1. Isingeniso

Naphezu kwamashumi eminyaka ocwaningo, i-heteroepitaxial 3C-SiC ekhuliswe kuma-silicon substrates ayikazuzi ikhwalithi eyanele yekristalu yezinhlelo zokusebenza ze-electronic zezimboni. Ukukhula ngokuvamile kwenziwa kuma-substrates e-Si(100) noma e-Si(111), ngayinye yethula izinselele ezihlukile: izizinda eziphikisana nesigaba zokuthi (100) kanye nokuqhekeka kokuthi (111). Nakuba amafilimu aqondiswe ku- [111] ebonisa izici ezithembisayo ezifana nokuncishiswa kwesici, i-surface morphology ethuthukisiwe, nokucindezeleka okuphansi, ukuthambekela okunye okufana ne-(110) kanye (211) kuhlala kungafundiwe. Idatha ekhona iphakamisa ukuthi izimo zokukhula ezilungile zingase ziqonde ngqo, zibe nzima uphenyo oluhlelekile. Ngokuphawulekayo, ukusetshenziswa kwe-high-Miller-index Si substrates (isb, (311), (510)) ye-3C-SiC heteroepitaxy akukaze kubikwe, okushiya indawo ebalulekile yocwaningo lokuhlola ngezindlela zokukhula ezincike ekuzimbeni.

2. Okokuhlola

Izendlalelo ze-3C-SiC zafakwa nge-atmospheric-pressure chemical vapor deposition (CVD) kusetshenziswa amagesi andulela i-SiH4/C3H8/H2. Ama-substrates ayengama-1 cm² ama-Si wafer anemikhombandlela ehlukahlukene: (100), (111), (110), (211), (311), (331), (510), (553), kanye (995). Wonke ama-substrates aye-on-eksisi ngaphandle kuka-(100), lapho amawafa angasikiwe angu-2° aphinde ahlolwa. Ukuhlanza kwangaphambi kokukhula kwakuhilela ukukhishwa kwe-ultrasonic ku-methanol. Iphrothokholi yokukhula yayihlanganisa ukususwa kwe-oxide yendabuko ngokusebenzisa i-H2 annealing ku-1000 ° C, kulandelwa inqubo yezinyathelo ezimbili ezijwayelekile: i-carburization imizuzu engu-10 ku-1165 ° C ne-12 sccm C3H8, bese i-epitaxy imizuzu engu-60 ku-1350 ° C (C/Si ratio = 4) isebenzisa i-2 sccm 8 C H 4 kanye ne-2 sccm H4 sccm 4 ne-1. Ukugijima ngakunye kokukhula kuhlanganisa ukuqondiswa kwe-Si okune kuya kwemihlanu okuhlukile, okungenani okukodwa (100) okuyireferensi yesinkwa.

