Kusukela ngawo-1980s, ukuminyana kokuhlanganiswa kwamasekethe e-elekthronikhi bekukhula ngenani lonyaka le-1.5× noma ngokushesha. Ukuhlanganiswa okuphezulu kuholela ekukhuleni okukhulu kwamanje kanye nokukhiqizwa kokushisa ngesikhathi sokusebenza.Uma kungahlakazwanga kahle, lokhu kushisa kungabangela ukwehluleka kokushisa futhi kunciphise isikhathi sokuphila sezingxenye ze-elekthronikhi.

Ukuze kuhlangatshezwane nezidingo ezikhulayo zokuphatha okushisayo, izinto zokupakisha ezithuthukisiwe ze-elekthronikhi ezinokuhanjiswa okuphezulu kwe-thermal ziyacwaningwa kabanzi futhi zenziwa ngcono.

Impahla eyinhlanganisela yedayimane/yethusi

01 Idayimane neCopper

Izinto zokupakisha zendabuko zifaka i-ceramics, amapulasitiki, izinsimbi, nama-alloys awo. Ama-Ceramics afana ne-BeO kanye ne-AlN abonisa ama-CTE afanayo nama-semiconductors, ukuqina okuhle kwamakhemikhali, kanye nokusebenza kahle kwe-thermal. Kodwa-ke, ukucubungula kwabo okuyinkimbinkimbi, izindleko eziphezulu (ikakhulukazi i-BeO enobuthi), kanye nezinhlelo zokusebenza ezikhawulela i-brittleness. Ukupakishwa kwepulastiki kunikeza izindleko eziphansi, isisindo esincane, kanye nokufakwa kwe-insulation kodwa kunenkinga yokungahambi kahle kwe-thermal kanye nokungazinzi kwezinga lokushisa eliphezulu. Izinsimbi ezihlanzekile (Cu, Ag, Al) zinokusebenza okuphezulu kwe-thermal kodwa i-CTE eyeqile, kuyilapho ama-alloys (Cu-W, Cu-Mo) ebeka engozini ukusebenza okushisayo. Ngakho-ke, izinto zokupakisha zenoveli ezilinganisa ukuguquguquka okuphezulu kwe-thermal kanye ne-CTE efanele zidingeka ngokushesha.

| Ukuqiniswa | I-Thermal Conductivity (W/(m·K)) | I-CTE (×10⁻⁶/℃) | Ukuminyana (g/cm³) |

| Idayimane | 700-2000 | 0.9–1.7 | 3.52 |

| Izinhlayiya ze-BeO | 300 | 4.1 | 3.01 |

| Izinhlayiya ze-AlN | 150–250 | 2.69 | 3.26 |

| Izinhlayiya ze-SiC | 80–200 | 4.0 | 3.21 |

| Izinhlayiya ze-B₄C | 29–67 | 4.4 | 2.52 |

| I-Boron fiber | 40 | ~5.0 | 2.6 |

| Izinhlayiya ze-TiC | 40 | 7.4 | 4.92 |

| Izinhlayiya ze-Al₂O₃ | 20–40 | 4.4 | 3.98 |

| Izindevu ze-SiC | 32 | 3.4 | - |

| Si₃N₄ izinhlayiya | 28 | 1.44 | 3.18 |

| TiB₂ izinhlayiya | 25 | 4.6 | 4.5 |

| Izinhlayiya ze-SiO₂ | 1.4 | <1.0 | 2.65 |

Idayimane, into yemvelo enzima kakhulu eyaziwayo (Mohs 10), nayo inezinto ezihlukilei-thermal conductivity (200–2200 W/(m·K)).

I-micro-powder yedayimane

Ithusi, nge high thermal/electrical conductivity (401 W/(m·K)), i-ductility, kanye nokusebenza kahle kwezindleko, kusetshenziswa kakhulu kuma-IC.

Ukuhlanganisa lezi zakhiwo,idayimane/ithusi (Dia/Cu) izinhlanganisela—nge-Cu njenge-matrix kanye nedayimane njengesiqiniseko—zivela njengesizukulwane esilandelayo sezinto zokuphatha ezishisayo.

