I-SiC wafer's abstract

Ama-wafers we-silicon carbide (SiC).seziphenduke isizinda esikhethwayo samandla aphezulu, imvamisa ephezulu, kanye nezinga eliphezulu lokushisa kukagesi kuyo yonke imikhakha yezimoto, amandla avuselelekayo, kanye ne-aerospace. Iphothifoliyo yethu ihlanganisa ama-polytypes abalulekile nezikimu ze-doping—i-nitrogen-doped 4H (4H-N), i-high-purity semi-insulating (HPSI), i-nitrogen-doped 3C (3C-N), kanye nohlobo lwe-p 4H/6H (4H/6H-P)—ihlinzekwa ngamamaki amathathu ekhwalithi: PRIME (iphucuziwe ngokugcwele, ipholishiwe ngokugcwele, inqubo ye-DUMMY engafakwanga), i-unplished yedivayisi UCWANINGO (izendlalelo ze-epi zangokwezifiso namaphrofayela e-doping we-R&D). Amadayamitha e-wafer abanzi 2″, 4″, 6″, 8″, kanye no-12″ ukuze afanele womabili amathuluzi wefa nezindwangu ezithuthukisiwe. Siphinde sihlinzeke ngama-monocrystalline boules namakristalu embewu aqondiswe kahle ukuze sisekele ukukhula kwekristalu kwangaphakathi.

Amawafa ethu e-4H-N afaka ukuminyana kwenkampani yenethiwekhi ukusuka ku-1×10¹⁶ ukuya ku-1×10¹⁹ cm⁻³ nokuphikiswa kokungu-0.01–10 Ω·cm, alethela ukuhamba kahle kwama-electron nezinkambu zokuhlukanisa ngaphezu kuka-2 MV/cm—ilungele ama-Schottky diode, nama-JMOSsFET. Ama-substrates e-HPSI adlula u-1×10¹² Ω·cm ukumelana nokuminyana kwe-micropipe ngaphansi kuka-0.1 cm⁻², okuqinisekisa ukuvuza okuncane kwamadivayisi e-RF nawe-microwave. I-Cubic 3C-N, etholakala ngamafomethi angu-2″ kanye no-4″, yenza i-heteroepitaxy ku-silicon futhi isekele izinhlelo zokusebenza ze-photonic ne-MEMS. Amawafa ohlobo lwe-P-4H/6H-P, ahlanganiswe ne-aluminium kuya ku-1×10¹⁶–5×10¹⁸ cm⁻³, asiza ukwakhiwa kwedivayisi okuhambisanayo.

I-SiC wafer, amawafa e-PRIME apholishwa ngamakhemikhali-mechanical kuya ku-<0.2 nm RMS yobulukhuni bobuso, ukuhluka okuphelele kogqinsi ngaphansi kuka-3 µm, kanye nokukhothama <10 µm. Ama-substrates e-DUMMY asheshisa ukuhlolwa kokuhlanganisa nokupakisha, kuyilapho ama-wafers oCWANINGO abonisa ugqinsi lwe-epi-layer engu-2–30 µm kanye ne-doping ye-bespoke. Yonke imikhiqizo iqinisekiswa nge-X-ray diffraction (ijika elinyakazisayo <30 arcsec) kanye ne-Raman spectroscopy, enokuhlolwa kukagesi—Izilinganiso zehholo, iphrofayili ye-C–V, nokuskena kwe-micropipe—okuqinisekisa ukuthi i-JEDEC ne-SEMI iyahambisana.

Amabhowula afika kububanzi obungu-150 mm atshalwa nge-PVT kanye ne-CVD ngokuminyana kokuhlukaniswa okungaphansi kuka-1×10³ cm⁻² kanye nezibalo zamapayipi amancane aphansi. Amakristalu embewu asikwa phakathi kuka-0.1° we-c-eksisi ukuze kuqinisekiswe ukukhula okuphindaphindekayo kanye nesivuno esikhulu sokusika.

