Ukuhlanza okumanzi (Ukuhlanzeka Okumanzi) kungenye yezinyathelo ezibalulekile ezinqubweni zokukhiqiza ze-semiconductor, okuhloswe ngazo ukususa ukungcola okuhlukahlukene ebusweni be-wafer ukuze kuqinisekiswe ukuthi izinyathelo zenqubo ezilandelayo zingenziwa endaweni ehlanzekile.

Njengoba usayizi wamadivayisi we-semiconductor uqhubeka nokuncipha kanye nezimfuneko zokunemba zikhuphuka, izimfuno zobuchwepheshe zezinqubo zokuhlanza i-wafer seziqine kakhulu. Ngisho nezinhlayiya ezincane kakhulu, izinto eziphilayo, ama-ion ensimbi, noma izinsalela ze-oxide endaweni eyisicwecwana ingaba nomthelela omkhulu ekusebenzeni kwedivayisi, ngaleyo ndlela kuthinte isivuno nokuthembeka kwamadivayisi we-semiconductor.

Izimiso Eziyinhloko Zokuhlanza I-wafer

Umnyombo wokuhlanza i-wafer usekukhipheni ngempumelelo ukungcola okuhlukahlukene endaweni eyi-wafer ngokusebenzisa ngokomzimba, amakhemikhali, nezinye izindlela zokuqinisekisa ukuthi i-wafer inendawo ehlanzekile elungele ukucutshungulwa okulandelayo.

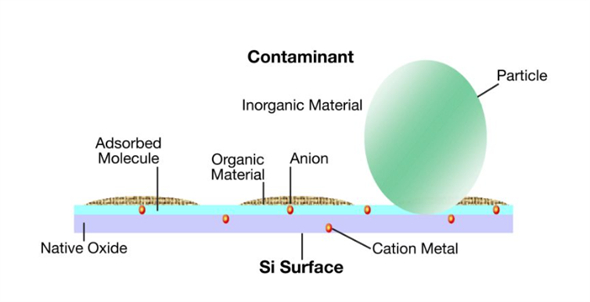

Uhlobo Lokungcola

Imithelela Eyinhloko Ezicini Zedivayisi

| isihloko Ukungcoliswa | Amaphethini amaphutha

Izinkinga zokufakelwa kwe-ion

Amaphutha wokuhlukaniswa kwefilimu evikelayo

| |

| Ukungcoliswa kwe-Metallic | Izinsimbi ze-Alkali | Ukungazinzi kwe-MOS transistor

Ukuwohloka/ukuwohloka kwefilimu yesango le-oxide

|

| Izinsimbi Ezisindayo | Ukuvuza kwamanje kokuvuza kwe-PN junction reverse

Amaphutha okuhlukaniswa kwefilimu yesango le-oxide

Ukucekelwa phansi kwempilo yenkampani yenethiwekhi encane

Ukukhiqizwa kwesiphambeko sesendlalelo se-oxyde excitation

| |

| Ukungcoliswa kwamakhemikhali | Izinto Eziphilayo | Amaphutha okuhlukaniswa kwefilimu yesango le-oxide

Ukuhluka kwefilimu ye-CVD (izikhathi zokufukamela)

Ukuhlukahluka kokuqina kwefilimu ye-thermal oxide (i-oxidation esheshayo)

Ukuvela kobungu (wafer, lens, mirror, mask, reticle)

|

| I-Inorganic Dopants (B, P) | I-MOS transistor Vth amashifu

I-Si substrate kanye nokwehluka okuphezulu kokumelana ne-poly-silicon sheet resistance

| |

| Izisekelo ze-Inorganic (ama-amine, i-ammonia) nama-Acids (SOx) | Ukucekelwa phansi kokuxazululwa kokuphikiswa okukhuliswe ngamakhemikhali

Ukwenzeka kokunukubezeka kwezinhlayiyana kanye nenkungu ngenxa yokukhiqiza usawoti

| |

| Amafilimu Omdabu Nawe-Chemical Oxide Ngenxa Yomswakama, Umoya | Ukwenyuka kokumelana nokuxhumana

Ukuwohloka/ukuwohloka kwefilimu yesango le-oxide

| |

Ikakhulukazi, izinhloso zenqubo yokuhlanza i-wafer zifaka:

Ukususwa Kwezinhlayiyana: Ukusebenzisa izindlela ezingokomzimba noma zamakhemikhali ukususa izinhlayiya ezincane ezinamathele endaweni eyi-wafer. Izinhlayiya ezincane kunzima kakhulu ukuzisusa ngenxa yamandla aqinile kagesi phakathi kwazo nendawo eyiluphala, edinga ukwelashwa okukhethekile.

