I-High-purity silicon carbide (SiC) Ceramics ivele njengezinto ezifanele zezingxenye ezibalulekile ku-semiconductor, i-aerospace, kanye nezimboni zamakhemikhali ngenxa ye-thermal conductivity engavamile, ukuqina kwamakhemikhali, namandla emishini. Ngokukhula kwezidingo zemishini ye-ceramic esebenza kahle kakhulu, engcoliswa kancane, ukuthuthukiswa kobuchwepheshe bokulungiselela obusebenzayo nobungacutshungulwayo bezinto zobumba ze-SiC ezihlanzeke kakhulu sekuyinto okugxilwe kuyo ocwaningweni lomhlaba wonke. Leli phepha libuyekeza ngokuhlelekile izindlela zamanje zokulungiselela ezinkulu ze-ceramics ze-SiC ezihlanzekile, kufaka phakathi i-recrystallization sintering, i-pressureless sintering (PS), i-hot pressing (HP), i-spark plasma sintering (SPS), kanye nokukhiqiza okungeziwe (AM), kugcizelelwa ukuxoxisana ngezinqubo ze-sintering, imingcele ebalulekile, izakhiwo zezinto ezibonakalayo, nezinselele ezikhona zenqubo ngayinye.

Ukusetshenziswa kwezitsha zobumba ze-SiC emkhakheni wezempi nobunjiniyela

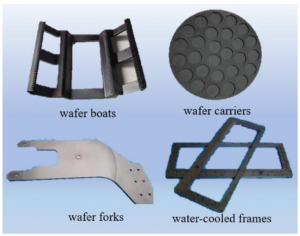

Njengamanje, izingxenye ze-ceramic ze-SiC ezihlanzekile zisetshenziswa kakhulu emishinini yokukhiqiza i-silicon wafer, ebamba iqhaza ezinqubweni eziyinhloko ezifana ne-oxidation, i-lithography, i-etching, kanye nokufakwa kwe-ion. Ngokuthuthuka kobuchwepheshe be-wafer, ukwanda kwamasayizi ama-wafer sekuyinto ebalulekile. Usayizi wamanje we-wafer ovamile ungu-300 mm, ozuza ibhalansi enhle phakathi kwezindleko namandla okukhiqiza. Kodwa-ke, kuqhutshwa uMthetho kaMoore, ukukhiqizwa ngobuningi kwama-wafers angu-450 mm sekuvele ku-ajenda. Amawafa amakhulu ngokuvamile adinga amandla aphezulu esakhiwo ukuze amelane nokungqubuzana nokuguqulwa, okuqhubekisela phambili isidingo esikhulayo sosayizi omkhulu, amandla aphezulu, izingxenye ze-ceramic ze-SiC ezihlanzeke kakhulu. Eminyakeni yamuva nje, ukukhiqiza okungeziwe (ukuphrinta kwe-3D), njengobuchwepheshe be-prototyping obusheshayo obungadingi isikhunta, kubonise amandla amakhulu ekwakhiweni kwezingxenye ze-ceramic ze-SiC eziyinkimbinkimbi ngenxa yokwakhiwa kwe-lay-by-layer kanye nekhono lokuklama eliguquguqukayo, eliheha ukunaka okubanzi.

Leli phepha lizohlaziya ngokuhlelekile izindlela ezinhlanu ezimele ukulungiselela ama-ceramics e-SiC ahlanzekile kakhulu-i-recrystallization sintering, i-sinterless sintering, i-hot pressing, i-spark plasma sintering, kanye nokukhiqiza okungeziwe - kugxilwe ezindleleni zabo ze-sintering, amasu okuthuthukisa inqubo, izici zokusebenza kwempahla, kanye namathemba okusebenza kwezimboni.

Izidingo zezinto ezingavuthiwe ze-silicon carbide ezihlanzekile

I. Recrystallization Sintering

I-recrystallized silicon carbide (RSiC) iyimpahla ye-SiC ehlanzeke kakhulu elungiselelwe ngaphandle kwezinsiza zokushisa emazingeni okushisa aphezulu angama-2100-2500 ° C. Selokhu uFredriksson eqala ukuthola i-recrystallization phenomenon ngasekupheleni kwekhulu le-19, i-RSiC ithole ukunakwa okubalulekile ngenxa yemingcele yayo ehlanzekile yokusanhlamvu kanye nokungabikho kwezigaba zengilazi nokungcola. Emazingeni okushisa aphezulu, i-SiC ibonisa ukucindezelwa komhwamuko ophakeme kuqhathaniswa, futhi indlela yayo yokufaka i-sintering ngokuyinhloko ihilela inqubo yokuhwamuka kwe-condensation: okusanhlamvu okuhle kuyahwamuka futhi kuphinde kubekwe endaweni yezinhlamvu ezinkulu, kukhuthaze ukukhula kwentamo kanye nokubopha okuqondile phakathi kwezinhlamvu, ngaleyo ndlela kuthuthukise amandla ezinto ezibonakalayo.