02 Izindlela Zokukhiqiza Ezibalulekile

Izindlela ezijwayelekile zokulungiselela idayimane/ithusi zihlanganisa: i-powder metallurgy, izinga lokushisa eliphezulu kanye nendlela yokucindezela okukhulu, indlela yokuncibilikisa yokucwilisa, indlela yokukhipha i-plasma sintering, indlela yokufafaza okubandayo, njll.

Ukuqhathaniswa kwezindlela ezihlukene zokulungiselela, izinqubo kanye nezakhiwo zezinhlanganisela zedayimane/zethusi ezinosayizi wezinhlayiyana eyodwa

| Ipharamitha | I-Powder Metallurgy | Vacuum Hot-pressing | I-Spark Plasma Sintering (SPS) | I-High-Pressure High-Temperature (HPHT) | I-Cold Spray Deposition | Ncibilikisa Ukungena |

| Uhlobo Lwedayimane | I-MBD8 | HFD-D | I-MBD8 | I-MBD4 | I-PDA | I-MBD8/HHD |

| I-Matrix | 99.8% Cu powder | I-99.9% ye-electrolytic Cu powder | 99.9% Cu powder | Ingxubevange/i-Cu powder ehlanzekile | I-Cu powder ehlanzekile | Pure Cu inqwaba/induku |

| Ukuguqulwa kwesixhumi esibonakalayo | - | - | - | B, Ti, Si, Cr, Zr, W, Mo | - | - |

| Usayizi Wezinhlayiyana (μm) | 100 | 106–125 | 100–400 | 20–200 | 35–200 | 50–400 |

| Ingxenye Yevolumu (%) | 20–60 | 40–60 | 35–60 | 60–90 | 20–40 | 60–65 |

| Izinga lokushisa (°C) | 900 | 800–1050 | 880–950 | 1100–1300 | 350 | 1100–1300 |

| Ingcindezi (MPa) | 110 | 70 | 40–50 | 8000 | 3 | 1–4 |

| Isikhathi (imizuzu) | 60 | 60–180 | 20 | 6–10 | - | 5–30 |

| Ukuminyana Okuhlobene (%) | 98.5 | 99.2–99.7 | - | - | - | 99.4–99.7 |

| Ukusebenza | ||||||

| I-Optimal Thermal Conductivity (W/(m·K)) | 305 | 536 | 687 | 907 | - | 943 |

Amasu ajwayelekile we-Dia/Cu ahlanganisa:

(1)I-Powder Metallurgy

Izimpushana zedayimane/Cu ezixubile ziyahlanganiswa futhi zisindwe. Nakuba ingabizi futhi ilula, le ndlela ikhiqiza ukuminyana okulinganiselwe, ama-microstructures angalingani, kanye nobukhulu besampula obunomkhawulo.

Siyunithi ephakathi

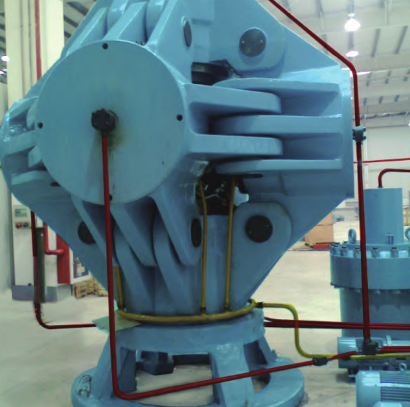

(1)I-High-Pressure High-Temperature (HPHT)

Isebenzisa umshini wokunyathelisa onama-anvil amaningi, i-Cu encibilikisiwe ingena ezindlini zedayimane ngaphansi kwezimo ezimbi kakhulu, ikhiqize izinhlanganisela eziminyene. Kodwa-ke, i-HPHT idinga isikhunta ezibizayo futhi ayifaneleki ukukhiqiza ngezinga elikhulu.