Ngokuhlanganisa ama-polytypes amaningi, okuhlukile kwe-doping, amamaki ekhwalithi, osayizi be-SiC wafer, kanye nokukhiqizwa kwangaphakathi kwendlu kanye nokukhiqizwa kwe-seed-crystal, inkundla yethu ye-SiC substrate isakaza amaketanga okuhlinzeka futhi isheshisa ukuthuthukiswa kwedivayisi yezimoto zikagesi, amagridi ahlakaniphile, nezinhlelo zokusebenza zemvelo ezinokhahlo.

I-SiC wafer's abstract

Ama-wafers we-silicon carbide (SiC).seziphenduke isizinda se-SiC esikhethwayo samandla aphezulu, ama-high-frequency, kanye ne-high-temperature electronics kuyo yonke imikhakha yezimoto, amandla avuselelekayo, kanye ne-aerospace. Iphothifoliyo yethu ihlanganisa ama-polytypes abalulekile nezikimu ze-doping—i-nitrogen-doped 4H (4H-N), i-high-purity semi-insulating (HPSI), i-nitrogen-doped 3C (3C-N), kanye nohlobo lwe-p-4H/6H (4H/6H-P)—inikezwa ngamabanga amathathu ekhwalithi:SiC waferI-PRIME (apholishwe ngokugcwele, ama-substrates ebanga ledivayisi), i-DUMMY (egqitshiwe noma engapholishiwe ukuze kuhlolwe inqubo), kanye NOSESHO (izendlalelo ze-epi zangokwezifiso namaphrofayela e-doping we-R&D). I-SiC Wafer diameters ispan 2″, 4″, 6″, 8″, kanye no-12″ ukuze ifanele womabili amathuluzi wefa nezindwangu ezithuthukisiwe. Siphinde sihlinzeke ngama-monocrystalline boules namakristalu embewu aqondiswe kahle ukuze sisekele ukukhula kwekristalu kwangaphakathi.

Amawafa ethu e-4H-N SiC afaka ukuminyana kwenkampani yenethiwekhi ukusuka ku-1×10¹⁶ ukuya ku-1×10¹⁹ cm⁻³ nokuphikiswa kokungu-0.01–10 Ω·cm, alethela ukuhamba kahle kwama-electron nezinkambu zokuhlukanisa ngaphezu kuka-2 MV/cm—ilungele ama-Schottky diode, ama-MOSFET, nama-JFET. Ama-substrates e-HPSI adlula u-1×10¹² Ω·cm ukumelana nokuminyana kwe-micropipe ngaphansi kuka-0.1 cm⁻², okuqinisekisa ukuvuza okuncane kwamadivayisi e-RF nawe-microwave. I-Cubic 3C-N, etholakala ngamafomethi angu-2″ kanye no-4″, yenza i-heteroepitaxy ku-silicon futhi isekele izinhlelo zokusebenza ze-photonic ne-MEMS. I-SiC wafer P-type 4H/6H-P yama-wafer, ahlanganiswe ne-aluminium kuya ku-1×10¹⁶–5×10¹⁸ cm⁻³, asiza ukwakhiwa kwedivayisi okuhambisanayo.

Amawafa e-SiC PRIME enziwa ukupholishwa ngamakhemikhali-mechanical kuya ku-<0.2 nm RMS yobulukhuni bobuso, ukuhluka okuphelele kogqinsi ngaphansi kuka-3 µm, kanye nokukhothama <10 µm. Ama-substrates e-DUMMY asheshisa ukuhlolwa kokuhlanganisa nokupakisha, kuyilapho ama-wafers oCWANINGO abonisa ugqinsi lwe-epi-layer engu-2–30 µm kanye ne-doping ye-bespoke. Yonke imikhiqizo iqinisekiswa nge-X-ray diffraction (ijika elinyakazisayo <30 arcsec) kanye ne-Raman spectroscopy, enokuhlolwa kukagesi—Izilinganiso zehholo, iphrofayili ye-C–V, nokuskena kwe-micropipe—okuqinisekisa ukuthi i-JEDEC ne-SEMI iyahambisana.