3. Imiphumela Nezingxoxo

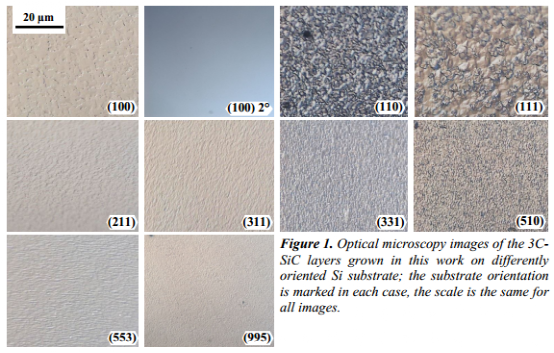

I-morphology yezendlalelo ze-3C-SiC ezitshalwe kuma-substrates ahlukahlukene we-Si (Fig. 1) ibonise izici ezihlukile zendawo kanye nobulukhuni. Ngokubukeka, amasampula akhule ku-Si(100), (211), (311), (553), kanye (995) abonakale njengesibuko, kanti amanye asukela ku-milky ((331), (510)) kuya ebuthuntu ((110), (111)). Indawo ebushelelezi (ebonisa i-microstructure enhle kakhulu) itholwe ku-(100)2° off kanye (995) substrates. Ngokumangazayo, zonke izendlalelo zahlala zingaqhekeki ngemva kokupholisa, kuhlanganise ne-3C-SiC(111) ethambekele ekucindezelekeni. Usayizi wesampula olinganiselwe kungenzeka uvimbele ukuqhekeka, nakuba amanye amasampuli abonisiwe ukugoba (ukuchezuka okungu-30-60 μm ukusuka phakathi nendawo kuye konqenqema) kutholakale ngaphansi kwe-microscope yokubona ku-1000× magnification ngenxa yokucindezeleka okushisayo okunqwabelene. Izendlalelo ezikhotheme kakhulu ezikhule ku-Si(111), (211), kanye (553) nama-substrates abonisa umumo we-concave okhombisa ubunzima obuqinile, odinga umsebenzi wokuhlola nowethiyori ukuze uhlotshaniswe nokuma kwekristalu.

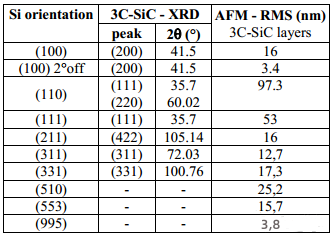

Umfanekiso 1 ufingqa imiphumela ye-XRD ne-AFM (ukuskena ku-20×20 μ m2) yezendlalelo ze-3C-SC ezitshalwe kuma-substrates e-Si anemikhombandlela ehlukene.

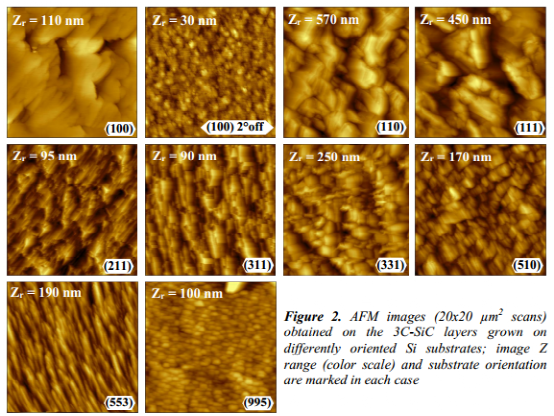

Izithombe ze-atomic force microscopy (AFM) (Fig. 2) ziqinise ukubhekwa kokubona. Amanani e-Root-mean-square (RMS) aqinisekise izindawo ezibushelelezi ku-(100)2° off kanye (995) substrates, afaka izakhiwo ezifana nokusanhlamvu ezinobukhulu obuseceleni obungu-400-800 nm. Isendlalelo esikhule (110) sasiqinile kakhulu, kuyilapho izici ezinde kanye/noma ezihambisanayo ezinemingcele ebukhali ngezikhathi ezithile zivele kwezinye izimo ((331), (510)). I-X-ray diffraction (XRD) θ-2θ scans (efingqiwe kuThebula 1) yembule i-heteroepitaxy eyimpumelelo ye-low-Miller-index substrates, ngaphandle kwe-Si(110) ebonise iziqongo ezixubile ze-3C-SiC(111) kanye (110) ezibonisa i-polycrystallinity. Lokhu kuxutshwa kokuma kubikwe ngaphambilini ku-Si(110), nakuba ezinye izifundo zibone okukhethekile (111)-oriented 3C-SiC, okuphakamisa ukuthi ukuthuthukiswa kwesimo sokukhula kubalulekile. Ngezinkomba ze-Miller ≥5 ((510), (553), (995)), azikho iziqongo ze-XRD ezitholwe ekucushweni okujwayelekile kwe-θ-2θ njengoba lezi zindiza ezinenkomba ephezulu azihlukani kule geometry. Ukungabikho kweziqongo ze-3C-SiC ezinenkomba ephansi (isb, (111), (200)) kuphakamisa ukukhula kwe-crystalline eyodwa, okudinga ukutshekiswa kwesampula ukuze kutholwe ukuhluka kusuka ezindizeni ezinenkomba ephansi.

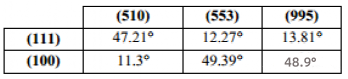

Umfanekiso 2 ubonisa ukubalwa kwe-engeli yendiza ngaphakathi kwesakhiwo sekristalu ye-CFC.