Cubic press

(1)Ncibilikisa Ukungena

I-Molten Cu ingena kuma-preform edayimane ngokungeniswa okusizwa yingcindezi noma okuqhutshwa yi-capillary. Izinhlanganisela eziphumayo zithola >446 W/(m·K) ukuhanjiswa kwe-thermal.

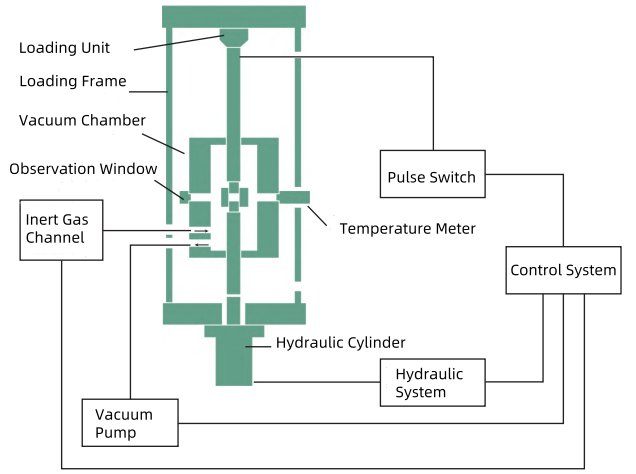

(2)I-Spark Plasma Sintering (SPS)

I-pulsed current ngokushesha i-siners ixube izimpushana ngaphansi kwengcindezi. Nakuba kusebenza kahle, ukusebenza kwe-SPS kuyehla ezingxekweni zedayimane>65 vol%.

Umdwebo we-schematic wesistimu yokukhipha i-plasma sintering

(5) I-Cold Spray Deposition

Ama-powder ayasheshiswa futhi afakwe kuma-substrates. Le ndlela yokusafufusa ibhekene nezinselelo ekulawuleni ukuphela kwendawo kanye nokuqinisekisa ukusebenza okushisayo.

03 Ukuguqulwa kwesixhumi esibonakalayo

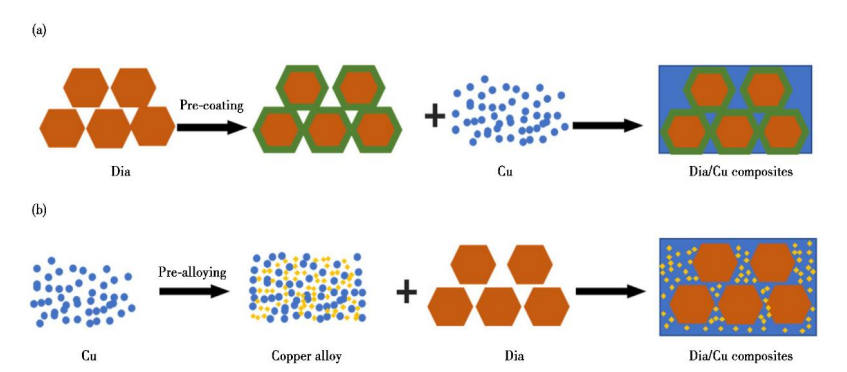

Ukuze kulungiswe izinto eziyinhlanganisela, ukumanzisa okuhlangene phakathi kwezingxenye kuyimfuneko edingekayo yenqubo eyinhlanganisela kanye nesici esibalulekile esithinta ukwakheka kwesixhumi esibonakalayo kanye nesimo sokubopha isixhumi esibonakalayo. Isimo esingamanzisi kusixhumi esibonakalayo phakathi kwedayimane ne-Cu siholela ekubhekaneni nokushisa okuphezulu kakhulu kwesixhumi esibonakalayo. Ngakho-ke, kubaluleke kakhulu ukwenza ucwaningo lokuguqulwa kwesixhumi esibonakalayo phakathi kwalokhu kokubili ngezindlela ezihlukahlukene zobuchwepheshe. Njengamanje, kunezindlela ezimbili eziyinhloko zokuthuthukisa inkinga yesixhumi esibonakalayo phakathi kwedayimane ne-Cu matrix: (1) Ukwelashwa kokuguqulwa kobuso bedayimane; (2) Ukwelashwa kwe-alloying ye-matrix yethusi.

