I-Silicon carbide (i-SiC) akubona nje kuphela ubuchwepheshe obubalulekile bokuvikela izwe kodwa futhi iyingxenye ebalulekile yezimboni zezimoto nezamandla emhlabeni jikelele. Njengesinyathelo sokuqala esibalulekile ekucutshungulweni kwekristalu elilodwa le-SiC, ukusikwa kwe-wafer kunquma ngokuqondile ikhwalithi yokucwenga nokupholisha okulandelayo. Izindlela zendabuko zokusika zivame ukwethula imifantu engaphezulu nendawo engaphansi, zikhuphule amazinga okuphuka kwe-wafer kanye nezindleko zokukhiqiza. Ngakho-ke, ukulawula ukulimala kokuqhekeka kwendawo kubalulekile ekuthuthukiseni ukukhiqizwa kwedivayisi ye-SiC.

Njengamanje, ukusika i-SiC ingot kubhekene nezinselelo ezimbili ezinkulu:

- Ukulahlekelwa okuphezulu kwempahla ku-sawing yendabuko ye-multi-wire:Ubulukhuni obukhulu be-SiC kanye nokuba brittleness kuyenza ithambekele ekujikekeni nasekuqhekekeni ngesikhathi sokusika, ukugaywa, nokupholishwa. Ngokusho kwedatha ye-Infineon, ukusaha okungokwesiko kwedayimane-resin-bonded multi-wire kufinyelela kuphela u-50% wokusetshenziswa kwempahla ekusikeni, nokulahlekelwa okuphelele kwe-wafer eyodwa kufinyelela ku-~250 μm ngemva kokupholishwa, okushiya into encane esebenzisekayo.

- Ukusebenza okuphansi kanye nemijikelezo yokukhiqiza emide:Izibalo zokukhiqiza zamazwe ngamazwe zibonisa ukuthi ukukhiqiza amawafa angu-10,000 kusetshenziswa ukusaha ngezintambo eziningi okuqhubekayo amahora angu-24 kuthatha izinsuku ezingu-~273. Le ndlela idinga izinto eziningi ezisetshenziswayo kanye nezinto ezisetshenziswayo kuyilapho idala ukuhwaqeka okuphezulu nokungcola (uthuli, amanzi angcolile).

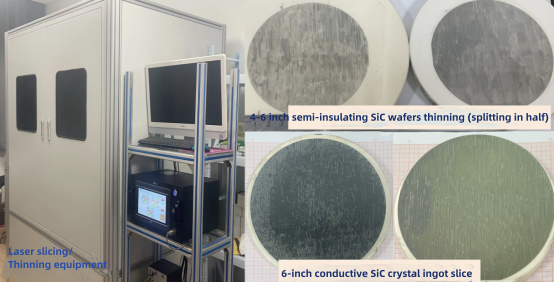

Ukuze kubhekwane nalezi zinkinga, ithimba likaProfessor Xiu Xiangqian eNyuvesi yaseNanjing, lenze imishini yokusika i-laser enembayo ephezulu, ye-SiC, esebenzisa ubuchwepheshe be-laser obushesha kakhulu ukuze kuncishiswe amaphutha futhi kukhuphule umkhiqizo. Ngengot ye-SiC engu-20-mm, lobu buchwepheshe buphinda kabili isivuno se-wafer uma kuqhathaniswa nokusaha ngocingo okuvamile. Ukwengeza, ama-wafers ane-laser-sliced akhombisa ukufana kwejometri okuphezulu, okuvumela ukuncishiswa kokuqina kuye ku-200 μm isinkwa esisicwecwana ngasinye kanye nokukhula okuphumayo.

Izinzuzo Eziyinhloko:

- I-R&D eqediwe kumishini ye-prototype enkulu, egunyazwe ukusika amawafa we-SiC angama-4–6-inch semi-insulating kanye nama-ingots angu-6-inch conductive SiC.

- Ukusikwa kwe-ingot okungu-8 intshi kungaphansi kokuqinisekiswa.

- Isikhathi sokusika esifushane kakhulu, okukhiphayo okuphezulu konyaka, kanye nokuthuthukiswa kwesivuno esingu->50%.