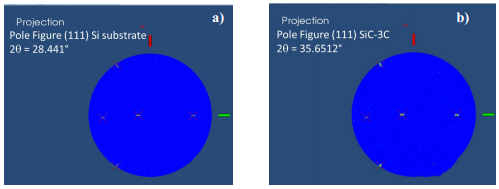

Ama-engeli e-crystallographic abaliwe phakathi kwezindiza ezinenkomba ephezulu nezinenkomba ephansi (Ithebula 2) abonise ukungalungi okukhulu (>10°), echaza ukungabikho kwawo kuzikena ezijwayelekile ezingu-θ-2θ. Ngakho-ke ukuhlaziya isibalo se-Pole kwenziwa kusampula (995)-oriented ngenxa ye-granular morphology yayo engavamile (okungenzeka isuka ekukhuleni kwekholomu noma i-twinning) kanye nobulukhuni obuphansi. Izibalo ze-pole (111) (Umfanekiso 3) ezivela ku-Si substrate kanye nesendlalelo se-3C-SiC zazicishe zifane, okuqinisekisa ukukhula kwe-epitaxial ngaphandle kwe-twinning. Indawo emaphakathi ivele kokuthi χ≈15°, ihambisana ne-engeli yethiyori (111)-(995). Amabala amathathu alinganayo avela ezindaweni ezilindelekile (χ=56.2°/φ=269.4°, χ=79°/φ=146.7° kanye no-33.6°), nakuba indawo ebuthaka engalindelekile kokuthi χ=62°/φ=93.3° idinga uphenyo olwengeziwe. Ikhwalithi yekristalu, ehlolwe ngobubanzi bendawo ku-φ-scans, ibonakala ithembisa, nakuba izilinganiso zejika elinyakazayo zidingeka ukuze kulinganiswe umthamo. Izibalo ze-Pole zamasampuli (510) kanye (553) zisazoqedwa ukuze kuqinisekiswe isimo sazo se-epitaxial.

Umfanekiso wesi-3 ubonisa umdwebo ophakeme we-XRD oqoshwe kusampula eqondisiwe engu-(995), ebonisa izindiza ezingu-(111) ze-Si substrate (a) kanye nosendlalelo se-3C-SiC (b).

4. Isiphetho

Ukukhula kwe-Heteroepitaxial 3C-SiC kuphumelele kuma-orientation amaningi we-Si ngaphandle kwe-(110), okuveze impahla ye-polycrystalline. I-Si(100)2° off futhi (995) substrates ikhiqize izendlalelo ezibushelelezi (RMS <1 nm), kuyilapho (111), (211), kanye (553) ibonise ukukhothama okubalulekile (30-60 μm). Ama-substrates anenkomba ephezulu adinga ukucaciswa kwezinhlamvu okuthuthukisiwe kwe-XRD (isb, izibalo zezigxobo) ukuze kuqinisekiswe i-epitaxy ngenxa yokungabikho kweziqongo ezingu-θ-2θ. Umsebenzi oqhubekayo uhlanganisa izilinganiso zejika elinyakazisayo, ukuhlaziya ingcindezi ye-Raman, kanye nokunwetshwa kokuqondiswa okwengeziwe kwenkomba ephezulu ukuze kuqedelwe lolu cwaningo lokuhlola.

Njengomkhiqizi ohlanganisiwe oqondile, i-XKH inikeza izinsiza zokucubungula ezenziwe ngokwezifiso ezinephothifoliyo ebanzi ye-silicon carbide substrates, ehlinzeka ngezinhlobo ezijwayelekile nezikhethekile ezihlanganisa i-4H/6H-N, 4H-Semi, 4H/6H-P, kanye ne-3C-SiC, etholakala ngobubanzi ukusuka ku-2-intshi ukuya ku-12-intshi. Ubungcweti bethu bokugcina ekugcineni ekukhuleni kwekristalu, ukwenziwa kwemishini enembile, nokuqinisekisa ikhwalithi kuqinisekisa izixazululo eziklanyelwe ugesi wamandla, i-RF, nezinhlelo zokusebenza ezivelayo.

Isikhathi sokuthumela: Aug-08-2025