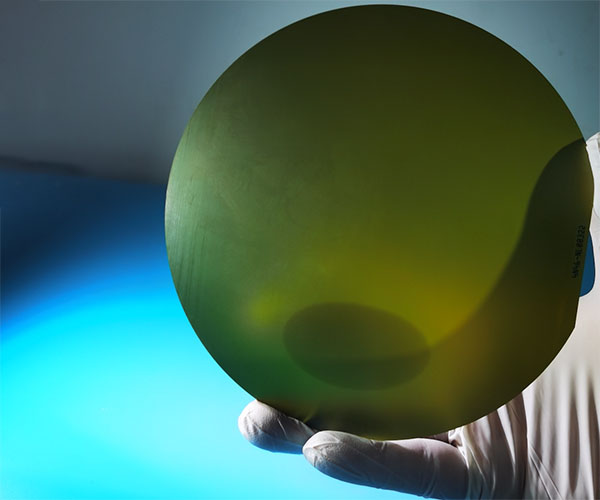

Njengamanje, inkampani yethu ingaqhubeka nokuhlinzeka ngeqoqo elincane lama-wafers e-SiC ohlobo lwe-8inchN, uma unezidingo zesampula, sicela ukhululeke ukuxhumana nami. Sinesampula yamawafa alungele ukuthunyelwa.

Emkhakheni wezinto zokwakha ze-semiconductor, inkampani yenze intuthuko enkulu ocwaningweni nasekuthuthukisweni kwamakristalu amakhulu e-SiC. Ngokusebenzisa amakristalu ayo embewu ngemuva kwemizuliswano eminingi yokukhulisa ububanzi, inkampani ikhule ngempumelelo amakristalu angu-8-inch N-type SiC, axazulula izinkinga ezinzima ezifana nenkundla yokushisa engalingani, ukuqhekeka kwekristalu nokusatshalaliswa kwezinto ezingavuthiwe kwesigaba segesi ekukhuleni kwamakristalu angu-8-intshi e-SIC, futhi isheshisa ukukhula kosayizi omkhulu wamakristalu e-SIC kanye nokulawula okuzenzakalelayo kobuchwepheshe. Thuthukisa kakhulu ukuncintisana okuyisisekelo kwenkampani embonini ye-SiC single crystal substrate. Ngesikhathi esifanayo, inkampani ikhuthaza ngenkuthalo ukuqoqwa kobuchwepheshe kanye nenqubo yomugqa wokuhlola wokulungiselela usayizi omkhulu we-silicon carbide substrate, iqinisa ukushintshaniswa kwezobuchwepheshe kanye nokusebenzisana kwezimboni emikhakheni ekhuphuka nomfula, futhi isebenzisane namakhasimende ukuze ihlale iphindaphinda ukusebenza komkhiqizo, futhi ikhuthaza ngokuhlanganyela ijubane lokusetshenziswa kwezimboni ze-silicon carbide materials.

| 8inch N-uhlobo lweSiC DSP Specs | |||||

| Inombolo | Into | Iyunithi | Ukukhiqiza | Ucwaningo | Dummy |

| 1. Amapharamitha | |||||

| 1.1 | i-polytype | -- | 4H | 4H | 4H |

| 1.2 | ukuma komhlaba | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Ipharamitha kagesi | |||||

| 2.1 | i-dopant | -- | n-uhlobo lweNitrojeni | n-uhlobo lweNitrojeni | n-uhlobo lweNitrojeni |

| 2.2 | ukumelana | ohm ·cm | 0.015~0.025 | 0.01~0.03 | NA |

| 3. Ipharamitha yemishini | |||||

| 3.1 | ububanzi | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | ukujiya | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | I-notch orientation | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Ukujula Kwenotshi | mm | 1~1.5 | 1~1.5 | 1~1.5 |

| 3.5 | I-LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | I-TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Khothama | μm | -25 ~ 25 | - 45-45 | - 65-65 |

| 3.8 | I-Wap | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | I-AFM | nm | I-Ra≤0.2 | I-Ra≤0.2 | I-Ra≤0.2 |

| 4. Isimo | |||||

| 4.1 | ukuminyana kwe-micropipe | eya cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | okuqukethwe kwensimbi | ama-athomu/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | I-TSD | eya cm2 | ≤500 | ≤1000 | NA |

| 4.4 | I-BPD | eya cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | I-TED | eya cm2 | ≤7000 | ≤10000 | NA |

| 5. Ikhwalithi enhle | |||||

| 5.1 | ngaphambili | -- | Si | Si | Si |

| 5.2 | ukuphela kwendawo | -- | I-Si-face CMP | I-Si-face CMP | I-Si-face CMP |

| 5.3 | izinhlayiyana | i/isinkwa | ≤100(usayizi≥0.3μm) | NA | NA |

| 5.4 | ukunwaya | i/isinkwa | ≤5, Ubude Obuphelele≤200mm | NA | NA |

| 5.5 | Umphetho ama-chips/ama-indenti/imifantu/amabala/ukungcola | -- | Lutho | Lutho | NA |

| 5.6 | Izindawo ze-Polytype | -- | Lutho | Indawo ≤10% | Indawo ≤30% |

| 5.7 | ukumaka ngaphambili | -- | Lutho | Lutho | Lutho |

| 6. Ikhwalithi yangemuva | |||||

| 6.1 | buyela emuva | -- | I-C-face MP | I-C-face MP | I-C-face MP |

| 6.2 | ukunwaya | mm | NA | NA | NA |

| 6.3 | Ingemuva elinamaphutha onqenqemeni ama-chips/ama-indenti | -- | Lutho | Lutho | NA |

| 6.4 | Ukuqina kweqolo | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Ukumaka emuva | -- | Inothi | Inothi | Inothi |

| 7. Umphetho | |||||

| 7.1 | umphetho | -- | I-Chamfer | I-Chamfer | I-Chamfer |

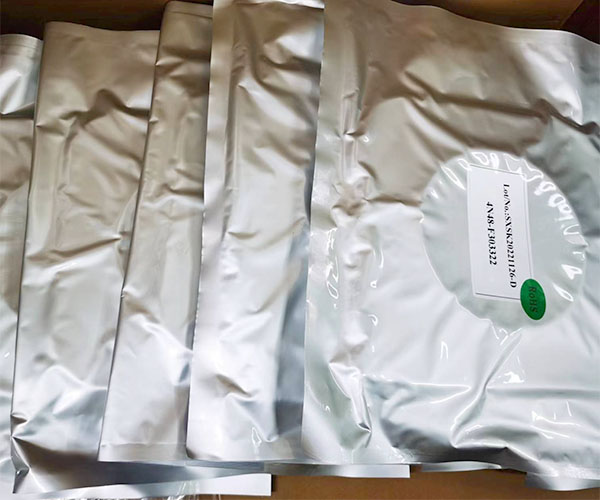

| 8. Iphakheji | |||||

| 8.1 | ukupakisha | -- | I-Epi ilungile nge-vacuum ukupakisha | I-Epi ilungile nge-vacuum ukupakisha | I-Epi ilungile nge-vacuum ukupakisha |

| 8.2 | ukupakisha | -- | I-Multi-wafer ukupakishwa kwekhasethi | I-Multi-wafer ukupakishwa kwekhasethi | I-Multi-wafer ukupakishwa kwekhasethi |

Isikhathi sokuthumela: Apr-18-2023