Ngo-1990, u-Kriegesmann walungisa i-RSiC enenani elilinganiselwe lama-79.1% esebenzisa i-slip casting ku-2200 ° C, ne-cross-section ebonisa i-microstructure eyakhiwe okusanhlamvu okuqinile nama-pores. Kamuva, u-Yi et al. isebenzise ukufakwa kwejeli ukuze ilungise imizimba eluhlaza yaphinde yacwiliswa ku-2450°C, ithola izinto zobumba ze-RSiC ezinenqwaba yokuminyana okungu-2.53 g/cm³ namandla okuguquguquka angu-55.4 MPa.

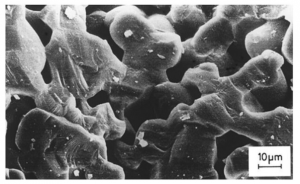

Ingxenye ye-SEM ephukile ye-RSiC

Uma kuqhathaniswa ne-SiC eminyene, i-RSiC inokuminyana okuphansi (cishe u-2.5 g/cm³) kanye nokuvuleka okungama-20%, okukhawulela ukusebenza kwayo ezinhlelweni zokusebenza zamandla aphezulu. Ngakho-ke, ukwenza ngcono ukuminyana kanye nezakhiwo zemishini ze-RSiC sekuyiyona nto ebalulekile ekugxilwe kuyo ocwaningweni. Sung et al. okuhlongozwayo ukufaka i-silicon encibilikisiwe ku-carbon / β-SiC ehlanganisiwe exutshwe futhi iphinde ikristale ku-2200 ° C, yakha ngempumelelo isakhiwo senethiwekhi esakhiwe ngezinhlamvu ze-α-SiC ezimahhadla. I-RSiC eyaba umphumela yazuza ukuminyana okungu-2.7 g/cm³ namandla okuguquguquka angu-134 MPa, igcina ukuzinza okuhle kakhulu kokusebenza emazingeni okushisa aphezulu.

Ukuze kuthuthukiswe ukuminyana, uGuo et al. kusetshenziswe ubuchwepheshe be-polymer infiltration kanye ne-pyrolysis (PIP) yokwelashwa okuningi kwe-RSiC. Kusetshenziswa izixazululo ze-PCS/xylene kanye ne-SiC/PCS/xylene slurries njengabangenisi, ngemva kwemijikelezo engu-3–6 ye-PIP, ukuminyana kwe-RSiC kuye kwathuthukiswa kakhulu (kufika ku-2.90 g/cm³), kanye namandla ayo okuguquguquka. Ukwengeza, bahlongoze isu le-cyclic elihlanganisa i-PIP kanye ne-recrystallization: i-pyrolysis ku-1400 ° C elandelwa i-recrystallization ku-2400 ° C, isula ngokuphumelelayo ukuvinjelwa kwezinhlayiyana nokunciphisa i-porosity. Into yokugcina ye-RSiC ithole ukuminyana okungu-2.99 g/cm³ namandla aguqukayo angu-162.3 MPa, okubonisa ukusebenza okuphelele okuvelele.

Izithombe ze-SEM ze-microstructure evolution ye-RSiC epholishiwe ngemva kwemijikelezo ye-polymer impregnation kanye ne-pyrolysis (PIP)-recrystallization: I-RSiC yokuqala (A), ngemva komjikelezo wokuqala we-PIP-recrystallization (B), nangemuva komjikelezo wesithathu (C)

II. I-Sinterreless Sintering

Izitsha zobumba ze-silicon carbide (SiC) ezingena-Pressureless-sintered (SiC) zilungiswa kusetshenziswa impushana ye-SiC ene-high-purity, i-ultrafine ye-SiC njengempahla eluhlaza, enenani elincane lezinsiza zokupholisa, futhi zifakwe endaweni engasebenzi noma i-vacuum ku-1800-2150 ° C. Le ndlela ifaneleka ukukhiqiza izingxenye ze-ceramic ezinobukhulu obukhulu neziyinkimbinkimbi. Kodwa-ke, njengoba i-SiC ihlanganiswe ngokuyinhloko, i-coefficient yayo yokuzihlukanisa iphansi kakhulu, okwenza ukuminyana kube nzima ngaphandle kwezinsiza-sintering.

