Enqubweni yokuthuthukiswa kwemboni ye-semiconductor, ikristalu eyodwa epholishiweizinkwa ze-silicondlala indima ebalulekile. Zisebenza njengezinto eziyisisekelo zokukhiqiza amadivaysi e-microelectronic ahlukahlukene. Kusukela kumasekethe ahlanganisiwe ayinkimbinkimbi nanembile kuye kuma-microprocessors anesivinini esikhulu nezinzwa ezisebenza ngezinto eziningi, ikristalu eyodwa epholishiwe.izinkwa ze-siliconzibalulekile. Umehluko ekusebenzeni kwawo nasekucacisweni kwawo kuthinta ngokuqondile ikhwalithi nokusebenza kwemikhiqizo yokugcina. Ngezansi kukhona ukucaciswa okuvamile kanye nemingcele yamawafa e-silicon ecwebezelayo eyodwa:

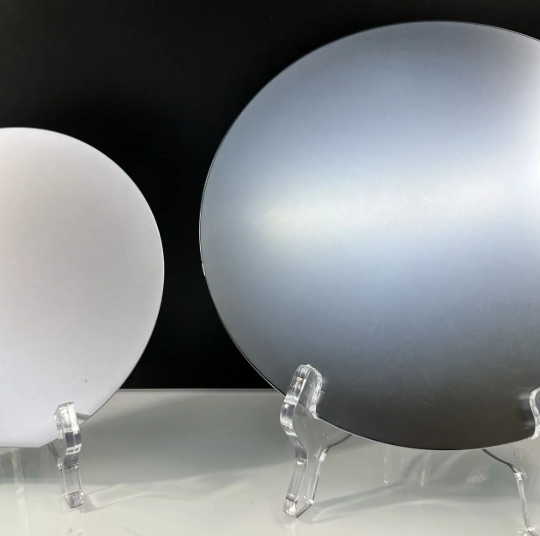

Ububanzi: Usayizi wama-semiconductor we-crystal silicon wafers eyodwa ulinganiswa ngobubanzi bawo, futhi afika ngezindlela ezihlukahlukene zokucaciswa. Amadayamitha avamile ahlanganisa ama-intshi angu-2 (50.8mm), 3 amayintshi (76.2mm), 4 amayintshi (100mm), 5 amayintshi (125mm), 6 amayintshi (150mm), 8 amayintshi (200mm), 12 amayintshi (300mm), futhi 18 amayintshi (450mm). Amadayamitha ahlukene afanele izidingo ezihlukahlukene zokukhiqiza kanye nezidingo zenqubo. Isibonelo, ama-wafer ama-diameter amancane avame ukusetshenziswa kumadivayisi akhethekile, anevolumu encane ye-microelectronic, kuyilapho ama-wafer ama-diameter amakhulu abonisa ukusebenza kahle kokukhiqiza okuphezulu kanye nezinzuzo zezindleko ekukhiqizeni isekethe enkulu ehlanganisiwe. Izidingo zomphezulu zihlukaniswa njenge-single-side polished (SSP) kanye ne-double side polished (DSP). Amawafa aphucuziwe anohlangothi olulodwa asetshenziselwa amadivayisi adinga ukucaba okuphezulu ohlangothini olulodwa, njengezinzwa ezithile. Amawafa aphucuziwe anezinhlangothi ezimbili ajwayele ukusetshenziselwa amasekhethi ahlanganisiwe neminye imikhiqizo edinga ukunemba okuphezulu kuzo zombili izindawo. Isidingo Somphezulu (Qeda): I-SSP epholishelwe ohlangothini olulodwa / i-DSP ephucuziwe yohlangothi olukabili.

