ukuthi i-chip ngayinye ingena ezigabeni zokupakisha nokuhlola ezilandelayo isesimweni esifanele.

Ukuhlolwa Kwangemva Kokusika Nokuhlolwa

| Isinyathelo | Okuqukethwe | Umthelela |

| Isinyathelo Sokuhlola | 1.Ukuhlola Okubonakalayo: Sebenzisa okokusebenza kokuhlola okubonakalayo noma okuzenzakalelayo ukuze uhlole ukukhubazeka okubonakalayo njengokuqhekeka, ukuqhekeka, noma ukungcola endaweni ye-chip. Khomba ngokushesha ama-chips alimele ukuze ugweme ukumosha. | Isiza ekuhlonzeni nasekususeni ama-chips angasebenzi ekuqaleni kwenqubo, kwehlise ukulahleka kwezinto. |

| 2.Ukulinganisa Usayizi: Sebenzisa amadivayisi okulinganisa ukunemba ukuze ulinganise ngokunembile ubukhulu be-chip, uqinisekise ukuthi usayizi osikiwe uhlangabezana nezicaciso zedizayini futhi uvimbele izinkinga zokusebenza noma ubunzima bokupakisha. | Iqinisekisa ukuthi ama-chips angaphakathi kwemikhawulo yosayizi edingekayo, ivimbela ukuwohloka kokusebenza noma izinkinga zokuhlanganisa. | |

| 3.Ukuhlolwa kokusebenza kukagesi: Hlola amapharamitha kagesi abalulekile njengokumelana, amandla, kanye ne-inductance, ukuze uhlonze ama-chips angahambisani nokuqinisekisa ukuthi ama-chips afanelekayo kuphela aqhubekela esigabeni esilandelayo. | Iqinisekisa kuphela ama-chips asebenzayo futhi ahlolwe ukusebenza aqhubekela phambili enqubweni, enciphisa ingcuphe yokwehluleka ezigabeni zakamuva. | |

| Isinyathelo Sokuhlola | 1.Ukuhlola Okusebenzayo: Qinisekisa ukuthi ukusebenza okuyisisekelo kwe-chip kusebenza njengokuhlosiwe, ukuhlonza nokuqeda ama-chips anokusebenza okungavamile. | Iqinisekisa ukuthi ama-chips ahlangabezana nezidingo eziyisisekelo zokusebenza ngaphambi kokudlulela ezigabeni zakamuva. |

| 2.Ukuhlola Ukuthembeka: Hlola ukuqina kokusebenza kwe-chip ngaphansi kokusetshenziswa isikhathi eside noma izindawo ezinokhahlo, ngokuvamile ezibandakanya ukuguga okuphezulu kwethempelesha, izinga lokushisa eliphansi, nokuhlolwa komswakamo ukuze kulingise izimo ezimbi zomhlaba wangempela. | Iqinisekisa ukuthi ama-chips angakwazi ukusebenza ngokuthembekile ngaphansi kwezinhlobonhlobo zezimo zemvelo, ukuthuthukisa impilo ende yomkhiqizo nokuzinza. | |

| 3.Ukuhlola Ukuhambisana: Qinisekisa ukuthi i-chip isebenza kahle nezinye izingxenye noma amasistimu, uqinisekise ukuthi awekho amaphutha noma ukonakala kokusebenza ngenxa yokungahambisani. | Iqinisekisa ukusebenza kahle ezinhlelweni zokusebenza zomhlaba wangempela ngokuvimbela izinkinga zokusebenzisana. |

3.3 Ukupakisha Nokugcina

Ngemuva kokusikwa kwe-wafer, ama-chips awumphumela obalulekile wenqubo yokukhiqiza i-semiconductor, futhi izigaba zawo zokupakisha nezokugcina zibaluleke ngokulinganayo. Izinyathelo ezifanele zokupakisha nezokugcina zibalulekile hhayi kuphela ekuqinisekiseni ukuphepha nokuzinza kwama-chip ngesikhathi sokuthutha nokugcinwa kodwa futhi nokuhlinzeka ngokusekela okuqinile kokukhiqizwa okulandelayo, ukuhlolwa, nezigaba zokupakisha.