Ngokusekelwe kumshini we-sintering, i-sinteringless sintering ingahlukaniswa ngezigaba ezimbili: i-pressure liquid-phase sintering (PLS-SiC) kanye ne-pressure solid-state sintering (PSS-SiC).

1.1 PLS-SiC (Liquid-Phase Sintering)

I-PLS-SiC ivamise ukucwiliswa ngaphansi kuka-2000 ° C ngokwengeza cishe u-10 wt.% wezinsiza ze-eutectic sintering (ezifana ne-Al₂O₃, CaO, MgO, TiO₂, nama-oxides ayivelakancane RE₂O₃) ukuze kwakheke isigaba se-liquid, ukugqugquzela ukufinyelelwa kwezinhlayiya emuva. Le nqubo ifanele izitsha zobumba ze-SiC yezinga lezimboni, kodwa akubanga khona imibiko ye-SiC yokuhlanzeka okuphezulu okuzuzwe ngokusebenzisa i-liquid-phase sintering.

1.2 I-PSS-SiC (Solid-State Sintering)

I-PSS-SiC ibandakanya ukuminyana kombuso oqinile emazingeni okushisa angaphezu kuka-2000°C cishe no-1 wt.% wezithasiselo. Le nqubo incike kakhulu ekusakazeni kwe-athomu kanye nokuhlelwa kabusha kokusanhlamvu okuqhutshwa amazinga okushisa aphezulu ukuze kwehliswe amandla angaphezulu futhi kuzuzwe ukuminyana. Uhlelo lwe-BC (i-boron-carbon) luyinhlanganisela evamile yokuhlanganisa, enganciphisa amandla omngcele wokusanhlamvu futhi isuse i-SiO₂ ebusweni be-SiC. Kodwa-ke, izithasiselo zendabuko ze-BC zivame ukwethula ukungcola okuyinsalela, zinciphisa ubumsulwa be-SiC.

Ngokulawula okuqukethwe okungeziwe (B 0.4 wt.%, C 1.8 wt.%) kanye ne-sintering ku-2150 ° C amahora angu-0.5, i-ceramics ye-SiC ehlanzekile enobumsulwa obungu-99.6 wt.% kanye nokuminyana okuhlobene kwe-98.4%. I-microstructure ibonise izinhlamvu zekholomu (ezinye zidlula u-450 µm ubude), ezinezimbotshana ezincane emingceleni yokusanhlamvu kanye nezinhlayiya zegraphite ngaphakathi kwezinhlamvu. I-ceramics ibonise amandla aguquguqukayo angu-443 ± 27 MPa, i-elastic modulus engu-420 ± 1 GPa, kanye ne-thermal expansion coefficient engu-3.84 × 10⁻⁶ K⁻¹ ebangeni lokushisa kwegumbi ukuya ku-600°C, ebonisa ukusebenza okuhle kakhulu kukonke.

I-Microstructure ye-PSS-SiC: (A) Isithombe se-SEM ngemva kokupholishwa kanye nokufakwa kwe-NaOH; (BD) Izithombe ze-BSD ngemuva kokupholisha nokushumeka

III. I-Hot Pressing Sintering

I-Hot pressing (HP) sintering iyindlela yokuqinisa esebenza kanyekanye ukushisa nokucindezela uniaxial ezintweni eziyimpushana ngaphansi kwezimo ezishisa kakhulu nezinomfutho ophezulu. Ukucindezela okuphezulu kuvimbela ngokuphawulekayo ukwakheka kwama-pore futhi kukhawulele ukukhula okusanhlamvu, kuyilapho izinga lokushisa eliphezulu likhuthaza ukuhlanganisa okusanhlamvu kanye nokwakheka kwezakhiwo eziminyene, ekugcineni kukhiqizwa ama-ceramics e-SiC aphezulu, ahlanzekile kakhulu. Ngenxa yemvelo yokuqondisa yokucindezela, le nqubo ijwayele ukuheha i-anisotropy yokusanhlamvu, ithinte izakhiwo zomshini kanye nokugqoka.