Uhlobo/I-Dopant: (1) I-Semiconductor yohlobo lwe-N: Uma ama-athomu athile okungcola ethulwa ku-semiconductor yangaphakathi, ashintsha ukusebenza kwawo. Isibonelo, lapho izakhi ze-pentavalent ezifana ne-nitrogen (N), i-phosphorus (P), i-arsenic (As), noma i-antimony (Sb) yengezwa, ama-electron awo e-valence enza izibopho eziqinile nama-electron e-valence ama-athomu e-silicon azungezile, ashiya i-electron eyengeziwe engaboshiwe ibhondi ehlangene. Lokhu kuphumela ekugxiliseni kwe-electron okukhulu kunokugxiliswa kwembobo, okwenza i-semiconductor yohlobo lwe-N, eyaziwa nangokuthi i-electron-type semiconductor. Ama-semiconductors ohlobo lwe-N abalulekile ekukhiqizeni amadivaysi adinga ama-electron njengabathwali abashaja abakhulu, njengamadivayisi athile kagesi. (2) I-Semiconductor yohlobo lwe-P: Uma izakhi zokungcola ezincanyana njenge-boron (B), i-gallium (Ga), noma i-indium (In) yethulwa ku-silicon semiconductor, ama-electron e-valence ama-athomu okungcola akha izibopho eziqinile nama-athomu e-silicon azungezile, kodwa ashoda okungenani i-electron eyodwa ye-valence futhi awakwazi ukwakha ibhondi ephelele. Lokhu kuholela ekugxilweni kwembobo okukhulu kunokugxilwa kwe-electron, okwenza i-semiconductor yohlobo lwe-P, eyaziwa nangokuthi i-semiconductor yohlobo lwe-hole. Ama-semiconductors ohlobo lwe-P adlala indima ebalulekile kumadivayisi okukhiqiza lapho izimbobo zisebenza njengezithwali zokushaja eziyinhloko, njengama-diode nama-transistors athile.

I-Resistivity: I-Resistivity iyinani elibalulekile lomzimba elikala ukuqhutshwa kukagesi kwamawafa e-silicon ecwebezelayo e-crystal eyodwa. Inani layo libonisa ukusebenza kwe-conductive kokokusebenza. Lapho i-resistivity iphansi, ngcono ukuqhutshwa kwe-silicon wafer; ngokuphambene, i-resistivity ephakeme kakhulu, i-conductivity impofu kakhulu. Ukumelana nama-wafers e-silicon kunqunywa izakhiwo zawo zemvelo, futhi izinga lokushisa linomthelela omkhulu futhi. Ngokuvamile, ukumelana nama-wafers e-silicon kukhuphuka ngokushisa. Kuzinhlelo zokusebenza ezisebenzayo, amadivaysi e-microelectronic ahlukene anezidingo ezihlukile zokumelana nama-silicon wafers. Isibonelo, amawafa asetshenziswa ekwenziweni kwesekethe edidiyelwe adinga ukulawulwa okunembile kokumelana nokuqinisekisa ukusebenza kwedivayisi okuzinzile nokuthembekile.

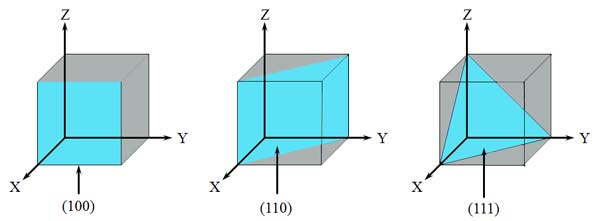

Umumo: I-crystal orientation ye-wafer imelela isiqondiso se-crystallographic se-silicon lattice, ngokuvamile ecaciswa izinkomba ze-Miller ezifana nokuthi (100), (110), (111), njll. Ukuma kwekristalu okuhlukile kunezinto ezibonakalayo ezihlukile, njengokuminyana komugqa, okuhlukayo ngokuya ngomumo. Lo mehluko ungathinta ukusebenza kwe-wafer ezinyathelweni zokucubungula ezilandelayo kanye nokusebenza kokugcina kwamadivayisi e-microelectronic. Enqubweni yokukhiqiza, ukukhetha iwafa ye-silicon enomumo ofanele wezidingo ezihlukile zedivayisi kungathuthukisa ukusebenza kwedivayisi, kuthuthukise ukusebenza kahle kokukhiqiza, futhi kuthuthukise ikhwalithi yomkhiqizo.