Amabhowula afika kububanzi obungu-150 mm atshalwa nge-PVT kanye ne-CVD ngokuminyana kokuhlukaniswa okungaphansi kuka-1×10³ cm⁻² kanye nezibalo zamapayipi amancane aphansi. Amakristalu embewu asikwa phakathi kuka-0.1° we-c-eksisi ukuze kuqinisekiswe ukukhula okuphindaphindekayo kanye nesivuno esikhulu sokusika.

Ngokuhlanganisa ama-polytypes amaningi, okuhlukile kwe-doping, amamaki ekhwalithi, osayizi be-SiC wafer, kanye nokukhiqizwa kwangaphakathi kwendlu kanye nokukhiqizwa kwe-seed-crystal, inkundla yethu ye-SiC substrate isakaza amaketanga okuhlinzeka futhi isheshisa ukuthuthukiswa kwedivayisi yezimoto zikagesi, amagridi ahlakaniphile, nezinhlelo zokusebenza zemvelo ezinokhahlo.

Ishidi ledatha le-SiC wafer engu-6inch 4H-N

| 6inch SiC wafers idatha sheet | ||||

| Ipharamitha | Ipharamitha engaphansi | Ibanga le-Z | Ibanga le-P | D Ibanga |

| Ububanzi | 149.5–150.0 mm | 149.5–150.0 mm | 149.5–150.0 mm | |

| Ubukhulu | 4H‑N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Ubukhulu | 4H‑SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| I-Wafer Orientation | Ku-axis evaliwe: 4.0° kuya ku-<11-20> ±0.5° (4H-N); Ku-eksisi: <0001> ±0.5° (4H-SI) | Ku-axis evaliwe: 4.0° kuya ku-<11-20> ±0.5° (4H-N); Ku-eksisi: <0001> ±0.5° (4H-SI) | Ku-axis evaliwe: 4.0° kuya ku-<11-20> ±0.5° (4H-N); Ku-eksisi: <0001> ±0.5° (4H-SI) | |

| I-Micropipe Density | 4H‑N | ≤ 0.2 cm⁻² | ≤ 2 cm⁻² | ≤ 15 cm⁻² |

| I-Micropipe Density | 4H‑SI | ≤ 1 cm⁻² | ≤ 5 cm⁻² | ≤ 15 cm⁻² |

| Ukungazweli | 4H‑N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Ukungazweli | 4H‑SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1×10⁵ Ω·cm | |

| Isisekelo se-Flat Orientation | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Ubude Befulethi obuyisisekelo | 4H‑N | 47.5 mm ± 2.0 mm | ||

| Ubude Befulethi obuyisisekelo | 4H‑SI | Inothi | ||

| Ukukhishwa komkhawulo | 3 mm | |||

| I-Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Ubulukhuni | IsiPolish | I-Ra ≤ 1 nm | ||

| Ubulukhuni | I-CMP | I-Ra ≤ 0.2 nm | I-Ra ≤ 0.5 nm | |

| Ama-Edge Cracks | Lutho | Ubude obuqongelelwayo ≤ 20 mm, eyodwa ≤ 2 mm | ||

| Amapuleti e-Hex | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 0.1% | Indawo eqongelelwe ≤ 1% | |

| Izindawo ze-Polytype | Lutho | Indawo eqoqiwe ≤ 3% | Indawo eqoqiwe ≤ 3% | |

| I-Carbon Inclusions | Indawo eqoqiwe ≤ 0.05% | Indawo eqoqiwe ≤ 3% | ||

| Ukuklwebheka Okungaphezulu | Lutho | Ubude obuqongelelwayo ≤ 1 × ububanzi bewafa | ||

| Ama-Edge Chips | Akukho okuvunyelwe ≥ 0.2 mm ububanzi nokujula | Kufika kuma-chips angu-7, ≤ 1 mm ngalinye | ||

| I-TSD (I-Threading Screw Dislocation) | ≤ 500 cm⁻² | N/A | ||

| I-BPD (Base Plane Dislocation) | ≤ 1000 cm⁻² | N/A | ||

| Ukungcoliswa kobuso | Lutho | |||

| Ukupakisha | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa | |

Ishidi ledatha le-SiC wafer ye-4inch 4H-N

| Ishidi ledatha le-4inch SiC wafer | |||

| Ipharamitha | Zero MPD Production | Ibanga Elijwayelekile Lokukhiqiza (iBanga le-P) | I-Dummy Grade (D Grade) |

