I-SPC (Statistical Process Control) iyithuluzi elibalulekile enqubweni yokukhiqiza ama-wafer, elisetshenziselwa ukuqapha, ukulawula, kanye nokwenza ngcono ukuzinza kwezigaba ezihlukahlukene zokukhiqiza.

1. Uhlolojikelele Lwesistimu ye-SPC

I-SPC iyindlela esebenzisa amasu ezibalo ukuqapha nokulawula izinqubo zokukhiqiza. Umsebenzi wayo oyinhloko uwukuthola okudidayo enqubweni yokukhiqiza ngokuqoqa nokuhlaziya idatha yesikhathi sangempela, ukusiza onjiniyela benze izinguquko ezifike ngesikhathi nezinqumo. Umgomo we-SPC ukunciphisa ukuhluka kwenqubo yokukhiqiza, ukuqinisekisa ukuthi ikhwalithi yomkhiqizo ihlala izinzile futhi ihlangabezana nezimfuneko.

I-SPC isetshenziswa kunqubo yokuhlanganisa ukuze:

Gada amapharamitha wemishini ebalulekile (isb., isilinganiso se-etch, amandla e-RF, ukucindezela kwegumbi, izinga lokushisa, njll.)

Hlaziya izinkomba zekhwalithi yomkhiqizo oyinhloko (isb., ububanzi bomugqa, ukujula kwe-etch, ukuhwaqeka konqenqema, njll.)

Ngokuqapha le mingcele, onjiniyela bangakwazi ukubona amathrendi abonisa ukuwohloka kokusebenza kwemishini noma ukuchezuka enqubweni yokukhiqiza, ngaleyo ndlela behlise izilinganiso zokulahlwa.

2. Izingxenye Eziyisisekelo Zohlelo lwe-SPC

Uhlelo lwe-SPC lwakhiwe amamojula abalulekile amaningana:

Imojula Yokuqoqwa Kwedatha: Iqoqa idatha yesikhathi sangempela evela kumishini kanye nokugeleza kwenqubo (isb, ngezinhlelo ze-FDC, EES) futhi irekhoda imingcele ebalulekile nemiphumela yokukhiqiza.

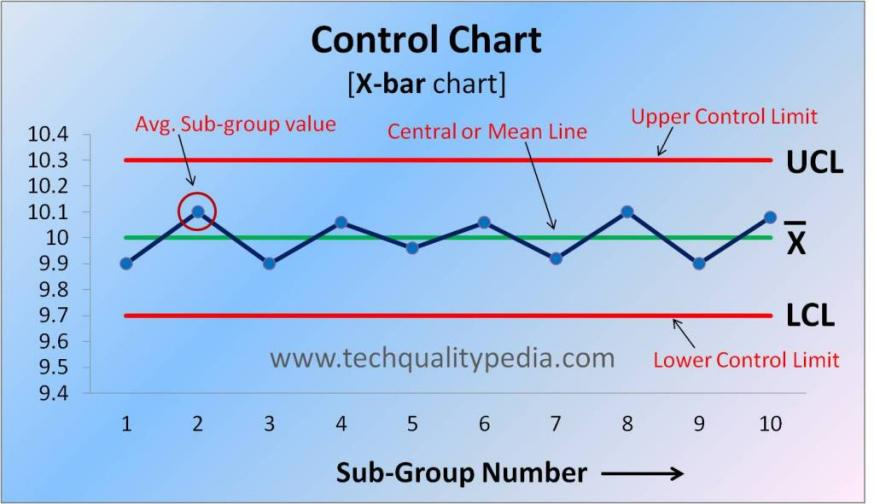

Imojuli Yeshadi Lokulawula: Isebenzisa amashadi okulawula ezibalo (isb, ishadi le-X-Bar, ishadi le-R, ishadi le-Cp/Cpk) ukuze libone ngeso lengqondo ukuzinza kwenqubo nokusiza ekunqumeni ukuthi inqubo iyalawula yini.

Isistimu ye-alamu: Icupha ama-alamu uma amapharamitha abalulekile eqa imikhawulo yokulawula noma abonise izinguquko zethrendi, okwenze ukuthi onjiniyela bathathe isinyathelo.

Imojuli yokuhlaziya neyokubika: Ihlaziya umsuka wezinkinga ezisuselwe kumashadi e-SPC futhi ivame ukukhiqiza imibiko yokusebenza yenqubo namathuluzi.