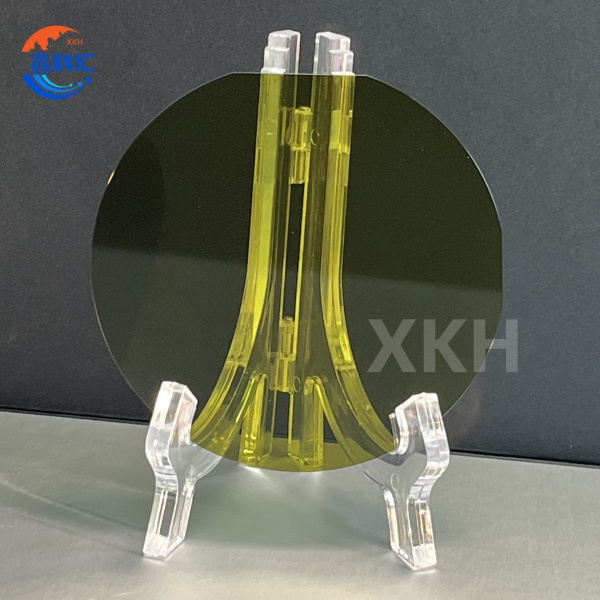

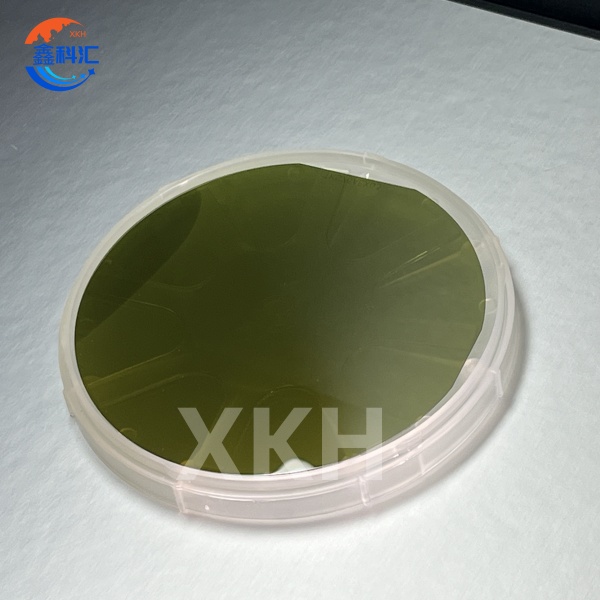

I-XKH's SiC substrate yohlobo 4H-N

Amandla Wemakethe:

Lesi sixhobo sikulungele ukuba yisixazululo esiyinhloko sokusikwa kwe-ingot ye-SiC engu-8-intshi, okwamanje okubuswa ukuthengiswa kwe-Japan okunezindleko eziphezulu kanye nemikhawulo yokuthumela ngaphandle. Isidingo sasekhaya semishini yokusika/yokunciphisa i-laser sidlula amayunithi angu-1,000, nokho azikho ezinye izindlela ezivuthiwe ezenziwe ngamaShayina ezikhona. Ubuchwepheshe baseNanjing University buphethe inani elikhulu lemakethe namandla omnotho.

Ukuhambisana Kwezinto Eziningi:

Ngaphandle kwe-SiC, okokusebenza kusekela ukucutshungulwa kwe-laser kwe-gallium nitride (GaN), i-aluminium oxide (Al₂O₃), kanye nedayimane, kunwetshwe ukusetshenziswa kwayo kwezimboni.

Ngokuguqula ukucubungula kwe-SiC wafer, lokhu kuqanjwa okusha kubhekana nezingqinamba ezibalulekile ekukhiqizeni ama-semiconductor kuyilapho kuhambisana namathrendi embulungeni yonke emayelana nokusebenza okuphezulu, izinto ezonga amandla.

Isiphetho

Njengomholi wemboni ekukhiqizeni i-silicon carbide (SiC) substrate, i-XKH igxile ekuhlinzekeni ama-SiC substrates angusayizi ogcwele angu-2-12-intshi (okuhlanganisa nohlobo lwe-4H-N/SEMI-uhlobo, 4H/6H/3C-uhlobo) eklanyelwe imikhakha ekhula kakhulu njengezimoto zamandla amasha (i-NEVs, ama-voltage angu-5), ukuxhumana nezithombe zamandla (i-5G). Ngokusebenzisa ubuchwepheshe bokusika i-wafer enobukhulu obuncane obulahleka kancane, kanye nobuchwepheshe bokucubungula obunembayo, sizuze ukukhiqizwa okukhulu kwama-substrates angu-8-intshi kanye nempumelelo kubuchwepheshe bokukhula kwekristalu obungu-12-intshi be-SiC, sehlise kakhulu izindleko zeyunithi ngayinye. Ukuqhubekela phambili, sizoqhubeka nokuthuthukisa i-ingot-level laser slicing kanye nezinqubo zokulawula ukucindezeleka ezihlakaniphile ukuze sikhuphule isivuno se-substrate engu-12-intshi siye kumazinga okuncintisana omhlaba, sinikeze amandla imboni ye-SiC yasekhaya ukuthi iphule ukubusa kwamazwe ngamazwe nokusheshisa izinhlelo zokusebenza eziyingozi ezizindeni eziphezulu njengama-chips amandla e-auto-grade AI.

I-XKH's SiC substrate yohlobo 4H-N

Isikhathi sokuthumela: Aug-15-2025