I-Ceramics ehlanzekile ye-SiC kunzima ukuminyanisa ngaphandle kwezithasiselo, ezidinga i-ultrahigh-pressure sintering. Nadeau et al. ulungiselele ngempumelelo i-SiC eminyene ngokugcwele ngaphandle kwezithasiselo ku-2500 ° C naku-5000 MPa; Ilanga et al. ithole izinto eziyinqwaba ze-β-SiC ezinobunzima be-Vickers obufika ku-41.5 GPa ku-25 GPa no-1400°C. Kusetshenziswa ingcindezi ye-4 GPa, izitsha zobumba ze-SiC ezinokuminyana okuhlobene cishe okungama-98% no-99%, ubulukhuni be-35 GPa, kanye ne-elastic modulus ye-450 GPa zilungiswe ku-1500 ° C no-1900 ° C, ngokulandelana. I-Sintering micron-size SiC powder ku-5 GPa kanye ne-1500 ° C ikhiqize izinto zobumba ezinobunzima obungu-31.3 GPa kanye nokuminyana okuhlobene kuka-98.4%.

Nakuba le miphumela ikhombisa ukuthi umfutho ophakeme kakhulu ungafinyelela ukuminyana okungangezelelwe, ubunkimbinkimbi nezindleko eziphakeme zemishini edingekayo kunciphisa izicelo zezimboni. Ngakho-ke, ekulungiseleleni okungokoqobo, izithasiselo zokulandela umkhondo noma i-powder granulation ngokuvamile zisetshenziselwa ukuthuthukisa amandla okushayela e-sintering.

Ngokungeza i-4 wt.% i-phenolic resin njengesengezo kanye ne-sintering ku-2350 ° C no-50 MPa, izitsha zobumba ze-SiC ezinezinga lokuminyana lama-92% kanye nobumsulwa obungu-99.998%. Ukusebenzisa amanani aphansi e-additive (i-boric acid ne-D-fructose) kanye ne-sintering ku-2050 ° C kanye ne-40 MPa, i-SiC ehlanzekile kakhulu enobukhulu obuhlobene> 99.5% kanye nokuqukethwe okusele kwe-B kwe-556 ppm kuphela kwalungiswa. Izithombe ze-SEM zibonise ukuthi, uma kuqhathaniswa namasampuli angenasici, amasampula acindezelwe ngokushisayo anezinhlamvu ezincane, ama-pores ambalwa, kanye nokuminyana okuphezulu. Amandla e-flexural ayengu-453.7 ± 44.9 MPa, futhi i-elastic modulus yafinyelela ku-444.3 ± 1.1 GPa.

Ngokunweba isikhathi sokubamba ku-1900 ° C, usayizi wokusanhlamvu ukhuphuke ukusuka ku-1.5 μm kuya ku-1.8 μm, futhi ukuhanjiswa kwe-thermal kwaba ngcono ukusuka ku-155 kuya ku-167 W·m⁻¹·K⁻¹, kuyilapho kuthuthukisa ukumelana nokugqwala kwe-plasma.

Ngaphansi kwezimo ezingu-1850°C kanye no-30 MPa, ukucindezela okushisayo nokucindezela okushisayo okusheshayo kwempushane ye-SiC ene-granulated kanye ne-annealed kukhiqizwe ngokuphelele izitsha zobumba ze-β-SiC ezingenazo izithasiselo, ezinobunzima obungu-3.2 g/cm³ kanye nezinga lokushisa elingu-150–200°C eliphansi kunezinqubo zendabuko. I-ceramics ibonise ubulukhuni be-2729 GPa, ukuqina kokuphuka okungu-5.25–5.30 MPa·m^1/2, kanye nokumelana okuhle nokukhuphuka (amazinga okukhuphuka angu-9.9 × 10⁻¹⁰ s⁻¹ no-3.8 × 10⁻⁻¹0 ° C1° no-C1⁻⁻¹0 ° C1° no-C1°4° 100 MPa).