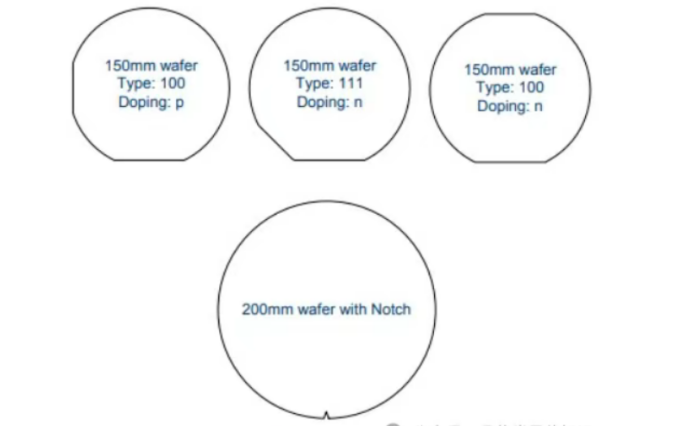

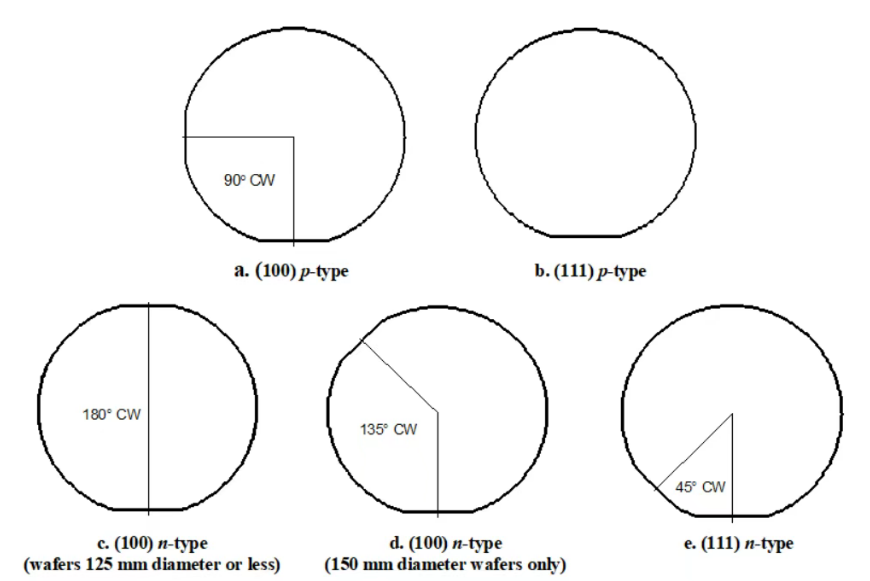

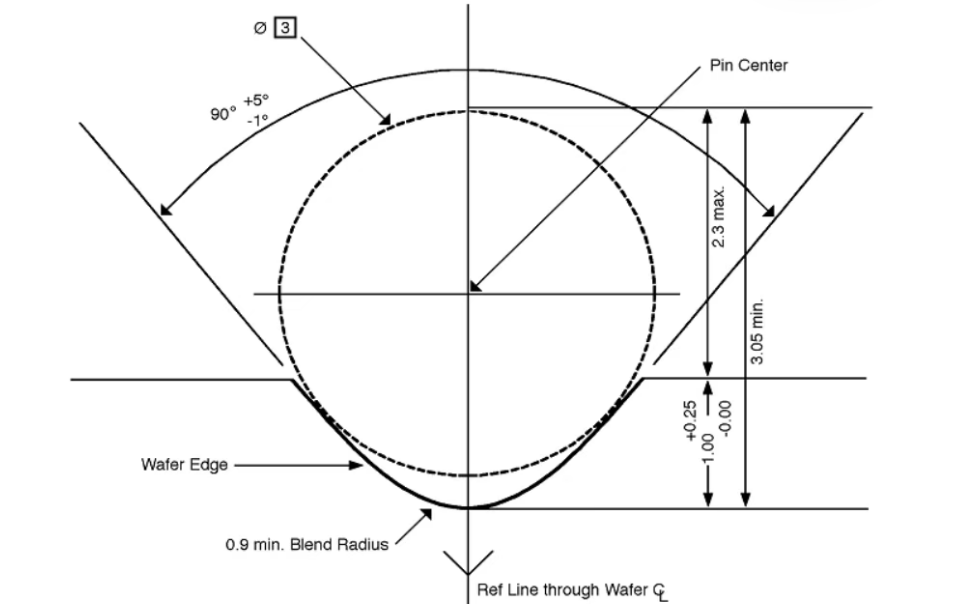

I-Flat/Notch: Unqenqema oluyisicaba (I-Flat) noma i-V-notch (I-notch) kusiyingi se-wafer ye-silicon idlala indima ebalulekile ekuqondaneni nokuma kwekristalu futhi iyinkomba ebalulekile ekwenziweni nasekucutshungulweni kwe-wafer. Ama-wafer anobubanzi obuhlukene ahambisana namazinga ahlukene obude be-Flat noma i-Notch. Amaphethelo okuqondanisa ahlukaniswa abe yifulethi eliyisisekelo nelesibili. Ifulethi eliyinhloko lisetshenziselwa kakhulu ukunquma ukuma kwekristalu okuyisisekelo kanye nereferensi yokucubungula yewafa, kuyilapho iflethi lesibili lisiza ngokunembile ukuqondanisa nokucutshungulwa, ukuqinisekisa ukusebenza okunembile nokuvumelana kwewafa kuwo wonke umugqa wokukhiqiza.

Ubukhulu: Ubukhulu be-wafer ngokuvamile bucaciswa kuma-micrometers (μm), ububanzi obujwayelekile bokujiya obuphakathi kuka-100μm no-1000μm. Ama-wafer anobukhulu obuhlukene afanele izinhlobo ezahlukene zemishini ye-microelectronic. Amawafa azacile (isb., 100μm – 300μm) avame ukusetshenziselwa ukukhiqiza ama-chip adinga ukulawulwa okuqinile okujiya, ukunciphisa usayizi nesisindo se-chip nokwandisa ukuminyana kokuhlanganisa. Amawafa ashubile (isb., 500μm – 1000μm) asetshenziswa kakhulu kumadivayisi adinga amandla aphezulu emishini, njengamadivayisi we-semiconductor yamandla, ukuze kuqinisekiswe ukuzinza ngesikhathi sokusebenza.