Isifinyezo Sezigaba Zokuhlola Nezokuhlola:

Izinyathelo zokuhlola nokuhlola ama-chips ngemva kokusikwa kwe-wafer zimboza izici eziningi, okuhlanganisa ukuhlola okubonakalayo, ukukalwa kosayizi, ukuhlolwa kokusebenza kukagesi, ukuhlola ukusebenza, ukuhlola ukwethembeka, nokuhlola ukuhambisana. Lezi zinyathelo zixhumene futhi ziyahambisana, zakha umgoqo oqinile wokuqinisekisa ikhwalithi nokuthembeka komkhiqizo. Ngezinqubo eziqinile zokuhlola nokuhlola, izinkinga ezingaba khona zingabonwa futhi zixazululwe ngokushesha, kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana nezidingo zamakhasimende kanye nokulindelwe.

| Isici | Okuqukethwe |

| Izinyathelo zokupakisha | 1.I-Anti-static: Izinto zokupakisha kufanele zibe nezakhiwo ezinhle kakhulu zokulwa ne-static ukuvimbela ugesi omile ukuthi ungalimazi amadivaysi noma uphazamise ukusebenza kwawo. |

| 2.Ukufaka umswakama: Izinto zokupakisha kufanele zibe nokumelana okuhle komswakama ukuvimbela ukugqwala kanye nokuwohloka kokusebenza kukagesi okubangelwa umswakama. | |

| 3.I-Shockproof: Izinto zokupakisha kufanele zinikeze ukumuncwa okusebenzayo kokushaqeka ukuze kuvikelwe ama-chips ekudlidlizeni nomthelela ngesikhathi sokuthutha. | |

| Indawo Yesitoreji | 1.Ukulawula Umswakama: Lawula ngokuqinile umswakama ngaphakathi kwebanga elifanele ukuze uvimbele ukumuncwa komswakamo kanye nokugqwala okubangelwa ukuswakama okweqile noma izinkinga ezimile ezibangelwa umswakama ophansi. |

| 2.Inhlanzeko: Gcina indawo yokugcina ihlanzekile ukuze ugweme ukungcoliswa kwama-chips ngothuli nokungcola. | |

| 3.Ukulawula izinga lokushisa: Setha ibanga lokushisa elinengqondo futhi ugcine ukuzinza kwezinga lokushisa ukuze uvimbele ukuguga okusheshayo ngenxa yokushisa okukhulu noma izinkinga zokufingqa okubangelwa amazinga okushisa aphansi. | |

| Ukuhlola Okuvamile | Hlola futhi uhlole njalo ama-chips agciniwe, usebenzisa ukuhlola okubonakalayo, izilinganiso zosayizi, nokuhlolwa kokusebenza kukagesi ukuze uhlonze futhi ulungise izinkinga ezingase zibe khona ngesikhathi. Ngokusekelwe esikhathini sokugcina nezimo, hlela ukusetshenziswa kwama-chip ukuze uqinisekise ukuthi asetshenziswa esimweni esifanele. |

Udaba lwama-microcracks kanye nomonakalo phakathi nenqubo yokudayela ama-wafer kuyinselele enkulu ekukhiqizeni ama-semiconductor. Ingcindezi yokusika iyimbangela eyinhloko yalesi simo, njengoba idala imifantu emincane kanye nomonakalo endaweni ewucwecwe, okuholela ekwenyukeni kwezindleko zokukhiqiza kanye nokuncipha kwekhwalithi yomkhiqizo.

Ukuze kuxazululwe le nselelo, kubalulekile ukunciphisa ukucindezeleka futhi usebenzise amasu okusika angcono, amathuluzi, nezimo. Ukunaka ngokucophelela izici ezifana ne-blade material, isivinini sokusika, ukucindezela, nezindlela zokupholisa kungasiza ekunciphiseni ukwakheka kwama-microcracks futhi kuthuthukise isivuno sonke senqubo. Ukwengeza, ucwaningo oluqhubekayo kubuchwepheshe bokusika obuthuthuke kakhulu, obufana ne-laser dicing, luhlola izindlela zokuqhubeka nokunciphisa lezi zinkinga.

Njengempahla entekenteke, ama-wafer athambekele ekushintsheni kwesakhiwo sangaphakathi uma engaphansi kwengcindezi yemishini, eshisayo, noma yamakhemikhali, okuholela ekwakhekeni kwama-microcracks. Nakuba le mifantu ingase ingabonakali ngokushesha, ingakhula futhi ibangele umonakalo omkhulu njengoba inqubo yokukhiqiza iqhubeka. Le nkinga iba yinkinga ikakhulukazi phakathi nezigaba zokupakisha nokuhlola ezilandelayo, lapho ukushintshashintsha kwezinga lokushisa kanye nokucindezeleka okwengeziwe kwemishini kungabangela ukuthi lama-microcracks aguquke abe ukuphuka okubonakalayo, okungase kuholele ekuhlulekeni kwe-chip.