(A) isithombe se-SEM sendawo epholishiwe; (B) Isithombe se-SEM sendawo ephukile; (C, D) Isithombe se-BSD sendawo epholishiwe

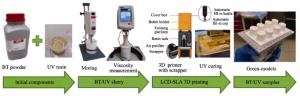

Ocwaningweni lokuphrinta lwe-3D lwe-piezoelectric ceramics, i-ceramic slurry, njengesici esiyinhloko esithonya ukwakheka nokusebenza, sekugxilwe kakhulu kuleli zwe nakwamanye amazwe. Ucwaningo lwamanje lubonisa ukuthi amapharamitha afana nosayizi wezinhlayiyana zempushana, i-slurry viscosity, nokuqukethwe okuqinile kuthinta kakhulu ikhwalithi yokwakha kanye nezakhiwo ze-piezoelectric zomkhiqizo wokugcina.

Ucwaningo luthole ukuthi i-ceramic slurries elungiselelwe kusetshenziswa i-micron-, submicron-, kanye nezimpushana ze-barium titanate ezinosayizi we-nano zibonisa umehluko omkhulu ezinqubweni ze-stereolithography (isb, i-LCD-SLA). Njengoba usayizi wezinhlayiyana uncipha, i-slurry viscosity ikhula ngokuphawulekayo, ngezimpushana ezinosayizi we-nano ezikhiqiza ama-slurries anama-viscosity afinyelela kuzigidigidi zama-mPa·s. Ama-slurries anezimpushana ezinosayizi omncane we-micron athambekele ekuqhekekeni nasekuxebukeni ngesikhathi sokuphrinta, kuyilapho ama-submicron kanye nezimpushana ezinosayizi we-nano zibonisa ukuziphatha kokwakheka okuzinzile. Ngemuva kokushiswa kwezinga lokushisa eliphezulu, amasampula e-ceramic abe umphumela athole ukuminyana okungu-5.44 g/cm³, i-piezoelectric coefficient (d₃₃) ecishe ibe ngu-200 pC/N, nezici zokulahlekelwa okuphansi, ezibonisa izici ezinhle kakhulu zokuphendula ngomshini womshini.

Ukwengeza, ezinqubweni ze-micro-stereolithography, ukulungisa okuqukethwe okuqinile kwama-slurries ohlobo lwe-PZT (isb, 75 wt.%) kunikeze imizimba e-sintered enobuningi obungu-7.35 g/cm³, kuzuzwe ukuguquguquka kwe-piezoelectric okungafika kokungu-600 pC/N ngaphansi kwezinkundla zikagesi zokupholisa. Ucwaningo mayelana nesinxephezelo sokuwohloka kwezinga elincane kuthuthukise kakhulu ukunemba kokwakheka, kwathuthukisa ukunemba kwejometri ngokufika ku-80%.

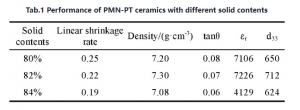

Olunye ucwaningo ku-PMN-PT piezoelectric ceramics lwembula ukuthi okuqukethwe okuqinile kunethonya elibucayi isakhiwo se-ceramic kanye nezakhiwo zikagesi. Kokuqukethwe okuqinile okungu-80 wt.%, imikhiqizo evela kalula ivela kuma-ceramics; njengoba okuqukethwe okuqinile kwenyuke kwafinyelela ku-82 wt.% nangaphezulu, imikhiqizo yanyamalala kancane kancane, futhi isakhiwo se-ceramic saba msulwa, nokusebenza okuthuthuke kakhulu. Ku-82 wt.%, izitsha zobumba zibonise izakhiwo zikagesi ezisezingeni eliphezulu: i-piezoelectric constant engu-730 pC/N, imvume ehlobene ye-7226, kanye nokulahlekelwa kwe-dielectric okungu-0.07 kuphela.

Kafushane, usayizi wezinhlayiya, okuqukethwe okuqinile, kanye nezakhiwo ze-rheological zama-slurries e-ceramic akuthinti nje kuphela ukuzinza nokunemba kwenqubo yokunyathelisa kodwa futhi kunquma ngokuqondile ukuminyana kanye nokusabela kwe-piezoelectric yemizimba e-sintered, okwenza kube yimingcele ebalulekile yokufeza ukusebenza okuphezulu kwe-3D-printed piezoelectric ceramics.