| Ububanzi | 99.5 mm–100.0 mm | ||

| Ubukhulu (4H-N) | 350 µm±15µm | 350 µm±25µm | |

| Ukuqina (4H-Si) | 500 µm±15µm | 500 µm±25µm | |

| I-Wafer Orientation | Ku-axis evaliwe: 4.0° kuya ku-<1120> ±0.5° ku-4H-N; Ku-eksisi: <0001> ±0.5° ku-4H-Si | ||

| Ukuminyana kweMibhobho (4H-N) | ≤0.2 cm⁻² | ≤2 cm⁻² | ≤15 cm⁻² |

| I-Micropipe Density (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Ukungazweli (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Ukumelana (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Isisekelo se-Flat Orientation | [10-10] ±5.0° | ||

| Ubude Befulethi obuyisisekelo | 32.5 mm ±2.0 mm | ||

| Ubude Befulethi besibili | 18.0 mm ±2.0 mm | ||

| I-Flat Orientation yesibili | I-silicon ibheke phezulu: 90° CW ukusuka ku-prime flat ±5.0° | ||

| Ukukhishwa komkhawulo | 3 mm | ||

| I-LTV/TTV/I-Bow Warp | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Ubulukhuni | I-Polish Ra ≤1 nm; I-CMP Ra ≤0.2 nm | I-Ra ≤0.5 nm | |

| I-Edge Cracks By High Intensity Light | Lutho | Lutho | Ubude obuqongelelwayo ≤10 mm; ubude obubodwa ≤2 mm |

| I-Hex Plates Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤0.05% | Indawo eqoqiwe ≤0.05% | Indawo eqoqiwe ≤0.1% |

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | Lutho | Indawo eqoqiwe ≤3% | |

| I-Visual Carbon Inclusions | Indawo eqoqiwe ≤0.05% | Indawo eqoqiwe ≤3% | |

| I-Silicon Surface Scratches By High Intensity Light | Lutho | Ubude obuqongelelwayo ≤1 ububanzi bewafa | |

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥0.2 mm ububanzi nokujula | 5 okuvunyelwe, ≤1 mm ngakunye | |

| I-Silicon Surface Contamination By High Intensity Light | Lutho | ||

| Ukukhipha isikulufu sochungechunge | ≤500 cm⁻² | N/A | |

| Ukupakisha | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa |

Ishidi ledatha le-SiC wafer engu-4inch HPSI

| Ishidi ledatha le-SiC wafer engu-4inch HPSI | |||

| Ipharamitha | Ibanga le-Zero MPD Production (Ibanga le-Z) | Ibanga Elijwayelekile Lokukhiqiza (iBanga le-P) | I-Dummy Grade (D Grade) |

| Ububanzi | 99.5–100.0 mm | ||

| Ukuqina (4H-Si) | 500 µm ±20 µm | 500 µm ±25 µm | |

| I-Wafer Orientation | Ku-axis evaliwe: 4.0° kuya ku-<11-20> ±0.5° ku-4H-N; Ku-eksisi: <0001> ±0.5° ku-4H-Si | ||

| I-Micropipe Density (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Ukumelana (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Isisekelo se-Flat Orientation | (10-10) ±5.0° | ||

| Ubude Befulethi obuyisisekelo | 32.5 mm ±2.0 mm | ||

| Ubude Befulethi besibili | 18.0 mm ±2.0 mm | ||

| I-Flat Orientation yesibili | I-silicon ibheke phezulu: 90° CW ukusuka ku-prime flat ±5.0° | ||

| Ukukhishwa komkhawulo | 3 mm | ||

| I-LTV/TTV/I-Bow Warp | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Ukuqina (C face) | IsiPolish | I-Ra ≤1 nm | |

| Ukuqina (Si face) | I-CMP | I-Ra ≤0.2 nm | I-Ra ≤0.5 nm |

| I-Edge Cracks By High Intensity Light | Lutho | Ubude obuqongelelwayo ≤10 mm; ubude obubodwa ≤2 mm | |