Ukuze unciphise le ngozi, kubalulekile ukulawula inqubo yokusika ngokucophelela ngokulungisa imingcele efana nesivinini sokusika, ingcindezi, nezinga lokushisa. Ukusebenzisa izindlela zokusika ezinolaka oluncane, njengokudayela nge-laser, kunganciphisa ukucindezelwa komshini ku-wafer futhi kunciphise ukwakheka kwama-microcracks. Ukwengeza, ukusebenzisa izindlela zokuhlola ezithuthukile njengokuskena kwe-infrared noma i-X-ray imaging ngesikhathi senqubo yokudayela eyi-wafer kungasiza ukuthola le mifantu yesigaba sangaphambi kwesikhathi ngaphambi kokuthi idale omunye umonakalo.

Ukulimala kwendawo eyisicwecwana kuyinto ekhathaza kakhulu inqubo yokudayela, njengoba ingaba nomthelela oqondile ekusebenzeni nasekuthembekeni kwe-chip. Umonakalo onjalo ungadalwa ukusetshenziswa okungafanele kwamathuluzi okusika, imingcele yokusika engalungile, noma ukukhubazeka kwempahla etholakala ku-wafer ngokwayo. Kungakhathaliseki ukuthi iyini imbangela, le monakalo ingaholela ekuguqulweni kokumelana nogesi noma i-capacitance yesifunda, okuthinta ukusebenza okuphelele.

Ukuze kuxazululwe lezi zinkinga, kucutshungulwa amasu amabili abalulekile:

1.Ukuthuthukisa amathuluzi okusika kanye nemingcele: Ngokusebenzisa ama-blade abukhali, ukulungisa isivinini sokusika, nokuguqula ukujula kokusika, ukugxila kokucindezeleka ngesikhathi sokusika kungancishiswa, ngaleyo ndlela kunciphise amandla okulimala.

2.Ukuhlola ubuchwepheshe obusha bokusika: Amasu athuthukile afana nokusika i-laser nokusika i-plasma kunikeza ukunemba okuthuthukisiwe ngenkathi kunciphisa izinga lomonakalo owenziwe ku-wafer. Lobu buchwepheshe buyacwaningwa ukuze kutholwe izindlela zokufinyelela ukunemba okuphezulu kokusika kuyilapho kunciphisa ukucindezeleka okushisayo nokokusebenza ku-wafer.

I-Thermal Impact Area kanye Nemiphumela Yayo Ekusebenzeni

Ezinqubweni zokusika ezishisayo ezifana nokusika kwe-laser ne-plasma, amazinga okushisa aphezulu adala indawo yomthelela oshisayo endaweni ye-wafer. Le ndawo, lapho i-gradient yezinga lokushisa ibalulekile, ingashintsha izici zezinto ezibonakalayo, ithinte ukusebenza kokugcina kwe-chip.

Umthelela Wendawo Ethintekile Eshisayo (TAZ):

Izinguquko Zesakhiwo Sekristalu: Ngaphansi kwamazinga okushisa aphezulu, ama-athomu angaphakathi kwento eyisicwecwana angase ahlele kabusha, abangele ukuhlanekezela esakhiweni sekristalu. Lokhu kuhlanekezela kwenza into ibe buthaka, inciphise amandla ayo okusebenza nokuzinza, okwandisa ingozi yokuhluleka kwe-chip ngesikhathi sokusetshenziswa.

Izinguquko Ezimpahleni zikagesi: Amazinga okushisa aphezulu angashintsha ukugxilwa kwenkampani yenethiwekhi kanye nokuhamba kwezinto ze-semiconductor, okuthinta ukuqhutshwa kukagesi we-chip kanye nokusebenza kahle kokudlulisela kwamanje. Lezi zinguquko zingase ziholele ekwehleni kokusebenza kwe-chip, okungenzeka kuyenze ingafaneleki injongo yayo.

Ukunciphisa le miphumela, ukulawula izinga lokushisa ngesikhathi sokusika, ukuthuthukisa imingcele yokusika, nezindlela zokuhlola ezifana namajethi okupholisa noma ukwelapha ngemva kokucubungula amasu abalulekile okunciphisa izinga lomthelela oshisayo nokugcina ubuqotho bezinto ezibonakalayo.