Inqubo eyinhloko yokuphrinta kwe-LCD-SLA 3D yamasampuli e-BT/UV

Izici ze-PMN-PT zobumba ezinokuqukethwe okuqinile okuhlukile

IV. I-Spark Plasma Sintering

I-Spark plasma sintering (SPS) ubuchwepheshe obuthuthukisiwe be-sintering obusebenzisa ingcindezi yamanje nemishini kanye kanye esetshenziswa kumampushana ukuze kufinyelelwe ukuminyana ngokushesha. Kule nqubo, okwamanje ishisa ngokuqondile isikhunta kanye ne-powder, ikhiqiza ukushisa kwe-Joule ne-plasma, okwenza i-sintering ephumelelayo ngesikhathi esifushane (imvamisa phakathi kwemizuzu eyi-10). Ukushisa okusheshayo kukhuthaza ukusakazeka kwendawo, kuyilapho ukuphuma kwenhlansi kusiza ukususa amagesi adsorbed nezendlalelo ze-oxide endaweni eyimpuphu, kuthuthukisa ukusebenza kwe-sintering. Umthelela we-electromigration obangelwa izinkundla ze-electromagnetic nawo uthuthukisa ukusakazeka kwe-athomu.

Uma kuqhathaniswa nokucindezela okuvamile okushisayo, i-SPS isebenzisa ukushisisa okuqondile, okuvumela ukuminyana emazingeni okushisa aphansi kuyilapho kuvimbela ngempumelelo ukukhula okusanhlamvu ukuze kutholwe izakhiwo ezincane nezifanayo. Ngokwesibonelo:

- Ngaphandle kwezithasiselo, ukusebenzisa i-ground SiC powder njengento eluhlaza, i-sintering ku-2100 ° C kanye ne-70 MPa imizuzu engu-30 ikhiphe amasampula ane-98% yesihlobo esihlobene.

- I-Sintering ku-1700 ° C kanye ne-MPa engu-40 imizuzu engu-10 ikhiqize i-cubic SiC ene-98% yokuminyana kanye nobukhulu bokusanhlamvu obungama-30-50 nm kuphela.

- Ukusebenzisa u-80 µm granular SiC powder kanye ne-sintering ku-1860°C kanye nama-MPa angu-50 imizuzu emi-5 kubangele ukusebenza okuphezulu kwe-Ceramics ye-SiC enobukhulu obuhlobene obungu-98.5%, ubulukhuni be-Vickers obungu-28.5 GPa, amandla aguquguqukayo angu-395 MPa, kanye nokuphuka kwe-4.5/m2 kokuqina.

Ukuhlaziywa kwe-Microstructural kubonise ukuthi njengoba izinga lokushisa le-sintering lenyuka lisuka ku-1600 ° C laya ku-1860 ° C, i-porosity yezinto ezibonakalayo yehla kakhulu, isondela ukuminyana okugcwele emazingeni okushisa aphezulu.

I-microstructure ye-ceramics ye-SiC sintered emazingeni okushisa ahlukene: (A) 1600°C, (B) 1700°C, (C) 1790°C kanye (D) 1860°C.

V. Ukukhiqiza Okungeziwe

I-Additive Production (AM) isanda kukhombisa amandla amakhulu ekwenzeni izingxenye ze-ceramic eziyinkimbinkimbi ngenxa yenqubo yayo yokwakha isendlalelo nesendlalelo. Ezitshalweni ze-SiC Ceramics, kuthuthukiswe ubuchwepheshe obuningi be-AM, okuhlanganisa i-binder jetting (BJ), i-3DP, i-selective laser sintering (SLS), ukubhala kukayinki oqondile (DIW), kanye ne-stereolithography (SL, DLP). Kodwa-ke, i-3DP ne-DIW inokunemba okuphansi, kuyilapho i-SLS ijwayele ukubangela ukucindezeleka okushisayo nokuqhekeka. Ngokuphambene, i-BJ ne-SL zinikeza izinzuzo ezinkulu ekukhiqizeni izitsha zobumba eziyinkimbinkimbi ezihlanzekile, ezinembayo.

- I-Binder Jetting (BJ)

Ubuchwepheshe be-BJ bubandakanya ukufuthwa kwe-layer-by-layer ye-binder kuya kumpushana webhondi, okulandelwa ukubopha nokucwiliswa ukuze kutholwe umkhiqizo wokugcina we-ceramic. Ukuhlanganisa i-BJ ne-chemical vapor infiltration (CVI), i-high-purity, i-Ceramics ye-SiC ecwebe ngokugcwele ilungiswe ngempumelelo. Inqubo ihlanganisa:

① Ukwakha imizimba ye-SiC Ceramic eluhlaza kusetshenziswa i-BJ.

② Ukuminyana nge-CVI ku-1000°C naku-200 Torr.