| I-Hex Plates Ngokukhanya Okunamandla Okuphezulu | Indawo eqoqiwe ≤0.05% | Indawo eqoqiwe ≤0.05% | Indawo eqoqiwe ≤0.1% |

| Izindawo ze-Polytype Ngokukhanya Okunamandla Okuphezulu | Lutho | Indawo eqoqiwe ≤3% | |

| I-Visual Carbon Inclusions | Indawo eqoqiwe ≤0.05% | Indawo eqoqiwe ≤3% | |

| I-Silicon Surface Scratches By High Intensity Light | Lutho | Ubude obuqongelelwayo ≤1 ububanzi bewafa | |

| Ama-Edge Chips Ngokukhanya Okunamandla Okuphezulu | Akukho okuvunyelwe ≥0.2 mm ububanzi nokujula | 5 okuvunyelwe, ≤1 mm ngakunye | |

| I-Silicon Surface Contamination By High Intensity Light | Lutho | Lutho | |

| Ukukhipha Isikulufu sochungechunge | ≤500 cm⁻² | N/A | |

| Ukupakisha | Ikhasethi le-wafer eningi noma isiqukathi se-wafer esisodwa | ||

Isicelo se-SiC wafer

-

I-SiC Wafer Power Modules ye-EV Inverters

Ama-MOSFET asekelwe ku-SiC wafer nama-diode akhelwe kuma-wafer substrates e-SiC wekhwalithi ephezulu aletha ukulahlekelwa kokushintsha okuphansi kakhulu. Ngokusebenzisa ubuchwepheshe be-SiC wafer, lawa mamojula amandla asebenza kuma-voltage aphezulu kanye namazinga okushisa, okwenza ama-inverter asebenza kahle kakhulu. Ukuhlanganisa i-SiC wafer ifa ezigabeni zamandla kunciphisa izimfuneko zokupholisa kanye nokugxilwa kwezinyawo, okubonisa amandla aphelele e-SiC wafer innovation. -

I-High-Frequency RF & 5G Amadivayisi ku-SiC Wafer

Ama-amplifiers e-RF namaswishi akhiwe kumapulatifomu e-SiC wafer afaka i-semi-insulating abonisa ukuqhutshwa kwe-thermal okuphezulu kanye nogesi wokuwohloka. I-SiC wafer substrate inciphisa ukulahleka kwe-dielectric kumafrikhwensi e-GHz, kuyilapho amandla we-SiC wafer evumela ukusebenza okuzinzile ngaphansi kwezimo zamandla aphezulu, izinga lokushisa eliphezulu—okwenza i-SiC wafer ibe i-substrate ekhethwayo yeziteshi eziyisisekelo ze-5G nezinhlelo ze-radar. -

Ama-Optoelectronic & LED Substrates avela ku-SiC Wafer

Ama-LED aluhlaza okwesibhakabhaka nama-UV akhuliswe kuma-SiC wafer substrates azuza ekufanisweni kwe-lattice okuhle kakhulu kanye nokukhishwa kokushisa. Ukusebenzisa iwafa ye-SiC ephucuziwe ye-C-face kuqinisekisa izendlalelo ze-epitaxial ezifanayo, kuyilapho ubulukhuni bemvelo be-SiC wafer buvumela ukucwiliswa kwe-wafer okuhle nokupakishwa kwedivayisi okuthembekile. Lokhu kwenza i-SiC wafer ibe inkundla yokuya phezulu yamandla aphezulu, izinhlelo zokusebenza ze-LED zempilo ende.

