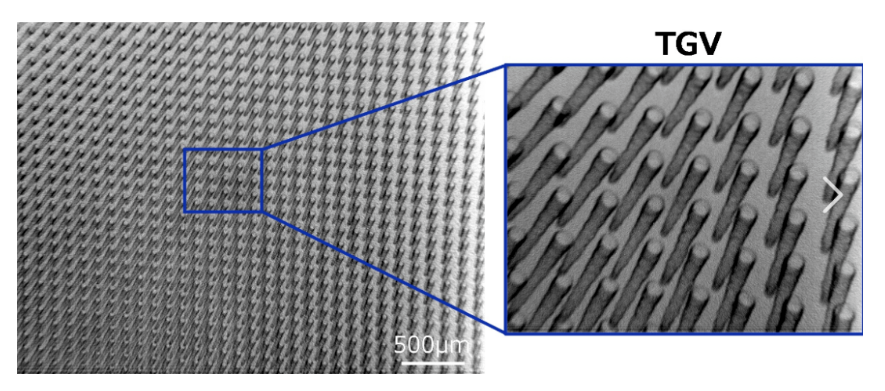

Iyini i-TGV?

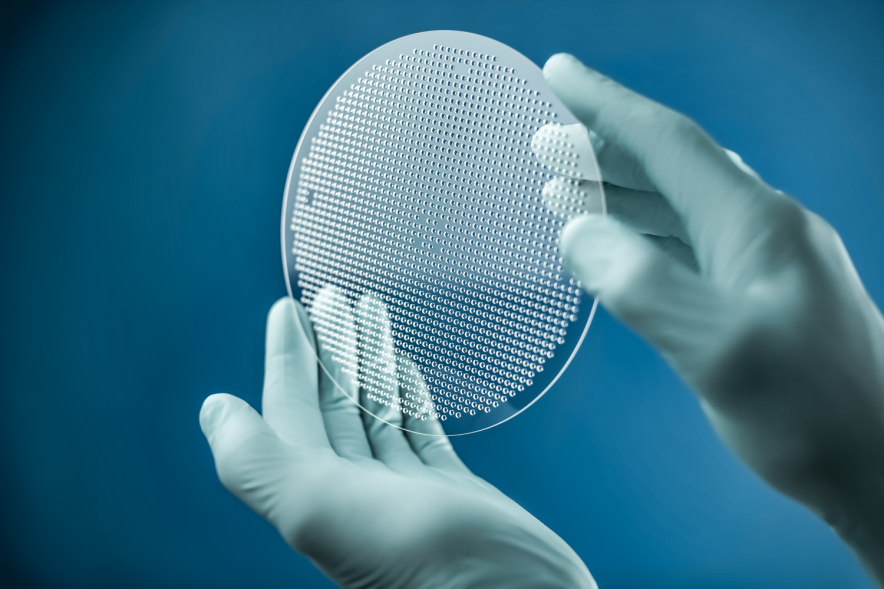

I-TGV, (Nge-Glass nge), ubuchwepheshe bokudala izimbobo ku-substrate yengilazi, Ngamagama alula, i-TGV iyisakhiwo esiphezulu esishaya, sigcwalise futhi sixhuma phezulu naphansi kweglasi ukuze kwakhiwe ama-circuits ahlanganisiwe phansi kwengilazi. Lobu buchwepheshe buthathwa njengobuchwepheshe obubalulekile esizukulwaneni esilandelayo sokupakishwa kwe-3D.

Yiziphi izici ze-TGV?

1. Isakhiwo: I-TGV iyi-conductive engena iqonde ngembobo eyenziwe engxenyeni yengilazi. Ngokufaka ungqimba lwensimbi olubambayo odongeni lwembotshana, izingqimba ezingenhla nezingezansi zezimpawu zikagesi zixhumene.

2. Inqubo yokukhiqiza: Ukukhiqizwa kwe-TGV kufaka phakathi ukulungiswa kwe-substrate, ukwakhiwa kwemigodi, ukubekwa kongqimba lwensimbi, ukugcwaliswa kwemigodi kanye nezinyathelo zokucaba. Izindlela zokukhiqiza ezijwayelekile yi-chemical etching, i-laser drilling, i-electroplating nokunye.

3. Izinzuzo zohlelo lokusebenza: Uma iqhathaniswa nensimbi yendabuko ngembobo, i-TGV inezinzuzo zosayizi omncane, ukuminyana kwezintambo okuphezulu, ukusebenza okungcono kokukhipha ukushisa nokunye. Isetshenziswa kakhulu kuma-microelectronics, i-optoelectronics, i-MEMS nezinye izinkambu zokuxhumanisa okuphezulu kakhulu.