Sekukonke, kokubili ama-microcracks kanye nezindawo zomthelela oshisayo ziyizinselelo ezibalulekile kubuchwepheshe bokudayela ama-wafer. Ucwaningo oluqhubekayo, oluhambisana nentuthuko yezobuchwepheshe kanye nezinyathelo zokulawula ikhwalithi, kuzodingeka ukuze kuthuthukiswe ikhwalithi yemikhiqizo ye-semiconductor futhi kuthuthukiswe ukuncintisana kwayo ezimakethe.

Izinyathelo Zokulawula Indawo Yomthelela Oshisayo:

Ukuthuthukisa Amapharamitha wenqubo yokusika: Ukunciphisa isivinini sokusika namandla kunganciphisa ngempumelelo usayizi wendawo yomthelela we-thermal (TAZ). Lokhu kusiza ekulawuleni inani lokushisa okukhiqizwa ngesikhathi sokusika, okuthinta ngokuqondile izakhiwo ze-wafer.

I-Advanced Cooling Technologies: Ukusetshenziswa kobuchwepheshe obufana nokupholisa i-nitrogen ewuketshezi nokupholisa nge-microfluidic kungakhawulela kakhulu ububanzi bendawo yomthelela oshisayo. Lezi zindlela zokupholisa zisiza ekukhipheni ukushisa ngendlela efanele, ngaleyo ndlela kugcinwe izinto ezibonakalayo ze-wafer futhi kunciphise umonakalo oshisayo.

Ukukhetha Okubalulekile: Abacwaningi bahlola izinto ezintsha, njenge-carbon nanotubes ne-graphene, ezinokusebenza okuhle kakhulu kwe-thermal namandla emishini. Lezi zinsiza zinganciphisa indawo yomthelela oshisayo ngenkathi zithuthukisa ukusebenza okuphelele kwama-chips.

Kafushane, nakuba indawo yomthelela oshisayo ingumphumela ongenakugwemeka wobuchwepheshe bokusika okushisayo, ingalawulwa ngempumelelo ngamasu okucubungula athuthukisiwe kanye nokukhetha impahla. Ucwaningo lwangomuso luzogxila ekulungiseni kahle nasekuzenzeleni izinqubo zokusika ezishisayo ukuze kuzuzwe ukudayela kwe-wafer okusebenza kahle kakhulu nokunembe.

I-Balance Strategy:

Ukuzuza ibhalansi elungile phakathi kokuvunwa kwe-wafer nokusebenza kahle kokukhiqiza kuyinselele eqhubekayo kubuchwepheshe bokudayela ama-wafer. Abakhiqizi badinga ukucabangela izici eziningi, njengesidingo semakethe, izindleko zokukhiqiza, nekhwalithi yomkhiqizo, ukuze bakhe isu lokukhiqiza eliphusile kanye nemingcele yokucubungula. Ngesikhathi esifanayo, ukwethula imishini yokusika ethuthukisiwe, ukuthuthukisa amakhono omqhubi, kanye nokuthuthukisa ukulawulwa kwekhwalithi yezinto ezingavuthiwe kubalulekile ekugcineni noma ukuthuthukisa isivuno ngenkathi kukhulisa ukusebenza kahle kokukhiqiza.

Izinselele Namathuba Azayo:

Ngokuthuthuka kobuchwepheshe be-semiconductor, ukusika ama-wafer kubhekana nezinselelo ezintsha namathuba. Njengoba osayizi bama-chip bencipha futhi ukuhlanganiswa kuyanda, izimfuno zokunemba nekhwalithi zikhula kakhulu. Ngesikhathi esifanayo, ubuchwepheshe obusafufusa bunikeza imibono emisha yokuthuthukiswa kwamasu okusika ama-wafer. Abakhiqizi kumele bahlale behambisana nokuguquguquka kwemakethe kanye nokuthambekela kwezobuchwepheshe, ngokuqhubekayo balungise futhi bathuthukise amasu okukhiqiza kanye nemingcele yokucubungula ukuze bahlangabezane nezinguquko zemakethe kanye nezidingo zobuchwepheshe.