I-Q&A ye-SiC wafer

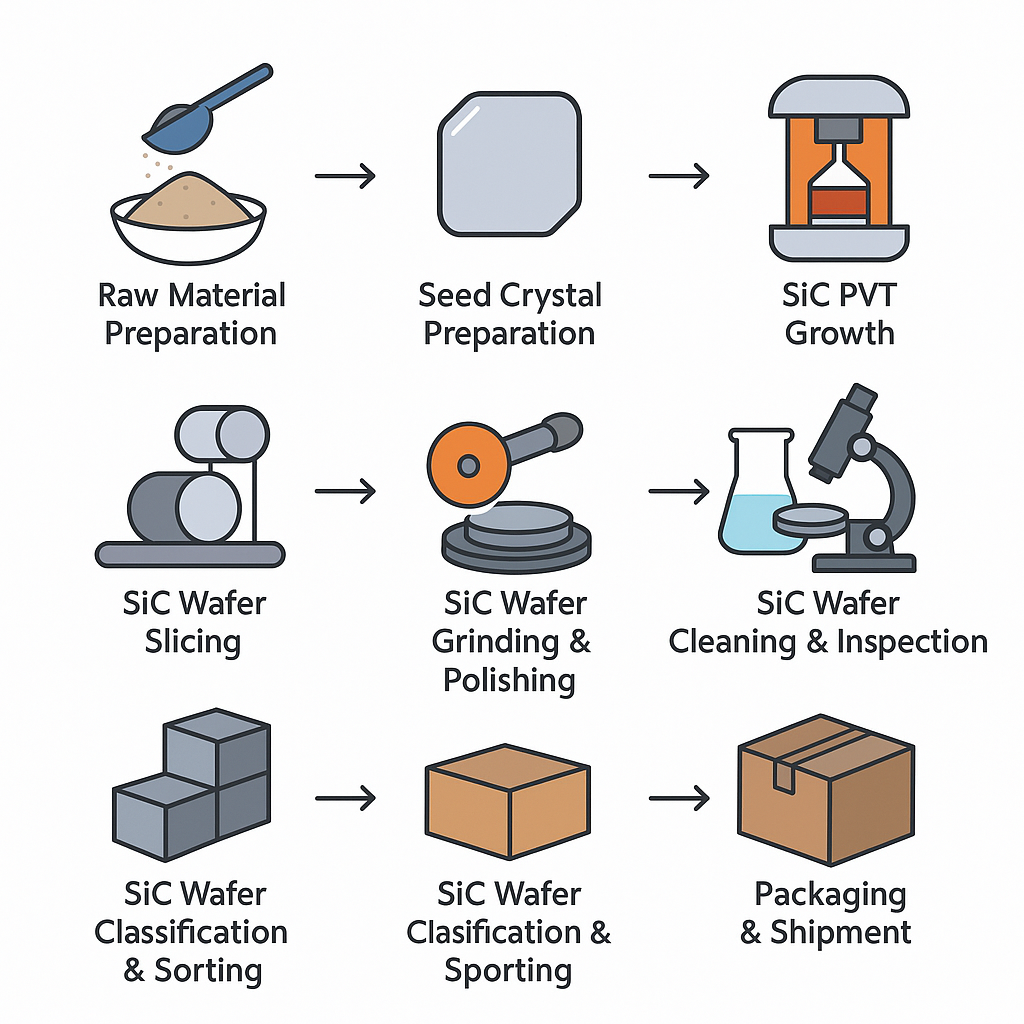

1. Q: Akhiwa kanjani amawafa e-SiC?

A:

Ama-wafers e-SiC akhiqizwaIzinyathelo ezinemininingwane

-

Ama-wafers e-SiCUkulungiswa Kwempahla Engahluziwe

- Sebenzisa i-≥5N-grade SiC powder (ukungcola ≤1 ppm).

- Sefa futhi ubhake ngaphambili ukuze ususe izinsalela zekhabhoni noma izinhlanganisela zenitrogen.

-

I-SiCImbewu Ukulungiselela Crystal

-

Thatha ucezu lwekristalu eyodwa ye-4H-SiC, sika ngomumo wokuthi 〈0001〉 uye ku-~10 × 10 mm².

-

Ipholishi enembile ukuya ku-Ra ≤0.1 nm futhi imake umumo wekristalu.

-

-

I-SiCUkukhula kwe-PVT (Izokuthutha Ngomphunga Womzimba)

-

Layisha i-graphite crucible: phansi nge-SiC powder, phezulu ngekristalu lembewu.

-

Phuma uye ku-10⁻³–10⁻⁵ Torr noma gcwalisa emuva nge-helium ehlanzekile ngo-1 atm.