4. Inkambiso yentuthuko: Ngokuthuthukiswa kwemikhiqizo ye-elekthronikhi ebheke ekwenzeni izinto ezincane kanye nokuhlanganiswa okuphezulu, ubuchwepheshe be-TGV buya ngokuya buthola ukunakwa kanye nokusebenza okwengeziwe. Ngokuzayo, inqubo yayo yokukhiqiza izoqhubeka nokuthuthukiswa, futhi ubukhulu bayo nokusebenza kuzoqhubeka nokuba ngcono.

Ithini inqubo ye-TGV:

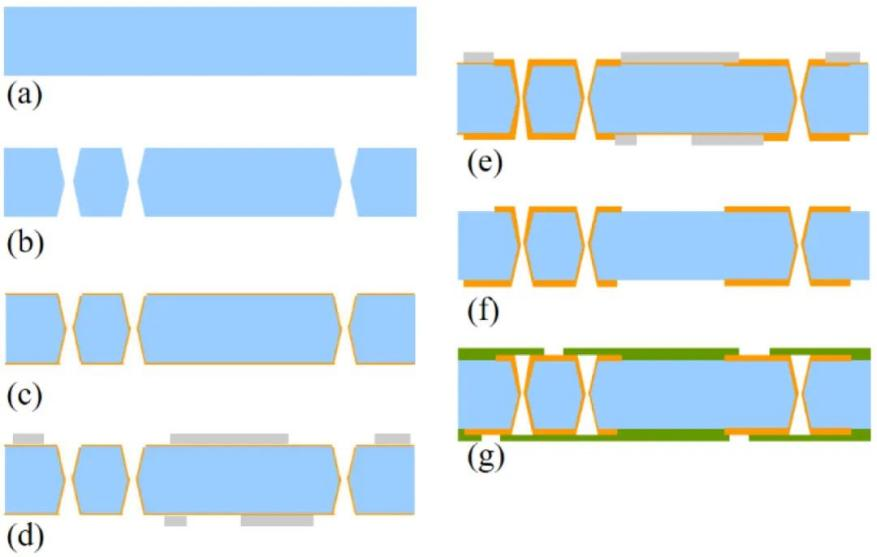

1. Ukulungiswa kwe-substrate yengilazi (a) : Lungiselela i-substrate yengilazi ekuqaleni ukuze uqinisekise ukuthi ubuso bayo bushelelezi futhi buhlanzekile.

2. Ukubhola kwengilazi (b) : I-laser isetshenziselwa ukwakha imbobo yokungena engxenyeni yengilazi. Umumo wembobo ngokuvamile uyi-conical, futhi ngemva kokwelashwa nge-laser ngakolunye uhlangothi, iyaphendulwa futhi icutshungulwe ngakolunye uhlangothi.

3. I-Metallization yodonga lwembobo (c) : Ukwenziwa kwensimbi kwenziwa odongeni lwembobo, ngokuvamile nge-PVD, i-CVD nezinye izinqubo ukuze kwakhiwe ungqimba lwembewu yensimbi eqhubayo odongeni lwembobo, njenge-Ti/Cu, Cr/Cu, njll.

4. I-Lithography (d) : Ingaphezulu le-substrate yengilazi liboshwe nge-photoresist kanye ne-photopatterned. Veza izingxenye ezingadingi i-plating, ukuze kuvele izingxenye ezidinga ukucwenga.

5. Ukugcwaliswa kwezimbobo (e) : I-Electroplating yethusi ukuze igcwalise ingilazi ngezimbobo ukuze kwakhiwe indlela ephelele yokuqhuba. Ngokuvamile kuyadingeka ukuthi imbobo igcwaliswe ngokuphelele ngaphandle kwezimbobo. Qaphela ukuthi i-Cu esemdwebeni ayigcwele ngokugcwele.

6. Indawo eyisicaba ye-substrate (f) : Ezinye izinqubo ze-TGV zizothambisa ingaphezulu le-substrate yengilazi egcwele ukuze kuqinisekiswe ukuthi ingaphezulu le-substrate libushelelezi, elihambisana nezinyathelo zenqubo ezilandelayo.

7.Isendlalelo esivikelayo noxhumano lwetheminali (g) : Isendlalelo esivikelayo (njenge-polyimide) sakhiwe phezu kwendawo engaphansi yengilazi.

Ngamafuphi, zonke izinyathelo zenqubo ye-TGV zibalulekile futhi zidinga ukulawula okunembayo nokwenza kahle. Njengamanje sinikeza ingilazi ye-TGV ngobuchwepheshe bembobo uma kudingeka. Sicela ukhululeke ukuxhumana nathi!

(Lolu lwazi olungenhla luvela ku-inthanethi, i-censoring)

Isikhathi sokuthumela: Jun-25-2024