Sengiphetha, ngokuhlanganisa ukucatshangelwa kwesidingo semakethe, izindleko zokukhiqiza, kanye nekhwalithi yomkhiqizo, futhi ngokwethula imishini ethuthukisiwe nobuchwepheshe, ukuthuthukisa amakhono omqhubi, nokuqinisa ukulawulwa kwezinto ezingavuthiwe, abakhiqizi bangakwazi ukuzuza ibhalansi engcono kakhulu phakathi kwesivuno se-wafer nokusebenza kahle kokukhiqiza ngesikhathi sokudayela kwe-wafer, okuholela ekukhiqizeni umkhiqizo osebenza kahle futhi ophezulu we-semiconductor.

I-Outlook Yesikhathi esizayo:

Ngokuthuthuka okusheshayo kwezobuchwepheshe, ubuchwepheshe be-semiconductor buthuthuka ngesivinini esingakaze sibonwe. Njengesinyathelo esibalulekile sokukhiqiza ama-semiconductor, ubuchwepheshe bokusika i-wafer bulungele ukuthuthukiswa okusha okujabulisayo. Uma ubheka phambili, ubuchwepheshe bokusika i-wafer kulindeleke ukuthi bufinyelele ekuthuthukisweni okubalulekile kokunemba, ukusebenza kahle, kanye nezindleko, bufake ubungqabavu obusha ekukhuleni okuqhubekayo kwemboni ye-semiconductor.

Ukwandisa Ukunemba:

Ekuphishekeleni ukunemba okuphezulu, ubuchwepheshe bokusika i-wafer buzohlala bucindezela imikhawulo yezinqubo ezikhona. Ngokufunda ngokujulile izindlela ezingokwenyama namakhemikhali zenqubo yokusika kanye nokulawula ngokunembile imingcele yokusika, imiphumela yokusika kahle izofinyelelwa ukuze kuhlangatshezwane nezidingo zomklamo wesifunda eziyinkimbinkimbi. Ukwengeza, ukuhlolwa kwezinto ezintsha nezindlela zokusika kuzothuthukisa kakhulu isivuno kanye nekhwalithi.

Ukuthuthukisa Ukusebenza Ngempumelelo:

Imishini entsha yokusika i-wafer izogxila ekwakhiweni okuhlakaniphile nokuzenzakalelayo. Ukwethulwa kwezinhlelo zokulawula ezithuthukisiwe kanye nama-algorithms kuzokwenza ukuthi imishini ikwazi ukulungisa ngokuzenzakalelayo imingcele yokusika ukuze ihlanganise izinto ezahlukene kanye nezidingo zokuklama, ngaleyo ndlela ithuthukise kakhulu ukusebenza kahle kokukhiqiza. Izinto ezintsha ezifana nobuchwepheshe bokusika ama-wafer amaningi kanye nezinhlelo ezishintsha ngokushesha izinsimbi zizodlala indima ebalulekile ekuthuthukiseni ukusebenza kahle.

Ukunciphisa Izindleko:

Ukunciphisa izindleko kuyisiqondiso esibalulekile sokuthuthukiswa kobuchwepheshe bokusika ama-wafer. Njengoba kwakhiwa izinto ezintsha nezindlela zokusika, izindleko zemishini kanye nezindleko zokuyilungisa kulindeleke ukuthi zilawulwe ngempumelelo. Ukwengeza, ukwenza ngcono izinqubo zokukhiqiza kanye nokunciphisa amanani ezinto ezilahliwe kuzophinde kunciphise imfucuza ngesikhathi sokukhiqiza, okuholela ekwehleni kwezindleko zokukhiqiza zizonke.

I-Smart Manufacturing ne-IoT:

Ukuhlanganiswa kokukhiqiza okuhlakaniphile kanye nobuchwepheshe be-inthanethi Yezinto (IoT) kuzoletha izinguquko ezishintshayo kubuchwepheshe bokusika ama-wafer. Ngokuxhumana nokwabelana ngedatha phakathi kwamadivayisi, zonke izinyathelo zenqubo yokukhiqiza zingaqashwa futhi zenziwe ngcono ngesikhathi sangempela. Lokhu akuthuthukisi ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo kuphela kodwa futhi kunikeza izinkampani ukubikezela kwemakethe okunembe kakhudlwana nokwesekwa kokuthatha izinqumo.

Ngokuzayo, ubuchwepheshe bokusika i-wafer buzokwenza intuthuko emangalisayo ekunembeni, ukusebenza kahle, kanye nezindleko. Le ntuthuko izoqhubeza intuthuko eqhubekayo yemboni ye-semiconductor futhi ilethe ukusungulwa okwengeziwe kwezobuchwepheshe kanye nokunethezeka emphakathini wesintu.

Isikhathi sokuthumela: Nov-19-2024