Ukususwa Kwezinto Eziphilayo: Ukungcola kwe-organic okufana namafutha kanye nezinsalela ze-photoresist kungase kunamathele endaweni eyi-wafer. Lokhu kungcola ngokuvamile kususwa kusetshenziswa ama-oxidizing aqinile noma izinyibilikisi.

Ukususwa kwe-Metal Ion: Izinsalela ze-ion zensimbi endaweni eyi-wafer zingehlisa ukusebenza kukagesi futhi zithinte nezinyathelo zokucubungula ezilandelayo. Ngakho-ke, izixazululo ezithile zamakhemikhali zisetshenziselwa ukususa la ma-ion.

Ukususwa kwe-Oxide: Ezinye izinqubo zidinga ukuthi indawo eyisicwecwana ingabi nengqimba ye-oxide, njenge-silicon oxide. Ezimweni ezinjalo, izingqimba ze-oxide yemvelo zidinga ukususwa phakathi nezinyathelo ezithile zokuhlanza.

Inselele yobuchwepheshe bokuhlanza i-wafer ilele ekususeni ukungcola ngaphandle kokuthinta kabi indawo eyisicwecwana, njengokuvimbela ukuhwalala komhlaba, ukugqwala, noma omunye umonakalo obonakalayo.

2. Ukugeleza Kwenqubo Yokuhlanza I-wafer

Inqubo yokuhlanza i-wafer ngokuvamile ihilela izinyathelo eziningi zokuqinisekisa ukususwa okuphelele kokungcola kanye nokuzuza indawo ehlanzekile ngokuphelele.

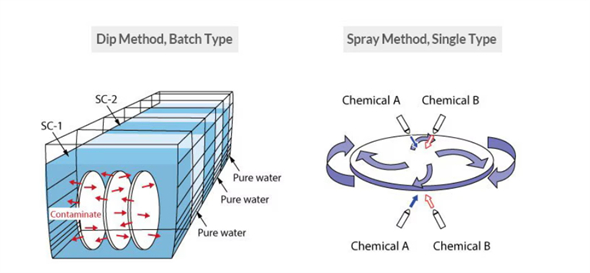

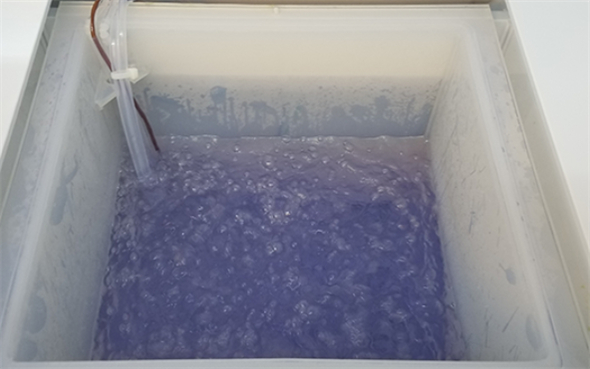

Umfanekiso: Ukuqhathaniswa Phakathi Kohlobo Lweqoqo kanye Nokuhlanza Kwe-Single-Wafer

Inqubo evamile yokuhlanza i-wafer ihlanganisa izinyathelo ezilandelayo eziyinhloko:

1. Ukuhlanza ngaphambilini (Ukuhlanzeka kwangaphambili)

Inhloso yokuhlanza ngaphambilini ukususa ukungcola okuxekethile kanye nezinhlayiya ezinkulu endaweni eyi-wafer, etholakala ngokujwayelekile ngamanzi acwebile (i-DI Water) ukuhlanza nokuhlanza nge-ultrasonic. Amanzi akhishwe nge-deionized ekuqaleni angakwazi ukususa izinhlayiya kanye nokungcola okuncibilikisiwe kusuka endaweni eyi-wafer, kuyilapho ukuhlanzwa kwe-ultrasonic kusebenzisa imiphumela ye-cavitation ukuphula isibopho phakathi kwezinhlayiya ne-wafer surface, okwenza kube lula ukuyikhipha.

2. Ukuhlanza Amakhemikhali

Ukuhlanzwa kwamakhemikhali kungenye yezinyathelo ezibalulekile enqubweni yokuhlanza i-wafer, kusetshenziswa izixazululo zamakhemikhali ukususa izinto eziphilayo, ama-ion ensimbi nama-oxides endaweni eyiwafa.