-

Indawo yomthombo wokushisa ibe ngu-2100–2300 ℃, gcina indawo yembewu ipholile ku-100–150 ℃.

-

Lawula izinga lokukhula ku-1–5 mm/h ukuze ulinganisele ikhwalithi kanye nokuphumayo.

-

-

I-SiCIngot Annealing

-

Anneal ingot ye-SiC esekhulile ku-1600–1800 ℃ amahora angu-4–8.

-

Inhloso: khulula izingcindezi ezishisayo futhi unciphise ukuminyana kokuhlukaniswa.

-

-

I-SiCI-Wafer Slicing

-

Sebenzisa isaha yocingo lwedayimane ukuze usike ingot ibe amawafa awugqinsi angu-0.5–1 mm.

-

Nciphisa ukudlidliza namandla angemuva ukuze ugweme imifantu emincane.

-

-

I-SiCI-waferUkugaya & Ukupholisha

-

Ukugaya okumahhadlaukususa umonakalo wokusaha (ubukhulu ~10–30 µm).

-

Ukugaya kahleukuze uthole flatness ≤5 µm.

-

I-Chemical-Mechanical polishing (CMP)ukuze ufinyelele ekugcineni okufana nesibuko (Ra ≤0.2 nm).

-

-

I-SiCI-waferUkuhlanza & Ukuhlola

-

Ukuhlanza kwe-ultrasonickusixazululo se-Piranha (H₂SO₄:H₂O₂), amanzi e-DI, bese kuba yi-IPA.

-

XRD/Raman spectroscopyukuze uqinisekise i-polytype (4H, 6H, 3C).

-

I-Interferometryukukala ukucaba (<5 µm) kanye nokujika (<20 µm).

-

Uphenyo lwamaphuzu amaneukuhlola ukumelana (isb. HPSI ≥10⁹ Ω·cm).

-

Ukuhlola iphuthangaphansi kwe-polarized light microscope kanye ne-scratch tester.

-

-

I-SiCI-waferUkuhlukanisa nokuhlunga

-

Hlunga ama-wafer nge-polytype kanye nohlobo lukagesi:

-

4H-SiC N-uhlobo (4H-N): ukugxiliswa kwenkampani yenethiwekhi 10¹⁶–10¹⁸ cm⁻³

-

I-4H-SiC High Purity Semi-Insulating (4H-HPSI): ukumelana ≥10⁹ Ω·cm

-

6H-SiC N-uhlobo (6H-N)

-

Abanye: 3C-SiC, P-uhlobo, njll.

-

-

-

I-SiCI-waferUkupakisha nokuthunyelwa

2. Q: Yiziphi izinzuzo ezibalulekile zamawafa e-SiC ngaphezu kwamawafa e-silicon?

A: Uma kuqhathaniswa namawafa e-silicon, ama-wafers e-SiC anika amandla:

-

Ukusebenza kwe-voltage ephezulu(>1,200 V) enokumelana okuphansi.

-

Ukuzinza okuphezulu kwezinga lokushisa(>300 °C) nokuphathwa kwezinga lokushisa okuthuthukisiwe.

-

Isivinini sokushintsha ngokusheshangokulahleka kokushintsha okuphansi, ukunciphisa ukupholisa kwezinga lesistimu kanye nosayizi kuziguquli zamandla.

4. Q: Yiziphi izici ezivamile ezithinta isivuno se-SiC wafer nokusebenza?

A: Ukukhubazeka okuyinhloko kuma-wafer we-SiC kufaka phakathi amapayipi amancane, i-basal plane dislocations (BPDs), kanye nokuklwebheka kwendawo. Amapayipi amancane angabangela ukwehluleka kwedivayisi okuyinhlekelele; Ama-BPD akhulisa ukumelana nesikhathi; futhi imihuzuko engaphezulu iholela ekuqhekekeni kwe-wafer noma ukukhula okungekuhle kwe-epitaxial. Ukuhlolwa okuqinile kanye nokunciphisa amaphutha kubalulekile ukuze kwandiswe isivuno se-SiC wafer.

Isikhathi sokuthumela: Jun-30-2025