③ Iceramic yokugcina ye-SiC ibe nokuminyana okungu-2.95 g/cm³, ukuqhutshwa kwe-thermal okungu-37 W/m·K, namandla okuguquguquka angu-297 MPa.

Umdwebo we-Schematic we-adhesive jet (BJ) yokuphrinta. (A) Imodeli yomklamo osizwa ngekhompiyutha (CAD), (B) umdwebo wohlelo lwesimiso se-BJ, (C) ukuphrinta kwe-SiC nge-BJ, (D) ukuminyana kwe-SiC ngokungeniswa komhwamuko wamakhemikhali (CVI)

- I-Stereolithography (SL)

I-SL iwubuchwepheshe bokwakha i-ceramic obususelwe ekuphulukiseni i-UV obunembayo obuphakeme kakhulu namandla okwenziwa kwesakhiwo esiyinkimbinkimbi. Le ndlela isebenzisa ama-slurries e-ceramic e-photosensitive anokuqukethwe okuqinile okuphezulu kanye ne-viscosity ephansi ukwakha imizimba ye-ceramic eluhlaza ye-3D ngokusebenzisa i-photopolymerization, elandelwa ukubopha kanye ne-high-tempering sintering ukuze kutholwe umkhiqizo wokugcina.

Kusetshenziswa i-SiC slurry engu-35 vol.%, imizimba eluhlaza yekhwalithi ephezulu ye-3D yalungiswa ngaphansi kwemisebe ye-UV engu-405 nm futhi yaqina nakakhulu ngokushiswa kwe-polymer ku-800°C kanye nokwelashwa kwe-PIP. Imiphumela yabonisa ukuthi amasampula alungiselelwe nge-35 vol.% slurry azuze ukuminyana okulinganiselwe okungama-84.8%, asebenza kahle kakhulu kunamaqembu okulawula angama-30% nama-40%.

Ngokwethula i-lipophilic SiO₂ kanye ne-phenolic epoxy resin (PEA) ukuze kulungiswe i-slurry, ukusebenza kwe-photopolymerization kwathuthukiswa ngempumelelo. Ngemuva kokucwiliswa ku-1600 ° C ngehora le-4, ukuguqulwa okuseduze kokuphelela ku-SiC kwafinyelelwa, ngokuqukethwe kwe-oksijini yokugcina ye-0.12% kuphela, okuvumela ukwakhiwa kwesinyathelo esisodwa se-ceramics ye-SiC ehlanzekile, eyinkimbinkimbi-eyinkimbinkimbi ngaphandle kwe-oxidation yangaphambili noma izinyathelo zokungena ngaphambi kokungena.

Umdwebo wesakhiwo sokuphrinta kanye nenqubo yayo ye-sintering. Ukubonakala kwesampula ngemva kokoma ku-(A) 25°C, i-pyrolysis ku-(B) 1000°C, kanye ne-sintering ku-(C) 1600°C.

Ngokudizayina ama-slurries e-ceramic e-Si₃N₄ e-ceramic ezwelayo yokuphrinta kwe-3D ye-3D nokusebenzisa izinqubo zokuhoxisa nokuguga nezisezingeni eliphezulu lokushisa, i-Si₃N₄ Ceramics eno-93.3% wokuminyana kwethiyori, amandla aqinile angu-279.8 MPa angu-279.8 MPa, kanye namandla angu-3a303. Ucwaningo luthole ukuthi ngaphansi kwezimo zokuqukethwe okuqinile okungu-45 vol.% kanye nesikhathi sokuchayeka se-10s, imizimba eluhlaza esendlalelo esisodwa enezinga le-IT77 lokunemba lokwelapha ingatholwa. Inqubo yokukhipha izinga lokushisa eliphansi elinezinga lokushisa elingu-0.1 °C/min lisize ukukhiqiza imizimba eluhlaza engena-crack.