Ukususwa Kwezinto Eziphilayo: Ngokuvamile, i-acetone noma ingxube ye-ammonia/peroxide (SC-1) isetshenziselwa ukuncibilikisa kanye ne-oxidize ukungcola kwezinto eziphilayo. Isilinganiso esijwayelekile sesixazululo se-SC-1 sithi NH₄OH

₂O₂

₂O = 1:1:5, nezinga lokushisa elisebenzayo elicishe libe ngu-20°C.

Ukususwa kwe-Metal Ion: Izingxube ze-nitric acid noma i-hydrochloric acid/peroxide (SC-2) zisetshenziselwa ukususa ama-ion ensimbi endaweni eyiwafa. Isilinganiso esijwayelekile sesixazululo se-SC-2 yi-HCl

₂O₂

₂O = 1:1:6, izinga lokushisa ligcinwa licishe libe ngu-80°C.

Ukususwa kwe-Oxide: Kwezinye izinqubo, ukususwa kongqimba lwe-oxide yendabuko endaweni eyi-wafer kuyadingeka, lapho kusetshenziswa isisombululo se-hydrofluoric acid (HF). Isilinganiso esijwayelekile sesixazululo se-HF yi-HF

₂O = 1:50, futhi ingasetshenziswa ekamelweni lokushisa.

3. Final Clean

Ngemuva kokuhlanza amakhemikhali, ama-wafers ngokuvamile athatha isinyathelo sokugcina sokuhlanza ukuqinisekisa ukuthi azikho izinsalela zamakhemikhali ezihlala phezulu. Ukuhlanza okokugcina kusebenzisa amanzi akhishiwe ukuze kuhlanzwe kahle. Ukwengeza, ukuhlanzwa kwamanzi e-ozone (O₃/H₂O) kusetshenziselwa ukuqhubeka nokususa noma yikuphi ukungcola okusele endaweni eyiwafa.

4. Ukomisa

Ama-wafer ahlanziwe kufanele omiswe ngokushesha ukuvimbela ama-watermark noma ukunamathiselwa kabusha kokungcola. Izindlela zokomisa ezijwayelekile zihlanganisa ukomisa nge-spin kanye nokuhlanzwa kwe-nitrogen. Owokuqala ususa umswakama endaweni eyi-wafer ngokuphotha ngesivinini esikhulu, kuyilapho lokhu okulandelayo kuqinisekisa ukomiswa okuphelele ngokufutha igesi eyomile ye-nitrogen endaweni eyilutshwana.

Okungcolisayo

Igama Lenqubo Yokuhlanza

Incazelo Yengxube Yekhemikhali

Amakhemikhali

| Izinhlayiya | I-Piranha (SPM) | I-sulfuric acid/hydrogen peroxide/DI amanzi | H2SO4/H2O2/H2O 3-4:1; 90°C |

| I-SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI amanzi | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| Izinsimbi (hhayi ithusi) | I-SC-2 (HPM) | I-Hydrochloric acid/i-hydrogen peroxide/amanzi e-DI | HCl/H2O2/H2O1:1:6; 85°C |

| I-Piranha (SPM) | I-sulfuric acid/hydrogen peroxide/DI amanzi | H2SO4/H2O2/H2O3-4:1; 90°C | |

| I-DHF | Dilute hydrofluoric acid/DI amanzi (ngeke asuse ithusi) | HF/H2O1:50 | |

| Izinto eziphilayo | I-Piranha (SPM) | I-sulfuric acid/hydrogen peroxide/DI amanzi | H2SO4/H2O2/H2O 3-4:1; 90°C |

| I-SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI amanzi | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| I-DIO3 | I-ozone emanzini e-de-ionized | O3/H2O Izingxube Ezilungiselelwe | |

| I-Native oxide | I-DHF | Nciphisa amanzi e-hydrofluoric acid/DI | HF/H2O 1:100 |

| BHF | I-hydrofluoric acid ehlanganisiwe | I-NH4F/HF/H2O |

3. Izindlela Ezivamile Zokuhlanza I-wafer

1. Indlela Yokuhlanza I-RCA

Indlela yokuhlanza i-RCA ingenye yezindlela zakudala zokuhlanza iwafa embonini ye-semiconductor, eyathuthukiswa yi-RCA Corporation eminyakeni engama-40 edlule. Le ndlela ngokuyinhloko isetshenziselwa ukususa ukungcola okuphilayo kanye nokungcola kwe-ion yensimbi futhi ingaqedwa ngezinyathelo ezimbili: SC-1 (Standard Clean 1) kanye ne-SC-2 (Standard Clean 2).