Ukuma Kobuso: Ukumahhadla kwendawo kungenye yezimiso ezibalulekile zokuhlola ikhwalithi ye-wafer, njengoba kuthinta ngokuqondile ukunamathela phakathi kwe-wafer nezinto zefilimu ezacile ezifakiwe kamuva, kanye nokusebenza kukagesi kwedivayisi. Ivamise ukuvezwa njengempande isho isikwele (RMS) ubuhwaqane (nge-nm). Ubulukhuni obungaphansi busho ukuthi indawo eyisicwecwana ishelela, esiza ukunciphisa izinto ezifana nokuhlakazeka kwe-electron futhi kuthuthukise ukusebenza kwedivayisi nokuthembeka. Ezinqubweni ezithuthukisiwe zokukhiqiza ama-semiconductor, izimfuneko zokuqina kwendawo ziya ngokuya ziba nzima, ikakhulukazi ekukhiqizeni isekethe edidiyelwe yezinga eliphezulu, lapho ubulukhuni bendawo kufanele bulawuleke bube ngama-nanometer ambalwa noma ngisho ngaphansi.

Ukwehluka Kokuqina Kwengqikithi (i-TTV): Ukwehluka kogqinsi okuphelele kubhekisela emehlukweni phakathi kobukhulu nobuncane bokujiya obukalwa kumaphoyinti amaningi endaweni eyi-wafer, ngokuvamile evezwa ngo-μm. I-TTV ephezulu ingase iholele ekuphambukeni ezinqubweni ezifana ne-photolithography kanye ne-etching, kube nomthelela ekusebenzeni kwedivayisi kanye nenzuzo. Ngakho-ke, ukulawula i-TTV ngesikhathi sokwenziwa kwe-wafer kuyisinyathelo esibalulekile sokuqinisekisa ikhwalithi yomkhiqizo. Ngokwenziwa kwedivayisi ye-microelectronic enemba okuphezulu, i-TTV ngokuvamile idingeka ukuthi ibe phakathi kwama-micrometer ambalwa.