Umdwebo wohlelo lokushintsha: (a) Ukucwenga okuqondile phezu kwedayimane; (b) Ukuhlanganiswa kwe-matrix

(1) Ukulungiswa komphezulu wedayimane

Ukucwenga izakhi ezisebenzayo ezifana ne-Mo, Ti, W kanye ne-Cr phezu kongqimba olungaphezulu lwesigaba sokuqinisa kungathuthukisa izici ezihlangene zobuso bedayimane, ngaleyo ndlela kuthuthukise ukusebenza kwalo okushisayo. I-Sintering ingenza izinto ezingenhla zisabele nekhabhoni engaphezulu kwempushana yedayimane ukuze zakhe isendlalelo soshintsho lwe-carbide. Lokhu kuthuthukisa isimo sokumanzisa phakathi kwedayimane nesisekelo sensimbi, futhi ukunamathela kungavimbela ukwakheka kwedayimane ekushintsheni ekushiseni okuphezulu.

(2) Ukuhlanganiswa kwe-matrix yethusi

Ngaphambi kokucubungula okuhlanganisiwe kwezinto, ukwelashwa kwangaphambili kwe-alloying kwenziwa ngethusi lensimbi, elingakhiqiza izinto ezihlanganisiwe ezine-conductivity ephezulu yokushisa evamile. Izakhi ezisebenzayo zokudotshwa ku-matrix yethusi azikwazi nje ukunciphisa ngempumelelo i-engeli yokumanzisa phakathi kwedayimane nethusi, kodwa futhi zikhiqize ungqimba lwe-carbide oluncibilika okuqinile ku-matrix yethusi kusixhumi esibonakalayo sedayimane/Cu ngemva kokusabela. Ngale ndlela, izikhala eziningi ezikhona kusixhumi esibonakalayo ziyashintshwa futhi zigcwaliswe, ngaleyo ndlela kuthuthukiswe ukuqhutshwa kwe-thermal.

04 Isiphetho

Izinto zokupakisha ezijwayelekile ziyasilela ekulawuleni ukushisa okuvela kuma-chips athuthukile. Izinhlanganisela ze-Dia/Cu, ezine-CTE eguqulekayo kanye ne-ultrahigh thermal conductivity, zimelela isisombululo esishintshayo se-electronics yesizukulwane esilandelayo.

Njengebhizinisi lobuchwepheshe obuphezulu elihlanganisa imboni nohwebo, i-XKH igxile ocwaningweni nasekuthuthukisweni nasekukhiqizweni kwezinhlanganisela zedayimane/ zethusi nezinhlanganisela zensimbi ezisebenza kahle ezifana ne-SiC/Al kanye ne-Gr/Cu, ehlinzeka ngezixazululo ezintsha zokuphatha okushisayo ngokuhambisa okushisayo okungaphezu kuka-900W/(m·K) emikhakheni yephakeji ye-electronic space kanye ne-aerospace.

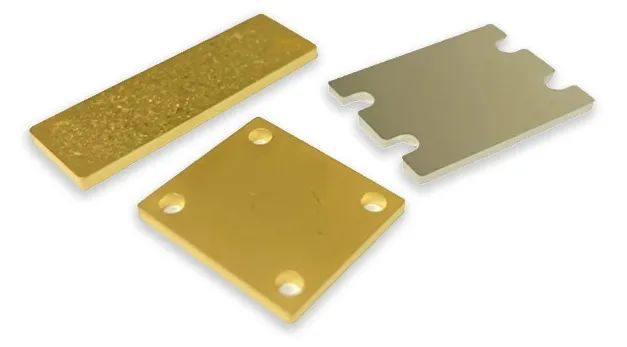

XKH's I-Diamond copper clad laminate composite material:

Isikhathi sokuthumela: May-12-2025