3. Incazelo Eningiliziwe Yamashadi Okulawula ku-SPC

Amashadi okulawula angelinye lamathuluzi asetshenziswa kakhulu ku-SPC, asiza ukuhlukanisa phakathi "kokuhlukahluka okuvamile" (okubangelwa ukuhlukahluka kwenqubo yemvelo) kanye "nokwehluka okungavamile" (okubangelwa ukwehluleka kwezisetshenziswa noma ukuchezuka kwenqubo). Amashadi okulawula ajwayelekile afaka:

Amashadi e-X-Bar kanye no-R: Asetshenziselwa ukuqapha incazelo nobubanzi phakathi kwamaqoqo okukhiqiza ukuze kubhekwe ukuthi inqubo izinzile yini.

Izinkomba ze-Cp ne-Cpk: Isetshenziselwa ukukala amandla enqubo, okungukuthi, ukuthi inqubo ephumayo ingahlangabezana yini nezimfuneko zokucaciswa. I-Cp ikala amandla angaba khona, kuyilapho i-Cpk ibheka ukuchezuka kwesikhungo senqubo kusukela kumikhawulo ebekiwe.

Isibonelo, enqubweni yokuqopha, ungase uqaphe amapharamitha afana nesilinganiso se-etch kanye nobukhulu bendawo. Uma izinga le-etch locezu oluthile lwesisetshenziswa lidlula umkhawulo wokulawula, ungasebenzisa amashadi okulawula ukuze unqume ukuthi lokhu kuwukwehluka okungokwemvelo noma inkomba yokungasebenzi kahle kwemishini.

4. Ukusetshenziswa kwe-SPC ku-Etching Equipment

Enqubweni yokubhala, ukulawula amapharamitha wemishini kubalulekile, futhi i-SPC isiza ukuthuthukisa ukuzinza kwenqubo ngalezi zindlela ezilandelayo:

Ukuqapha Isimo Sezisetshenziswa: Amasistimu afana ne-FDC aqoqa idatha yesikhathi sangempela kumapharamitha angukhiye wemishini yokufaka (isb, amandla e-RF, ukugeleza kwegesi) futhi ahlanganise le datha namashadi okulawula e-SPC ukuze kutholwe izinkinga zemishini engase ibe khona. Isibonelo, uma ubona ukuthi amandla e-RF eshadini lokulawula aya ngokuya ehlehla enanini elimisiwe, ungathatha isinyathelo kusenesikhathi ukulungisa noma ukulungisa ukuze ugweme ukuba nomthelela kwikhwalithi yomkhiqizo.

Ukuqapha Ikhwalithi Yomkhiqizo: Ungakwazi futhi ukufaka amapharamitha angukhiye wekhwalithi yomkhiqizo (isb, ukujula kwe-etch, ububanzi bomugqa) ohlelweni lwe-SPC ukuze ugade ukuqina kwawo. Uma ezinye izinkomba zomkhiqizo ezibucayi zichezuka kancane kancane kumanani okuhlosiwe, isistimu ye-SPC izokhipha i-alamu, ebonisa ukuthi ukulungiswa kwenqubo kuyadingeka.

I-Preventive Maintenance (PM): I-SPC ingasiza ekuthuthukiseni umjikelezo wokuvikela wokulungisa okokusebenza. Ngokuhlaziya idatha yesikhathi eside ekusebenzeni kwemishini kanye nemiphumela yokucubungula, ungakwazi ukunquma isikhathi esilungile sokunakekelwa kwemishini. Isibonelo, ngokuqapha amandla e-RF kanye nempilo ye-ESC, unganquma ukuthi kunini lapho ukuhlanza noma ukushintshwa kwengxenye kuyadingeka, unciphise amazinga okuhluleka kwemishini kanye nesikhathi sokukhiqiza.

5. Amathiphu Okusebenzisa Nsuku Zonke Ohlelo Lwe-SPC

Uma usebenzisa uhlelo lwe-SPC ekusebenzeni kwansuku zonke, izinyathelo ezilandelayo zingalandelwa:

Chaza Amapharamitha Okulawula Okubalulekile (KPI): Khomba amapharamitha abaluleke kakhulu kunqubo yokukhiqiza futhi uwafake ekuqaphelweni kwe-SPC. Le mingcele kufanele ihlobane eduze nekhwalithi yomkhiqizo nokusebenza kwemishini.