I-Sintering yisinyathelo esibalulekile esithinta ukusebenza kokugcina ku-stereolithography. Ucwaningo lubonisa ukuthi ukungeza izinsiza zokugcoba kungathuthukisa ngempumelelo ukuminyana kwe-ceramic kanye nezakhiwo zemishini. Isebenzisa i-CeO₂ njengosizo lwe-sintering kanye nobuchwepheshe be-sintering obusiza ugesi ukuze kulungiswe ama-ceramics e-Si₃N₄ aphezulu, i-CeO₂ itholakale ihlukanisa emingceleni yokusanhlamvu, ikhuthaza ukushelela komngcele wokusanhlamvu kanye nokuminyana. Izitsha zobumba eziwumphumela zibonise ubulukhuni be-Vickers be-HV10/10 (1347.9 ± 2.4) nokuqina kokuphuka kwe-(6.57 ± 0.07) MPa·m¹/². Nge-MgO–Y₂O₃ njengezithasiselo, i-ceramic microstructure homogeneity iye yathuthukiswa, yathuthukisa kakhulu ukusebenza. Ezingeni eliphelele le-doping elingu-8 wt.%, amandla e-flexural kanye nokusebenza okushisayo kufinyelele ku-915.54 MPa no-59.58 W·m⁻¹·K⁻¹, ngokulandelanayo.

VI. Isiphetho

Kafushane, izitsha zobumba ze-silicon carbide (SiC) ezihlanzekile, njengezinto zobumba zobunjiniyela ezivelele, zibonise amathuba okusebenza okubanzi kuma-semiconductors, i-aerospace, kanye nemishini enesimo esibucayi. Leli phepha lihlaziye ngokuhlelekile izindlela ezinhlanu ezijwayelekile zokulungiselela ama-ceramics e-SiC ahlanzekile-i-recrystallization sintering, i-sinterless sintering, i-hot pressing, i-spark plasma sintering, kanye nokukhiqiza okungeziwe - ngezingxoxo ezinemininingwane mayelana nezinqubo zabo zokuminyana, ukuthuthukiswa kwepharamitha eyinhloko, ukusebenza kwempahla, kanye nezinzuzo nokulinganiselwa ngokulandelanayo.

Kusobala ukuthi izinqubo ezahlukene ngayinye inezici ezihlukile mayelana nokuzuza ubumsulwa obuphezulu, ukuminyana okuphezulu, izakhiwo eziyinkimbinkimbi, kanye nokuba nokwenzeka kwezimboni. Ubuchwepheshe bokukhiqiza okungeziwe, ikakhulukazi, buye babonisa amandla aqinile ekwenzeni izingxenye ezimise okuyinkimbinkimbi nezenziwe ngendlela oyifisayo, ngokuthuthuka kwezindawo ezingaphansi njenge-stereolithography kanye nejetting ye-binder, okuyenza ibe isiqondiso esibalulekile sokuthuthukiswa kokulungiswa kwe-ceramic ye-SiC ehlanzekile.

Ucwaningo lwesikhathi esizayo mayelana nokuhlanzeka okuphezulu kokulungiswa kwe-ceramic ye-SiC kudinga ukujula, kuthuthukiswe inguquko esuka esilinganisweni saselabhorethri iye kwenkulu, izicelo zobunjiniyela ezinokwethenjelwa kakhulu, ngaleyo ndlela inikeze ukwesekwa kwezinto ezibalulekile zokukhiqiza imishini ephezulu kanye nobuchwepheshe bolwazi besizukulwane esilandelayo.

I-XKH yibhizinisi lobuchwepheshe obuphezulu eligxile ocwaningweni nasekukhiqizweni kwezinto zobumba ezisebenza kahle kakhulu. Inikezelwe ekuhlinzekeni izixazululo ezenziwe ngokwezifiso zamakhasimende ngendlela ye-high-purity silicon carbide (SiC) ceramics. Inkampani inobuchwepheshe obuphambili bokulungiselela izinto kanye nekhono eliqondile lokucubungula. Ibhizinisi layo lihlanganisa ucwaningo, ukukhiqizwa, ukucutshungulwa okunembile, kanye nokwelashwa okungaphezulu kwezitsha zobumba ze-SiC ezihlanzekile, ezihlangabezana nezidingo eziqinile ze-semiconductor, amandla amasha, i-aerospace kanye neminye imikhakha yezingxenye ze-ceramic ezisebenza kahle kakhulu. Ngokusebenzisa izinqubo ze-sintering ezivuthiwe kanye nobuchwepheshe bokukhiqiza okungeziwe, singanikeza amakhasimende isevisi yokuma okukodwa kusukela ekwenziweni kahle kwefomula yezinto, ukwakheka kwesakhiwo esiyinkimbinkimbi kuya ekucutshungulweni okunembile, siqinisekise ukuthi imikhiqizo inezinto ezinhle kakhulu zokusebenzisa imishini, ukuzinza okushisayo kanye nokumelana nokugqwala.

Isikhathi sokuthumela: Jul-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)