I-SC-1 Cleaning: Lesi sinyathelo sisetshenziswa kakhulu ukususa ukungcola kwezinto eziphilayo kanye nezinhlayiya. Isixazululo siyingxube ye-ammonia, i-hydrogen peroxide, namanzi, eyenza ungqimba oluncane lwe-silicon oxide endaweni eyilucwecwe.

I-SC-2 Cleaning: Lesi sinyathelo sisetshenziswa ngokuyinhloko ukususa ukungcola kwe-ion yensimbi, kusetshenziswa ingxube ye-hydrochloric acid, i-hydrogen peroxide, namanzi. Ishiya ungqimba oluncane lwe-passivation endaweni eyilutshwana ukuvimbela ukungcoliswa kabusha.

2. Indlela Yokuhlanza I-Piranha (I-Piranha Etch Clean)

Indlela yokuhlanza i-Piranha iyindlela ephumelela kakhulu yokususa izinto eziphilayo, kusetshenziswa ingxube ye-sulfuric acid ne-hydrogen peroxide, ngokuvamile ngokwesilinganiso esingu-3:1 noma 4:1. Ngenxa yezakhiwo eziqinile ze-oxidative zalesi sixazululo, singasusa inani elikhulu lezinto eziphilayo kanye nokungcola okunenkani. Le ndlela idinga ukulawulwa okuqinile kwezimo, ikakhulukazi mayelana nezinga lokushisa nokugxila, ukugwema ukulimaza i-wafer.

Ukuhlanza kwe-Ultrasonic kusebenzisa umphumela we-cavitation okhiqizwe amaza omsindo we-high-frequency oketshezini ukuze kususwe ukungcola endaweni eyi-wafer. Uma kuqhathaniswa nokuhlanza okungokwesiko kwe-ultrasonic, ukuhlanzwa kwe-megasonic kusebenza ngemvamisa ephezulu, okuvumela ukususwa okuphumelelayo kwezinhlayiya ezinosayizi omncane we-micron ngaphandle kokudala umonakalo endaweni eyi-wafer.

4. Ukuhlanza Ozone

Ubuchwepheshe bokuhlanza i-ozone busebenzisa izakhiwo eziqinile ze-oxidizing ze-ozone ukubola nokususa ukungcola okuphilayo endaweni eyi-wafer, ekugcineni kuguqule kube yi-carbon dioxide namanzi angenabungozi. Le ndlela ayidingi ukusetshenziswa kwama-reagents amakhemikhali abizayo futhi ibangela ukungcoliswa kwemvelo okuncane, okwenza kube ubuchwepheshe obuvelayo emkhakheni wokuhlanza i-wafer.

4. Isisetshenziswa Senqubo Yokuhlanza Isicwecwana

Ukuqinisekisa ukusebenza kahle nokuphepha kwezinqubo zokuhlanza i-wafer, izinhlobonhlobo zemishini yokuhlanza ethuthukisiwe isetshenziswa ekwenzeni i-semiconductor. Izinhlobo eziyinhloko zihlanganisa:

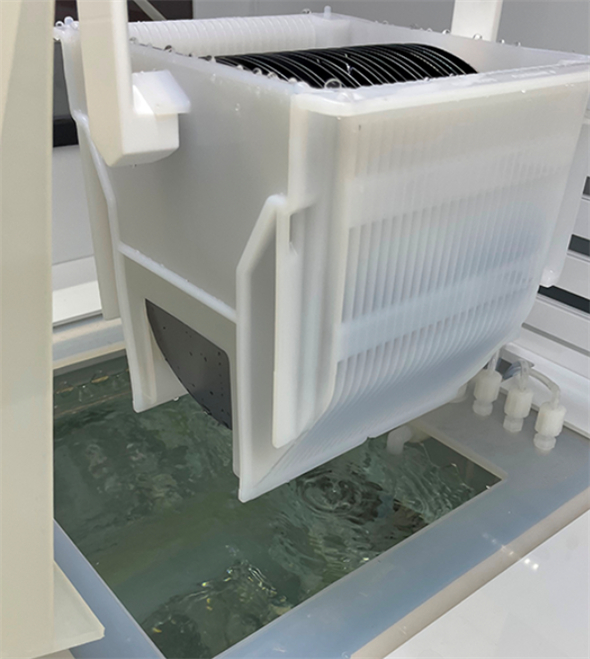

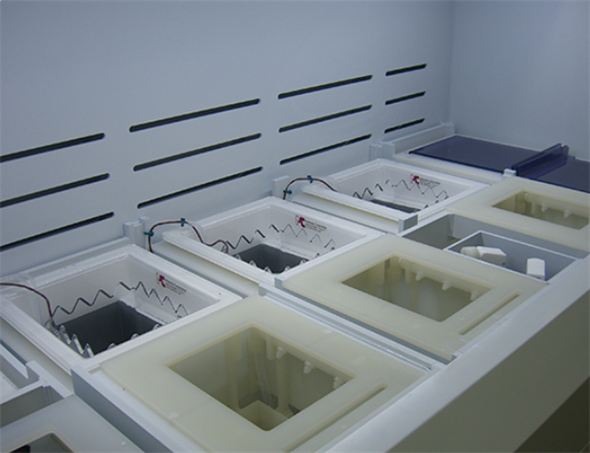

1. Izinsiza Zokuhlanza Ezimanzi

Imishini yokuhlanza emanzi ihlanganisa amathangi okucwilisa ahlukahlukene, amathangi okuhlanza ama-ultrasonic, nama-spin dryers. Lawa madivaysi ahlanganisa amandla emishini nama-reagents amakhemikhali ukuze asuse ukungcola endaweni eyi-wafer. Amathangi okucwiliswa ngokuvamile afakwe izinhlelo zokulawula izinga lokushisa ukuze kuqinisekiswe ukuzinza nokusebenza kahle kwezixazululo zamakhemikhali.

2. Izinsiza Zokuhlanza Ezomile

Imishini yokuhlanza okomile ikakhulukazi ihlanganisa izihlanzi ze-plasma, ezisebenzisa izinhlayiya ezinamandla ku-plasma ukuze zisabele futhi zikhiphe izinsalela endaweni eyisicwecwana. Ukuhlanzwa kwe-plasma kulungele ikakhulukazi izinqubo ezidinga ukugcinwa kobuqotho ngaphandle kokwethula izinsalela zamakhemikhali.

3. Amasistimu Okuhlanza Okuzenzakalelayo

Ngokukhula okuqhubekayo kokukhiqizwa kwe-semiconductor, izinhlelo zokuhlanza ezizenzakalelayo seziphenduke inketho ekhethwayo yokuhlanza ama-wafer ngezinga elikhulu. Lezi zinhlelo ngokuvamile zihlanganisa izindlela zokudlulisa ezizenzakalelayo, amasistimu okuhlanza amathangi amaningi, kanye nezinhlelo zokulawula ukunemba ukuze kuqinisekiswe imiphumela yokuhlanza engaguquki yewafa ngayinye.

5. Amathrendi Akusasa

Njengoba amadivaysi e-semiconductor eqhubeka nokuncipha, ubuchwepheshe bokuhlanza i-wafer buyathuthukela kuzixazululo ezisebenza kahle nezingangeni imvelo. Ubuchwepheshe bokuhlanza esikhathini esizayo buzogxila kulokhu:

Ukususwa kwe-Sub-nanometer Particle: Ubuchwepheshe bokuhlanza obukhona bungaphatha izinhlayiya zesikali se-nanometer, kodwa ngokuncipha okwengeziwe kosayizi wedivayisi, ukususa izinhlayiya ze-nanometer kuzoba inselele entsha.

Ukuhlanza Okuhlaza Okuhlaza Nemvelo: Ukunciphisa ukusetshenziswa kwamakhemikhali alimaza imvelo kanye nokuthuthukisa izindlela zokuhlanza ezivumelana nemvelo, njengokuhlanza i-ozone nokuhlanza i-megasonic, kuzobaluleke kakhulu.

Amazinga Aphakeme Okuzenzakalela Nobuhlakani: Izinhlelo ezihlakaniphile zizovumela ukuqapha kwesikhathi sangempela kanye nokulungiswa kwemingcele ehlukahlukene phakathi nenqubo yokuhlanza, kuthuthukiswe ukusebenza kahle kokuhlanza nokusebenza kahle kokukhiqiza.

Ubuchwepheshe bokuhlanza i-wafer, njengesinyathelo esibalulekile ekwenziweni kwe-semiconductor, budlala indima ebalulekile ekuqinisekiseni izindawo ezicwebezelayo ezihlanzekile ngezinqubo ezilandelayo. Ukuhlanganiswa kwezindlela ezihlukahlukene zokuhlanza kususa ngokuphumelelayo ukungcola, kunikeze indawo ehlanzekile ye-substrate yezinyathelo ezilandelayo. Njengoba ubuchwepheshe buthuthuka, izinqubo zokuhlanza zizoqhubeka nokuthuthukiswa ukuze kuhlangatshezwane nezidingo zokunemba okuphezulu kanye namazinga aphansi amaphutha ekukhiqizeni ama-semiconductor.

Isikhathi sokuthumela: Oct-08-2024