Setha Imikhawulo Yokulawula kanye Nemikhawulo Ye-alamu: Ngokusekelwe kudatha yomlando nezimfuneko zenqubo, setha imikhawulo yokulawula enengqondo kanye nemikhawulo ye-alamu kupharamitha ngayinye. Imikhawulo yokulawula ivamise ukusethwa kokuthi ±3σ (ukuchezuka okujwayelekile), kuyilapho imikhawulo ye-alamu isekelwe ezimeni ezithile zenqubo namathuluzi.

Ukuqapha Nokuhlaziya Okuqhubekayo: Buyekeza njalo amashadi okulawula e-SPC ukuze uhlaziye izitayela zedatha nokuhluka. Uma amanye amapharamitha eqa imikhawulo yokulawula, kudingeka isinyathelo esisheshayo, njengokulungisa amapharamitha wemishini noma ukulungisa okokusebenza.

Ukuphatha Okungavamile kanye Nokuhlaziywa Kwembangela Yezimpande: Uma kwenzeka okungavamile, uhlelo lwe-SPC luqopha ulwazi oluningiliziwe mayelana nesigameko. Udinga ukuxazulula inkinga futhi uhlaziye umsuka wokungajwayelekile ngokusekelwe kulolu lwazi. Ngokuvamile kungenzeka ukuhlanganisa idatha evela ezinhlelweni ze-FDC, izinhlelo ze-EES, njll., ukuze kuhlaziywe ukuthi inkinga ibangelwa ukwehluleka kwemishini, ukuchezuka kwenqubo, noma izici zangaphandle zemvelo.

Ukuthuthukiswa Okuqhubekayo: Ukusebenzisa idatha yomlando erekhodwe uhlelo lwe-SPC, thola amaphuzu abuthakathaka enqubeni futhi uphakamise izinhlelo zokuthuthukisa. Isibonelo, enqubweni yokubhala, hlaziya umthelela wesikhathi sempilo ye-ESC nezindlela zokuhlanza emijikelezweni yokulungisa izinto zokusebenza futhi uthuthukise ngokuqhubekayo amapharamitha wokusebenza kwemishini.

6. Icala Lesicelo Esisebenzayo

Njengesibonelo esisebenzayo, ake sithi unesibopho semishini yokunamathisela i-E-MAX, futhi i-chamber cathode ihlangabezana nokuguga ngaphambi kwesikhathi, okuholela ekwenyukeni kwamanani e-D0 (BARC defect). Ngokugada amandla e-RF nezinga le-etch ngohlelo lwe-SPC, ubona ithrendi lapho la mapharamitha achezuka kancane kancane emananini awo amisiwe. Ngemva kokuba i-alamu ye-SPC icushiwe, uhlanganisa idatha evela ohlelweni lwe-FDC bese unquma ukuthi inkinga ibangelwa ukulawulwa kwezinga lokushisa okungazinzile ngaphakathi kwegumbi. Bese usebenzisa izindlela ezintsha zokuhlanza namasu okunakekela, ekugcineni wehlise inani le-D0 ukusuka ku-4.3 ukuya ku-2.4, ngaleyo ndlela uthuthukisa ikhwalithi yomkhiqizo.

7.Ku-XINKEHUI ungathola.

Kwa-XINKEHUI, ungakwazi ukuzuza isinkwa esicwebezelayo, noma ngabe i-wafer ye-silicon noma i-wafer ye-SiC. Sisebenza ngokukhethekile ekuletheni amawafa ekhwalithi ephezulu ezimbonini ezahlukahlukene, sigxile ekunembeni nasekusebenzeni.

(isinkwa se-silicon)

Ama-silicon wafers ethu aklanywe ngobumsulwa obuphakeme nokufana, aqinisekisa izakhiwo zikagesi ezinhle kakhulu ngezidingo zakho ze-semiconductor.

Ukuthola izinhlelo zokusebenza ezidinga kakhulu, amawafa ethu e-SiC ahlinzeka ngokusebenza okushisayo okuhlukile nokusebenza kahle kwamandla aphezulu, alungele ama-electronics amandla kanye nezindawo ezinezinga lokushisa eliphezulu.

(Isicwecwe se-SiC)

Nge-XINKEHUI, uthola ubuchwepheshe obusezingeni eliphezulu nokusekelwa okuthembekile, amawafa aqinisekisayo ahlangabezana nezindinganiso eziphakeme kakhulu zomkhakha. Sikhethele ukuphelela kwakho kwe-wafer!

Isikhathi sokuthumela: Oct-16-2024