Umnsalo: Umnsalo ubhekisela ekuphambukeni phakathi kwendawo eyisicwecwana kanye nendiza ekahle eyisicaba, evame ukukalwa ngo-μm. Ama-wafer akhothama ngokweqile angase aphule noma abe nengcindezi engalingani ngesikhathi sokucutshungulwa okulandelayo, kuthinte ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo. Ikakhulukazi ezinqubweni ezidinga ukucaba okuphezulu, njenge-photolithography, ukukhothama kufanele kulawulwe ngaphakathi kwebanga elithile ukuze kuqinisekiswe ukunemba nokuvumelana kwephethini ye-photolithographic.

I-Warp: I-Warp ibonisa ukuchezuka phakathi kwendawo eyi-wafer kanye nomumo oyindilinga ofanelekile, obuye ulinganiswe ngo-μm. Ngokufana nomnsalo, i-warp iyinkomba ebalulekile ye-wafer flatness. I-warp eyeqile ayithinti nje kuphela ukunemba kokubekwa kwewafa ekucubunguleni okokusebenza kodwa kungase futhi kubangele izinkinga phakathi nenqubo yokupakishwa kwe-chip, njengokungahlangani kahle phakathi kwe-chip nokokusebenza kokupakisha, okuphinde kuthinte ukwethembeka kwedivayisi. Ekwenziweni kwama-semiconductor asezingeni eliphezulu, izidingo ze-warp ziya ziba nzima kakhulu ukuze zihlangabezane nezidingo zokwenziwa kwe-chip ethuthukisiwe nezinqubo zokupakisha.

Iphrofayili ye-Edge: Iphrofayili esemaphethelweni ye-wafer ibalulekile ekucubunguleni nasekuphathweni kwayo okulandelayo. Ivamise ukucaciswa yi-Edge Exclusion Zone (EEZ), echaza ibanga ukusuka kunqenqema lwe-wafer lapho kungavunyelwe ukucubungula. Iphrofayili enqenqemeni eklanywe kahle kanye nokulawula okunembile kwe-EEZ kusiza ukugwema amaphutha, ukugxila kwengcindezi, nezinye izinkinga ngesikhathi sokucutshungulwa, ukuthuthukisa ikhwalithi ephelele ye-wafer kanye nesivuno. Kwezinye izinqubo zokukhiqiza ezithuthukisiwe, ukunemba kwephrofayela esemaphethelweni kuyadingeka ukuze kube sezingeni le-sub-micron.

Ukubalwa Kwezinhlayiyana: Inombolo nosayizi wokusabalalisa kwezinhlayiya endaweni eyi-wafer kuthinta kakhulu ukusebenza kwamadivayisi e-microelectronic. Izinhlayiya ezeqile noma ezinkulu zingaholela ekuhlulekeni kwedivayisi, njengamasekhethi amafushane noma ukuvuza, ukwehlisa isivuno somkhiqizo. Ngakho-ke, isibalo sezinhlayiyana ngokuvamile silinganiswa ngokubala izinhlayiya endaweni yeyunithi ngayinye, njengenani lezinhlayiya ezinkulu kuno-0.3μm. Ukulawula okuqinile kokubala kwezinhlayiyana ngesikhathi sokukhiqizwa kwamawafa kuyisinyathelo esibalulekile sokuqinisekisa ikhwalithi yomkhiqizo. Ubuchwepheshe bokuhlanza obusezingeni eliphezulu kanye nendawo yokukhiqiza ehlanzekile kusetshenziswa ukunciphisa ukungcoliswa kwezinhlayiyana endaweni eyiwafa.

![]()

![]()

![]()

![]()

![]()

Ukukhiqizwa okuhlobene

I-Single Crystal Silicon Wafer Si Substrate Uhlobo lwe-N/P Ongakukhetha lwe-Silicon Carbide Wafer

I-FZ CZ Si wafer esitokweni esingu-12inch Silicon wafer Prime noma Test

Isikhathi sokuthumela: Apr-18-2025